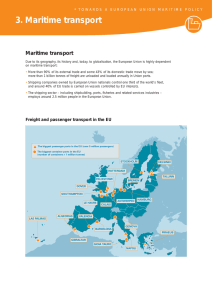

Maritime sector developments in the global markets

advertisement