New Technologies in Cable Compounds

advertisement

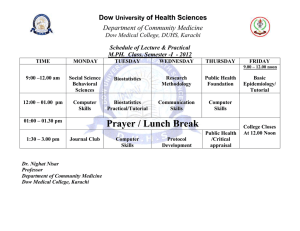

Midwest Energy Association 16th Annual Electric Operations Technical & Leadership Summit Recent Developments in MV Cable Materials Dow Electrical & Telecommunications Brent Richardson May 2015 Dow.com The Cable Value Chain Feed-stocks Base Resin Compound Cable Manufacturers Utilities Consumers Regulators 2 DOW CONFIDENTIAL - Do not share without permission Insulation Manufacturing Process Packaging Bin Resin/Additive Feeder Reactor Mixing Equipment ®™Trademark of The Dow Chemical Company (“Dow”) or an affiliated company of Dow Hopper Car Uniclean Package 3 Insulation Compound Cleanliness Specifications Cleanliness is critical: • Contaminants reduce breakdown strength • Contaminants act as electrical stress enhancers Extra Clean (EC) insulation is recommended for MV applications with a specifications of no more than 2 contaminants between 127 and 254 mm, and zero contaminants greater than 254 mm (per 1.6 kg basis)* Super Clean (SC) insulation is recommended for HV/EHV up to 230 kV applications with a specification of zero contaminants greater than 100 mm (per kg basis) EHV insulation is recommended for EHV above 230 kV with a specification of zero contaminants greater than 70 mm (per kg basis) * European EC specs allow 3 contaminants between 100 and 200 mm and zero contaminants greater than 200mm ®™Trademark of The Dow Chemical Company (“Dow”) or an affiliated company of Dow 4 Insulation Compound Cleanliness Camera Tape Contamination Test System Clean Room (Class 10,000) Clean Box (Class 1000) Labeler Camera Box T-Die Extruder Tape Take-up Roll Detector ®™Trademark of The Dow Chemical Company (“Dow”) or an affiliated company of Dow 5 Insulation Manufacturing Product Packaging EC for MV packaged into railcars ®™Trademark of The Dow Chemical Company (“Dow”) or an affiliated company of Dow SC for HV packaged into boxes 6 Insulation Types for Medium Voltage Cables The Insulated Conductors Engineering Association (ICEA) recognizes four types of material for the purpose of providing insulation for MV cables •Cross Linked Polyethylene (XLPE) •Tree Retardant Cross Linked Polyethylene (TR-XLPE) •Ethylene Propylene Rubber (EPR) •Ethylene Alkene Copolymer (EAM) ®™Trademark of The Dow Chemical Company (“Dow”) or an affiliated company of Dow 7 Chronology of TR-XLPE Insulation 1983 – Market Introduction by Union Carbide First commercial TR-XLPE insulation with demonstrated long life performance-HFDA-4202 1998 – Processing Improvements Provided Maintained the excellent electrical performance of the A4202 with improved properties for more robust cable manufacturingHFDB-4202 2001-Competitive Materials Introduced Borealis enters the NA market with LE-4212 2010 – Longer Life Materials Introduced Advancements to enhance longer life, ease of installation and further manufacturing robustness to ensure quality and consistency-HFDC-4202 ®™Trademark of The Dow Chemical Company (“Dow”) or an affiliated company of Dow 8 8 TR-XLPE Insulation Components Polyethylene Tree Retardant Antioxidant package Cure System ®™Trademark of The Dow Chemical Company (“Dow”) or an affiliated company of Dow 9 Chronology of EPR Insulation 1955 – Polymer Technology Developed Carl Ziegler developed a novel catalyst for polymerization of ethylene to polyethelyne-copolymerizing ethylene with propylene yields a new elastomer, EPM Early 1960’s– EPM Compound Production Begun 1962- Cable Applications Begun Late 1960’s- Compounded EPDM introduced for Crosslinking Attributes 1970’s-Broad Molecular Weight Distribution improves processing 1990’s-Development of Mettalocene Catalyst Technology ®™Trademark of The Dow Chemical Company (“Dow”) or an affiliated company of Dow 10 10 EPR Insulation Components (typical formulation) Elastomer Kaolin clay Antioxidant package Vinyl Silane Heat Stabilizer Red Lead Wax Low Density Polyethylene Dicumyl Peroxide ®™Trademark of The Dow Chemical Company (“Dow”) or an affiliated company of Dow 11 TR-XLPE & EPR Insulation materials Generic Material Properties TR-XLPE EPR • Unfilled • Highly filled material • Pure, simple polymer • Complex mixtures • Extra clean, natural • Cannot see contaminants • Dry cure • Steam cure • True-triple extrusion • Mostly 2+1 extrusion • Clean interfaces • More interfacial stress risers • Higher aged electrical strength • Lower aged electrical strength • Deformation resistant • Deformation resistant • Tougher • Softer / more flexible ®™Trademark of The Dow Chemical Company (“Dow”) or an affiliated company of Dow 12 NEETRAC 35 KV Test Results Nominal AC Breakdown Strength (V/mil) 1000 900 Cable Design Aging Test NEETRAC Project Number 97-409 AC Breakdown Results Averages, 345 Mil Wall New and Aged 4 Years @ 90 & 45 Deg. C, 69 kV 924 924 948 860 860 844 764 780 800 724 700 564 600 560 476 500 476 500 452 467 372 400 404 TR-XLPE 1 TR-XLPE 2 300 TR-XLPE 3 200 TR-XLPE 4 100 EPR 1 EPR 2 0 New 90° C 45° C Note: The insulation shield used on EPR1was found to be incompatible with the insulation at the elevated conductor temperature of 90 Deg. C This graph is a compilation of data from various figures included in NEETRAC Baseline Project Report 97-409. It was prepared and provided under Clause 6 of the terms and conditions outlined in the NEETRAC Publication Policy on the use of Baseline Project Results/Data. In keeping with that policy, the graph was reviewed and approved by NEETRAC and only Dow Chemical products can be identified outside the NEETRAC Membership. It is also important to note that ac breakdown was one of several tests used to evaluate the performance of complete cable designs in this accelerated aging test program. While comparing average ac breakdown strength values provides some insight into cable performance differences (or similarities), a statistical analysis/review of all measured performance values and characteristics is required to provide a complete indication of performance. ®™Trademark of The Dow Chemical Company (“Dow”) or an affiliated company of Dow 13 EAM Background The medium voltage filled insulation market has been dominated by Ethylene Propylene Rubber (EPR) based “leaded” insulations for the last forty (40) years The solution for increasing cable performance, dealing with environmental concerns, and addressing changing market dynamics requires modifications to the insulation system’s base polymer and stabilization package Over the last ten (10) years the performance of metallocene catalyzed Ethylene-Alkene Copolymers (EAM’s) have improved significantly; in concert with stabilizer package development, leadfree EAM insulation meeting utility MV performance requirements has been created ®™Trademark of The Dow Chemical Company (“Dow”) or an affiliated company of Dow 14 Definition of Insulation Materials per ANSI/ICEA ANSI/ICEA S-94-649 and S-97-682 allow alternate EAM insulating materials meeting the same physical and electrical requirements of XLPE, TRXLPE, and EPR EAM materials are first identified in a footnote under Table 4-1 in ANSI/ICEA S-94-649 and S-97-682 and are further explained in Appendix I and Appendix H respectively. EAM materials have been listed since 1996 ®™Trademark of The Dow Chemical Company (“Dow”) or an affiliated company of Dow 15 Definition of Insulation Materials per ANSI/ICEA ®™Trademark of The Dow Chemical Company (“Dow”) or an affiliated company of Dow 16 Why Elastomers are Used in MV Cable Applications Elastomers are polymers that exhibit high extension and flexibility when placed under low mechanical stress Low crystallinity of elastomers permit excellent flexibility that enables ease of cable installation Low crystallinity of elastomers require higher filler incorporation that in turn permits cross linked compounds to exhibit high heat and oil resistance ®™Trademark of The Dow Chemical Company (“Dow”) or an affiliated company of Dow 17 LF Filled EAM Insulation for Cable Applications Continuing technological developments in polymer catalyst technology make available more diverse polymers suitable for medium voltage cable applications General Cable developed LF Filled EAM with a Dow elastomer which uses the traditional ethylene backbone of an EPR formulation, but with a longer side chain The increasing side chain lengths in EAM compounds improves flexibility and the resulting electrical performance is improved without lead Ease of installation: Improved flexibility and trainability; Less spring-back Environmental sustainability is gained and recyclability is improved LF Filled EAM retains the inherent benefits of EPR insulations with improved thermal stability ®™Trademark of The Dow Chemical Company (“Dow”) or an affiliated company of Dow 18 Why Lead-Free? With safety as a top concern, the industry has focused on removing hazardous materials from cable products RoHS, California Prop. 65, REACH all restrict lead use; EPA currently says that the lead content in MV EPR insulation is below threshold limit, but what will be the future limits? > 250,000 lb of red lead oxide used in MV EPR insulation production by one manufacturer per year; Each year as the volume of traditional EPR consumption keeps growing the amount of red lead oxide grows ≈ 43 lb of red lead oxide per circuit mile of 4/0 Al 220 mils wall EPRinsulated MV cable ®™Trademark of The Dow Chemical Company (“Dow”) or an affiliated company of Dow 19 LF Filled EAM Insulation Cable Testing Flexibility Testing Lead-Free EAM Leaded EPR Lead-Free EAM is more flexible than Leaded EPR; 33% reduction in flex modulus when compared to semicrystalline Leaded EPR. ®™Trademark of The Dow Chemical Company (“Dow”) or an affiliated company of Dow 20 Comparison of Insulation Materials The chart below compares key attributes of MV cables for each of the three major insulation types Cable Attribute Insulation by Type TR-XLPE EPR EAM Greater flexibility for ease of installation C B A Environmental Sustainability A C A Recyclability B C B Suitability for constrained space C B A 105/140 C insulation rating A A A Dielectric losses (dissipation factor) A C B Highest Retained Breakdown Strength (AWTT) A C B ®™Trademark of The Dow Chemical Company (“Dow”) or an affiliated company of Dow 21 Features & Benefits of EAM Insulated Cables Lead-Free Filled EAM compounds offer improved installation performance and an environmentally conscious alternative for demanding MV Utility insulation applications Lead-free Filled EAM has demonstrated thermal, wet & dry electrical stability Improved flexibility; Improved trainability and less spring-back o Easier handling during installations o Appealing for the installation crew; Better ergonomics; Less fatigue after handling Better wet electrical aging performance vs. a Leaded EPR as demonstrated by AWTT and ACLT testing Meets or exceeds ANSI/ICEA S-94-649 & S-97-682 and AEIC CS8 A “Green” Sustainable Solution o Eliminates the last hazardous material from MV cable designs o Low and stable dissipation factor (lower losses) at elevated temperatures o Green solution may aid in rate case approvals ®™Trademark of The Dow Chemical Company (“Dow”) or an affiliated company of Dow 22 Summary Today’s MV insulations have positive and negative attributes and should be evaluated based on the utility need Continued research and development of materials and manufacturing methods has produced longer lasting cables for the industry Update your cable specification and consider the purchase of cables that best meet your specific application ®™Trademark of The Dow Chemical Company (“Dow”) or an affiliated company of Dow 23 Brent Richardson brichardson@dow.com 704-721-0288 ®™Trademark of The Dow Chemical Company (“Dow”) or an affiliated company of Dow 24 24