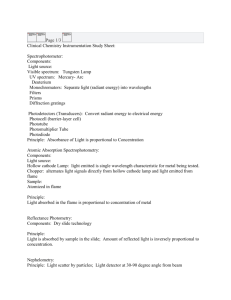

Agilent 50/55 AA

advertisement