8 x8 Coop Notes and Plans March 2009

advertisement

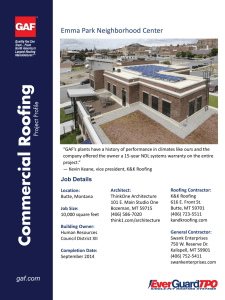

The Playhouse Coop © Construction Notes 8 ft. X 8 ft. Model Updated March 2009-03-20 Hello Builder, Thanks for joining the hundreds other builders who have chosen the Playhouse Coop for as their choice for their backyard poultry flock. In addition to the plans and these notes, you can access additional photos on Photobuket. Go to www.photobucket.com and use the ID isthmushandyman and the password playhouse. Also you will find the 2 videos on Youtube at the following URLs. http://www.youtube.com/watch?v=Znjc1qSfCX0 http://www.youtube.com/watch?v=ULvlZ94aZN4&feature=related I also post periodic updates based on builders feedback. Please read my blog at: http://playhousecoop.blogspot.com/. If during the building process you discover new and easier ways to buld the coop, please send them to me (imhandy@sbcglobal .net) and I will post them on the blog for others to enjoy. These plans, while admittedly providing me with an income, are a communty project and as such rely on the input of all of you. Please help me maintain the highest quality possible. I wish you the best of building success! Building Instructions and Notes These are my notes for the construction and assembly of the Playhouse Coop. This backyard urban poultry house was designed to with three groups in mind: chickens, predators and neighbors. It is comfortable, impenetrable and cute. It is adequate to house up to 5 large breed chickens, providing a nest box, roost space and an adequate outdoor run, all under one roof. Besides providing a shield against the rain, the roof may also prevent your chickens from coming in contact with bird poop from the wild birds. This may help protect your small flock from avian viruses. Materials: Please read carefully the Materials/Cut List. Most of the materials can be obtained from a lumberyard or big box building supply store. Roofing The roofing is called standing seam metal roof and can be obtained at a roofing supply company. You can see the roofing materials and locate a distributor closest to you at the Metal Sales web site: http://www.metalsales.com/. Prices vary on this item from region to region. Before starting to purchase other item, decide on the type of roofing material you can afford. The standing metal seam material is available through ABC Roofing Supply. This is a roofing supply company so be prepared to be treated with not the same customer service that your local hamburger chain might offer. Use their store locator in the upper right hand part of their home page to find a distributor nearest to you. Their URL is http://www.abcsupply.com/. The company Metal Sales, Inc. that manufactures the metal roofing that I used, is one of a handful of such companies. The do have a nice web site with valuable information, but buyers need to purchase their product through a dealer such as ABC Supply. The matching screws for these roofs are often pricey and come bags of 250 or more. You can substitute these with screw with rubber washers found at the the big box chain lumber yards. Prices vary widely on the standin metal seam seam roofing from region to region. Before starting to purchase other item, decide on the type of roofing material you can afford. If you prefer not do deal with the roofing contractor world, I suggest you check out your local Home Depot to see what kinds of roofing material they offer. Most will have a corrugated vinyl type roofing product that is less expensive and easier to work with Admittedly, it is not as attractive Lumber The framing members are cut from 5/4” x 6” cedar deck boards. (These boards measure 5 ½” x 1” thick) . I have a nice table saw that allowed me rip (cut the long way) the board and get two pieces from each board. If you don’t have access to a table saw, ask the lumberyard what they would charge to rip the board for you) Caution: Some of my boards warped, and bowed after the initial cut. However, I let them stabilize for few days and most of them straightened out. Cedar is very stable, more so than other species of wood. You may want to try one or two board from your yard before investing in the entire quantity. Different woods at different times of the year have different moisture contents. If you do not wish to rip the deck boards, then I suggest you consider using 2” x 4” or 2” x 3” (check your big box store) in cedar or spruce, pine or fir (SPF). If properly sealed, the pine will last quite a long time. I do not recommend using treated lumber such as ACQ or CCA, but this is personal choice. Environmental concerns abound, especially around egg and meat producing birds. The plywood for the gables (sides with the roof points) is a rough cedar or fir siding sheet. Some know it as T-111. The actual dimension may be a bit wider than 4’, and may have to be trimmed a bit to 48”. Since the outside corner boards cover the seams, cutting it a little short will not be a problem. Too long, however, may cause the trim pieces not to sit flat on the siding. If you do the math for a roof with an 8/12 pitch, you will find the height of the triangle part of the gable panels to be 16”. I suggest you draw these two polygon- shaped gable plywood pieces on paper so you can get an idea of how to measure and cut them. They are very critical to making the other pieces work. After ripping the cedar-framing members, you can round the cut edges to match the round over of the deck board edge. While this is not necessary, it does soften the look a little. A sharp block plane or sandpaper will do the job. Making the Frames I laid the frames out in my driveway and used scraps of the plywood as gussets to join them. The gussets are the triangle pieces at the corners of the walls. Most of the gussets are 7” x 7”. Here is a plan view of the detail to show how the gussets need to be kept back from the edge of the wall stud in order to avoid overlapping with the gable wall stud. Not shown is the bottom gusset on the gable wall. Glue and screw the gussets to the wall frame. Check for square. While still on a flat surface, attach the wire to the inside and bottom side of the 4 wall frames and floor frame. Use wire only on spaces not covered by the plywood siding. Make the doorframe to fit the opening. Secure with gussets. Cover with wire. Note: The wire used on the floor has very large spaces to allow for the grass to stand up. If you like, you can cut out the center of the floor leaving a 10” or so perimeter around the edge to prevent digging predators from gaining entry. The birds like to be able to take a dust bath in the coop and having the wire in the center of the floor removed gives them an area to dig. Note: With a little planning, the triangle gussets can be used as doorstops to keep the door from swinging into the coop. I like the door to swing out to avoid hitting the birds upon entry. Use gussets on the lock side doorjamb. After the 4 walls are covered with wire and plywood they are ready for assembly. Stand the walls on top of the floor frame. Secure the corner studs to each other with 3” galvanized deck screws. The walls can be secured to the floor frame with metal “L” brackets or salvaged hinges. Next, install the 2 long roof support boards that run from gable to gable. They attach approximately 7" down from the peak of the roof. Check your roofing metal ridge cap to see where you want to screw the cap to the roof panels. These roof support boards also serve to as nailers for the screws on the lower side of the roof cap. Building the Roost Box Here you will need to calculate what type of framing you want to use to attach the top, and bottom plywood panels. I specified the same ripped deck boards as used elsewhere, but scrap lumber can be used. Pine is fine, as it is a watertight space. Remember to cut a couple of 3”-4” ventilation holes on the top of the roost box. This will allow airflow during the seasons when the hinged roost door is in the up or closed position. This space above the roost ceiling and the metal roof is a great place for storage, although some birds will try to fly up there and perch. I put enough cans of grit and other supplies there to keep them off. Inside the roost box I use a scrap of vinyl to make cleanout easier. The roost bar can be any dowel rod of at least 1 ½” diameter. The chickens need something this wide to prevent feet cramping. I used a maple sapling to simulate a tree branch. Stair rails also work well. I attached the front of the roost box with 4 galvanized screws that I remove when I want to do a thorough cleaning of the roost and nest box. The hinged door allows for periodic cleaning, but a more thorough job can be done with the entire front removed. In the warmer weather, I leave the door open so that the birds can roost on the edge of the lower wall and the hinged door. I screwed a strip of decking board to the edge of the door in order to give the birds a fatter roost. They seem to like the fresh air and the higher view. Many ask what is inside the roost box. Besides the wood flat ceiling and wood floor, I have the next box (12” cube) and the roost bar (a 2” x 4’ maple sapling). The nest box (one needed for every 5 layers) is removable for cleaning. It has no bottom and sits on the vinyl floor covering of the roost box. If you like you can build two next boxes and place them side by side. They both can be accessed from the egg door located on the outside of the next box. You may want to downsize them slightly to accomodate the space. Mobility: On the 4’ x 8’ model, we screwed galvanized gate hardware (not sure what they are called) on the four corners. With two, 8’ long 1 x 4s, we are able to easily move the coop around the yard. Two wheels could also be installed in order to aid in the moving or reduce from 4 to 1 or 2 the number of people required to move it. The coop can be made into a chicken tractor by installing two wheels on the roost box end. I have no specific design, but vision a couple of 12” diameter lawn mower wheels mounted away from the side. When the lighter end is lifted, the coop will lift onto the wheels and thus can be moved to a different spot. This will still be a 2 person job, but easier than carrying the coop. Attaching the Roof The standing seam panels can be purchased pre-cut from a building supply store. The J-channel and ridge cap come in 10 or 12 foot sections and need to be cut. I attached the J-channel edges with a combination of rivets and sheet metal screws. Take your time here and you will have a really nice finished roof. The big box stores also sell a rubberized, wavy type of roofing materials that might be preferred. It is sold here in a forest green color. Other notes: The measurements are based on having constructed several of these coops. I realize that more details might help the novice builder. I also realize that I may have a wrong measurement or two. I encourage you to check over my measurements and make sure that all the parts fit together properly. I strongly encourage you to wait until you lay out the framing parts before making the final length cuts on the shorter pieces. This will allow you to make some changes in the design that may better your personal preference or building skills. Purchasing a few extra framing pieces will also be necessary as I may have overlooked a scrap or two in my materials list. Let me know if you find any omissionI am always trying to improve. Example: Some prefer to attach the plywood triangular gussets to the outside of the frames so that the wire does not have to rest on them on the inside. If you like the look, then go for it. The photo in the magazines sometimes show my shorter coop which measures 4’ x 6’. If you chop off the longer version by 2 feet, you will have the 4 x 6 version. All other features are the same. In the winter, I stapled a 6 mil layer of clear plastic the inside of the wire to serve as a wind and snow shield. Although the hens did grow to accept the snow under their feet, they prefer the bare ground or straw. Some have preferred to hinge the inside wall of the roost box vertically as a conventional door. While this method does allow for easier and more frequent cleaning without the need to remove the screws, it does eliminate the extra perch area for the birds when the horizontally hinged door is open. The choice is really yours. There are many other substitutions and alterations possible with this design. What I have given you will help you build an exact duplicate of my coop. I encourage you to use recycled or less expensive materials when possible. While my goal was to design and build an upscale looking backyard poultry house that the neighbors would find attractive, I realize that not all neighborhoods demand such a preoccupation with aesthetics. Still, part of the joy of this hobby for me is to have attractive chickens living in an attractive house. Raising chickens is as much an art form as a food source for me. Winter Considerations In general, no insulation or auxiliary heat is needed for this coop. I live in Madison, Wisconsin, where the nighttime winter temps hit 17 below zero last February. The only winter consideration I made was in the type of breed I chose. The larger breeds seem to do better in the colder climates, and since I like the Rhode Island Reds, Orpingtons and Wyandotte, the choice was easy. Smaller, more delicate breeds may need a heat lamp on cold nights. I did us a plug-in water heater base to eliminate the need to chip out ice every morning. They are available at a farm supply store. I am always looking for feedback and ways to make the building process easier. If you are able to photograph any part of the building process that would make the plans and photos more complete, please send them to me and I will consider including them in the set of pics. I put the plans together after building the 4 x 8 and the 4 x 6 models. As a result, I do not have a set of step by step assembly photos. . Wire Fencing As for the wire, the 48” wide x 1” square is generally a special order item from local farm supply stores. Other sizes are available and depending on your fussiness level, fine to use. Some chicken keepers have reported that any wire fencing with an opening larger than 1” can allow raccoons to reach through and grab a bird. Since birds tend to try to hide in the corners when frightened, a case or two has been reported where the coon killed the bird by reaching in at a corner of the coop. The small wire will avoid this heart wrenching scenario. That said, one has to wonder what the chances of this occurring. I suggest you weigh the chances of this happening against the extra cost and trouble it takes to locate or order the 100’ roll of 4 feet wide wire with the 1” squares. Check with the Mazel Company for a local distributor. Their URL is http://www.mazelandco.com/. . Cut List Comments I want to comment on the length of the stick lumber used for the frame of the coop. From experience I have found it wiser not to try to calculate in the design stage the exact length of the studs and other framing members. This is due in part to the fact that the frame can be build in several different ways. Which board overlaps the other is sometimes a question of the builder’s choice. As a builder I tend to cut as I build. While this might add a bit of time to the overall project, I find it the only sure way to avoid being caught with a pile of precut boards that don’t fit the building method that I chose. While you experienced builders may disagree with me, I am speaking for most Do-It-Yourselfers who might not be able to think out each stage of the building process ahead of time. . Wood Treatment There are several non toxic wood treatments on the market. The claims of the manufacturers vary from product to product, so make sure that the wood preservative or sealant does what you intend it to do. Cedar is naturally rot resistant will last many years if kept dry. Sealants will prolong the life and the durability of the wood, but at some loss to the non-toxic status. Choose carefully. I like the Valhalco http://www.valhalco.com/ product that I list in the materials list. It grays the wood in a few days and is completely non-toxic when dry. Notes on the 8 ft. X 8 ft. Model The basic structure of the double wide version is the same as for the 4’ x 8’ design. I have lowered the angle of the roof in order to keep the height reasonable. A nest box will serve up to 5 layers, I have added a second nest box to the drawing. Both nest boxes can be accessed through the egg door. The roost pole sits on top of the two nest boxes. If you are not concerned about weight, you may want to consider framing this version with a stardard 2 x 4. This will give extra strength to the structure. As for portability, I am not sure how easy it will be to move it around the yard. I suggest mounting brackets on the coners into which 12” long 2 x 4s can be installed when you wish to move it. This will give each mover a 2’ handle the can be used to raise and carry the coop. Mount the brackets at a comfortable height for lifting. In Gratitude for You and all of God’s Creatures, Dennis Harrison-Noonan Isthmus Handyman LLC 3633 Alpine Road Madison, WI 53704 608 244-8473 im-handy@sbcglobal.net =