Environmental Management of Firefighting Foam Policy

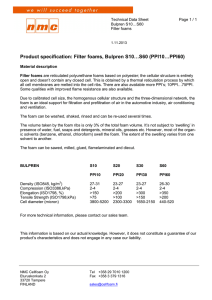

advertisement