Advances in Atomic Force Microscopy in the 21st

advertisement

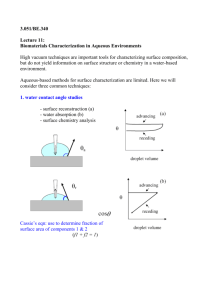

Advances in Atomic Force Microscopy in the 21st Century Ewan Marshall H.H. Wills Physics Laboratory May 14, 2011 1 Introduction The invention of the Atomic Force Microscope (AFM) in 1986 by Binning et al.[1] heralded a new era in scanning microscopy, in which forces were probed directly. Unlike scanning tunnelling or scanning electron microscopes, AFM is able to image non conductive structures in aqueous environments with atomic level resolution. Its importance in biological imaging has been cemented. Developments in reference to this will be discussed in this Figure 1: A tapping mode image of an E. Coli K12 paper. bacteria clearly showing tip artifacts on one side of the 1.1 structure. The artefact is due to the cantilever arms contacting the bacteria before the tip is able to touch the surface. The white bar represents 1µm. a shows a height image and b a phase image taken simultaneously. This image was taken from [4]. Background An AFM measures surface forces from a sample on a soft cantilever. The bending of the cantilever gives an indication of the strength of the force. By taking force measurements at different points on a samples surface, a topographical map can be built up. Different forces can be investigated utilising their distance dependence or by functionalisation of cantilevers. The forces incident on a typical cantilever are essentially electro-statically based with a long range attractive force and short range repulsive Van der Waals force, thus the cantilever will generally experience a Lennard-Jones type potential. 1.1.1 the laser spot on the PSD will move accordingly, thus a measure of the force made (see figure 2). It is also possible to gain information on the friction forces and elasticity of the sample using its lateral bending. Any force measured will also be felt by the sample so minimisation of imaging forces is of great importance in imaging soft biological samples. The bending of a cantilever touching the surface is the simplest method of imaging a sample’s topography. The tip is moved across the sample with a constant cantilever deflection. A feedback system limits the force incident on the surface but, damage will inevitably occur as the tip is raster scanned over surface of the sample. Contact mode allows extremely high resolution images to be taken. Other modes of imaging have been developed. Tapping and dynamic modes limit damage by subjecting the sample to smaller forces. Tapping mode imaging uses an oscillating probe driven by a piezoelectric crystal to intermittently Methods and Modes of Imaging Standard AFM cantilevers are etched from silicon, a beam to deflect when forces are incidnet on the sharp tip used to probe the surface. The sharp tip is needed due to the tip shape affecting the resolution of the image[2] (figure 1). Detection of the cantilever bend is achieved using a laser reflected onto a Position Sensitive Detector (PSD) from the back of the cantilever[3]. As the cantilever bends, 1 Figure 2: Illustration of cantilever bending in the imaging of a sample and the use of a PSD in measuring this deflection. The first image shows a cantilever undergoing no force so the laser spot is directed into the centre of the PSD. The second shows the tip bending due to a feature on the surface. The amount of bend shows the height of the step and the spot on the PSD moves accordingly. The last image shows the lateral bending of the cantilever as it scans into the step. This bending with scanning shows the frictional forces between the tip and the surface. processes and conformal changes. Standard AFM takes over a minute to create an image. With high speed imaging a larger area of a sample could be covered in an imaging scan. The use of AFM in lithography and manipulation of structures would also benefit from high speed scanning and imaging. contact the sample. The probe is oscillated at or near its resonant frequency. The output of the PSD shows the tapping amplitude. When a force is incident on the probe, the amplitude of oscillation changes and the tip is moved in the z axis in order to maintain a constant amplitude set point. In this mode image resolution is still limited by the tip size[5] but is not as high as in contact mode. Dynamic mode imaging[6] oscillates the tip at its resonant frequency. When a cantilever senses a surface force its effective spring constant will change and its amplitude will decrease as the resonant frequency is depressed. Dynamic mode imaging measures the frequency of the cantilevers’ oscillation in order to map surface forces without contacting the sample, thus minimal damage is caused and very high quality images are formed. The quality factors (Q) of probes used in this mode are of great importance as lowering Q will increase the signal to noise ratio but decrease the available bandwidth. However, this problem can be solved by fast frequency demodulation[7]. 2.1 As the AFM is a mechanical microscope, mechanical speed limits were met first. The speed of scanning the sample, the speed of the cantilever bend in measuring the force at every point, and the speed of response of the z distance maintaining head are all examples of imaging bottlenecks. Therefore the inertia of the system limits the ability of the microscope to respond to features in both x, y and z directions as well as the movement of the cantilever itself limiting the capturing of data. 2.2 2 Problems Associated with High Speed Imaging High Speed AFM Improving the System A simple development in High Speed AFM (HSAFM) imaging was attempted by Anwar et al. [9] Many physical biological processes occur on time- in which a stroboscopic method of imaging was scales of milliseconds [8] and high resolution im- utilised giving a temporal resolution of 5µs. A ages need to be acquired fast enough to track these closed loop scanner images a periodic process and 2 the movement of the sample is reconstructed from a set of points taken by shifting the phase of the scan in relation to the cyclical motion of the sample. Due to the nature of the technique, it is not applicable to many processes as it relies on a defined periodic movement. 2.2.1 Cantilevers The most important development in raising the speed of image acquisition in tapping mode is made by improving the response of cantilevers. Tapping mode was focused upon as the intermittent contact of the tip limits sample damage. In order for a cantilever to react quickly to a force in tapping mode the resonant frequency of the cantilever must be raised. The resonant frequency of a rectangular cantilever is given by equation 1 where d and l refer to the dimensions of the rectangular cantilever with the cantilever density given by ρ and E the Young modulus. Figure 3: Diagram showing an AFM with particular reference to the feedback system. The amplitude of the 21 E 3.516 d cantilever is measured and subtracted from the amplifres = tude set-point in order to give an error signal. This 2π l2 12ρ (1) error signal is fed into a proportional integral differen 12 k tial feedback controller. The signal is then amplified =⇒fres ∝ m∗ and sent to the z piezo controller. Image taken from [13] This simplifies to an equation involving the effective mass of the cantilever (M ∗) and its spring constant k. Therefore by decreasing the mass of the cantilever or increasing the stiffness the resonant frequency can be raised. In order for small forces to be sensed a low spring constant is required so the cantilever undergoes bending easily. Thus, a lowering of mass is needed with a corresponding lowering of spring constant. This is achieved by making cantilevers smaller, in which case both of these conditions are automatically met. Fabrication of these small cantilevers was achieved by the Hansma group using micromachining methods[10]. It was shown that smaller cantilevers were more sensitive to weak forces as well as resonating at > 500KHz in air. Using small cantilevers required developments in the optical detection system, in order to reflect a smaller laser spot off a reflective pad on the back of the cantilever. In using these small cantilevers to image DNA, image acquisition was hugely increased to give > 12fps using spring constants < 0.5N/m, limiting sample damage[11]. 2.2.2 Scanning and Feedback Next the scanning stage was upgraded. A scan head with high resonant frequencies is needed to remove noise. The scanning stage also suffers from inertial problems and so, by decreasing the mass of the scanning stage, faster raster scans can be completed. When moving the components at speed, mechanical and thermal noise between components must be minimised. These issues can be solved by careful material choice and construction for the scanning stage and head[12]. The cantilever in tapping mode is given an amplitude set-point that the feedback system attempts to maintain. This occurs constantly so the cantilever tracks the surface accurately. This is shown in the schematic of an AFM in figure 3. The speed of this feedback system directly affects the speed of image acquisition. Although proportional integral differential controllers are sufficient for high speed imaging in sim3 ple oscillation modes. With this method fast image acquisition is impossible for oscillation modes greater than two, due to the complexity of the oscillation of the cantilever[13]. Thus advances in controller designs were paramount in speeding up imaging. Feedback electronics are continually developing to push the limits of bandwidth and decrease noise (related in electronic components by noise ∝ √ fbw ). Also needed are low noise scan generators, fast DAQ system and data analysis. Developments in this field include the use of analogue scan generators in order to avoid mechanical resonances instigated by a digital signal and the use of recording the error values and using them in feedback in order to image in a hybrid mode was also used[14]. Dual actuation systems have also been utilised in stabilising the movement of the head[15]. These Figure 4: Diagram showing the stage set-up for ultra electronic improvements will effect all SPMs. high speed AFM obtaining KHz frame rates. Image adapted from [18]. 2.2.3 Contact Mode In 2005, a Bristol team discovered a huge leap in imaging speed was possible when using a HS-AFM in contact mode[16]. Here a tip is scanned at high speed across a sample with an astounding velocity of 22.4cms−1 . In this case a micro resonant scanner (a quartz tuning fork[17]) oscillates the sample relative to the tip thus utilising the mechanical resonances that were so problematic in the tapping mode case. The electronic feedback system is done away with in favour of a mechanical force pushing the cantilever into the sample and a damping system to minimise oscillations and parachuting. This allows the tip to track the surface of the sample. Due to this feedback system the tip is forced to follow the trajectory of the surface at a frequency faster than its fundamental resonance. This method allowed images at 67fps with vertical resolutions of 1nm. Further work used a combined resonant and flexure scanning system shown in figure 4. This research resulted in the imaging of collagen samples at 1300fps and the imaging of human chromosomes at 30fps [19]. With large features such as a chromosome (∼ 80nm), the issue of tip damage in HSAFM should be marked, but little damage actually Figure 5: A montage of HS-AFM images taken in water occurs. The results of these high speed scans are at 20fps clearly showing the structure of human chroshown in figure 5. mosomes with minimal damage. Image taken from[19]. The reason for the minimal damage in contact 4 3.1 Cantilever and Tip Modifications The simplest way of reducing the force incident upon a sample is done via a blunt tip. This is often achieved by mounting a silica sphere onto a cantilever. The large surface of the sphere allows forces to be measured and surface roughness to be explored but image resolution is heavily limited due to tip artefacts. this is known as colloidal force microscopy[23]. A better mode of imaging with low force was needed. A method of increasing the Q factor of a probe via an active resonance control, in which the driving force supplied to the cantilever is modified to take into account damping effects was developed in order to reduce forces in tapping mode[24]. In controlling the Q factor via the feedback mechanism, Figure 6: AFM image displaying a cell, the features on the cell membrane are the cytoskeleton pushing through forces as low as 50pN were used in imaging samples. the membrane as the tip deforms the surface of the cell The ability to control the Q factor can also influence the speed of image capture in imaging large into the micro-tubules. Image taken from [22]. features [25]. 3.2 mode is hypothesised to be due to a super lubrication effect of the water in which imaging occurs (even in air the sample and tip will be coated in a thin film of water). Results suggest that the cantilever and sample are not technically in contact due to a planing effect of the tip at speed, thus removing the surface friction [20]. Research is ongoing in order to analyse the dynamics of cantilevers in imaging utilising a laser Doppler vibrometer to map their movements[21]. 3 TDFM Another issue is that of cantilevers snapping to the surface due to the attractive force being larger than the one demonstrated by the cantilever’s spring constant[26]. The tip is oscillated normal to the surface meaning that however you modify the system the forces involved are pressing into the sample. Transverse Dynamic Force Microscopy (TDFM ) negates both of these problems due to the fact that the tip is oscillated perpendicular to the sample[27], therefore imparting very low forces upon it. As the probe (a vertical cylinder usually tapered glass fibre or FIB etched cantilever) effectively has an infinite spring constant in z, no snapping can take place. The action of a TDFM is illustrated in figure 7. Sample Deformation After solving the high speed issues of imaging biological processes, the next factor is the damage done to the sample by standard imaging and the development of low force systems. If smaller forces can be detected by a microscope the sample will be put under less stress and so finer features will be imaged and less damage will be incurred, often an issue in biological imaging. An example of this effect is given in figure 6. 3.2.1 Tip Detection TDFM was a development from a shear force microscope in which the movement of a vertical cylindrical probe is used to measure forces. The use of this probe as an imaging device occurred after developments in its detection systems. Originally an interferometry method was used, quickly superseded by a laser deflection method similar to 5 Figure 7: The image on the left shows a simple schematic of the TDFMusing a laser deflection method (two lasers could be used for monitoring movement in two axis). This schematic is remarkably similar to the AFM in figure 4. The diagram on the right shows the forces involved acting horizontally on the probe from a sample. Images taken from [28, 29]. that used in standard AFM[28]. This detection method had associated issues involved in monitoring the tip. In order to combat these issues a detection system based on scattered evanescent waves (SEW) is now used[30]. This detection method uses technology developed for scattered near-field optical microscopy. When a sharp cantilever enters an evanescent field (generated via total internal reflection of a laser from the surface of a high NA lens below the sample[31]), a coupling occurs and photons are scatted from the tip. These photons are collected by the lens and detected by a PSD giving an accurate tip position in both x and y (shown in figure 8), although this requires a thin transparent sample. 3.2.2 ing up image capture of this microscope is ongoing with many of the same methods as HS-AFM being utilised, such as Q control and tip design[33, 34]. Tips are designed to suppress higher eigenmodes of oscillation, so as to maximise the movement of the end of the probe, and have low spring constants. 4 The Influence of Optical Tweezers Optical tweezers were developed the same year as the AFM[35] using photons to impart momentum on a transparent micro-sphere. With a highly focused Gaussian laser beam and liquid crystal holographic lenses, these spheres can be trapped in potential wells which can be moved in three dimensions. These beads can then be used to interact with the sample, as with the colloidal probes mentioned earlier. The use of optical tweezers allows 3D images of a sample to be performed. This is known as photonic force microscopy (PFM). Use in Imaging The SEW detection system was found to monitor tip displacements with nanometre resolution and, by oscillating the tip at amplitudes of ∼ 2nm[32], images can be taken using forces of only 10fN using smaller cantilevers, allowing image taking in the order of µs. 4.1 Photonic Force Microscopy These force measurements are remarkable. Imaging takes place a few water molecules away from the The trapping potential creates a force on the surface so sample damage is almost zero. Speed- trapped particle, which can be regarded as a 6 hookean spring in each axis, a cantilever in 3D. Using the trapped bead to explore the surface of a sample allows an image to be formed. Beads with nanometer sized radii are used as a ‘tip’ to explore the surface[36]. The beads can be monitored as they affect the laser beam that traps them. They will cause diffraction patterns and refraction around them which can be used to monitor the position of the bead. In order to accurately define the force interaction the trapping potential must be calibrated so the spring constant can be found. This can be achieved via viscosity measurements or, more accurately, via a statistical analysis of the bead undergoing Brownian motion. This method gives information about the shape and strength of the potential[37]. The bead is scanned over the surface of the sample and forces measured are approximately two orders of magnitude smaller than a standard AFM cantilever[38]. In order to fully realise the potential of PFM, the thermal motion of the bead is utilised to explore the surface of the sample in 3D without relying on scanning the trap. This thermal exploration of the trapping potential is shown in figure 9. As the surface of a sample enters the potential, the surface forces will modify the shape of the potential, allowing a picture of the surface to be built up. PFM can thus be used to image samples in 3D with surfaces that would obscure themselves in AFM. The resolutions of these images are limited by the bead diameter, just as with colloidal force microscopy, giving images as shown in figure 10. Current research in PFM uses the optical trap alongside nanorods in order to beat the resolution limits set by the beads. Nanorods are difficult to trap and stabilise due to their high aspect ratio, unlike large beads which suffer from low imaging resolution. Research has now combined these factors to use nanorods controlled by micosphere handles to probe a sample in 3D with forces of 50fN[40]. Figure 8: Digram showing the SEW detection method. Light grey shows the laser reflected from the sample slide to create the evanecent field. The circle on the tip of the probe represents the scattering site. Photons are then collected by the high NA lens and sent to the detector. Diagram taken from [30]. 5 Interface These tools, developed by physicists to solve the problems of imaging biological samples, must be simple and intuitive to operate in order that researchers in a wide range of disciplines are able 7 to perform experiments. Many interface developments have come out of optical tweezers, giving force feedback and control of multiple traps for the user[41, 42]. Touch screen manipulation of HSAFM is used to explore large areas of a sample in real time[43], even on an ipad[44]. It is also possible to look around inside a nano-structure with 3D goggles. 6 Conclusion Developments like these open up a new world for researchers in all disciplines. The field of SPM is continually growing and becoming more exciting. These tools will be paramount in ushering in a new technological age, where all the sciences meet. Figure 9: Position histograms for a bead trapped above a cover-slip at distances d1 , d2 and d3 . The surface of the cover-slip can be inferred from these histograms. The bead is shown with a dashed line, the trapping potential is the grey ellipse and the path of exploration the solid black lines. Image taken from [39]. Figure 10: This is a PFM image using thermal exploration of a bead inside a polymer network, impossible with AFM. The proteins are artificially thick due to the bead diameter. Image taken from [39]. 8 References [11] M. B. Viani, T. E. Schaffer, G. T. Paloczi, L. I. Pietrasanta, B. L. Smith, J. B. Thomp[1] G. Binnig, C. F. Quate, and C. Gerber, son, M. Richter, M. Rief, H. E. Gaub, K. W. “Atomic force microscope,” Phys. Rev. Lett., Plaxco, A. N. Cleland, H. G. Hansma, and vol. 56, pp. 930–933, Mar 1986. P. K. Hansma, “Fast imaging and fast force spectroscopy of single biopolymers with a new [2] K. L. Westra, A. W. Mitchell, and D. J. Thomatomic force microscope designed for small son, “Tip artifacts in atomic force microscope cantilevers,” Review of Scientific Instruments, imaging of thin film surfaces,” Journal of Apvol. 70, no. 11, pp. 4300–4303, 1999. plied Physics, vol. 74, pp. 3608 –3610, sep [12] T. Ando, N. Kodera, E. Takai, D. Maruyama, 1993. K. Saito, and A. Toda, “A high-speed [3] E. Silva and K. Van Vliet, “Robust approach atomic force microscope for studying biological to maximize the range and accuracy of force macromolecules,” Proceedings of the National application in atomic force microscopes with Academy of Sciences of the United States of nonlinear position-sensitive detectors,” NanAmerica, vol. 98, no. 22, pp. pp. 12468–12472, otechnology, vol. 17, no. 21, p. 5525, 2006. 2001. [4] S. B. Velegol, S. Pardi, X. Li, D. Velegol, and [13] G. Schitter, P. Menold, H. F. Knapp, F. Allgower, and A. Stemmer, “High performance B. E. Logan, “Afm imaging artifacts due to feedback for fast scanning atomic force mibacterial cell height and afm tip geometry,” croscopes,” Review of Scientific Instruments, Langmuir, vol. 19, no. 3, pp. 851–857, 2003. vol. 72, no. 8, pp. 3320–3327, 2001. [5] E. Meyer, H. Hug, and R. Bennewitz, Scanning Probe Microscopy - The Lab on a Tip. [14] M. J. Rost, L. Crama, P. Schakel, E. van Tol, G. B. E. M. van Velzen-Williams, C. F. OverSpringer, 2004. gauw, H. ter Horst, H. Dekker, B. Okhuijsen, M. Seynen, A. Vijftigschild, P. Han, A. J. [6] F. Giessibl, “Atomic-Resolution of the Katan, K. Schoots, R. Schumm, W. van Loo, Silicon(111)-(7X7) Surface by Atomic-Force T. H. Oosterkamp, and J. W. M. Frenken, Microscopy,” Science, vol. 267, pp. 68–71, Jan “Scanning probe microscopes go video rate 6 1995. and beyond,” Review of Scientific Instru[7] T. Albrecht, P. Grutter, D. Horne, and D. Ruments, vol. 76, no. 5, p. 053710, 2005. gar, “Frequency Modulation Detection using High-Q Cantilevers for Enhanced Force Micro- [15] G. Schitter, W. Rijkee, and N. Phan, “Dual actuation for high-bandwidth nanopositioning,” scope Sensitivity,” Journal of Applied Physics, in Decision and Control, 2008. CDC 2008. vol. 69, pp. 668–673, Jan 15 1991. 47th IEEE Conference on, pp. 5176 –5181, dec. 2008. [8] R. Meyers, Molecular Biology and Biotechnology: A Comprehensive Desk Reference. Wiley, [16] A. D. L. Humphris, M. J. Miles, and 1st ed., 1995. J. K. Hobbs, “A mechanical microscope: High-speed atomic force microscopy,” Applied [9] M. Anwar and I. Rousso, “Atomic force miPhysics Letters, vol. 86, no. 3, p. 034106, 2005. croscopy with time resolution of microseconds,” Applied Physics Letters, pp. 014101 –014101–3, jan 2005. vol. 86, [17] A. D. L. Humphris, J. K. Hobbs, and M. J. Miles, “Ultrahigh-speed scanning near-field optical microscopy capable of over 100 frames [10] M. B. Viani, T. E. Schaffer, A. Chand, per second,” Applied Physics Letters, vol. 83, M. Rief, H. E. Gaub, and P. K. Hansma, no. 1, pp. 6–8, 2003. “Small cantilevers for force spectroscopy of single molecules,” Journal of Applied Physics, [18] L. M. Picco, L. Bozec, A. Ulcinas, D. J. vol. 86, no. 4, pp. 2258–2262, 1999. Engledew, M. Antognozzi, M. A. Horton, 9 and M. J. Miles, “Breaking the speed limit [27] A. Ustione, A. Cricenti, M. Piacentini, and with atomic force microscopy,” NanotechnolA. C. Felici, “New implementation of a shearogy, vol. 18, no. 4, p. 044030, 2007. force microscope suitable to study topographical features over wide areas,” Review of Sci[19] L. M. Picco, P. G. Dunton, A. Ulcinas, D. J. entific Instruments, vol. 77, no. 9, p. 093702, Engledew, O. Hoshi, T. Ushiki, and M. J. 2006. Miles, “High-speed afm of human chromosomes in liquid,” Nanotechnology, vol. 19, [28] M. Antognozzi, H. Haschke, and M. J. Miles, “A new method to measure the oscillation of a no. 38, p. 384018, 2008. cylindrical cantilever: “the laser reflection detection system”,” Review of Scientific Instru[20] J. M. Skotheim and L. Mahadevan, “Soft luments, vol. 71, no. 4, pp. 1689–1694, 2000. brication: The elastohydrodynamics of nonconforming and conforming contacts,” Physics [29] A. D. L. Humphris, M. Antognozzi, T. J. of Fluids, vol. 17, no. 9, p. 092101, 2005. McMaster, and M. J. Miles, “Transverse dynamic force spectroscopy: a novel approach to [21] O. D. Payton, L. Picco, A. R. Champneys, determining the complex stiffness of a single M. E. Homer, M. J. Miles, and A. Ramolecule,” Langmuir, vol. 18, no. 5, pp. 1729– man, “Experimental observation of contact 1733, 2002. mode cantilever dynamics with nanosecond resolution,” Review of Scientific Instruments, [30] M. Antognozzi, A. Ulcinas, L. Picco, S. H. vol. 82, no. 4, p. 043704, 2011. Simpson, P. J. Heard, M. D. Szczelkun, B. Brenner, and M. J. Miles, “A new detection [22] T. G. Kuznetsova, M. N. Starodubtseva, N. I. system for extremely small vertically mounted Yegorenkov, S. A. Chizhik, and R. I. Zhdanov, cantilevers,” Nanotechnology, vol. 19, no. 38, “Atomic force microscopy probing of cell elasp. 384002, 2008. ticity,” Micron, vol. 38, no. 8, pp. 824 – 833, 2007. Microscopy in Nanobiotechnology. [31] E. Betzig, J. K. Trautman, T. D. Harris, J. S. Weiner, and R. L. Kostelak, “Breaking the [23] W. A. Ducker, T. J. Senden, and R. M. Pshley, diffraction barrier: Optical microscopy on a “Direct measurement of colloidal forces using nanometric scale,” Science, vol. 251, no. 5000, an atomic force microscope,” Nature, vol. 353, pp. 1468–1470, 1991. pp. 239 – 241, Sept 1991. [24] J. Tamayo, A. D. L. Humphris, and M. J. Miles, “Piconewton regime dynamic force microscopy in liquid,” Applied Physics Letters, vol. 77, no. 4, pp. 582–584, 2000. [32] M. Antognozzi, D. R. Binger, A. D. L. Humphris, P. J. James, and M. J. Miles, “Modeling of cylindrically tapered cantilevers for transverse dynamic force microscopy (tdfm),” Ultramicroscopy, vol. 86, no. 1-2, pp. 223 – 232, 2001. [25] T. Sulchek, R. Hsieh, J. D. Adams, G. G. Yaralioglu, S. C. Minne, C. F. Quate, J. P. [33] M. Antognozzi, M. D. Szczelkun, A. D. L. Cleveland, A. Atalar, and D. M. Adderton, Humphris, and M. J. Miles, “Increasing shear “High-speed tapping mode imaging with acforce microscopy scanning rate using active tive q control for atomic force microscopy,” quality-factor control,” Applied Physics LetApplied Physics Letters, vol. 76, no. 11, ters, vol. 82, no. 17, pp. 2761–2763, 2003. pp. 1473–1475, 2000. [34] T. Scholz, J. A. Vicary, G. M. Jeppesen, A. Ul[26] J. L. Hutter and J. Bechhoefer, “Calibration cinas, J. K. H. Hrber, and M. Antognozzi, of atomic x2010;force microscope tips,” Review “Processive behaviour of kinesin observed usof Scientific Instruments, vol. 64, pp. 1868 – ing micro-fabricated cantilevers,” Nanotech1873, jul 1993. nology, vol. 22, no. 9, p. 095707, 2011. 10 [35] S. Chu, J. E. Bjorkholm, A. Ashkin, and Nanotechnology, vol. 20, no. 43, p. 434018, A. Cable, “Experimental observation of opti2009. cally trapped atoms,” Phys. Rev. Lett., vol. 57, [44] R. W. Bowman, G. Gibson, D. Carberry, pp. 314–317, Jul 1986. L. Picco, M. Miles, and M. J. Padgett, “itweezers: optical micromanipulation controlled by [36] C. J. Murphy, T. K. Sau, A. M. Gole, C. J. an apple ipad,” Journal of Optics, vol. 13, Orendorff, J. Gao, L. Gou, S. E. Hunyadi, no. 4, p. 044002, 2011. and T. Li, “Anisotropic metal nanoparticles: synthesis, assembly, and optical applications,” The Journal of Physical Chemistry B, vol. 109, no. 29, pp. 13857–13870, 2005. [37] E. Florin, A. Pralle, E. Stelzer, and J. Hrber, “Photonic force microscope calibration by thermal noise analysis,” Applyed Physics Journal A, vol. 66, pp. 75–78, 1998. [38] E.-L. Florin, A. Pralle, J. K. H. Horber, and E. H. K. Stelzer, “Photonic force microscope based on optical tweezers and two-photon excitation for biological applications,” Journal of Structural Biology, vol. 119, no. 2, pp. 202 – 211, 1997. [39] A. Rohrbach, C. Tischer, D. Neumayer, E.-L. Florin, and E. H. K. Stelzer, “Trapping and tracking a local probe with a photonic force microscope,” Review of Scientific Instruments, vol. 75, no. 6, pp. 2197–2210, 2004. [40] L. Ikin, D. M. Carberry, G. M. Gibson, M. J. Padgett, and M. J. Miles, “Assembly and force measurement with spm-like probes in holographic optical tweezers,” New Journal of Physics, vol. 11, no. 2, p. 023012, 2009. [41] C. Pacoret, R. Bowman, G. Gibson, S. Haliyo, D. Carberry, A. Bergander, S. Régnier, and M. Padgett, “Touching the microworld with force-feedback optical tweezers,” Opt. Express, vol. 17, pp. 10259–10264, Jun 2009. [42] J. A. Grieve, A. Ulcinas, S. Subramanian, G. M. Gibson, M. J. Padgett, D. M. Carberry, and M. J. Miles, “Hands-on with optical tweezers: a multitouch interface for holographicoptical trapping,” Opt. Express, vol. 17, pp. 3595–3602, Mar 2009. [43] D. M. Carberry, L. Picco, P. G. Dunton, and M. J. Miles, “Mapping real-time images of high-speed afm using multitouch control,” 11