complete product - Hansen Electric spol. s ro

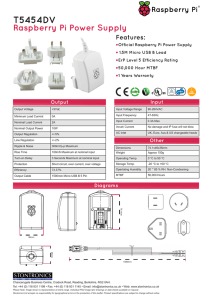

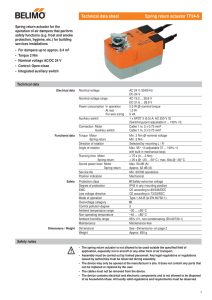

advertisement

2 3 Company profile .................................….............................................…..... 4-5 Assortment ................................................................................................. 6-7 Vacuum contactors description ......................…….................................... 8 Vacuum contactors 3,3kV …….............................…….............................… 9-10 Vacuum contactors 400А, 315A .………...................….............................… 11-13 Vacuum contactors 450А ……..………….....................…...........................… 14-15 Vacuum contactors 200А ............................................……........................ 16-19 Vacuum contactors 80А ..................................................…….................... 20-21 Certifications ........................................................................……............... 22 Cross-reference list ....................................................................…............ 23 Recommendation ........................................................................……......... 24 Ordering ………..........................................................................................… 25 Contact information …......................................................................…….... 26 4 Hansen Electric, spol. s r.o. company is the holder of the Certificate of quality according to ČSN EN ISO 9001. In 2001, our company was ATEX certified. The District mining authority in Ostrava authorized our company to instal, run, service and maintain the dedicated electrical apparatuses, to produce switchboards up to 6 kV (including explosion-proof switchboards), to develop and design electronic apparatuses and to perform consulting activities in the field of electronical devices for gaseous mines. The members of the company management are holders of the Certificate for expert approval issued by the District mining authority in Ostrava. Each particular of our products has an EC declaration of conformity and EC certificates of type verification issued for the market in the Czech Republic and also for the EU. Products for markets outside the EU have approbations and certificates valid in the given countries. The company Hansen Electric, spol. s r.o. has become an advanced company with modern technology and high KNOW-HOW to provide development, construction, production, installation and maintenance of electrical equipment particularly for explosion-prone environment. A large production schedule allows the supply of complete electrical equipment for mining units. 5 The main products of the company are: • Explosion-proof transformer sets • Explosion-proof switchboards for straight switching or with control-start of electromotors • Explosion-proof frequency converters • Explosion-proof ripping machine switchboards, loading machines and other machines • Intrinsically safe control systems enabling besides speech communication also programmable control, monitoring and the visualisation of technological processes within mines • vacuum contactor up to 450A/ 1200 Besides the production activity of our company, it also has servicing and overhauling of electromotors, generators and transformers in its program. Approximately 65% of products are exported to Poland, Russia, the Ukraine, Kazakhstan, Mexico and other countries. The most important business activities in Russia are performed especially in Kuzbas and in Vorkuta. Our subsidiary company „Sib-Hansen“ has its headquarters in Leninsk-Kuzneckiy (Kemerovska area). In the Ukraine, our company thrives with the help of our subsidiary company „Hansen Ukraine“, with HQ in the city of Doneck (Doneck area). Supply of electronic devices is in increasingly high demand, particularly in the field of switching technology and the automatic band conveyors - APD1. Qualified employees of the company, the continuous innovation of products, the application of modern technologies with constant pursuit of perfect quality control are the elements that guarantee efficient cooperation for both current and future customers. 6 Vacuum contactors View Type Voltage Current JCZ9-3,6/D400 3,6kV, 50-60Hz 400А HR-VS 4/450 450А 1,2kV, 50-60Hz HR-VS 4 400А HR-VS 3 1,2kV, 50-60Hz 315А HR-VS 200 1,2kV, 50-60Hz 200А HE-VS 200B 1,2kV, 50-60Hz 200А HR-VS 80 1,2kV, 50-60Hz 80А 7 Vacuum interrupters View Type Voltage Current TJ-3,6/400 3,6kV, 50-60Hz 450А VS1/04 1,2kV, 50-60Hz 450А WL-35082D, E 1,2kV, 50-60Hz 450А TJ-1,14/400 1,2kV, 50-60Hz 450А HR-VR200/11,4 1,2kV, 50-60Hz 200A TJ-1,14/80 1,2kV, 50-60Hz 80A 8 Vacuum contactors are electromagnetically operated switching devices, designed for switching three phase motors and other electrical equipments with voltages up to 3300 V and operational current up to 450 A respectivelly, at switching and interrupting capacities corresponding AC1, AC2, AC3, AC4 duty. The contactors construction complies the function and utilization requirements of the standards Application: The contactors are intended namely for the switching of squirrel-cage and slipring motors. They are suitable for switching of resistance and mixed loads, too. Because of minimal dimensions, minimal weight, high electrical resistance, resistance to atmospheric corrosion and minimal maintenance requirements are the contactors namely suitable in underground coal mining and industrial installations with arduous operating conditions (coal-winning machines, drives of armoured face conveyors and belt conveyors etc.). Technical merits: high reliability; long lifetime; minimum maintenance demanded during its whole lifetime; high frequency of repeated switches; small size and low weight; high climatic resistance. Operational environment and conditions: Contactors are designed to operate in following indoor conventional environment: ambient temperatures -20°C ÷ +60°C relative humidity at 20°C max. 80 % altitude max. 1000 m mounting position vertical deflection in any direction max. 10° Material, workmanship (design): All structural parts of the contactor housing are moulded - used material is DUROFORM HUP 17/25 (so called reactoplasts - mixtures of polyester resin, filler and glass fibre reinforcement). The coil formers are manufactured from SILAMID 13.01-ESV 30 (polyamid with glass fibre reinforcement). The contactors are of open design IP 00. 9 VACUUM CONTACTORS JCZ9-3,6/D400 Technical data: Type Nominal operational voltage Testing voltage 50 Hz/60 sec. between poles and in breaking path Nominal operational and thermal current Nominal switching capacities making current Nominal switching capacities breaking current Nominal short-time current (4 sec.) Utilisation category Permissible switching frequency Mechanical life Electrical life: AC3 AC4 Closing time Breaking time Vacuum interrupters TJ-3,6/400 Contact operating travel Weight Dimensions Auxiliary circuits: Rated control supply voltage Rated hold-in consuption Auxiliary contacts (AC 15: 230V/6A) JCZ9-3,6/D400 3600V / 50-60Hz 10kV 400А 4000А 4000А 4000А АС1, АС2, АС3, АС4 1200 operations / hour 1·106 3·105 1·105 ≤ 120ms ≤ 54ms 3 pcs. 3mm 18,5kg see dimension drawing 230V, 120V, 50-60Hz; +15%,-20% 30VA a–3, b–3 Each manufactured contactor is submitted to the piece control checking in accordance with ČSN EN 60470:2001 art.7 and ČSN EN 60947-4-1 art.9.1.3 (9.3.6) to examinate, whether contactors correspond to requirements of mentioned IEC standard and whether in manufacturing process were maintained characteristic parameters and assured quality corresponding to the type test of the contactor. The checking results are notified and archived. 10 Type Drawing number Current [А] Vacuum interrupters Control supply voltage [V] Auxiliary contacts a/b 1) JCZ9-3,6/D400 56007-95-P01 400 TJ-3,6/400 230 3/3 JCZ9-3,6/D400 56007-95-P03 400 TJ-3,6/400 120 3/3 2 ) a – closing contact, b – breaking contact one breaking „b“ contact of the switch S1 is used by control circuit of contactor. Dimension drawing: 84 84 11 214 6 245 275 O 228 241 Spare parts: Name: Auxiliary switch Vacuum interrupters Drawing number or marking 9002276 TJ-3,6/400 11 VACUUM CONTACTORS HR-VS 4, HR-VS 3 Technical data: Type Nominal operational voltage Nominal insulation voltage Testing voltage 50 Hz/60 sec. between poles and in breaking path Nominal operational and thermal current Nominal switching capacities making current Nominal switching capacities breaking current Nominal short-time current (1 sec.) Nominal dynamic current Max. breaking capacity (cos φ = 0,35) Utilisation category Permissible switching frequency Mechanical life Electrical life: AC3 AC4 Closing time Breaking time Vacuum interrupters WL-35082E, TJ-1.14/400D, VS1/04 Contact operating travel: WL-35082E, TJ-1.14/400D VS1/04 Weight/Volume Dimensions Auxiliary circuits: Rated control supply voltage Peak switching current *) for control supply voltage 230V for control supply voltage 120V Rated hold-in consuption Auxiliary contacts (AC 11: 500V/3A) HR-VS 4 HR-VS 3 1200V / 50-60Hz 1200V / 50-60Hz 6,5kV 400А 315A 4800А 3800A 4000А 3150A 4,8kА 5kА 18kА 12,5kА 6kА 5kА АС1, АС2, АС3, АС4 1200 operations / hour 1·106 3·105 1·105 ≤ 65ms ≤ 35ms 3 pcs. 2,29mm 1,56mm 1,98mm 9kg/ 6,1dm3 see dimension drawing 230V, 120V, 50-60Hz; +15%,-25% 2,2А 3,8А 5,3VA a–3, b–2 or a-2, b-3 *) Switching current flows for max. 60 ms Each manufactured contactor is submitted to the piece control checking in accordance with ČSN EN 60470:2001 art.7 and ČSN EN 60947-4-1 art.9.1.3 (9.3.6) to examinate, whether contactors correspond to requirements of mentioned IEC standard and whether in manufacturing process were maintained characteristic parameters and assured quality corresponding to the type test of the contactor. The checking results are notified and archived. 12 Options of modification: Vacuum contactors HR-VS4, HR-VS3 is produced in several variants which differ in the size of the control voltage, by fitting auxiliary switches and auxiliary switches control S2. 1. Control supply voltage: … 001.2/ … 003.2/ … 003.2/5 230V / 50-60Hz 120V / 50-60Hz 110V / 50-60Hz 2. Auxiliary switches S1, S2 – number of auxiliary contacts a, b: (a – closing contact, NO, b – breaking contact, NC) … 001.2/, … 003.2/ S1: a-2, b-1 S2: a-1, b-2 … 002.2/ S1: a-1, b-2 S2: a-1, b-2 … 004.2/ S1: a-1, b-2 S2: a-2, b-1 total: a-3, b-2 1) total: a-2, b-3 1) total: a-3, b-2 1) 1) one breaking „b“ contact of the switch S1 is used by control circuit of contactor construction a-2, b-1: SIEMENS 3SE 023-1A construction a-1, b-2: SIEMENS 3SE 023-0A 3. Control of the auxiliary switch S2: … /x1 Breaking switch contacts S2 have not guaranteed time off in relation to the moment of switching the main contacts. … /x2 Breaking switch contacts S2 will disconnect in advance before switching the main contacts. TJ-1.14/400D VS1/04 2) 400А WL-35082D, E2) 315A Current Type Drawing number Control supply voltage [V] HR-VS 3 HR-VS 3 HR-VS 3 HR-VS 3 HR-VS 3 HR-VS 3 HR-VS 3 HR-VS 3 HR-VS 3 HR-VS 4 HR-VS 4 HR-VS 4 HR-VS 4 HR-VS 4 HR-VS 4 HR-VS 4 HR-VS 4 HR-VS 4 HR-VS 4 HR-VS 4 HR-VS 4 HR-VS 4 HR-VS 4 HR-VS 4 HR-VS 4 HR-VS 4 HR-VS 4 HR-VS 4 HR-VS 4 HR-VS 4 HR-VS 4 HR-VS 4 HR-VS 4 56006-91-001.2/01 56006-91-002.2/01 56006-91-003.2/01 56006-91-003.2/51 56006-91-001.2/02 56006-91-002.2/02 56006-91-003.2/02 56006-91-003.2/52 56006-91-004.2/02 56007-03-001.2/01 56007-03-002.2/01 56007-03-003.2/01 56007-03-001.2/02 56007-03-002.2/02 56007-03-003.2/02 56007-03-004.2/02 56007-03-001.2/31 56007-03-002.2/31 56007-03-003.2/31 56007-03-001.2/32 56007-03-002.2/32 56007-03-003.2/32 56007-03-004.2/32 56007-03-001.2/11 56007-03-001.2/61 56007-03-002.2/61 56007-03-002.2/11 56007-03-003.2/11 56007-03-001.2/12 56007-03-002.2/12 56007-03-002.2/62 56007-03-003.2/12 56007-03-004.2/12 230 230 120 110 230 230 120 110 230 230 230 120 230 230 120 230 230 230 120 230 230 120 230 230 230 230 230 120 230 230 230 120 230 1 Auxiliary contacts a/b ) Switch S1 Switch S2 2/0 1/1 2/0 2/0 2/0 1/1 2/0 2/0 1/1 2/0 1/1 2/0 2/0 1/1 2/0 1/1 2/0 1/1 2/0 2/0 1/1 2/0 1/1 2/0 1/2 1/1 2/0 2/0 1/1 1/2 2/0 1/1 1/2 1/2 1/2 1/2 1/2 1/2 1/2 1/2 2/1 1/2 1/2 1/2 1/2 1/2 1/2 2/1 1/2 1/2 1/2 1/2 1/2 1/2 2/1 1/2 1/2 1/2 1/2 1/2 1/2 1/2 1/2 2/1 Auxiliary switch S2, Breaking contact b without advance with advance without advance with advance without advance with advance without advance with advance 13 1 ) contacts available to the user; a – closing contact (NO), b – breaking contact (NC) S1=2/0: type of the switch … SIEMENS 3SE3 023-1A S1=1/1: type of the switch … SIEMENS 3SE3 023-0A S2=2/1: type of the switch … SIEMENS 3SE3 023-1A S2=1/2: type of the switch … SIEMENS 3SE3 023-0A 2 ) vacuum interrupters WL-35082D, E (Westinghouse) use Whitworth thread, VS1/04 use metric thread. The difference is also in contact pressure spring, at the stroke of contacts, set in the magnetic circuit. Note: Vacuum interrupters WL-35082D (Westinghouse) have been used since 2002, which have specifications changed of bellows and are replacing the previous version of WL-35082C. If you replace an older type WL-35082C in previously produced contactors, you might need to increase the strength of breaking spring - please contact the producer of the contactor. This also applies to upgraded version of the WL-35082E with better electrical characteristics. Dimension drawing: Spare parts: Name: Coil for electromagnet Control circuit Auxiliary switch 3SE3 023-1A (a-2, b-1) Auxiliary switch 3SE3 023-0A (a-1, b-2) Vacuum interrupter Block with varistors HR-V3 RC unit FZ 730 43 (FILTANA) Drawing number or marking 230V 120V 56006-91-084 56006-91-151 56007-03-069 56007-03-150 3539327 3539319 TJ-1.14/400D for HR-VS 3; WL-35082E, TJ-1.14/400D, VS1/04 for HR-VS 4 56007-44-001 9002154 14 VACUUM CONTACTORS HR-VS 4/450 Technical data: Type Nominal operational voltage Nominal insulation voltage Testing voltage 50 Hz/60 sec. between poles and in breaking path Nominal operational and thermal current Nominal switching capacities making current for 1250 V (for 725V) - closing (effective value) - breaking (peak value) Nominal dynamic current Nominal short-time current (1 sec.) Utilisation category Permissible switching frequency Mechanical life Electrical life: AC3 AC4 Closing time Breaking time Vacuum interrupters WL-35082E, TJ-1.14/400D, VS1/04 Contact operating travel: WL-35082E, TJ-1.14/400D VS1/04 Weight/Volume Dimensions Auxiliary circuits: Rated control supply voltage Peak switching current *) for control supply voltage 230V for control supply voltage 120V Rated hold-in consuption Auxiliary contacts (AC 11: 500V/3A) HR-VS 4/450 1200V / 50-60Hz 1200V / 50-60Hz 6,5kV 450А 3350A (5100А) 6300A (9250А) 9250А 3350А АС1, АС2, АС3, АС4 1200 operations / hour 1·106 3·105 1·105 ≤ 65ms ≤ 35ms 3 pcs. 2,29mm 1,98mm 9kg/ 6,1dm3 see dimension drawing 230V, 120V, 50-60Hz; +15%,-25% 2,2А 3,8А 5,3VA a–3, b–2 or a-2, b-3 *) Switching current flows for max. 65 ms Each manufactured contactor is submitted to the piece control checking in accordance with ČSN EN 60470:2001 art.7 and ČSN EN 60947-4-1 art.9.1.3 (9.3.6) to examinate, whether contactors correspond to requirements of mentioned IEC standard and whether in manufacturing process were maintained characteristic parameters and assured quality corresponding to the type test of the contactor. The checking results are notified and archived. 15 Type Drawing number Control supply voltage [V] HR-VS 4/450 HR-VS 4/450 HR-VS 4/450 HR-VS 4/450 HR-VS 4/450 HR-VS 4/450 HR-VS 4/450 HR-VS 4/450 HR-VS 4/450 HR-VS 4/450 HR-VS 4/450 HR-VS 4/450 HR-VS 4/450 HR-VS 4/450 HR-VS 4/450 HR-VS 4/450 HR-VS 4/450 HR-VS 4/450 56007-03-001.2/41 56007-03-002.2/41 56007-03-003.2/41 56007-03-001.2/42 56007-03-002.2/42 56007-03-003.2/42 56007-03-001.2/71 56007-03-002.2/71 56007-03-003.2/71 56007-03-001.2/72 56007-03-002.2/72 56007-03-003.2/72 56007-03-001.2/21 56007-03-002.2/21 56007-03-003.2/21 56007-03-001.2/22 56007-03-002.2/22 56007-03-003.2/22 230 230 120 230 230 120 230 230 120 230 230 120 230 230 120 230 230 120 TJ-1.14/400 VS1/04 450А WL-35082E Current 1 Auxiliary contacts a/b ) Switch S1 Switch S2 2/0 1/1 2/0 2/0 1/1 2/0 2/0 1/1 2/0 2/0 1/1 2/0 2/0 1/1 2/0 2/0 1/1 2/0 1/2 1/2 1/2 1/2 1/2 1/2 1/2 1/2 1/2 1/2 1/2 1/2 1/2 1/2 1/2 1/2 1/2 1/2 Auxiliary switch S2, Breaking contact b without advance with advance without advance with advance without advance with advance 1 ) contacts available to the user; a – closing contact, b – breaking contact S1=2/0: SIEMENS 3SE3 023-1A S1=1/1: SIEMENS 3SE3 023-0A S2=1/2: SIEMENS 3SE3 023-0A Dimension drawing: Spare parts: Name: Coil for electromagnet Control circuit Auxiliary switch 3SE3 023-1A (a-2, b-1) Auxiliary switch 3SE3 023-0A (a-1, b-2) Vacuum interrupter Block with varistors HR-V3 RC unit FZ 730 43 (FILTANA) Drawing number or marking 230V 120V 56006-91-084 56006-91-151 56007-03-069 56007-03-150 3539327 3539319 WL-35082E, TJ-1.14/400D, VS1/04 56007-44-001 9002154 16 VACUUM CONTACTORS HR-VS 200 Technical data: Type Nominal operational voltage Nominal insulation voltage Testing voltage 50 Hz/60 sec. between poles and in breaking path Nominal operational and thermal current Nominal switching capacities making current Nominal switching capacities breaking current Nominal short-time current (1 sec.) Nominal dynamic current Max. breaking capacity (cos φ = 0,35) Utilisation category Permissible switching frequency Mechanical life Electrical life: AC3 AC4 Closing time Breaking time Vacuum interrupters HR-VR200/11,4 Contact operating travel Weight/Volume Dimensions Auxiliary circuits: Rated control supply voltage Rated hold-in consuption Auxiliary contacts (AC 15: 230V/6A) HR-VS 200 1200V / 50-60Hz 1200V / 50-60Hz 6,5kV 200А 2400А 2000А 3,2kA 16kA 4kА АС1, АС2, АС3, АС4 1200 operations / hour 1·106 3·105 1·105 ≤ 45ms ≤ 30ms 3 pcs. 1,65mm 4,7kg / 2,1dm3 see dimension drawing 230V, 120V, 50-60Hz; +15%,-25% 3,2VA a–3, b–2 Each manufactured contactor is submitted to the piece control checking in accordance with ČSN EN 60470:2001 art.7 and ČSN EN 60947-4-1 art.9.1.3 (9.3.6) to examinate, whether contactors correspond to requirements of mentioned IEC standard and whether in manufacturing process were maintained characteristic parameters and assured quality corresponding to the type test of the contactor. The checking results are notified and archived. 17 Type Drawing number Current [А] Vacuum interrupters Control supply voltage [V] Auxiliary contacts a/b 1) HR-VS 200 56007-55-005 200 HR-VR200/11,4 230 3/2 HR-VS 200 56007-55-006 200 HR-VR200/11,4 120 3/2 2 ) a – closing contact, b – breaking contact one breaking „b“ contact of the switch S1 is used by control circuit of contactor. Dimension drawing: Spare parts: Name: Control circuit Auxiliary switch ATB11-S Vacuum interrupter Block with varistors HR-V3 Socket of the block with varistors HR-V3 Block with varistors HR-V3.1 Socket of the block with varistors HR-V3.1 Drawing number or marking 230V 120V 56007-55-069 56007-55-071 9002276 HR-VR200/11,4 56007-44-001 56007-55-156 56007-44-004 56007-55-155 18 VACUUM CONTACTORS HE-VS 200B Technical data: Type Nominal operational voltage Nominal insulation voltage Testing voltage 50 Hz/60 sec. between poles and in breaking path Nominal operational and thermal current Nominal switching capacities making current Nominal switching capacities breaking current Nominal short-time current (1 sec.) Nominal dynamic current Max. breaking capacity (cos φ = 0,35) Utilisation category Permissible switching frequency Mechanical life Electrical life: AC3 AC4 Closing time Breaking time Vacuum interrupters HR-VR200/11,4 Contact operating travel Weight/Volume Dimensions Auxiliary circuits: Rated control supply voltage Rated hold-in consuption Auxiliary contacts (AC 15: 230V/6A) HE-VS 200B 1200V / 50-60Hz 1200V / 50-60Hz 6,5kV 200А 2400А 2000А 3,2kА 16kА 4kА АС1, АС2, АС3, АС4 1200 operations / hour 1·106 3·105 1·105 ≤ 45ms ≤ 30ms 3 pcs. 1,65mm 4,7kg / 2,1dm3 see dimension drawing 230V, 120V, 50-60Hz; +15%,-25% 3,2VA a–3, b–2 Each manufactured contactor is submitted to the piece control checking in accordance with ČSN EN 60470:2001 art.7 and ČSN EN 60947-4-1 art.9.1.3 (9.3.6) to examinate, whether contactors correspond to requirements of mentioned IEC standard and whether in manufacturing process were maintained characteristic parameters and assured quality corresponding to the type test of the contactor. The checking results are notified and archived. 19 Type Drawing number Current [А] Vacuum interrupters Control supply voltage [V] Auxiliary contacts a/b 1) HE-VS 200B 56007-55-P01 200 HR-VR200/11,4 230 3/2 HE-VS 200B 56007-55-P03 200 HR-VR200/11,4 120 3/2 2 ) a – closing contact, b – breaking contact one breaking „b“ contact of the switch S1 is used by control circuit of contactor. Dimension drawing: 109 50 M8 50 56 144 165 16 43 43 133,5 Spare parts: Name: Control circuit Auxiliary switch ATB11-S Vacuum interrupter Block with varistors HR-V3 Socket of the block with varistors HR-V3 Block with varistors HR-V3.1 Socket of the block with varistors HR-V3.1 Drawing number or marking 230V 120V 56007-55-069 56007-55-071 9002276 HR-VR200/11,4 56007-44-001 56007-55-156 56007-44-004 56007-55-155 20 VACUUM CONTACTORS HR-VS 80 Technical data: Type Nominal operational voltage Nominal insulation voltage Testing voltage 50 Hz/60 sec. between poles and poles and nonvoltage parts Testing voltage 50 Hz/60 sec. in breaking path Nominal operational and thermal current Nominal switching capacities making current Nominal switching capacities breaking current Nominal short-time current (1 sec.) Nominal dynamic current Utilisation category Permissible switching frequency Mechanical life Electrical life: AC3 AC4 Closing time Breaking time Vacuum interrupters TJ-1.14/80 Contact operating travel Weight/Volume Dimensions Auxiliary circuits: Rated control supply voltage Peak value of switching current (flows for max. 30 ms) for control supply voltage 220 V Rated hold-in consuption Auxiliary contacts LX19K (AC380V DC220V 5A) HR-VS 80 1200V / 50-60Hz 1200V / 50-60Hz 4,2kV 10kV 80А 2360А 1340А 1340А 2360А АС1, АС2, АС3, АС4 1200 operations / hour 1·106 3·105 1·105 ≤ 30ms ≤ 80ms 3 pcs. 1,5 ± 0,2mm 1,8kg see dimension drawing 220V, 120V, 50-60Hz; +15%,-25% 1А 9VA 2x NO, 1x NC Each manufactured contactor is submitted to the piece control checking in accordance with ČSN EN 60470:2001 art.7 and ČSN EN 60947-4-1 art.9.1.3 (9.3.6) to examinate, whether contactors correspond to requirements of mentioned IEC standard and whether in manufacturing process were maintained characteristic parameters and assured quality corresponding to the type test of the contactor. The checking results are notified and archived. 21 Type Drawing number Current [А] Vacuum interrupters Control supply voltage [V] Auxiliary contacts a/b 1) HR-VS 80 56007-91-P01 80 TJ-1.14/80 220 2/1 HR-VS 80 56007-91-P03 80 TJ-1.14/80 120 2/1 2 ) a – closing contact, b – breaking contact one breaking „b“ contact of the switch S1 is used by control circuit of contactor. Dimension drawing: Spare parts: Name: Control circuit Auxiliary switch LX19K Vacuum interrupter Block with varistors HR-V3 Block with varistors HR-V3.1 Drawing number or marking 220V 120V TJ-1.14/80 56007-44-001 56007-44-004 22 23 We supply our equipment and spare parts to following countries: • Czech Republic • Slovakia • Poland • Germany • Austria • Russian Federation • Ukraine • Belarus • Kazakhstan • China • Australia • South Africa • England • Mexico • Turkey • Spain • Bosnia and Herzegovina 24 Contactor’s control circuit protection: If power supply of the control circuit is implemented from transformer, it is necessary to connect a series connected capacitor and resistor to terminals of transformer. Suitable type is 220N(X2)+220Ohm 250V (FILTANA). The overvoltage that can occur are limited in this way. Overvoltage by motor switching-off Vacuum contactors are characteristic for their affection to generate overvoltage in controlled inductive circuits. This happens by vacuum interrupters switching-off, when the current is suddenly interrupted shortly before AC current transits to the zero value as the result of an arc extinction in the vacuum. The overvoltage can reach a fairly high value; it is proportional to the switched-off circuit current and impedance and it can cause increase in the failure rate in electrical installations of electromotors -lowering of insulation resistance to earth, eventually line-to-earth failure). The manufacturer of vacuum contactors paid attention to the overvoltage problem in the course of type tests and is coming with the following recommendation to the user: а) The switching of loaded motors does not create any critical situation. The application of vacuum contactors without overvoltage protection is possible in all cases, where no prejudicial interference by short-time voltage pulses with frequency in the range 10-50 kHz can be expected. b) The overvoltage protection is recommended for the control of small electromotors, running on no load as well as for switching of unloaded transformers. In such cases, it is recommended to use varistor protection installed directly on terminals of the overvoltage source or close to them for confining the amplitude of overvoltage pulses generated by the contactor. The three-phase varistor overvoltage protection in delta connection in form of compact block can be ordered as a spare part for each type of contactor. 25 Please, state in your order the following information: - Name and type - Drawing number - Quantity in pieces - Quantity of varistor protection - Requested delivery time For special demands it is necessary to negotiate an agreement with the manufacturer. During ordering, please always specify contactor drawing number and short description, if necessary. In any case during ordering, drawing number will be considered as correct. The contactor is delivered in accordance with the specification given in the order. The Quality and Integrity Certificate is supplied together with these Instructions for Use with every contactor. The guarantee period is 6 months from the beginning of operation, however, up to the maximum of 12 months from the time of delivery. Time-limit for repairs is negotiated between the manufacturer and the user when making the reclamation report. Example of ordering: - Vacuum contactor HR-VS4 - Drawing number: 56007-03-001.2/31 - Required number: 40 pcs. - Quantity of varistor protection: 40 pcs. - Requested delivery time: 12 weeks after signing the contract 26 Name of the company Address Contact Hansen Electric, spol. s r.o. Těšínská 2977/79C 746 01 Opava Czech Republic Tel.: +420 553 816 958 Fax.: +420 553 816 930 E-mail: info@hansen-electric.cz www.hansen-electric.cz OOO «Сиб - Ханзен» ul. Ulyanovskaya 5 652507 Leninsk-Kuzneckiy Russian Federation Tel.: +7 38456 523 25 Fax.: +7 38456 523 25 E-mail: sib-hansen@yandex.ru ООО «Ханзен Украина» Sverdlovo 86193 Makeevka, Ukraine Tel.: +38 0623 227 949 Fax.: +38 0623 227 949 E-mail: hansenukr@ivc.com.ua 27