Enhancing Resilience in Boston

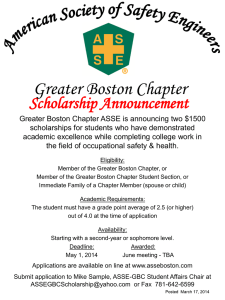

advertisement