Science 3102 Curriculum Guide 2005-06

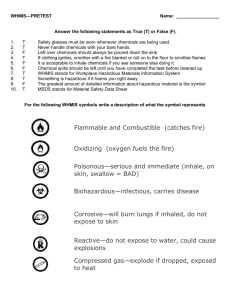

advertisement