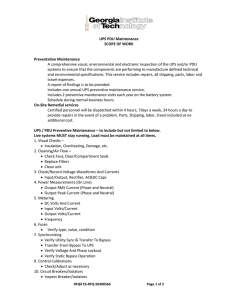

UPS SLC TWIN PRO series 4 to 20 kVA UNINTERRUPTIBLE

advertisement