New Acceptance Criteria for Deck Harnesses - ICC-ES

advertisement

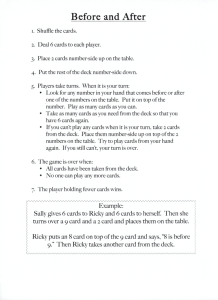

June 20, 2011 TO: PARTIES INTERESTED IN DECK HARNESSES FOR RESIDENTIAL DECKS SUBJECT: New Acceptance Criteria for Deck Harnesses for Residential Decks, Subject AC430-0611-R2 (MO/JS). Dear Colleague: We are enclosing the new ICC-ES Acceptance Criteria for Deck Harnesses for Residential Decks (AC430), which was approved by the Evaluation Committee during the June hearings. The committee made the following revisions to the document that the ICC-ES staff presented: 1. Revisions noted in the staff memo to the committee dated June 3, 2011. 2. Section 6.3.3 was revised to allow reference to the deck harness evaluation report in proprietary I-joist evaluation reports with installation details included. The new criteria covers proprietary deck harnesses for residential decks (lateral load capacity). Residential decks supported by attachment to an exterior wall are required to be positively anchored to the primary structure to resist lateral load under Section R502.2.2 of the 2009 International Residential Code® (IRC). Section R502.2.2.3 of the IRC prescribes the use of a minimum of two hold-down tension devices with an allowable stress design (ASD) tension capacity of not less than 1500 pounds (6672 N) for each device, to resist lateral loads perpendicular to the plane of the wall. The proprietary deck harness is evaluated as an alternative to the hold-down tension devices prescribed by the IRC. The ICC-ES staff is of the opinion that the devices specified in IRC Section R502.2.2.3 are prescriptively required, in lieu of engineered connections to the primary structure. Regardless of whether the hold-down tension devices specified in IRC Section R502.2.2.3 are to be considered components within the primary structural support system, or as safety devices within a backup system, the devices clearly serve a structural purpose, as indicated by the minimum required ASD capacity of 1500 pounds (6672 N). The product test and performance requirements are noted in Section 3.0 of the new criteria, with appropriate test methods and procedures noted in Section 4.0. The minimum performance requirements are specified in Section 4.5, and analysis of test data is specified in Section 4.6. AC430-0611-R2 2 Thank you for your interest. If you have any questions, please contact Michael O’Reardon, Regional Manager, at (800) 423-6587, extension 5685, or by e-mail at mo’reardon@icc-es.org . Yours very truly, Gary G. Nichols, P.E., SECB Vice President GGN/raf Enclosure cc: Evaluation Committee www.icc-es.org | (800) 423-6587 | (562) 699-0543 A Subsidiary of the International Code Council ® ACCEPTANCE CRITERIA FOR DECK HARNESSES FOR RESIDENTIAL DECKS AC430 Approved June 2011 PREFACE Evaluation reports issued by ICC Evaluation Service, LLC (ICC-ES), are based upon performance features of the International family of codes. (Some reports may also reference older code families such as the BOCA ® National Codes, the Standard Codes, and the Uniform Codes.) Section 104.11 of the International Building Code reads as follows: The provisions of this code are not intended to prevent the installation of any materials or to prohibit any design or method of construction not specifically prescribed by this code, provided that any such alternative has been approved. An alternative material, design or method of construction shall be approved where the building official finds that the proposed design is satisfactory and complies with the intent of the provisions of this code, and that the material, method or work offered is, for the purpose intended, at least the equivalent of that prescribed in this code in quality, strength, effectiveness, fire resistance, durability and safety. This acceptance criteria has been issued to provide interested parties with guidelines for demonstrating compliance with performance features of the codes referenced in the criteria. The criteria was developed through a transparent process involving public hearings of the ICC-ES Evaluation Committee, and/or on-line postings where public comment was solicited. New acceptance criteria will only have an “approved” date, which is the date the document was approved by the Evaluation Committee. When existing acceptance criteria are revised, the Evaluation Committee will decide whether the revised document should carry only an “approved” date, or an “approved” date combined with a “compliance” date. The compliance date is the date by which relevant evaluation reports must comply with the requirements of the criteria. See the ICC-ES web site for more information on compliance dates. If this criteria is a revised edition, a solid vertical line (│) in the margin within the criteria indicates a technical change from the previous edition. A deletion indicator (→) is provided in the margin where wording has been deleted if the deletion involved a technical change. ICC-ES may consider alternate criteria for report approval, provided the report applicant submits data demonstrating that the alternate criteria are at least equivalent to the criteria set forth in this document, and otherwise demonstrate compliance with the performance features of the codes. ICC-ES retains the right to refuse to issue or renew any evaluation report, if the applicable product, material, or method of construction is such that either unusual care with its installation or use must be exercised for satisfactory performance, or if malfunctioning is apt to cause injury or unreasonable damage. NOTE: The Preface for ICC-ES acceptance criteria was revised in July 2011 to reflect changes in policy. Acceptance criteria are developed for use solely by ICC-ES for purposes of issuing ICC-ES evaluation reports Copyright © 2011 ACCEPTANCE CRITERIA FOR DECK HARNESSES FOR RESIDENTIAL DECKS (AC430) 1.0 INTRODUCTION and Internally Threaded Fasteners, Washers, Direct Tension Indicators, and Rivets. 1.1 Purpose: The purpose of this criteria is to establish requirements for deck harnesses, for residential decks, to be recognized in an ICC Evaluation Service, LLC (ICC-ES), evaluation report under the 2009 International Residential Code® (IRC). The basis of recognition is IRC Section R104.11. Applicable code elements are IRC Sections R502.2.2 (Decks) and R502.2.2.3 (Deck Lateral Load Connection), and Figure 502.2.2.3 (Deck Attachment for Lateral Loads). 1.3.2.12 ASTM F 1575-03(2008), Standard Test Method for Determining Bending Yield Moment of Nails. 1.3.2.13 ASTM F 1667-05, Specification for Driven Fasteners, Nails, Spikes and Staples. 1.3.3 ANSI/AFPA NDS-05, National Design Specification (NDS) for Wood Construction—with 2005 Supplement, American Forest and Paper Association. 1.3.4 ANSI/MSS SP-58-09, Pipe Hangers and Supports—Materials, Design, Manufacture, Selection, Application and Installation, Manufacturers Standardization Society. The reason for the development of this criteria is to allow evaluation of proprietary deck harnesses, since the IRC and associated reference standards do not specify installation, test methods and quality requirements for these products. 1.3.5 ASCE 19-96, Standard for Structural Applications of Steel Cables for Buildings, American Society of Civil Engineers. 1.2 Scope: The deck harnesses are used as alternatives to hold-down tension devices prescribed in IRC Section R502.2.2.3 and shown in IRC Figure 502.2.2.3. Attachment is by means of mechanical fastenings (deck harness, wire or chain). 1.3 1.4 1.4.1 Deck Harness: For purposes of this criteria, a deck harness consists of one or more pieces or units so arranged as to transfer loads that are perpendicular to the wall, from an exterior deck joist to interior floor framing. The deck harness shall be as described in the approved quality documentation complying with the ICC-ES Acceptance Criteria for Quality Documentation (AC10), as submitted by the evaluation report applicant. Codes and Referenced Standards: 1.3.1 Codes: 1.3.1.1 2009 International (IRC), International Code Council. 1.3.2 Residential Code® ASTM International Standards: 1.4.2 Deck Harness Connector (Fastener): For purposes of this criteria, a deck harness connector consists of the hardware used to attach the deck harness to the exterior deck joist; and hardware used to attach the deck harness to the interior floor framing. Hardware materials consist of fasteners, bolts, U-bolts, nails and screws. 1.3.2.1 ASTM A 90/A 90M-09, Standard Test Method for Weight [Mass] of Coating on Iron and Steel Article with Zinc or Zinc-Alloy Coatings. 1.3.2.2 ASTM A 123-A 123M-09, Standard Specification for Zinc (Hot-Dip Galvanized) Coatings on Iron and Steel Products. 1.3.2.3 ASTM A 413/A 413M-07, Specification for Carbon Steel Chain. Definitions: Standard 2.0 BASIC INFORMATION AND TEST REPORTS 2.1 General: The following information shall be submitted: 1.3.2.4 ASTM A 924/A 924M-07, Standard Specification for General Requirements for Steel Sheet Metallic-Coated by Hot-Dip Process. 2.1.1 Product Description: Complete information pertaining to components, material specifications, and manufacturing processes for the deck harness and the deck harness connector. Materials shall comply with appropriate recognized national standards. 1.3.2.5 ASTM A 931-08, Standard Test Method for Tension Testing of Wire Ropes and Strand. 1.3.2.6 ASTM D 2395-07ae1, Standard Test Methods for Specific Gravity of Wood and Wood-Based Materials. 2.1.2 Installation Instructions: Installation details and drawings, noting installation requirements and/or limitations. 1.3.2.7 ASTM D 4442-07, Standard Test Methods for Direct Moisture Content Measurement of Wood and Wood-Base Materials. 2.1.3 Identification: Description of the method of identifying the product in the field. Each deck harness shall bear an imprint which clearly identifies the manufacturer. A registered trademark or logo may serve as such identity, provided a facsimile of the registered trademark or logo is included in the evaluation report. Labeling shall also include the model number and the ICCES evaluation report number. 1.3.2.8 ASTM D 4444-08, Standard Test Methods for Laboratory Standardization and Calibration of HandHeld Moisture Meters. 1.3.2.9 ASTM D 7032-08, Standard Specification for Establishing Performance Ratings for Wood-Plastic Composite Deck Boards and Guardrail Systems (Guards or Handrails). 1.3.2.10 ASTM E 4-10, Standard Practices for Force Verification of Testing Machines. 2.2 Testing Laboratories: Testing laboratories shall comply with Section 2.0 of the ICC-ES Acceptance Criteria for Test Reports (AC85) and Section 4.2 of the ICC-ES Rules of Procedure for Evaluation Reports. 1.3.2.11 ASTM F 606-10, Standard Test Methods for Determining the Mechanical Properties of Externally 2.2.1 Test Reports: Test reports shall comply with AC85. All test reports shall be prepared by an independent 2 ACCEPTANCE CRITERIA FOR DECK HARNESSES FOR RESIDENTIAL DECKS (AC430) 3.2.2 Deck Harness Connector: The deck harness connector shall be tested for tension capacity such that the connector mounted on to the deck/floor joists and/or blocking shall represent the worst-case application to be permitted. The test report shall include an explanation of why the tested condition represents the worst case application. Refer to Section 4.3.2 and Figures 2 and 3. testing laboratory in accordance with Section 4.2 of the ICC-ES Rules of Procedure for Evaluation Reports. Test reports shall include the following: 2.2.2 A description of the tested deck harness, including a drawing detailing all pertinent dimensions of the deck harness. The description shall also include information concerning each component of the tested deck harness (refer to Section 1.4.2 of this criteria) 3.3 Test Materials: Materials used to construct test specimens shall be of uniform quality and shall comply with the provisions of the IRC and this criteria. 2.2.3 Actual dimensions, species, specific gravity, and moisture content for each wood component of each tested deck harness assembly. 3.3.1 Deck Harness Materials: The wire and chain properties of the tested deck harness, including tensile strength and uncoated base-metal wire or chain thickness, shall be determined. Standard tensile tests of the wire or chain from which the deck harness was produced shall be conducted in accordance with ASTM A 931. The uncoated base-metal thickness of the wire or chain from which the tested deck harness is formed shall be measured or calculated. When the base-metal thickness is calculated by converting the coating weight to a coating thickness and subtracting it from the overall measured thickness coating weight, tests shall be performed on the wire or chain of the tested deck harness in accordance with the requirements of ASTM A 90, ASTM A 924 or ASTM A 123. The following relationship is permitted to be used to estimate the coating thickness from the coating weight 2 (mass): 1 oz/ft coating weight = 1.7 mills coating thickness (7:14 g/m2 coating mass = 1 μm coating and thickness). 2.2.4 A description of any modifications made to the wood members in deck harness assembly testing. 2.2.5 The measured steel physical properties of the deck harness, including yield strength, tensile strength, and base-metal thickness. 2.2.6 A description of the fasteners used for installation. 2.2.7 A detailed drawing of the test setup, depicting location and direction of load application, location of displacement instrumentation and its point of reference, and details of any deviations from the test requirements as outlined in Section 4.0 of this acceptance criteria. Additionally, photographs shall supplement the detailed drawings of the test setup and failure modes 2.2.8 Individual and average load-versusdeformation curves, as plotted directly, or as reprinted from data acquisition systems. 3.3.1.1 Minimum wire gauge shall be No. 10 gauge, U.S. Steel Wire Gauge. The wire shall be stainless steel, or shall be corrosion-resistant in accordance with ASCE 19-96 or protected by galvanizing or electroplating, or shall be protected with approved steel primer (refer to Section 3.4 for corrosion). 2.2.9 Individual and average maximum test load values observed. Description of the nature, type and location of failure exhibited by each deck harness tested, and a description of the general behavior of the harness during load application. 3.3.1.2 Chains shall comply with ASTM A413/A413M. Chains shall be protected by galvanizing or electroplating, or approved steel primer (refer to Section 3.4 for corrosion). 2.3 Sampling: Test specimens shall be sampled in accordance with Section 3.1 of AC85. 3.0 TEST AND PERFORMANCE REQUIREMENTS 3.1 General: Deck harness shall be tested for structural performance in accordance with Section 3.2. 3.3.2 joists): Joist Materials (Solid-sawn Lumber and I- 3.1.1 Load Capacity: Deck harness allowable stress design capacity shall be in accordance with Section R502.2.2.3 of the IRC, and this criteria. 3.3.2.1 All joist materials shall be of structural quality, with allowable values substantiated by accepted procedures, such as those referenced in the IRC. 3.1.2 Displacement Limit: The deck harness shall have a displacement limit of 0.179 inch (4.5 mm) at the allowable stress design capacity. The displacement shall be measured from the top edge of the deck ledger (midthickness along the deck ledger edge) to a point on the top edge of the deck joist (mid-thickness along the deck joist edge) measured 6 inches (152.4 mm) from the interface between the deck ledger and the deck joist (see Figures 2 and 3 for location). 3.3.2.2 The joist materials used in the deck harness connector testing shall have a tested specific gravity, determined in accordance with ASTM D 2395. Specific gravity measurements taken at moisture contents other than oven-dry condition shall be adjusted to the oven-dry moisture content in accordance with Appendix X1 of ASTM D 2395. 3.3.2.3 The moisture content of the joist members shall be determined in accordance with ASTM D 4442 or D 4444. 3.2 Tension Testing for Deck Harness and Deck Harness Connector 3.3.2.4 Testing shall be conducted using both solid sawn lumber framing and assemblies constructed with prefabricated wood I-joists (refer to Section 6.3) as floor joists. 3.2.1 Deck Harness: The deck harness shall be tested such that a tension load is applied in reference to the intended application of the deck harness. Refer to Section 4.3.1 and Figure 1. 3 ACCEPTANCE CRITERIA FOR DECK HARNESSES FOR RESIDENTIAL DECKS (AC430) 3.3.3 Other Wood Materials (Rim Board and Ledger Board): 4.1.1 4.1.2 Drawings and details of exterior deck and interior floor framing and components. 3.3.3.1 All wood materials, other than those described in Section 3.3.2, shall be solid-sawn lumber (ledger board) of structural quality with allowable values substantiated by accepted procedures, such as those referenced in Section 2302 of the IBC; or laminated structural members (rim board) with allowable values substantiated by accepted procedures. 4.1.3 Drawings and details showing attachment of the deck harnass to the test frame. 4.1.4 Details of analytical methods used to develop allowable load capacities for the deck harness. 4.2 3.3.3.2 The specific gravity of the wood members used in the deck harness connector testing shall be determined in accordance with ASTM D 2395. Specific gravity measurements taken at moisture contents other than oven-dry condition shall be adjusted to the oven-dry moisture content in accordance with Appendix X1 of ASTM D 2395. 4.2.2 Displacement Gauge: All tests shall use dial gauges or displacement transducers having a test reading of 0.001 inch (0.025 mm). 4.3 Deck Harness and Deck Harness Connector Testing 3.3.4 Joist Hangers: The joist hangers used in the deck harness connector testing shall be recognized in a current ICC-ES evaluation report. 4.3.1 3.3.5.1 U-bolts shall comply with ANSI/MSS SP-58 Bolt tensile strength shall be derived using the procedures of ASTM F 606. 4.3.1.2 If the maximum test load for the deck harness varies by more than 20 percent from the average, testing shall be conducted on three additional deck harnesses. 3.3.5.2 Anchor bolts/rods shall comply with a code-referenced standard specification. 3.3.5.3 Nails shall comply with ASTM F 1667. Nail bending yield strength, Fyb, shall be derived using the procedures of ASTM F 1575 or the ICC-ES Acceptance Criteria for Nails and Spikes (AC116), as applicable. 4.3.2 Deck Harness Connector Testing: 4.3.2.1 A minimum of three deck harness connectors shall be tested on each configuration of variables (e.g., solid sawn lumber joists or prefabricated wood I-joists) affecting the deck harness connector performance. 3.3.5.4 Wood screws shall comply with either ANSI/ASME B18.6.1 or the ICC-ES Acceptance Criteria for Alternate Dowel-type Threaded Fasteners (AC233). Bending yield strength of the screws shall be derived using the procedures of Section 4.4 of AC233. Predrilled holes shall be a field requirement when, for testing, wood screws are installed into predrilled holes. 4.3.2.1.1 A deck harness connector test specimen shall consist of deck harness, floor joists, deck ledger, rim board, deck joists, and fasteners of appropriate size fastened/assembled together. The connector shall be tested with each grade and species of the floor and deck joists used or the lowest grade material. The deck joist shall not be connected (fastened) to the deck ledger. A joist guide shall be used in place of fastening. The assembly shall be tested as illustrated in Figures 2 and 3. 3.4 Corrosion: The corrosion resistance of the deck harness materials listed in Section 3.3.1, and the deck harness connector materials listed in Section 3.3.5, shall be documented by material specifications and mill order certificates demonstrating compliance with Section R317.3.1 of the IRC. Electroplating and approved steel primer shall be evaluated for corrosion resistance in accordance with AC257. 4.3.2.1.2 The floor joists and deck joist material shall both be a minimum of 3 feet (914 mm) in length. 4.3.2.1.3 The wood material (deck ledger and rim board) shall be a minimum of 4 feet (1219 mm) in length. 3.5 Non-Metal Components: Non-metal components used in the deck harness shall be tension-tested as noted in Section 3.2. 4.4 be Test Setup 4.4.1 General 4.4.1.1 Deck harness and deck harness connector shall be tested individually in such a manner as to simulate the essential function of the deck harness and deck harness connector on the test assembly. Test loads shall be applied with reference to the intended end-use application of the deck harness. Low-friction rollers are permitted to be used in the test setup to prevent lateral movement of the test equipment due to eccentricity. 3.5.2 The non-metal components shall be subjected to freeze-thaw testing in accordance with Section 4.7 of ASTM D 7032 or another applicable test procedure. 4.0 Deck Harness Testing: 4.3.1.1 A minimum of three deck harnesses for each type (size, configuration, and material specification) shall be tested on a testing machine. The deck harnesses shall be tested as illustrated in Figure 1. Deck Harness Connector: 3.5.1 The non-metal components shall documented by applicable material specifications. Apparatus 4.2.1 Testing Machine: A testing machine that is capable of operation at a constant rate of motion of the movable crosshead or a constant rate of loading, and a force measuring device that is calibrated in accordance with Method ASTM E 4, shall be used. 3.3.3.3 The moisture content of the wood materials shall be determined in accordance with ASTM D 4442 or D 4444. 3.3.5 Drawings and details of the deck. TEST METHODS 4.1 General: The test program shall be submitted for approval by ICC-ES prior to commencement of any testing. The test plan shall include: 4 ACCEPTANCE CRITERIA FOR DECK HARNESSES FOR RESIDENTIAL DECKS (AC430) 4.4.1.2 The connector material which is attached to the end of the deck harness shall be fastened to the assembly material (floor joists, deck joists and/or blocking) in such a manner that the connection to the test equipment does not affect the test results. Additionally, the connector shall be fastened in accordance with the enduse application (manufacturer’s installation instructions). 4.6.4 The allowable load for the deck harness shall be the lowest value determined in accordance with Section 4.6.4.1 and shall not be less than the allowable stress design capacity of 1,500 pounds (6672 N) in accordance with Section 4.6.1. 4.6.4.1 The allowable load shall be determined for each test configuration, and the lowest value of each of the tested configurations shall be used. The allowable load shall be determined as follows: 4.4.1.3 If nuts are used with the bolts, they shall be at most finger-tight, to remove the effects of clamping when testing the deck harness and the deck harness connector to the assembly material (floor and deck joists). 4.6.4.1.1 The lowest ultimate load for a single test divided by 3 (where three tests are conducted for each configuration and no ultimate load varies by more than 20 percent from the average ultimate load). 4.4.1.4 An initial load or preload shall not be applied to the deck harness. 4.6.4.1.2 The average of the ultimate loads for the tested configuration divided by 3 (where six or more tests are conducted). 4.4.2 Deck Harness Connector Testing: The deck harness shall be tested on assemblies simulating critical field-installed conditions. Tension or slack and alignment of the cable shall simulate field installations that will be permitted in application. This information shall be described in the test report and repeated as the maximum permitted slack and horizontal/vertical misalignment tolerances in the Conditions of Use section of the evaluation report. 4.6.4.1.3 The average from all tests for a configuration that produces a displacement of 0.179 inch (4.50 mm) at the allowable stress design capacity. 4.6.4.1.4 The calculated ASD capacity for required construction details transferring load into and out of the deck harness device shall be in accordance with the NDS, assuming a load duration factor of 1.6 for an assumed 10-minute duration. 4.4.2.1 Wood test members shall be conditioned to reach equilibrium with a moisture content of 10 to 14 percent when tested for dry in-service conditions, except the deck joist members shall be conditioned for wet service conditions (> 19%). When the assemblies are tested for wet in-service conditions, wood test members shall be conditioned to an equilibrium moisture content greater than 19 percent. 4.6.4.2 The tested allowable load as determined under this section shall be used in Section 4.7 (Analysis of Test Data) for determining the capacity of the deck harness for compliance with the IRC. Allowable load determined from the tests shall be adjusted downward if tested strengths and physical dimensions of components (refer to Section 3.3.1) exceed specified values. 4.4.2.2 Installation of the deck harness to the wood members shall maintain fastener end and edge distances as expected in field conditions, with minimum distances complying with the NDS, where applicable. 4.5 4.7 4.7.1 Independent Third-party Analysis: An independent third-party analysis shall be provided evaluating the test data generated in accordance with Sections 4.1 through 4.5, to determine that the allowable load design stress capacity for the deck harness is in accordance with the IRC. The analysis shall include engineering calculations evaluating the conditions of acceptance listed in Sections 4.6.1 through 4.6.4, and shall be based on installation details in the manufacturer's installation instructions. The calculations shall be signed, sealed and dated by the responsible design professional. Test Procedure 4.5.1 Deck Harness Test: The deck harness shall be mounted in a tension machine such that the deck harness is subject to a direct tension load. 4.5.1.1 The deck harness plug shall be fitted on to a 12-inch (305 mm) block simulating field-installed rim board and deck ledger assembly (Figure 1). 4.5.1.2 A displacement transducer shall be mounted to monitor displacement of the deck harness from the connector to the ledger. The displacement shall be recorded to the nearest 0.001 inch (0.025 mm), and a sufficient number of readings shall be taken. 4.7.2 Fastener Values: When the transfer of loads on the deck harness is accomplished primarily by means of fasteners in wood, the allowable strength of fasteners specified in the NDS shall not be exceeded. 4.5.2 Deck Harness Connector Test: The deck harness connector shall be tested in tension with the connector mounted on the floor or deck joist simulating the worst-case condition. 4.6 Analysis of Test Data 4.7.3 Provision for Shrinkage: Dimensions of the deck harness, or methods of installation, shall make appropriate provisions for shrinkage of deck ledger, rim board, floor joist or deck joist relative to the deck harness. Conditions of Acceptance 4.7.4 Design Value Modifications for the Deck: Allowable loads of the deck harness shall not exceed the allowable load allowed by the code or applicable material standard. Allowable design values for the deck harness or similar devices that are determined by calculation shall be permitted to be modified by the appropriate duration of loading factors as specified in the NDS, except when limited by a test-based design value. All other applicable adjustment factors as specified in the NDS shall apply. 4.6.1 Deck harness shall have an allowable stress design capacity of not less than 1,500 pounds (6672 N). 4.6.2 The deck harness shall have a displacement at the load level allowed of no greater than 0.179 inch (4.5 mm). 4.6.3 Test results may be presented in tabular form or by means of a graph. 5 ACCEPTANCE CRITERIA FOR DECK HARNESSES FOR RESIDENTIAL DECKS (AC430) Allowable design values determined by test results shall not be modified by duration of load factors. conflict between this report and the manufacturer’s published installation instructions, this report governs. 4.7.5 Stresses in Framing Members: The determination of the allowable design value for the deck harness and deck harness connector shall take into consideration the stresses imposed on the framing members (wood joists, prefabricated wood I-joists, blocking maternal, and decking). Details of installation shall be provided documenting the method for transferring loads from the deck harness and deck harness connector into the floor diaphragms. 6.3.2 The required number and spacing of the deck harnesses used to resist lateral loads must be determined in accordance with the IRC. A minimum of two deck harnesses are required for each deck. 5.0 6.3.3 Calculations showing compliance with this report must be submitted to the code official. The calculations must determine the number of deck harnesses required for the deck design and details for the load transfer from the deck harness to the diaphragm. The calculations must be prepared by a registered design professional where required by the statutes of the jurisdiction in which the project is to be constructed. (Where recognition is sought for use in floor systems having prefabricated wood I-joists, the deck harness evaluation report shall be specific to the individual prefabricated wood I-joist evaluated, and shall include, with the I-joist manufacturer’s permission, the evaluation report number for the applicable I-joist products. As an alternative, the prefabricated wood I-joist evaluation report may include a reference to the deck harness report and include applicable details for installation. The following is additional wording for the conditions of use when the deck harness is tested with prefabricated wood I-joists: When using the deck harness with prefabricated wood I-joists, calculations shall be submitted for the specified I-joist product, with installation details for reinforcing the wood Ijoists and methods for transferring loads to floor diaphragms as shown in the evaluation report.) QUALITY CONTROL 5.1 Documentation complying with the ICC-ES Acceptance Criteria for Quality Documentation (AC10) shall be submitted. 5.2 Deck harness shall be manufactured under an approved quality control program with inspections by an inspection agency accredited by the International Accreditation Service (IAS) or otherwise acceptable to ICC-ES. 5.3 The quality documentation shall provide the material specifications for all metal and non-metal components of the deck harness as manufactured by the report holder. The documentation shall include procedures for splicing or crimping of wire rope cables. 6.0 EVALUATION REPORT The following information shall be included in the evaluation report: 6.1 Information described in Section 2.1. 6.3.4 Connected wood members and fasteners must comply with Sections [The evaluation report must include information noted in Sections 3.3.2 through 3.3.5 of this criteria, including framing details and reinforcement installation instructions where necessary to transfer loads into the floor diaphragm]. 6.2 Illustrations of the deck harness as installed, and all required fastening schedules (plywood flooring to joists and blocking). 6.3 The evaluation report shall include the following conditions of use: 6.3.5 No further duration of load increase for wind or seismic loading is allowed. 6.3.1 The deck harness described in this report must be manufactured, identified and installed in accordance with this report and the manufacturer’s published installation instructions. A copy of the manufacturer’s published installation instructions must be available at the jobsite at all times during installation. In the event of a 6.3.6 The deck harness shall be used only in new construction, except when it is determined by the local code official that an inspection can be conducted. ■ 6 ACCEPTANCE CRITERIA FOR DECK HARNESSES FOR RESIDENTIAL DECKS (AC430) FIGURE 1—DECK HARNESS TENSION TEST FIGURE 2—DECK HARNESS CONNECTOR WITH FLOOR AND DECK JOISTS PERPENDCIULAR TO RIMBOARD 7 ACCEPTANCE CRITERIA FOR DECK HARNESSES FOR RESIDENTIAL DECKS (AC430) FIGURE 3—DECK HARNESS CONNECTOR WITH FLOOR JOISTS PARALLEL TO RIM BOARD 16 INCHES O.C. 8