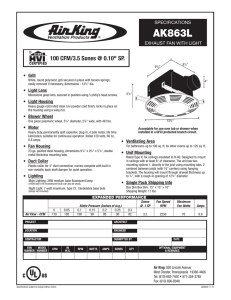

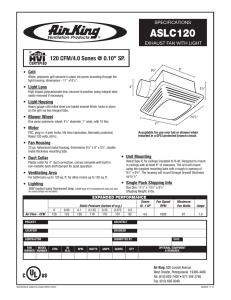

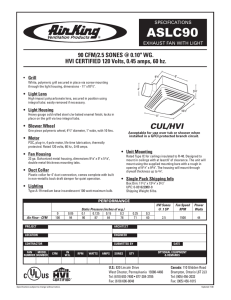

Centrifugal Inline Fans

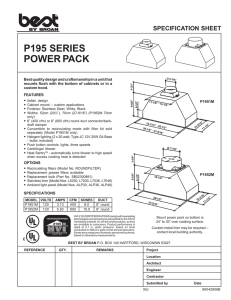

advertisement