Spring return actuator Belimo TF24

advertisement

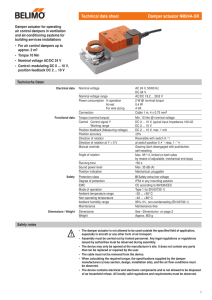

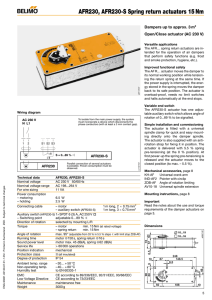

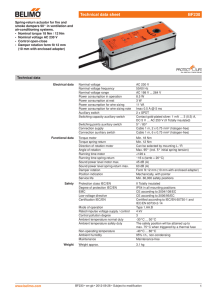

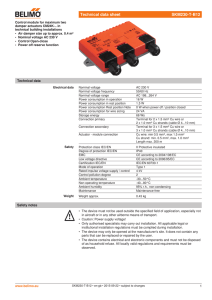

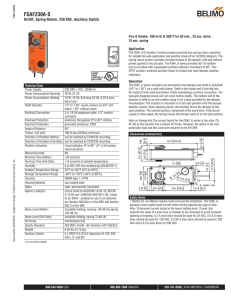

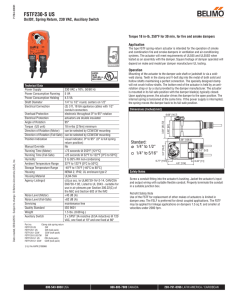

Technical data sheet Spring return actuator TF24-S Spring return actuator for the operation of air dampers that perform safety functions (e.g. frost and smoke protection, hygiene, etc.) for building services installations • • • • • For dampers up to approx. 0.4 m2 Torque 2 Nm Nominal voltage AC/DC 24 V Control: Open-close Integrated auxiliary switch Technical data Electrical data Nominal voltage Nominal voltage range Power consumption In operation At rest For wire sizing Auxiliary switch Connection Motor Auxiliary switch Functional data Safety Dimensions / Weight Torque Motor Spring return Direction of rotation Angle of rotation AC 24 V, 50/60 Hz DC 24 V AC 19.2 ... 28.8 V DC 21.6 ... 28.8 V 2.5 W @ nominal torque 1.5 W 5 VA 1 x SPDT 3 (0.5) A, AC 250 V (Switching point adjustable 0 ... 100% Cable 1 m, 2 x 0.75 mm2 Cable 1 m, 3 x 0.75 mm2 ) Running time Motor Spring return Sound power level Motor Spring return Service life Position indication Min. 2 Nm @ nominal voltage Min. 2 Nm Selected by mounting L / R Max. 95° (adjustable 37 ... 100% with built-in mechanical stop) < 75 s (0 ... 2 Nm) < 25 s @ –20 ... 50°C / max. 60s @ –30°C Max. 50 dB (A) Approx. 62 dB (A) Min. 60’000 operations Mechanical Protection class Degree of protection EMC Low voltage directive Mode of operation Overvoltage category Control pollution degree Ambient temperature range Non-operating temperature Ambient humidity range Maintenance III Safety extra-low voltage IP42 in any mounting position CE according to 89/336/EEC CE according to 73/23/EEC Type 1.AA.B (to EN 60730-1) III 3 –30 ... +50°C –40 ... +80°C 95% r.H., non-condensating (EN 60730-1) Maintenance-free Dimensions Weight See «Dimensions» on page 2 Approx. 650 g Safety notes ! • The spring return actuator is not allowed to be used outside the specified field of application, especially not in aircraft or any other form of air transport. • Assembly must be carried out by trained personnel. Any legal regulations or regulations issued by authorities must be observed during assembly. • The device may only be opened at the manufacturer‘s site. It does not contain any parts that can be replaced or repaired by the user. • The cables must not be removed from the device. • The device contains electrical and electronic components and is not allowed to be disposed of as household refuse. All locally valid regulations and requirements must be observed. 1 Open-close spring return actuator AC/DC 24 V, 2 Nm TF24-S Product features Mode of operation Simple direct mounting High functional reliability Flexible signalization The actuator moves the damper to its normal working position while tensioning the return spring at the same time. If the power supply is interrupted, the energy stored in the spring moves the damper back to its safe position. Simple direct mounting on the damper spindle with a universal spindle clamp. An antirotation device is supplied to prevent unwanted rotation of the whole unit. The actuator is overload-proof, requires no limit switches and automatically stops when the end stop is reached. Flexible signalization with adjustable auxiliary switch (0 ... 100% ) Electrical installation ~ T Wiring diagram – + Notes • Connection via safety isolating transformer. • Other actuators can be connected in parallel. Please note the performance data. ! 1 S1 S2 S3 2 <x >x M x = 0...100% Dimensions [mm] 84 6 61 17 Dimensional drawings 77 104 20 84 36 Data sheet T2-TF24-S • en • v1.1 • 04.2005 • Subject to modifications 6...12 2 70267-00001.C TF.. 1 2 L min. L 84 6 ... 12.7 3 4 R 37...100% R L ZG-TF1 max 1 Nm ! TF.. 1 2 ZDB-TF L min. 20 6 ... 12.7 3 4 R 37...100% R ZDB-TF L N L1 ~ ~ T T + – AC 24 V + – T N L1 ~ ! AC 230 V AC 24 V / DC 24 V a 2 1 M ~ + 2 5 TF24-3 + Y U5 DC 0…10 V DC 2…10 V 1 2 3 TF24-MFT 3 4 Y1 Y2 5 T Y Z U MP TF24-SR 2 x = 0...100% – 3 1 TF230-S / TF24-S Y U 1 <x >x T – S1 S2 S3 M TF230 / TF24 AC 24 V / DC 24 V 2 ~ 1 b DC 0…10 V DC 2…10 V