Forest Products - Miller Wood Trade Publications

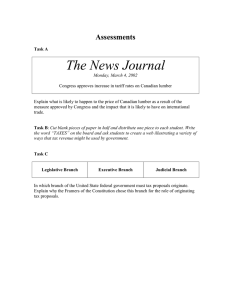

advertisement