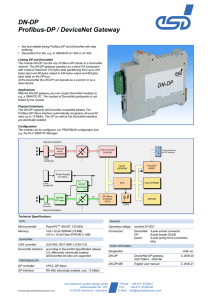

DN-2.15, DeviceNet System Overview

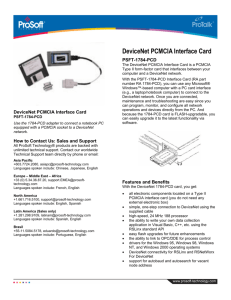

advertisement