Outline Commissioning programme

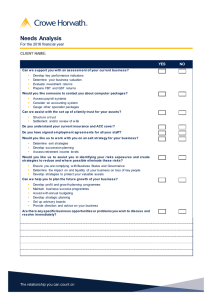

advertisement

A G R E E D FORM

O U T L IN E C O M M IS S IO N IN G P R O G R A M M E S C H E D U L E P A R T 10

In re s p e c t o f th e P ro je c t A g re e m e n t

B e tw e e n

A y r s h ir e & A rra n H e a lth B o a rd

And

B a lfo u r B e a tty H e a lth c a re (Irvine) L im ite d

Certified as being the Outline Commissioning Programme in the Agreed Form as referred to in

the Project Agreement between Ayrshire & Arran Health Board and Balfour Beatty Healthcare

(Irvine) Limited dated 2014

١٠١, ؟٧٠١٦٤

On behalf of A y rs h ir e & A rra n H e a lth B o a rd

Signature . J ú ' t k 'i.Y .... [٩٠. j. Y! ¿ .[5 r . C lij...

N a m e .C e؛i l & J C . . . M A؛C W e W J. . . L | M P S rA Y

On behalf of B a lfo u r B e a tty H e a lth c a re (Irvine) L im ite d

S ignature

Name .

UK-130942499.1

SCHEDULE PART 10: OUTLINE COMMISSIONING PROGRAMME

P re -C o m p le tio n C o m m is s io n in g

Project C o ’s P re-C om pletion C om m issioning shall com prise the activities identified

as such in T able A o f A ppendix A o f this S chedule Part 10 (O utline C om m issioning

Program m e).

Project Co shall give w ritten notice to the Independent Tester and the A uthority’s

R epresentative

of

the

com m encem ent

of

Project

Co's

Pre-C om pletion

C om m issioning not less than five 5 Business Days prior to the date w hen Project Co

(acting reasonably) considers that it shall com m ence Project C o’s Pre-C om pletion

C om m issioning.

The A uthority’s C om m issioning shall com prise the activities identified as such in

Table

A

of A ppendix

A

o f this

S chedule

Part

10

( Outline

C om m issioning

Program m e).

Project Co shall give w ritten notice to the A u th ority's R epresentative o f the date

upon

w hich

the

A uthority

shall

be

entitled

to

com m ence

the

Authority's

C om m issioning, such notice to be given at least 1 m onth prior to the date when

Project Co (acting reasonably) considers that the A uthority should com m ence the

A uthority's

C om m issioning

in

accordance

w ith

the

Final

C om m issioning

Program m e.

P o s t -C o m p le tio n C o m m is s io n in g

Project C o’s Post-C om pletion C om m issioning shall com prise the activities identified

as such in Table A o f A ppendix A of this S chedule Part 10 (O utline C om m issioning

Program m e).

The A u th ority’s

Post-C om pletion

C om m issioning

shall

com prise the

activities

identified as such in Table A of A ppendix A o f this Schedule Part 10 (Outline

C om m issioning Program m e).

E q u ip m e n t

Project Co shall not clean, or m ove to enable general cleaning any item s o f Group 2

Equipm ent or Group 3 Equipm ent unless the A u th o rity’s R epresentative has given

the w ritten prior consent, such consent not to be unreasonably w ithheld-.

The A uthority shall ensure that all o f the A u th ority’s existing E quipm ent that is

transferred to the Facilities has been cleaned in accordance with the Authority's

protocols prior to being transferred to the Facilities.

SCHEDULE PART 10: OUTLINE COMMISSIONING PROGRAMME

Appendix A: Appendix A: Commissioning Responsibilities

Table A:

A re a

R oom s/areas

P r e - C o m p le tio n C o m m is s io n in g

P ro je c t C o ’s

A u t h o r it y

Project Co to install,

com m ission and te st Group

1 E quipm ent as required in

a ccordance w ith S chedule

P art 11 {E q u ip m e n t) .

A u th ority to provide,

com m ission and test, G roup 2

E quipm ent as required

pursuant to S chedule Part 11

(E q u ip m e n t ) and the Final

C om m issioning Program m e.

Project Co to install G roup

2 E quipm ent as required in

a ccordance w ith S chedule

P art 1 1 { E q u ip m e n t ).

Project C o to carry out

H andover Clean.

Project Co to carry out

H andover Clean in

a ccordance w ith the Final

C om m issioning

Program m e.

P o s t - C o m p le t io n C o m m is s io n in g

P ro je c t C o ’s

A u th o r ity

A uthority to install, com m ission

and test, G roup 3 Equipm ent

as required pursuant to

Schedule Part 11 ( E q u ip m e n t)

and the Finai C om m issioning

P rogram m e.

A uthority tran sfe r o f patients to

be carried o ut in accordance

w ith the Final C om m issioning

P rogram m e.

A re a

ICT

P r e -C o m p le tio n C o m m is s io n in g

P o s t - C o m p ie t io n C o m m is s io n in g

P ro je c t C o ’s

A u t h o r it y

P ro je c t C o ’ s

P roject Co infrastructure

installed, com m issioned

and tested.

A u th o rity hardw are installed,

com m issioned and tested

(including data patch panels

and w ireless access points).

P roject Co to carry out

H andover C lean in

accordance w ith the Final

C om m issioning

P rogram m e.

A u th o r ity 's

A u th ority hardw are installed,

com m issioned and tested.

Appendix B: Appendix B - Completion Criteria

A P P E N D IX B - C O M P L E T IO N CR ITER IA

1.

General

1.1

General R equirem ents

1.1.1

Project Co shall provide such labour, m aterials, stores, test equipm ent, tools,

instrum ents, apparatus and assistance as are reasonably required fo r the purpose of

any inspection and /o r testing carried out by the Independent T ester and shall be

responsible fo r the provision of such electricity, fuel, w ater and other consum ables

and m aterials as m ay be reasonably re q u re d fo r the sam e. Invitations shall be

furnished to the A uthority and its technical advisers to w itness such inspections,

testing and com m issioning activities o f the W orks as the A uthority deem s necessary.

A t least fourteen (14) Business D ays' notice o f any testing shall be given.

1.1.2

Project Co shall ensure that m ajor item s of Plant shall be tested during the W orks fo r

both perform ance and safety prior to dispatch and provide docum entary evidence

that testing has been carried out if requested by the Independent T ester.

For the

purposes of this paragraph "m ajor item s of Plant" shall include, but not be limited to,

boilers, air handling units, generators, chillers, H V/M V sw itchgear and pressure

vessels. Project Co shall arrange to w itness sp ecific unit fa cto ry testing of m ajor

item s o f Plant and shall allow the A u thority's R epresentative and the A u th ority’s

technical advisers w ith the opportunity to w itness all such fa cto ry testing. The

A u th ority’s R epresentative and the A uthority's technical advisers shall be given at

least fourteen (14) Business D ays’ notice, or such reasonable notice as m ay be

agreed between Project Co and the Authority's R epresentative, o f such testing of

m ajor item s o f Plant.

2.

W o rk s Inspection, T estin g and A cc e p ta n c e A ctivitie s

2.1

Main Facility W orks Phase C om pletion C riteria

Project Co shall dem onstrate that the follow ing C om pletion C riteria have been achieved at the

com pletion o f the Main Facility W orks Phase w ithin the Main Facility W orks Site:

2.1.1

T he building is structurally com plete the external fa b ric is com plete,

w ind and

w atertight and a ir pressure testing has been com pleted. Internally all the Finishes

are com plete in accordance with the Room Data Sheets;

2.1.2

All incom ing Utilities including all relevant backup system s are tested, com m issioned

and operational;

2.1.3

All environm ental design param eters and m echanical and electrical Plant and

system s operate satisfactorily in accordance w ith the specified design criteria of

Section 3 (A u th ority's C onstruction R equirem ents) o f S chedule Part 6 (C onstruction

M atters), any m anufacturers’ operating requirem ents and the Room Data Sheets;

4

T he

building

m anagem ent

system

is

com plete,

tested,

com m issioned

and

layout drawings

(as

operational including the setting up o f graphs, logs or equivalent;

All furniture and

Equipm ent shown on the loaded room

supplem ented by Schedule Part 11 (E quipm ent)) as Project C o's responsibility have

been installed (and com m issioned if appropriate);

All keys, access cards, access codes and other access devices, fo r access to all

relevant areas o f the Facilities, com plete w ith all relevant schedules, including

agreed suiting schedules are ready fo r handover to the Authority;

Safe access and egress to and w ithin the Facilities has been established;

T he W orks shall be free from all surplus m aterials, plant and equipm ent and shall

com ply with the standards and requirem ents o f paragraph 3 (H andover C lean)

below;

Ali internal, external below and above ground drainage system s are installed and are

operational;

All external w orks as appropriate have been com pleted and are available fo r use by

the Authority;

All external so ft landscaping/planting is com plete (appropriate to the season) and

available fo r use by the Authority;

All dem olition w orks are com plete;

All hard-landscaped external w orks, including roads, car parks, pavem ents and

boundary w alls/fences are com plete and available fo r use by the Authority;

All lift system s are com plete, com m issioned and operational; including connection

and m onitoring o f lift car e m ergency call device;

All building, directional, departm ental, general Inform ation, room num bering

and

external signage as indicated w ithin Project C o’s Proposals and/or the Revlewable

Design Data to allow the operational Services to com m ence has been provided and

installed.

T his Includes both internal and external signage fo r the Facilities and

areas outwith the Site boundary to include the access routes and buildings on the

w ider Ayrshire Central Hospital site;

Those elem ents o f the fire m anagem ent strategy and fire safety risk assessm ent in

accordance with the Fire (Scotland) A ct 2005, fo r which Project Co is responsible,

have been produced;

AH fire detection, alarm and suppression system s, w here installed, are com plete,

tested com m issioned and operational;

All external lighting is installed, tested, com m issioned and operational;

A ll IT and com m unication system s to be installed by Project Co are com plete, tested

and te st results subm itted to the A uthority (and if appropriate com m issioned);

A ll security and surveillance system s, access controls and call alarm s are com plete,

tested, com m issioned, operational and available fo r use by the Authority;

All acoustic testing has been com pleted to prove com pliance with Section 3

(.A u th o rity’s C onstruction R equirem ents) of Schedule Part 6 (C onstruction M atters)

and Section 4 (P roject C o ’s Proposals) of Schedule Part 6 (C onstruction Matters)',

All m edical gas and vacuum system ’s are com plete, tested, com m issioned and

w itnessed by the A uthority’s ch ie f pharm acist and quality controller (m edical gas

pipeline system );

A ll builder’s w ork in connection w ith art installations a Te com plete;

Project Co has provided all docum entation relevant to the Main Facility W orks Phase

to the Independent T ester in accordance with this A greem ent and paragraph 4

(Indicative T esting and C om m issioning D ocum entation) below;

A final draft O perational M anual fo r the Facilities, in accordance w ith Clause 18 o f

this Agreem ent, (containing, as a m inimum, all the testing and com m issioning

Inform ation including as-built drawings / test results so fa r as it is reasonably

practicable) relevant to the Main Facility W orks Phase have been m ade available by

the C ontractor to Project Co to allow the Facilities to be operated safely;

C opies o f all available C onsents and w arranties relevant to the design and

construction have been supplied by Project Co to the Authority;

All elem ents of Section 7 ( Therm al & E nergy E fficie ncy Testing Procedures) o f

Schedule Part 6 ( C onstruction M atters) have been undertaken;

T herm ographic surveys, to the relevant British S tandards, of the agreed test area as

agreed w ith the Authority, both parties acting reasonably, to prove the quality of the

therm al perform ance o f the Facilities;

All elem ents of the H andover Clean, set out in paragraph 3 (H andover C lean) below

are com plete;

Project Co shall ensure the follow ing finishing W o rks are com pleted in the M ain

Facility W orks Site;

rem oval o f Site establishm ent;

cap of* and com pletely rem ove tem porary site services and record position; and

rem oval o f tem p ora ry m aterials, including surfacing, com plete w ith full reinstatem ent.

A dditional W orks Phase C om pletion C riteria

Project Co shall dem onstrate that the follow ing C om pletion C riteria have been achieved at the

com pletion o f the Additional W orks Phase w ithin the Additional W orks Site:

2.2.1

Safe access and egress to and w ithin the Facilities has been established;

2.2.2

All external w orks as appropriate have been com pleted and are available fo r use by

the Authority;

2.2.3

All external soft landscaping/planting is com plete (appropriate to the season) and

available for use by the Authority;

2.2.4

2.2.5

All dem olition w orks are com plete;

All hard-landscaped external w orks, including roads, car parks, pavem ents and

boundary w alls/fences are com plete and available fo r use by the Authority;

2.2.6

All building, directional, general inform ation, and external signage as indicated within

Project C o’s Proposals and/or the Reviewable D esign Data to allow the operational

Services to com m ence has been provided and installed.

This includes external

signage fo r the Facilities and areas outwith the Site boundary to include the access

routes and buildings on the w ide r Ayrshire C entral Hospital site;

2.2.7

Those elem ents of the fire m anagem ent strategy and fire safety risk assessm ent in

accordance with the Fire (Scotland) A ct 2005, fo r w hich Project Co is responsible,

have been produced;

2.2.8

All external lighting is installed, tested, com m issioned and operational;

2.2.9

All security and surveillance system s and access control are com plete, tested,

com m issioned, operational and available fo r use by the Authority;

2.2.10

2.2.11

All builder’s w ork in connection w ith art installations are com plete;

Project Co has provided all docum entation to the Independent Tester relevant to the

Additional W orks Phase in accordance with this Agreem ent and paragraph 4

(Indicative Testing and C om m issioning D ocum entation) below;

2.2.12

A final draft Operational M anual fo r the Facilities, in accordance with C lause 18 of

this Agreem ent, (containing, as a m inim um , all the testing and com m issioning

inform ation including as-built draw ings / test results so fa r as it is reasonably

practicable) relevant to the A dditional W orks Phase have been m ade available by

the C ontractor to Project Co to allow the Facilities to be operated safely;

2.2.13

Copies o f ail available C o rs e n ts and w arranties relevant to the

design

and

construction o f the Additional W orks Phase have been supplied by Project Co to the

Authority;

2.2.14

Project Co shall ensure the follow ing finishing W orks are com pleted in the Additional

W orks Site;

٠

rem oval o f Site establishm ent;

٠

cap off and co m pletely rem ove tem porary site services and record position; and

•

rem oval o f tem porary m aterials, including surfacing, com plete with full reinstatem ent

H a n d o v e r C lean

On com pletion of the construction of W orks, prior to handover, Project Co shall rem ove builders

debris, and clean all areas of the Facilities including Plant room s, to the standard defined below:

Floors

3.1.1

The flo o r is cleaned to rem ove paint, plaster, g rit and litter, w ater and other liquids;

3.1.2

The flo or is cleaned to rem ove stains, spots and scuffs;

3.1.3

Inaccessible areas (edges and corners) are cleaned to rem ove grit and lint;

3.1.4

All carpets, vinyls and the like flo o r coverings are clean and vacuum ed; and

3.1.5

Barrier m atting zones/entry flooring system s are vacuum ed and a ny w ells free of

debris.

Toilets, Sinks, Basins, Baths, Show ers, Taps and Fixtures

3.2.1

All labels, tape and sticky m arks to be rem oved;

3.2.2

Porcelain, cubicle rails and plastic surfaces are w iped clean;

3.2.3

Metal surfaces, show er screens and m irrors are w iped clean;

3.2.4

W all tiles and wall fixtures (including dispensers, to ile t holders, paper dispensers,

grab rails and the like) wiped clean to rem ove grit;

3.2.5

Inaccessible areas (edges, corners, folds and crevices) are cleaned to rem ove grit

and lint;

All pieces of fixed furniture, equipm ent and appliances

3.3.1

All high surfaces are w iped clean;

3.3.2

Blinds, curtains, screens including hanging rails, hooks and fixings are w iped clean;

3.3.3

Shelves, bench tops, cupboards and w ardrobes are wiped clean inside and out and

are free o f litter;

3.3.4

Protective film is rem oved from all hard surfaces and equipm ent unless otherw ise

requested by the Service Provider.

Low Level Surfaces

3.4.1

Internal walls cleaned to rem ove paint splashes, grit, soil and graffiti;

3.4.2

Skirtings, covings and the like are cleaned to rem ove paint or plaster splashes;

3.4.3

Light switches and data and electrical sockets are free from paint and plaster

splashes and wiped clean; and

3.4.4

All w indow s (glass internal and external), ironm ongery, vents w ind ow fram es

and

sills are free from paint and plaster splashes and are w iped cleaned.

High Level Surfaces

3.5.1

W alls and ceilings are cleaned to rem ove plaster splashes, paint splashes, grit, soil,

film and graffiti;

3.5.2

Ceilings and light fittings are cleaned to rem ove surface m arkings;

3.5.3

Doors and doorfram es are cleaned to rem ove grit, soil, and film ;

3.5.4

Air vents, grilles and other ventilation outlets are unblocked and cleaned to rem ove

grit, soil, scuffs and other m arks; and

3.5.5

Door tracks and door ja m b s are cleaned to rem ove grit and other debris.

IN D IC A T IV E T E S T I N G A N D C O M M IS S I O N IN G D O C U M E N T A T I O N

D ocum entation

The follow ing list is indicative of the test docum entation expected to be provided by Project Co

to the Independent Tester and the A uthority's R epresentative:

4.1.1

Building warrant com pletion certificates;

4.1.2

Evidence that all conditions fo r which Project Co is responsible attached to the

Planning Approval w hich are due to have been discharged to the satisfaction o f the

relevant local authority, have been so discharged;

4.1.3

All road construction consent rem edial works identified by the relevant local authority

should be undertaken prior to the Actual C om pletion Date, final road construction

consent certificate from the relevant local authority should be issued w ithin one (1)

m onth of the C ertificate o f Practical Com pletion;

4.1.4

Flushing cleaning and chlorination test certificates;

4.1.5

Boiler Plant m anufacturers fa cto ry test and com m issioning sheets in accordance

w ith CIBSE C om m issioning C ode B;

4.1.6

D uctw ork system s pressure test and volum e flow rate certificates if appropriate;

4.1.7

Kitchen equipm ent com m issioning certificate if appropriate;

4.1.8

Electrical installation com pletion and inspection certificates in accordance w ith (BS

7671 and N I€ E I€ requirem ents);

4.1.9

Lighting and pow er certificate of test;

4.1.10

Eire and intruder alarm s com m issioning certificates, including intruder detection and

alarm , access control system (s);

4.1.11

General electrical earth loop and insulation resistance test sheets;

4 .1 .12

T esting o f all hot w ater service therm ostatic m ixing valves ("T M V ’s") in accordance

w ith BS6700 and tests to com ply w ith HSE □ o cu m e n t 8 اand HGN ‘Safe H ot W ater

and Surface Tem peratures;

4.1.13

Em ergency lighting com pletion and test certificates;

4 .1.14

Security systems ct^missinning r.erfifteates;

4.1.15

C ertificate of soundness testing of gas installation;

4 .1 .1 6

G a s p ip e w o rk p re s s u r e te s t a n d p u rg e c e rtific a te s ;

4.1.17

Fire

suppression

system

certificates,

w here

such

system s

are

installed

(in

accordance w ith R-S6766 and tests to com ply w ith CIBSE G uidance E;

4.1.18

Fire alarm sound record sheets;

4.1.19

Eighting calculation sheets and lux level test results in accordance with CIBSE

C om m issioning C ode L;

4 .1 .26

M achine (generator/ups etc) specialist com m issioning and fa cto ry test sheets;

4.1.21

Acoustic te st sheets (in accordance with BS EN ISC 7 1 7 - 1 :1 9 9 7 ) ;

4.1.22

Lift C om m issioning in accordance with BS EN 81;

4.1.23

Eightning protection risk analysis and test/com m issioning sheets in accordance with

BS EN 62305 (2668):

4.1.24

W orks pressure tesf certificates ter all pressure vessels:

4 .1 .25

M echanical pipew ork system s pressure teste;

4.1.26

Equipm ent/F lant

item

m anufacturers

specialist

com m issioning

tests;

C ondensate clearance tests fo r HVAC Equipm ent;

4.1.27

BM S/EM S te ^s/co m m is s io n in g records in accordance w ith CIBSE C om m issioning

Code C;

4.1.28

Air distribution system s in accordance with CIBSE C om m issioning C ode ٨ ;

10

4.1.29

W ater

system s

(heating

and

dom estic

w ater)

in

accordance

w ith

CIBSE

C om m issioning Code W and SH TM 04-01 ;

4.1.30

Legionella testing (to include an organic check on the incom ing m ains) w ithin

tolerances given In HSE AC O P test sheets;

4.1.31

D om estic w ater system s bacteriological quality test sheets;

4.1.32

Plant (Calorific, Treatm ent etc.) specialist com m issioning and fa cto ry te st sheets, if

applicable;

4.1.33

Nurse C all/S taff A ttack and Assistance te st certificates;

4.1.34

Panic alarm test certificates;

4.1.35

T elem etry system test certificates;

4.1.36

Disabled Toilet Alarm test certificate;

4.1.37

Fire Alarm T est C ertificate;

4.1.38

C C TV and access control te st certificate;

4.1.39

T elephone and data structured cable schem e test certificate, te st results and copy of

m anufacturer’s warranty;

4.1.40

Induction loop test certificate;

4.1.41

Pipeline Pressure and flo w rate test certificates Steam boiler/generator te st fa cto ry

test and com m issioning certificates in accordance w ith CIBSE C om m issioning Code

B, w h e 'e applicable;

4.1.42

R efrigerant system fa cto ry test and com m issioning certificates, w here applicable, in

accordance with CIBSE C om m issioning Code R;

4.1.43

C hem ical clean and inhibitor dosing certification to heating/chilled w ater system s;

4.1.44

D uctw ork physical cleaning certification in accordance with SH TM 03-01 and the

B&ES (2005) ,T R /1 9 - G uide to good practice;

4.1.45

Building air pressure test certificate;

4.1.46

C om pletion o f NHS A yrshire and Arran's D om estic Services H andover C hecklist

included w ithin A ppendix C;

4.1.47

A ir tests and test records fo r the Facilities drains and drainage netw ork; and

4.1.48

Test certificates and sufficient w ritten evidence covering the design, construction and

repair etc fo r all protective devices such as pressure relief valves and the like.

Specific reference is m ade to com pliance with R egulation 5 of The Pressure

System s Safety R egulations 2000.

Appendix C: Appendix C - Domestic Services Handover Checklist

A c tiv ity

Yes

Design

Advice sought and im plem ented from

Legionella expert.

W ater supply to equipm ent protected

against back-flow

W a te r hardness level determ ined

Incom ing w ater quality determ ined

Separate supplies provided fo r labs &

m ortuary

Separate supplies provided fo r dialysis

Central filtration provided

Filtration plant m atched to incom ing

w ater quality and pipew ork m aterials

M eans o f isolating sections provided

R egulating / m easuring devices

provided

Chlorinated incom ing m ains confirm ed

C hloram inated incom ing mains

confirm ed

W ater treatm ent com pliant with w ater

quality legislation

D ead-legs elim inated

M aterials & equipm ent com pliant w ith

Scottish W a te r Byelaws and to Spec.

Above com pliance certified by

experienced public health engineer

E quipm ent liable to be replaced

dem onstrated spatially to that effect

M ethod of show er head disinfection

confirm ed

Incom ing cold w ater mains

tem peratures m onitored by BM S

S atisfactory m eans o f avoiding

excessive cold w ater circulating

pressures confirm ed

Pre-com m issioning checks

Installation as spec, charged & free

from leaks

Pipes adequately supported &

insulated, having m eans fo r venting &

draining, expansion, tem perature &

pressure m easurem ent

System flushed, disinfected and

certified to that effect

R egulating valves and flo w control

13

No

N/A

R e m a rk s

devices operating freely

W ater m eters correctly fitted

C ross bonding provided as required

A c tiv it y

Yes

No

W a te r treatm ent regim e certified

Com m issioning checks

System balanced - equal pressures

fo r hot & cold supplies at points o f use

C om m issioning results provided

D ocum entation, drawings and

schem atics provided

List of te st certificates provided and

signed ■off by supervising officer.

Risk assessm ent reports provided

indicating no outstanding issues

unresolved.

C om m issioning procedures fo r TM V s

as per MES D08

O verflow s running freely

Drain facilities shut tight

Float valves function satisfactorily

Control valves function satisfactorily

and sh ut-off tightly

Installation vented and regulated

Electrical circuitry tested satisfactorily

Pum ps operate w ith correct rotation

Pum ps operate free from noise

Pum ps therm al overloads set

Full load current o f com ponents not

exceeding recom m ended values

Running current of com ponents not

exceeding recom m ended values

A utom atic controls and alarm s

function correctly

Flow rates to and from storage

cisterns recorded

Heat exchangers operating

satisfactorily

T em peratures m aintained throughout

Installation as per SHTM 04-01

Secondary circuits regulated and

vented

Schem atics and valve schedules

displayed

Satisfactory m ethodology for

elim inating w aterborne bacteria

confirm ed

System drained and dried post

14

N/A

R e m a rk s

disinfection

M icrobiological tests carried out post

disinfection

A c tiv it y

C onfirm ation that biocide distribution

achieved throughout system

W eekly flushing carried after biocide

dosing

Yes

No

N/A

R e m a rk s