Requirements for process control of continuous processes

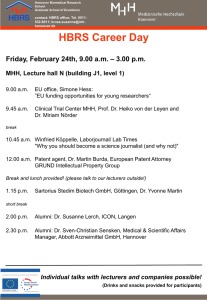

advertisement

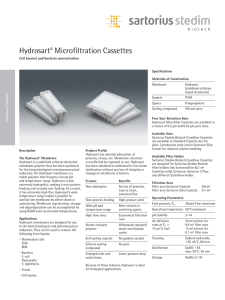

Requirements for Process Control of Continuous Processes: Sensorics and Automation Marek Hoehse 1/18/2014 CONFIDENTIAL - PROPERTY OF SARTORIUS STEDIM BIOTECH GmbH Potential advantages of continuous processing in cell cultivation Improved product quality Constant maintenance of nutrients Less cell stress (e.g. lag phase or drop off viability at the end of the culture) Reduction of product degradation by minimized processing delays Improved scalability Same equipment for process development and production (or marginal scale-up factor) “Number-up” instead of scale-up feasible Production of labile products 22. Octobre 2013 Increased profitability More efficient / economical facility utilization Smaller footprint smaller size Lower energy consumption Higher portability Higher flexibility (“Number-up”) Higher cell densities / titer Increase in automation Reduction in service requirements Reduction in operator labor Lower chance of product loss or reprocessing Shorter processing times Better material utilization CONFIDENTIAL - PROPERTY OF SARTORIUS STEDIM BIOTECH GmbH Page 2 Challenges of continuous cultivation Challenges (technical) Challenges (process) New forms of in-process testing More complex process Robust sensors Robust control systems Higher risk of failure Increased training requirements Demanding process requirements Minimizing blackout of operation units High oxygen consumption High CO2 formation Pot. challenging clarification Higher need of process understanding Full knowledge of CPP´s and CQA´s required Sophisticated process control strategies More complex DSP approach Online control of DSP process Complex batch definition Limited number of reliable & scaleable cell retention devices Raw material concerns New forms of release approaches Higher material control or higher process robustness required Sophisticated feeding technologies Regulatory aspects CONFIDENTIAL - PROPERTY OF SARTORIUS STEDIM BIOTECH GmbH Challenges of continuous cultivation Challenges (technical) Challenges (process) New forms of in-process testing More complex process Robust sensors Robust control systems Higher risk for failure Increased training requirements Demanding process requirements Minimizing blackout of operation units High oxygen consumption High CO2 formation Pot. challenging clarification Higher need of process understanding Full knowledge of CPP´s and CQA´s required Sophisticated process control strategies More complex DSP approach Online control of DSP process Complex batch definition Limited number of reliable & scaleable cell retention devices Raw material concerns New forms of release approaches Higher material control or higher process robustness required Sophisticated feeding technologies Regulatory aspects CONFIDENTIAL - PROPERTY OF SARTORIUS STEDIM BIOTECH GmbH But can single-use equipment cope with demanding process requirements? Connectivity to cell retention system? High oxygen demand? Media logistics? Sufficient CO2 removal? Long operation times (> 14d)? Robust Sensor Technology? High performance clarification? Proteinaceous aerosol formation? Predictive scale-down model? 22. Octobre 2013 CONFIDENTIAL - PROPERTY OF SARTORIUS STEDIM BIOTECH GmbH Page 5 BIOSTAT® STR single-use bioreactor designed for demanding processes Conventional stirred tank design Optical and redundant conventional pH and DO probes 3 blade segment & rushton impeller options Working volume: 50 L, 200 L, 500 L, 1000 L, 2000L Inhouse bag production Optimized for high cell density cultures 22. Octobre 2013 CONFIDENTIAL - PROPERTY OF SARTORIUS STEDIM BIOTECH GmbH Page 6 Continuous Biomanufacturing Critical Process Parameters (CPP) Cell Cultivation / MO Fermentation METABOLITES: Lactate Acetate Glutamate Acetoin Ammonia NUTRIENTS: Glucose Sucrose Glutamin Fructose Cell parameters: Biomass dry mass Total Cell Count OD600 Viability microbial contamination REACTOR PARAMETERS: Oxygen, CO2 Product (CQA): pH Antibody Spores Temperature Vaccines Enzymes CONFIDENTIAL - PROPERTY OF SARTORIUS STEDIM BIOTECH GmbH Analytical Systems NIR/ UV-VIS Spectroscopy Online Glucose | Lactate Analysis Viable Biomass Analysis Exhaust Gas Analysis 22. Octobre 2013 CONFIDENTIAL - PROPERTY OF SARTORIUS STEDIM BIOTECH GmbH Page 8 Automated monitoring and control of continuous processes – a reality? Implementation of glucose | lactate measurement and control strategy Single-use bioenzymatic sensors and fluidics Integrated autocalibration & autosampling BioPAT®Trace Global Trends DCU – Local Control Unit BioPAT®MFCS/win + Recipe Module Dialysis or filtration mode Compact design Reducing off-line sampling Direct display of glucose | lactate conc. Quick and simple process monitoring at a glance Fully automated glucose feed & perfusion rate control Recipes for automatic event-based control of cultures Improved batch-to batch consistency 22. Octobre 2013 CONFIDENTIAL - PROPERTY OF SARTORIUS STEDIM BIOTECH GmbH Page 9 Automation BioPAT®Xgas – Integrated Off-Gas Analysis and Process Control BioPAT®Xgas Global Trends Parallel measurement of O2 | CO2 Moisture and pressure independent Directly integrated into exhaust gas line Compact design for flexible integration DCU – Local Control Unit BioPAT®MFCS/win + Recipe Module Direct Display of %O2 | %CO2 Quick and simple process monitoring Functional monitoring of DO probe Automatic OUR | CER | RQ calculation Automatic event based control of microbial and animal cell cultivations: Adding feeds | induction media Harvest initiation Gas mixing strategies Process and yield optimization 22. Octobre 2013 CONFIDENTIAL - PROPERTY OF SARTORIUS STEDIM BIOTECH GmbH Page 10 Automated monitoring and control of continuous processes – a reality? In-line, real-time monitoring of viable biomass Automated process monitoring & control Automated control of cell bleed via BioPAT®MFCS Event based control (induction, temp change, point harvest, etc.) Dielectric Spectroscopy Dead cells “invisible” to radio frequency field Only viable cells polarized RF capacitance proportional to viable biomass Benefits Consistent cell count (operator and sampling independent) Consistent automated manufacturing Sensor integration for BIOSTAT®STR and BIOSTAT®RM CONFIDENTIAL - PROPERTY OF SARTORIUS STEDIM BIOTECH GmbH Bioprocess control with NIR spectroscopy and Multivariate Data Analysis NIR-System (Ingold-Adaption) - New system design – patent granted - Fiber free system - usable for 25mm standard Ingolt port - length 60mm (others on request) - sapphire window - Optical pathlength 1, 2 or 5mm - Sensor - 1100-1700 / 2500 nm spectrometer - Detector: diode array - IP65 Automatic detection of window fouling CIP/SIP ready Bigger measurement spot compared to fiber solutions SU adaption in progress NIR - Qualitative Multivariate Data Analysis PCA – The Score Plot (Spectra only) PC2 = Sum signal metabolites glutamine exhausted PC1 = cell count Start End NIR - Qualitative Qualitative Process Monitoring The Batch-Trajectory Score 1 contamination low performer (oxygen limitation) Comparison to “golden batch” Alteration within batches can be observed in process trajectories Ability to detect deviations and similarities CONFIDENTIAL - PROPERTY OF SARTORIUS STEDIM BIOTECH GmbH Qualitative Process Monitoring The Batch-Trajectory Score 3 contamination early glucose limitation CONFIDENTIAL - PROPERTY OF SARTORIUS STEDIM BIOTECH GmbH Qualitative Process Monitoring NIR Score 3 & Viability viability (offline analysis) !strong correlation! PCA-Score3 (spectral variations of NIR spectra) CONFIDENTIAL - PROPERTY OF SARTORIUS STEDIM BIOTECH GmbH NIR - Qualitative NIR Media Classification Media composition in bacillus spore production NH-Vibration Batch 2: Lower concentration of N-source 22. Octobre 2013 CONFIDENTIAL - PROPERTY OF SARTORIUS STEDIM BIOTECH GmbH Page 20 NIR - Quantitative CONFIDENTIAL - PROPERTY OF SARTORIUS STEDIM BIOTECH GmbH NIR - Quantitative prediction (Mio cells / ml) Total Cell Count reference (Mio cells / ml) Model Total Cell Count Concentration Range Algorithm PCs Cell count Mio/ml 0 – 16 PLS 1 Validation procedure Testset K06 Error of Prediction (SEP) 0.54 NIR - Quantitative Viability viable dead Model Viability Concentration Range Algorithm PCs Viability [%] 0 – 100 PLS 5 Validation procedure Testset K05 Error of Prediction (SEP) 3 direct scatter pattern or correlation to cell lyses? NIR - Quantitative prediction (g/l) Glucose reference (g/l) Model Glucose Glucose (g/l) Concentration Range 0–7 Algorithm PCs PLS 5 Validation procedure Testset K06 Error of Prediction (SEP) 0.24 Summary CONFIDENTIAL - PROPERTY OF SARTORIUS STEDIM BIOTECH GmbH Acknowledgements Co-workers Christian Grimm José Fernandes Roland Bienert Thomas Scheper Dörte Solle Marko Sandor Thank you ! 22. Octobre 2013 CONFIDENTIAL - PROPERTY OF SARTORIUS STEDIM BIOTECH GmbH Page 26 Agenda 1. Continuous Manufacturing in Cell Cultivations 2. Single Use in continuous Cell Cultivation 3. Sensors in Cell Cultivation 4. Multivariate Data Analysis for enhanced process control CONFIDENTIAL - PROPERTY OF SARTORIUS STEDIM BIOTECH GmbH High cell density inoculum production using Biostat® RM perfusion MCB/WCB vial Perfusion expansion Controlled freeze of HCD seed stocks References: Direct seed of production bioreactor N. C. Bögli et al.: Cell Banking, One-Step Inoculation, and Repeated Fed-Batch Expansion in a Single-Use Bioreactor. BioProcess International 10(5)s May 2012 G. Seth et al.: Development of a new bioprocess scheme using frozen seed train intermediates to inoculate CHO cell culture manufacturing campaigns. Biotech & Bioeng., Volume 110, Issue 5, May 2013, Pages: 1376–1385 CONFIDENTIAL - PROPERTY OF SARTORIUS STEDIM BIOTECH GmbH Multivariate Statistical Process Control (MSPC) Classification - Media composition in bacillus spore production 2-m01 1-m01 1-m02 4-m01 3-m01 3-m02 4-m03 4-m02 3-m03 2-m02 2-m03 1-m03 Building the model with high performance batches compare new batches with model significant deviations detected THANK YOU VERY MUCH FOR YOUR ATTENTION! QUESTIONS? 22. Octobre 2013 CONFIDENTIAL - PROPERTY OF SARTORIUS STEDIM BIOTECH GmbH Page 30 Example - Cultivation of CHO cells in a Biostat® RM Comparison of in-line (capacitance measurement) vs offline data (Cedex) 22. Octobre 2013 CONFIDENTIAL - PROPERTY OF SARTORIUS STEDIM BIOTECH GmbH Page 31 G. Seth et al.: Development of a new bioprocess scheme using frozen seed train intermediates to inoculate CHO cell culture manufacturing campaigns. Biotech & Bioeng., Volume 110, Issue 5, May 2013, Pages: 1376–1385 CONFIDENTIAL - PROPERTY OF SARTORIUS STEDIM BIOTECH GmbH Rec. blood factors, enzymes & mAbs commercially produced in continuous culture Protein Trade name/Company Driver rFVII NovoSeven (NovoNordisk) product quality (γ-carboxylated, labile) rFVIII Kogenate (Bayer) Refacto (Pfizer) Product quality (labile) rProtein C Xigris (Eli Lilly) Product quality (γ-carboxylated, labile) mAbs Reopro (Janzen) Remicade (Janzen) Simulect (Novartis) Rebif (Merck-Serono) Space-time yield Enzymes Genzyme Shire Biomarin Product quality (labile) 22. Octobre 2013 CONFIDENTIAL - PROPERTY OF SARTORIUS STEDIM BIOTECH GmbH Page 33 Continuous culture process modes Perfusion Concentrated fed-batch Y nutrients cells nutrients product cells product 5-20 days 10-80 days CONFIDENTIAL - PROPERTY OF SARTORIUS STEDIM BIOTECH GmbH Can perfusion help to address industry challenges of today? Industry drivers Opportunities - Perfusion reduce development costs reduce time to market reduce COGs reduce complexity regional production Only way forward for labile or difficult to express products Biopharma trends Better controlled product quality due to stable environment follow-on biologics biosimilars new mab formats smaller indications Faster material supply for medium – low titre products Reduced process development time line for non-platform processes Smaller production bioreactors Fewer seed steps CONFIDENTIAL - PROPERTY OF SARTORIUS STEDIM BIOTECH GmbH Where are we moving to in the age of single-use? Single-Use Multi-Use Low fixed cost High fixed cost No steam & CIP, limited WFI WFI, Steam, CIP system Decision late (<1y) Decision early (> 3 y) Equipment IQ/OQ Equipment IQ/OQ (significant!) Sterilisation via vendor Sterilisation No Cleaning Cleaning E&L PV risk based; generic E&L dossiers? Appropriate quality of materials! Carefully evaluate vendors! Carefully evaluate vendors! Does it work for my process? Stirred tank design dominating Refurbishment Very easy Challenging Footprint Reduced Investment/ Costs Qualification Design 22. Octobre 2013 CONFIDENTIAL - PROPERTY OF SARTORIUS STEDIM BIOTECH GmbH Page 36 BioPAT®Trace – Glucose | Lactate Analyzer Features Bioreactor Sampling Seed Bioreactor Bioreactor Celsius FFT • • • • • • • CONFIDENTIAL - PROPERTY OF SARTORIUS STEDIM BIOTECH GmbH Fully automated, self calibrating Modes: Filtration, Dialysis, Sampling Plug & Play Reusable system Fully disposable sensor & fluidics set Ethernet, Modbus, (OPC) Compact device CONFIDENTIAL - PROPERTY OF SARTORIUS STEDIM BIOTECH GmbH One key requirement of continuous processing is good process control to keep operations at steady state. Together with disposable technology this provides some powerful opportunities (K. Konstantinov, Genzyme) Industry leaders see the design of completely closed, disposable and continuous biomanufacturing systems for biopharma on the horizon (W.G. Whitford, Thermo Scientific cell culture and bioprocessing) 22. Octobre 2013 CONFIDENTIAL - PROPERTY OF SARTORIUS STEDIM BIOTECH GmbH Page 39 Principle of measurement Patch Composition DO-Sensor e offluorophore measurement Medical grade silicone with sinosoidal modulated light Determination of Fluorescence Lifetime•for Excitation DO-measurement Ind Ind Ind Ind Ind Ind Ind • • Ind Ind Ind Ind • Ind Timeshift of fluorescence due to fluorescence lifetime Measurement of phase-shift between Excitation-signal and fluorescence-signal Conversion of phase-shift to lifetime by: Ind Ind Ind N2 O2 22. Octobre 2013 CONFIDENTIAL - PROPERTY OF SARTORIUS STEDIM BIOTECH GmbH Page 40 Sensors & Automation: Implementation Along Production Chain (mAb) SCADA MFCS Automation Sensors pH cond. SCADA pH Biomass. flow. DO pH Glc pH pressure. flow. pressure. DCU DCU pH cond. pH cond. pressure. DCU Automation 22. Octobre 2013 flow. pH flow. pressure. pH flow. pressure. MFCS SCADA Sensors pressure. DCU DCU MFCS Automation Sensors DCU DCU pH pressure. DCU DCU flow. pH cond. CONFIDENTIAL - PROPERTY OF SARTORIUS STEDIM BIOTECH GmbH pressure. pH cond. flow. pressure. Page 41 Biostat STR set-up for continuous perfusion or concentrated fed-batch CONFIDENTIAL - PROPERTY OF SARTORIUS STEDIM BIOTECH GmbH ϕ [°] Principle of measurement Calibration for pH-Sensor A1 56 54 52 50 48 46 44 42 40 38 36 34 32 30 28 26 24 22 • Sigmoidal calibration function • Fit by Boltzmann-Equation: x0 dx A2 4 5 6 7 8 9 pH 22. Octobre 2013 CONFIDENTIAL - PROPERTY OF SARTORIUS STEDIM BIOTECH GmbH Page 43 SU sensor development – development process workflow Sensor Evaluation • Requirements • Specification • Performance tests Sensor Qualification • Qualification tests • Robustness • Production transfer Sensor Integration • Bag integration • DCU integration Application Qualification 22. Octobre 2013 CONFIDENTIAL - PROPERTY OF SARTORIUS STEDIM BIOTECH GmbH • Application test • Documentation Page 44 SU sensor development – general design rules / requirements Requirement Specification Shelf life < 3 years after Irradiation Sterility has to be confirmed Lipids, Oil, aqueous solutions, saline solutions, alcoholes, acids, alcalic solutions, WFI Media consistency Material properties FDA admission, USP Class VI certification, Whole production process TSE/BSE-free, Free of animal origin Irradiation consistency 50 kGray gamma irradiation Certificates / Qualification tests Performance Tests, Handling Tests, Partikel free (USP 788), Cleaning procedures, USP Class VI, Cytotoxicity, Biological assays, Extractable / Leachables, Bioburden 22. Octobre 2013 CONFIDENTIAL - PROPERTY OF SARTORIUS STEDIM BIOTECH GmbH Page 45 Application of Single Use pH and DO sensors Sensors integrated in the cultivation bags and Univessel-SU Example: pH, DO 22. Octobre 2013 CONFIDENTIAL - PROPERTY OF SARTORIUS STEDIM BIOTECH GmbH Page 46 Measurement principle: Dielectrically essential part of cell structure Cytoplasmic Lipid membrane impermeable to the free flow of ions 22. Octobre 2013 CONFIDENTIAL - PROPERTY OF SARTORIUS STEDIM BIOTECH GmbH Page 47 SU Biomass Sensor Status • Beta side tests in stirred bioreactors systems showing good results • Special algorithms for rocking systems is developed –> RM 50 plus •Software implementation in our DCU software is ongoing N Cultivation of CHO cells 22. Octobre 2013 CONFIDENTIAL - PROPERTY OF SARTORIUS STEDIM BIOTECH GmbH Page 48 Introduction Glucose / Lactate Measurement Connected to Univessel SU Online measurement for all fermentation system Easy to handle and easy connection Different measurement strategies (continuous or time dependent) Linear Measurement Range from 0 – 40 g/l Glucose and 0 – 5 g/l Lactate Connection to SU Bioreactors BioPAT®Trace 22. Octobre 2013 CONFIDENTIAL - PROPERTY OF SARTORIUS STEDIM BIOTECH GmbH Page 49 Application: BioPAT® Trace - System The BioPAT® Trace can be connected with every bioreactor | fermenter – coming from Sartorius or competitors 22. Octobre 2013 CONFIDENTIAL - PROPERTY OF SARTORIUS STEDIM BIOTECH GmbH Page 50 Online biomass detection (cell culture) Bioreactor Sampling Seed Bioreactor Bioreactor Celsius FFT •Real-time monitoring of viable biomass for entire batch allows automated process control and process modeling automated substrate feed strategies with MFCS harvest point determination time of induction / infection Targets: •Reduced risk of contamination due to limited sampling need •Reduced risk of unrepresentative samples (manual handling) •Decreased labor cost for offline analysis •Single use sensor integration for various SU bioreactors 22. Octobre 2013 CONFIDENTIAL - PROPERTY OF SARTORIUS STEDIM BIOTECH GmbH Page 51 Measurement principle: In situ four pin electrode probe used for radio-frequency impedance measurement Cytoplasmic Lipid membrane impermeable to the free flow of ions Dead cells “invisible” to RF Field Only live cells polarized field area approx 25mm 22. Octobre 2013 CONFIDENTIAL - PROPERTY OF SARTORIUS STEDIM BIOTECH GmbH Page 52 METABOLITES: Bioprocess – Cell Cultivation / MO Fermentation Critical Process Parameters (CPP) Lactate Acetate Glutamate Acetoin Ammonia Cell parameters: NUTRIENTS: Glucose Sucrose Glutamin Fructose Total Cell Count dry mass Viability OD600 microbial contamination REACTOR PARAMETERS: Product (CQA): pH Antibody Spores Temperature Vaccines Enzymes 7 6 800 5 600 100 1.6x107 90 1.4x107 80 1.2x107 70 7 60 1.0x10 50 200 1 0 0 12 24 36 48 60 72 time [h] 84 96 108 120 132 0 144 Cell Count Total 400 2 glutamate [mg/L] glucose [g/] 8.0x106 3 40 6.0x106 30 4.0x106 20 2.0x106 10 0.0 CONFIDENTIAL - PROPERTY OF SARTORIUS STEDIM BIOTECH GmbH 0 12 24 36 48 60 72 time [h] 84 96 108 120 132 0 144 Viability [%] 4 glutamine [mg/L] lactate [g/L] 1000 Cell Count Vital [N/mL] Oxygen, CO2