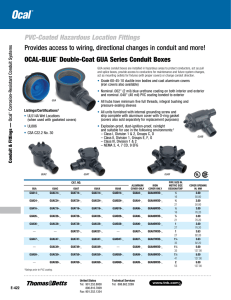

Rigid and Intermediate Metal Conduit Fittings

advertisement