A synopsis - Shodhganga

advertisement

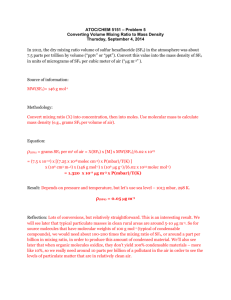

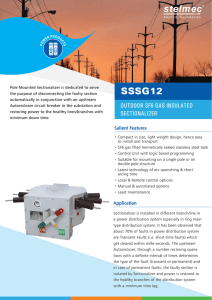

MODELLING AND ANALYSIS OF METALLIC PARTICLE CONTAMINATION IN GAS INSULATED SUBSTATION UNDER PURE SF6 AND SF6+N2 GAS MIXTURES “A synopsis” submitted in partial fulfillment of the requirements for the award of the degree of Doctor of Philosophy in “FACULTY OF ELECTRICAL ENGINEERING” By D.PADMAVATHI [REG.NO.30706EE/PH] RESEARCH AND DEVELOPMENT CELL JAWAHARLAL NEHRU TECHNOLOGICAL UNIVERSITY KUKATPALLY, HYDERABAD – 500 085, A.P. INDIA. September 2010 1 Synopsis on MODELLING AND ANALYSIS OF METALLIC PARTICLE CONTAMINATION IN GAS INSULATED SUBSTATION UNDER PURE SF6 AND SF6+N2 GAS MIXTURES Introduction: Demand for electrical power has become one of the major challenges faced by the developing countries. Considering the relative low per capita power consumption, there is a constant need for power capacity addition and technological upgradation whereas non-conventional energy systems have proved to be good alternative sources for energy. In developing countries like India most of the additional power has been met by conventional electric sources. Hence, the emphasis has shifted towards improving the reliability of transmission and distribution systems and ensuring that the innovations are not harmful to the environment. Due to rapid urbanization and overgrowing population is making the task of expanding transmission network very difficult due to right of way problem and limited space availability. Power needed a creative solution to its urbanization problem, a compact design on a smaller site with improved aesthetics to lessen the impact on the neighborhood. Gas Insulated Substation has found a broad range of applications in power systems for more than two decades because of their high reliability, easy maintenance and small ground space requirement etc. In our country, a few GIS units have 2 been in operation and a several large number of units are under various stages of installation. Gas Insulated Substations are essential in the transmission of electrical power to growing urban centers where conventional air insulated substations can no longer meet the requirements of available space, pollution, safety, maintenance and other similar expectations. The Gas Insulated Switchgear (GIS) contains major substation equipment, such as gas circuit breaker, disconnecting switch, earthing switch, voltage transformer, current transformer, and lightning arrester in the grounded metallic enclosure and is filled with SF6 gas, which has the best insulation and arc- quenching capabilities. The introduction of SF6 gas has revolutionized not only the technology of circuit breakers but also the layout of substations. Gases are used as an insulating medium for compact substation components and gas insulated cables. In recent years, sulphur hexafluoride (SF6) gas has been of considerable technological interest as an insulation medium in high voltage apparatus because of its superior insulating properties, high dielectric strength at relatively low pressure and its thermal and chemical stability. SF6 exhibits many properties that make it suitable for equipment utilized in the transmission and distribution of electric power SF6 has been found to be a greenhouse gas. It absorbs infrared radiation and is also immune to chemical and photolytic degradation. Therefore, its contribution to global warming is cumulative and virtually permanent. Over a 100 years, its global warming 3 potential (GWP) is estimated to be 24000 times greater than that of CO 2. For this reason it is included in the six gas basket of the Kyoto Protocol. Calculations based on atmospheric measurements show that the total worldwide emissions of SF6 contribute only about 0.1 percent of the overall anthropogenic greenhouse effect. This includes both the SF6 emissions from the major area of use in electricity transmission and distribution systems (about 70-80 % of the global SF6 production is used in this sector) and those from all other uses. The searches for even better gas insulation continues in order to develop gases and gas mixtures to satisfy specific requirements for various devices, provided such gases have dielectric properties comparable or superior to each other. There are two basic reasons for carrying out such investigations. Firstly, the aims are to develop an insulating medium, which is technically as well as economically attractive. The other reason is to obtain a better understanding of the breakdown mechanisms operating in compressed gases, and their gas mixtures. Most of the published data refer to uniform or nearly uniform field gaps for SF6, CO2, (carbon dioxide) N2 (nitrogen) and air [1-2]. In a typical industrial application the non-uniform field breakdown predominates. Earlier experimental results showed strong dependence of breakdown voltages upon applied voltage, voltage polarity, electrode spacing, pressure and the nature of the gas. It is recognized that Sulfur Hexafluoride (SF6) gas has excellent dielectric and heat transfer properties and is 4 increasingly being used in high-pressure gas insulated systems. However, in practice the electrical breakdown strength of compressed SF6 is often governed by a local field enhancement due to the protrusions, surface roughness, and the presence of conducting particles in the system. In addition the fact that SF6 is a strong greenhouse gas has prompted interest in substitute gases with lower or no environmental impact. Therefore, there is an increasing interest in the possible application of mixtures of SF6 and other gases to reduce insulation cost and to minimize the possible hazard of particle-initiated breakdown. Many researches have studied behavior of air, N2 and CO2 mixed with a small percentage of SF6 as an additive. The mixture of SF6+N2 gases is used for numerous applications, including use as insulation for high voltage equipment. From a practical point of view, only SF 6 mixtures with those common gases or buffer gases (air, N2) show an importance in most industrial applications [4]. L.G.Christophorou .et.al.,[3] stated that addition of small amount of SF6 to N2 gas can considerably improve the breakdown strength depending on the gas pressure and reduces insulation cost of the system at higher gas pressures. This type of behavior is more pronounced when the field configuration is highly non-uniform and/or gas pressure is high. SF6 is the main mode of insulation in a GIS. However, in recent years, the future use of SF6 has been debated throughout the world in spite of it having all the desirable properties of a good insulating and arc quenching medium. Sulfur hexafluoride (SF6) has been used as a gaseous dielectric (insulator) in 5 high voltage equipment since the1950s. It is now known that SF6 is a potent greenhouse warming gas with one of the highest global warming potentials (GWP) known. Because of its high GWP, it is being phased out of all frivolous applications.SF6 is an efficient absorber of infrared radiation, particularly at wavelengths near 10.5 µm. Additionally, unlike most other naturally occurring green house gases (e.g., CO2, CH4), SF6 is only slowly decomposed; therefore its contribution to global warming is expected to be cumulative and long lasting. The strong infrared absorption of SF6 and its long lifetime in the environment are the reasons for its extremely high global warming potential which for a 100yeartime horizon is estimated to be approximately 24,200 times greater (per unit mass) than that of CO2, the predominant contributor to the greenhouse effect. The concern about the presence of SF6 in the environment derives exclusively from this very high value of its potency as a greenhouse gas. However, the present inventors have determined that given the environmental difficulty of SF6 [3], it is necessary to relax certain of the requirements traditionally held as important and accept as an alternative gas, compromise candidates with a lower GWP. For example, gases which are nontoxic are often inert with long atmospheric lifetimes which can yield high GWP. By accepting a somewhat more reactive gas than SF6, the GWP can be greatly reduced. Among the environmentally benign insulating gases alternative to SF6 gas, SF6/N2 gas mixtures (at different percentages of SF6) is regarded as one of the most attractive gases because of the synergistic effect in electrical 6 insulation performance. By using SF6/N2 gas mixture, it is to reduce SF6 gas amount for power apparatus and this enables us to suppress the global warming effect. SF6-N2 mixtures are the most thoroughly investigated among all known gas mixtures. Based on the research conducted worldwide, the optimum composition of SF6-N2 mixture for practical applications is considered to be 40% SF6 - 60% N2 mixture [4]. But, recent studies carried out also suggest that SF6-N2 mixture with SF6 concentration as low as 20% can be used with an advantage [5]. Even with low SF6 content, this mixture has been found to exhibit many of the desirable properties of pure SF6 when used as an insulant. Although, GIS has been in operation for several years, some of the problems need full attention. These problems include generation of over voltages during switching operations like enclosure faults and particle contamination. Sulphur Hexafluoride (SF6) and SF6/N2 gas mixtures are generally found to be very sensitive to field perturbations such as those caused by conductor surface imperfections and by conducting particle contaminants [6-7]. A study of CIGRE group suggests that 20% of failures in Gas Insulated Substations (GIS) are due to the existence of various metallic contaminations in the form of loose particles. The presence of contamination can therefore be a problem with gasinsulated substations operating at high fields. If the effects of these particles could be eliminated, then this would improve there liability of compressed gas insulated substation. It would also offer the possibility of operating at higher 7 fields to affect a potential reduction in the GIS size with subsequent savings in the cost of manufacture and installation. Defects like metallic particles or protrusion or contamination on the surface of an epoxy spacer in GIS would be a cause of partial discharges (PD) which may lower the corona onset and can lead to final dielectric breakdown of the equipment. Metallic particles can be either free to move in the GIS or they may be stuck either to an energized electrode or to an insulator surface (spacer, bushing etc.). Depending on the shape of the particles, as well as the geometry and voltage levels of the system, the particles get more or less influenced by the electric field which, in turn, makes them hazardous to the electrical system. Particles in practical systems can exist in a wide variety of shapes and sizes, and of materials of different densities. However, most contaminating particles have been reported to be wire in shape in practical compressed gas insulated systems. The particles may be conducting or insulating in nature, the latter being not harmful. Conducting contaminants effects are more pronounced at higher gas pressures [9]. Conducting contaminant effects are more pronounced under application of lightning and switching impulse voltages superimposed on power frequency voltages. Metallic particles are known to drastically impair the insulation integrity of compressed gas insulated sub-station (GIS) equipment. Such particles present a special hazard when present in close proximity of support insulators. Most GIS equipment manufacturers employ a variety of techniques and devices, 8 such as electrostatic particle traps, to control metallic particle contamination. Further research is vitally needed to detect the presence of these particles and mitigate their effects, and thus minimize unplanned outages. Reliability of electric supply is important and its economic impact is recognized by all users and suppliers. Some of the methods of conducting particle control and deactivation are: 1. Conditioning by particle movement and trapping 2. Electrostatic particle traps 3. Dielectric coating 4. Discharging of conducting particles through radiation. Dielectric coating: A Dielectric coating on the inside of the enclosure can deactivate particles by delaying their acquiring the electrostatic charge necessary for elevation until significantly higher voltages than those needed to cause lift – off conditions with bare electrodes are applied. The efficiency and effectiveness of dielectric coatings on high voltage electrodes in gaseous insulation systems have been studied over the past several years. Data indicate that the dielectric coatings are beneficial and improve the breakdown voltage in gaseous insulation systems. Moreover, results of some preliminary studies show that such 9 coatings reduce the adverse impact of metallic particles in GIS equipment, thus increasing the reliability of the system [10-11]. STATEMENT OF THE PROBLEM: A method based on the particle motion is proposed to obtain the particle trajectory in a Gas Insulated Bus duct (GIB). In order to determine the movement of particle in a GIB, an inner conductor diameter of 55 mm and outer enclosure diameter of 152 mm is considered. Aluminum, copper and silver particles of size, length and radius of 10mm/0.25mm and also 10mm/0.3mm are considered to be present on the enclosure surface as well on the epoxy coated spacer inclined at an angle 450 with respect to the enclosure under SF6 Gas and SF6+N2 mixtures environment. The motion of a particle is simulated by using the charge acquired by the particles, the macroscopic field at the particle site, the drag coefficient, Reynolds’s number and coefficient of restitution. The distance traveled by the particle which is calculated by using appropriate equations is found to be in good agreement with the published work for a given set of parameters. To obtain the random behavior of moving particles, the calculation of movement in axial and radial directions was carried out by Monte-Carlo technique. Aluminum, copper and silver particles are considered for simulation purpose. 10 The thesis presents the movement pattern of metallic particles at different operating voltages in a single phase isolated conductor Gas insulated Bus duct (GIB) has been simulated with and without dielectric coated enclosure. The purpose of dielectric coating is to improve the insulation performance. Free conducting particles situated inside the GIS enclosure decrease high local fields caused by conductor roughness. The coating reduces the charge on the particle colliding with the coated enclosure, which in turn reduces the risk of breakdown due to increase of the lift-off field of particles. The equations governing the motion of the particle in a 64/500mm 3-phase common enclosure GIS have been formulated to obtain the conducting contaminant trajectories under pure SF 6 gas also with SF6+N2 Gas mixtures. For SF6+N2 gas mixtures with different concentrations of N2 in SF6+N2 gas mixtures the viscosity of gas mixtures changes number, and hence the Reynolds which is then substituted in motion equation to calculate the movement of the particle. The result obtained for particle trajectory in three phase common enclosure GIS with SF6+N2 gas mixtures is in good agreement with published work of pure SF6 gas and new results have been presented and analyzed in this thesis. MAIN CONTRIBUTION OF THE THESIS: In this thesis the following investigations have been carried out to obtain the particle movement in a Gas Insulated Substation (GIS) or Gas Insulated Bus duct (GIB).In order to determine the particle movement in a GIB of an 11 inner conductor and outer enclosure diameters of 55mm and 152 are considered. Metallic particles like Al, cu and Ag of wire type are considered to be present in Single phase GIB on bare electrode and also on coated enclosure under application of power frequency voltages and also with lightning impulse voltage superimposed on power frequency voltages with SF6 as well as with SF6+N2 gas mixtures as dielectric medium have been presented and analyzed for voltages of 75kV, 100kV, 120kV, 132kV, 145kV, 160kV, 200kV and 245kV respectively. The following studies have been analyzed and presented in this thesis: A) Modeling and analysis of a particle movement in a single phase GIB with Uncoated enclosure with electric field effect under pure SF6 gas environment is presented as follows: Modeling and analysis of particle trajectories in gas insulated Bus duct on application of power frequency voltage. Modeling and analysis of particle trajectories in gas insulated Bus duct on application of lightning impulse voltage superimposed on power frequency voltage. Modeling and analysis of particle trajectories in gas insulated Bus duct on application of switching impulse voltage superimposed on power frequency voltage on power frequency voltage. 12 B) Modeling and analysis of a particle movement in a single phase GIB with Uncoated enclosure with electric field effect SF6+N2 gas mixtures environment is presented as follows: Modeling and analysis of particle trajectories in gas insulated Bus duct on application of power frequency voltage. Modeling and analysis of particle trajectories in gas insulated Bus duct on application of lightning impulse voltage superimposed on power frequency voltage on power frequency voltage. Modeling and analysis of particle trajectories in gas insulated Bus duct on application of switching impulse voltage superimposed on power frequency voltage. C) Modeling and analysis of a particle movement in a single phase GIB under coated enclosure condition with electric field is presented as follows: Modeling and analysis of particle trajectories in gas insulated Bus duct on application of power frequency voltage with pure SF6 gas. Modeling and analysis of particle trajectories in gas insulated Bus duct on application of power frequency voltage with SF6+N2 gas mixtures. D) Modeling and analysis of a particle on epoxy coated conical spacer in a single phase GIB with contaminant at different positions on conical spacer inclined at an angle of 45 degrees under application of typical single phase power frequency voltages. 13 E) Modeling and analysis of a particle movement in three phase common enclosure GIS under application of power frequency voltage with SF6 gas and also with SF6+N2 gas mixtures considering wire like contaminant and also with spherical contaminant. ORGANISATION OF THESIS: CHAPTER I presents introduction to Gas Insulated Substations and adverse effects of conducting contaminant in GIS are discussed. Since SF6 Gas is the main dielectric medium which is a green house gas with highest GWP, the best substitute for SF6 gas is presented with literature survey. CHAPTER II Presents the statement of problem, Main contribution of the thesis and Organization of the thesis. CHAPTER III presents the modeling of metallic particles in a bare electrode and coated enclosure system with SF6 gas as well as with SF6+N2 gas mixtures as dielectric medium under application of power frequency voltage and also with lightning impulse voltage superimposed on power frequency voltage. Further modeling of single phase GIB With contaminant on the spacer is presented .Movement pattern is obtained for metallic particle considered to be present at different positions on the conical spacer inclined at 45 deg with respect to enclosure are presented. CHAPTER IV presents the modeling and analysis of metallic particle in common enclosure with pure SF6 gas as well as with SF6+N2 gas mixtures. Wire 14 like and spherical particles are considered under application of power frequency voltage. CHAPTER V presents the conclusions and results of dissertation. The future scope of this work is also discussed. CONCLUSIONS: Gas insulated substation, which has become the essentiality in this rapid energy demanding era, has inspired many with its varied characteristics. Apart from being compact it proved to be a fail- safe solution and also provided economic solution in easier installation and maintenance. The tech savvy and aesthetic GIS can be adopted almost anywhere, which was earlier only a dream. In my work, the major study constituted the discussion of excellent properties of the insulating gas ‘SF 6’ its potentiality and its possible effect on the environment has become a burning topic as “GREEN HOUSE” gas. Among the environmentally benign gases, alternative to SF6 gas, the SF6- N2 gas mixtures is regarded as one of the most attractive gases for the same setup used for SF6, because of the synergetic effect in electrical insulation performance. As the presence of conducting contaminants is a major threat to GIS leading to reduction in insulation integrity, the time taken for the breakdown of insulation can be estimated by obtaining the contaminant particle trajectory, which is carried out here with pure SF 6 gas and SF6/ N2 gas 15 mixtures. Defects occurring in Gas Insulated Substations and the methods for their control and deactivation are reviewed. An uncharged metallic particle resting on bare electrode in a Gas Insulated System will gradually acquire charge due to the application of electric field around it. The charge accumulated is a function of Electric field, shape, size and orientation of the particle. Three forces act on the particle: eg. Electrostatic force and oppositely acting gravitational and drag forces. When electrostatic force exceeds the gravitational and drag forces the particle lifts from its position. A further increase in the applied voltage makes the particle move into the inter electrode gap in the direction of applied field. This increases the probability of a flashover. If an investigation reveals the presence of a particle, it is required to analyze the particle i.e., find the material and approximate size of the particle as certain particles are more deleterious than others The influence of increased voltage level on the motion of the particles is also investigated. If the calculations, as described above, are performed at a higher voltage level, the particle will lift higher from the surface and the time between bounces will increase .Results are obtained with pure SF6 gas and also with SF6+N2 gas mixtures. The results obtained with mixture of gases are in good agreement with the published work of pure SF6 gas and new results with mixture of gases are presented. The results show that the movement of the particles increases as the applied voltage increases and it is found that the movement of aluminium particle is more when compared to copper and silver 16 particles due to its lighter mass, and hence acquiring greater charge/mass ratio. The purpose of dielectric coating is to improve the insulation performance. Free conducting particles situated inside the GIS enclosure decrease high local fields caused by conductor roughness. The coating reduces the charge on the particle colliding with the coated enclosure, which in turn reduces the risk of breakdown due to increase of the lift-off field of particles. As the thickness of the coating increases, the lift –off field increases and hence the movement of the particle decreases. Also the metallic contaminant have been considered on the conical spacer at different positions on the spacer reveal that the movement of the particle increases as the conducting contaminant is assumed to be present nearer to the hV conductor. The work reported in this thesis also deals with the movement of the metallic particles in a 3-phase common enclosure bus duct with bare electrodes. The macroscopic electric field at the surface of the enclosure for the 3-phase system is calculated in Cartesian coordinates. The electric field has been used to determine the charge as well as the force on the particle. The radial movement is calculated using the standard equation of motion. The calculations have been done for power frequency voltages. The results obtained from the calculations show that additional information about the particle could be obtained when voltage dependence is introduced in the calculations. The results are presented and analyzed by considering wire like particle and also 17 spherical particle under pure SF6 and SF6+N2 gas mixtures. As the operating voltage increases the axial and radial movement of the particles also increases in both the cases. In case of spherical particle, as the radius of the particle increases, the charge/mass ratio decreases resulting in the increase of lift-off field, thereby, decreasing the movement of the particle. It is found that 40%60% of N2 in SF6+N2 gas mixtures is the optimal mixture which can substitute for same set up of electrical equipment with pure SF6 gas. As the concentration of N2 in SF6 + N2 changes the viscosity of gas mixtures changes and hence the movement of the particle also changes and further, it is observed that the movement of the particle for optimal mixture of gases is found to be less when compared to the movement of particle under pure SF6 gas environment. REFERENCES: [1]Kevork Mardikyan, Orhan Ersen, Ergun Canarsian, "Ac Breakdown Strength of N2, SF6 and a Mixture of N2+SF6 containing a small amount of SF6”.IEEE conference on Electrical Insulation, Canada, June 16-19, 1996. [2] Emel Önal, “Breakdown Characteristics of Gases in Non Uniform Fields”. Journal of Electrical and Electronics Engg-Istanbul University, Vol 4 pp.11771182, 2004. [3] NIST Technical note-1425 : Gases for Electrical Insulation and arc interruption: Possible present and future alternatives to pure SF6 by L.G.Christophorou , J.K.Olthoff and D.S.Green. 18 [4]] L. G. Christophorou, J. K. Olthoff, R. J. Van Brunt, “SF6 /N2 mixtures, basic and HV Insulation properties”, IEEE Transactions,Dielectrics and Electrical Insulation 2 (5), October 1995 pp 952-1002. [5] Y.Hoshina et.al “ Dielectric properties of SF6/N2 gas mixtures on full scale model of the gas insulated bus bar ” , IEEE Transactions ,Dielectrics and Insulation 2000 IEEE pp-2129-2134. [7] N.H. Mallik and A.H.Qureshi , “Breakdown gradients in SF6-N2 ,SF6-AIR and SF6-Co2 Mixtures” . IEEE Transactions on Electrical Insulation Vol EI-15 No.5 october 1980. [8] N.J.Felici, “Forces et charges de petits objects en contact avec une electrode affectee d’un champ electrique”; Revue generale de I’electricite, pp. 1145-1160, October 1966. [9] Olivier. G, Gervais.Y, Mukhedkar.D, "A new approach to compute uniform field breakdown of gases", IEEE Trans. on Power Apparatus and Systems, Vol.4 PAS-97, pp.1177-1182, 2004. [10] G.V.Nagesh Kumar, J. Amarnath, B.P. Singh and K.D. Srivastava, “Electric Field Effect on Metallic Particle Contamination in a Common Enclosure Gas Insulated Bus duct ”, IEEE Transactions in Dielectrics and Electrical Insulation, April 2007, PP. 334-340. 19 [11] G.V.Nagesh Kumar, J. Amarnath, B.P. Singh and K.D. Srivastava, “Reduction of Particle Movement in a 3 phase common enclosure GIS with Dielectric Coated Electrodes” IEEE International Conference on Control, Instrumentation and Systems, University of Perdinya, Srilanka, 8th – 10th August 2007 20 LIST OF PUBLICATIONS FROM THIS THESIS: TECHNICAL PUBLICATIONS IN INTERNATIONAL JOURNALS: 1) D.Padmavathi, J.Amarnath and S.Kamakshaiah “Assessment of Dielectric Behavior of Sf6/N2 gas mixtures in the presence of metallic particle contamination in a common enclosure gas insulated bus duct”, International journal of applied Engineering and Research, ISSN 0973-4562 , Volume 5 Number 10 (2010) pp. 1789–1787. 2) D.Padmavathi, J.Amarnath and S.Kamakshaiah “Effect of lightning impulse voltage on the performance of 1-phase gas insulated bus duct in the presence of metallic particle contamination with SF6/N2 gas Mixtures” (Accepted for Journal of theoretical and applied and information technology International Journal –September2010 volume) 3) D.Padmavathi, J.Amarnath and S.Kamakshaiah “Conducting contaminant trajectory on Epoxy coated 1-Φ in Gas insulated Bus duct”(paper accepted for International journal of Industrial Engg and Technology,IJIET). 4) D.Padmavathi, J.Amarnath and S.Kamakshaiah “Conducting contaminant Movement restriction using coated enclosure in a single phase Gas insulated bus duct with SF6/N2 gas mixtures” (communicated to ARPN Journal) . 21 INTERNATIONAL CONFERENCES: 1) D.Padmavathi, J.Amarnath and S.Kamakshaiah “Behavior of metallic particle contamination in SF6/N2 Gas mixtures under the Influence of electric field in a Common enclosure gas insulated bus duct”, Proceedings of the 16th international symposium on high voltage ,Aug-2010,Cape Town, South Africa 2) D.Padmavathi, J.Amarnath and S.Kamakshaiah “Assessment of Dielectric Behavior of SF6/N2 Gas Mixtures with Dielectric coated Enclosure in A 1Phase Gas Insulated Bus duct In the Presence Of metallic Particle Contamination” Proceedings of the 16th international symposium on high voltage engineering -Aug-2010,Cape Town, South Africa 3) D.Padmavathi, J.Amarnath and G.V.Nagesh Kumar, Deepak Chowdary “Dielectric Behavior of Compact Design Three Phase Coated Gas Insulated Bus duct with Metallic Particle Contamination”, International Conference on High Voltage Engineering and Application, Chongqing, China, November 9-13, 2008 4) D.Padmavathi, J.Amarnath and S.Kamakshaiah “Effect of Lorentz Force on The Conducting Contaminant Trajectory In A Three Phase Gas Insulated Bus duct”, CEIDP-2009 18th-21st Virginia Beach, USA 5) D.Padmavathi, J.Amarnath and S.Kamakshaiah “Determination of particle Movement on Epoxy Coated Spacer in A single phase Gas Insulated Bus duct”, 22 presented at International conference on Power Modulator and high voltage Engg Atlanta from May 2010. 6) D.Padmavathi, J.Amarnath and S.Kamakshaiah “ Determination of conducting contaminant trajectory on Epoxy coated spacer using Monte-Carlo Technique” International conference on high voltage Engineering and Application (Oct ICHVE2010), Neworlans,USA.. (Accepted).