Installation, Operation and

Maintenance Manual

®

POWER SYSTEMS, INC.

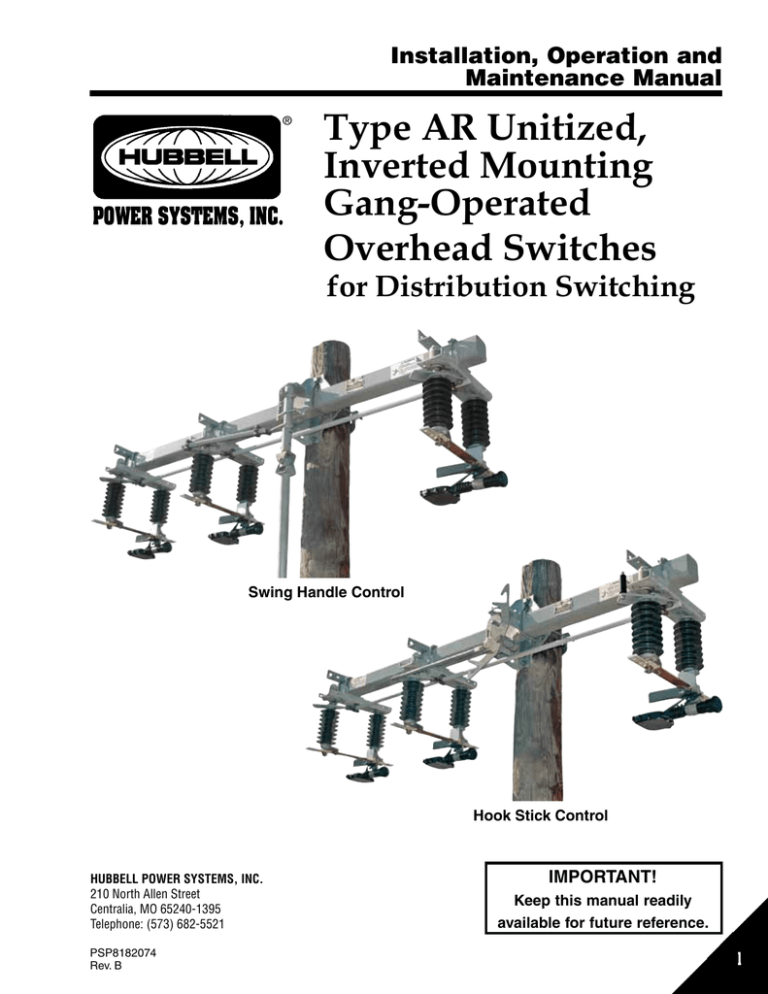

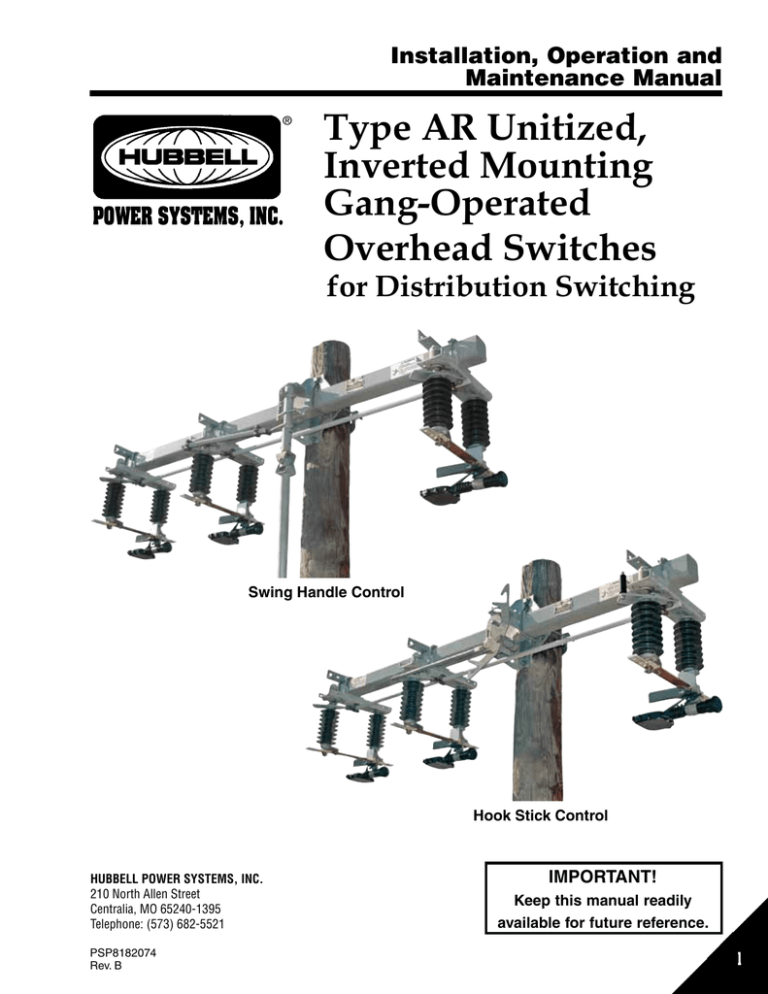

Type AR Unitized,

Inverted Mounting

Gang-Operated

Overhead Switches

for Distribution Switching

Swing Handle Control

Hook Stick Control

HUBBELL POWER SYSTEMS, INC.

210 North Allen Street

Centralia, MO 65240-1395

Telephone: (573) 682-5521

PSP8182074

Rev. B

IMPORTANT!

Keep this manual readily

available for future reference.

1

Warnings

! DANGER

Electrical equipment contains hazardous voltages and

high speed moving parts. Contact with these hazards will

cause death, serious personal injury or damage equipment.

Only qualified personnel shall install, operate and maintain this equipment.

Always properly ground equipment and lock out electric power (de-energize)

before maintenance. Using non-specified/ unauthorized parts or components to repair equipment, or tampering with safety devices/systems will

result in dangerous conditions which can cause death, severe personal

injury or damage to equipment. Take note of and follow all safety instructions

contained in this installation, operation and maintenance manual.

IMPORTANT

These installation, operation and maintenance instructions do not claim to cover all details or variations in

equipment. Nor do they provide for all possible conditions encountered while installing, operating or maintaining

this equipment. If further information is desired or needed to address any particular installation, operation or

maintenance problem not covered in this document, contact your authorized factory representative.

The information in this document does not relieve the user from exercising good judgment in selecting equipment for suitability of application. Nor does it relieve the user from using sound practices in installation, operation and maintenance of the equipment purchased.

Note: Because Hubbell has a policy of continuous product improvement, we reserve the right to change design

and specifications without notice. Should a conflict arise between the general information in this document and

the contents of drawings or supplementary material, or both, the latter shall take precedence.

QUALIFIED PERSON

For the purpose of this manual, a qualified person is:

(a)

familiar with the installation, construction or operation of the subject equipment and the hazards

involved with its installation, operation and maintenance.

(b)

trained to de-energize, clear, ground, and tag circuits and equipment in accordance with established

safety practices.

(c)

trained in the proper care and use of protective equipment such as rubber gloves, hard hat, safety

glasses or face shields, flash clothing, etc., in accordance with established utility safety practices.

(d)

trained to render first aid.

SUMMARY

The information in this document does not claim to cover all details or variations in equipment, nor to provide for

every possible contingency encountered with installation, operation, or maintenance. Should further information

be needed or problems arise that are not covered sufficiently, contact your factory representative.

The contents of this document are not part of, nor do they modify, any prior or existing agreement, commitment or

relationship. Hubbell Power Systems, Inc. terms and conditions of sale constitute the entire obligation of Hubbell

Power Systems, Inc. The warranty in the terms and conditions of sale is the sole warranty of Hubbell Power

Systems, Inc.. Any statements in this document do not create new warranties or modify any existing warranty.

2

PSP8182074

Rev. B

Contents

Section Subject............................................................Page Number

1 — Overview.......................................................................5

2 — Installation Requirements...........................................7

3 — Receiving and Handling..............................................8

3a – Inspect Packaging.......................................................................................8

3b – Switch..........................................................................................................8

3c – Swing Handle Control..................................................................................9

4 — Switch Installation.....................................................10

4a – Switch Options...........................................................................................10

4b – Switch........................................................................................................ 11

5 — Control Installation*...................................................12

5a – Swing Handle Control . .............................................................................12

6 — Control Adjustment....................................................16

6a – Swing Handle Control................................................................................16

7 — Pre-Operation Checks...............................................17

8 — Dead-Ending & Wiring...............................................19

8a – Dead-Ending ............................................................................................19

8b – Wiring........................................................................................................19

9 — Operation....................................................................20

9a – Swing Handle Control................................................................................20

9b – Hook Stick Control.....................................................................................20

10 — Maintenance...............................................................21

11 — Trouble Shooting........................................................22

12 — Control Drawing Sample...........................................23

*Hook stick operable control is factory assembled. No control components

installation required.

PSP8182074

Rev. B

©

2010 Hubbell Incorporated, 210 North Allen Street, Centralia, MO 65240

3

Contents

Tables.......................................................................... Page Number

Table 2-1

Table 11-1

Hardware torque specifications........................................... 7

Trouble shooting guide......................................................22

Figures......................................................................... Page Number

Figure 3-1

Figure 3-2

Figure 3-3

Figure 3-4

Figure 4-1

Figure 4-2

Figure 5-1

Figure 5-2

Figure 5-3

Figure 5-4

Figure 6-1

Figure 7-1

Figure 7-2

Figure 7-3

Figure 7-4

Figure 9-1

Figure 9-2

Figure 9-3

Figure 12-1

4

Switch in crate....................................................................8

Crate opened.......................................................................8

Remove straps....................................................................8

Swing handle control and mounting components............... 9

Mounting ......................................................................... 11

Hoisting............................................................................. 11

Swing handle control installation Steps 1–3..................... 12

Swing handle control installation Step 4........................... 13

Swing handle control installation Step 5........................... 14

Swing handle control installation Step 6........................... 15

Swing handle control adjustment...................................... 16

Switch sub-assembly components................................... 17

Switch sequencing 1.........................................................18

Switch sequencing 2.........................................................18

Switch sequencing 3.........................................................18

Hook stick control opening............................................... 20

Hook stick control closing.................................................20

Hook stick control lock out/tag out................................... 20

Sample control drawing........................................... 23 & 24

PSP8182074

Rev. B

1 — Overview

About This Manual

Each is clearly noted in the title. At the plied with this manual. It is specific

end of each is an arrow with directions to the particular configuration and

This manual covers the inverted

to the next appropriate sub-section. control ordered. It provides detailed

mounting of the Type AR unitized

information about the switch and must

switch and its various control types. Be sure you know the configuration

and control type you are installing. be used with this manual to assure a

This will greatly aid in navigating to proper installation. Refer to the control

the next step in the installation and drawing to obtain:

• Catalog numbers

adjustment process.

• Installation notes

Note: This manual does not contain • Phase-to-phase spacing

all necessary information. It is supple- • Pole mounting bracket and control pipe

Watch For This Arrow

mented with a “control drawing” that

hole drilling locations

The arrow at the end of each proce- presents dimensions and specifica•

Option

descriptions and installation locadure will direct you to the next appro- tions unique to the switch configurations

priate section and page number of the tion you are installing.

• Switch and option parts lists

installation process.

The Control Drawing

A sample control drawing is shown in

A separate control drawing is sup- Section 12.

Introduction

Signal Words

This manual is to guide you through

the installation, operation and maintenance of the inverted Type AR

unitized, gang-operated overhead

switch. This manual does not claim

to cover all situations that may arise

during installation. If additional information is needed, contact your

factory representative. Nor does this

manual supersede your company’s

established guidelines and practices

for similar equipment. Take note of and

heed all danger, warning and cautions

contained in this document.

Qualified Person

Only qualified trained and competent

personnel that understand proper

safety procedures must select, install

and service this equipment.

Read and understand these instructions before installing, operating or

maintaining this equipment.

This guide is not a substitute for

adequate training and experience

in safety procedures for this type of

equipment.

CAUTION

The signal words “DANGER,” “WARNING”

and “CAUTION” (along with their assigned

CAUTION used without the safety alert

symbol) throughout this manual indicate the

symbol indicates a potentially hazardous

degree of hazard the user may encounter.

situation which, if not avoided, may result in

These symbols and words are defined as:

property damage.

! DANGER

▲

Product

The products covered by this manual

DANGER indicates an imminently hazardous

are the inverted Type AR unitized

situation which, if not avoided, will result in

gang-operated overhead switches for

death or serious injury.

medium voltage electrical distribution

switching.

! WARNING

These products are designed for disWARNING indicates a potentially hazardous tribution switching only at their rated

situation which, if not avoided, could result in capacities. They cannot be field modified for capacities other than what was

death or serious injury.

shipped with the units. If a different

capacity is desired, contact your supervisor or factory representative to

CAUTION indicates a potentially hazardous secure the appropriate unit.

situation which, if not avoided, may result in

Function

minor or moderate injury.

These products are loadbreak switches designed to provide a means for

disconnecting, sectionalizing and

isolating the electrical distribution

system.

! CAUTION

! DANGER

Hazardous voltage.

Will cause death, severe personal injury, or property damage.

Only qualified personnel should work on or around this equipment

after becoming thoroughly familiar with this document and other

publications regarding this equipment.

PSP8182074

Rev. B

5

1 — Overview

Switch Control Types

Specifications

The inverted Type AR switch may be operated by two control types: down the pole

swing handle or hookstick operation. The

hook stick control is factory assembled and

requires no control installation.

Electrical

Application/Mounting

The inverted Type AR unitized gang-operated

overhead switch is designed for mounting on

wooden utility poles. If the utility pole is steel or

concrete, mounting may be accomplished by

means of holes made in the pole or by using

brackets. Contact your factory representative

for details on mounting the unit on steel or

concrete utility poles.

Swing Handle Control

Operating Environment

The inverted Type AR unitized switch is

designed for outdoor installation and can be

operated in direct sunlight in ambient temperatures between -40°C and +40°C.

• Nominal voltage ratings of 14.4 kV, 25

kV or 34.5 kV (model dependent)

• Lightning impulse peak withstand

ratings of 110 kV or 150 kV (model

dependent)

• Continuous current rating of 900

amperes

• Load current interrupt rating of 900

amperes

• Short time current withstand rating:

- 25 kA symmetrical, 3 seconds

- 65 kA peak

• Fault closing rating

(close time < 0.5 second):

- 25 kA asymmetrical 1 time

- 20 kA asymmetrical 3 times

Dead-Ending

Hook Stick Control

• Equal loading 8000 pounds (3630 kg)

• Unequal loading 700 pounds (320 kg)

Dimensions

! WARNING

6

High voltage electric contact hazard.

Refer to the separate control drawing supplied

with this manual for information specific to the

switch ordered.

Can cause death, severe personal injury or property damage.

Motor Operator

Install control handle with appropriate safeguards to prevent unauthorized

switch operation, such as mounting out of reach or inside a fenced area, and

padlocking control handle according to your company’s standard operating

procedures.

For motorized or remote operation of the Type

AR switch, review Catalog Section 14C or

contact your factory representative.

PSP8182074

Rev. B

2 — Installation Requirements

User Supplied Requirements Hubbell Supplied Requirements Required Torque Specifications

The following is required for installa- All necessary components and hard- It is the installing personnel’s retion. Be sure to have these items on ware specific to the installation of the sponsibility to be sure all threaded

hand before beginning installation.

Type AR switch ordered are included. fasteners are installed with the correct

Safety Equipment

Carefully check the components and torque. All user supplied hardware is

hardware items against those listed in to be torqued according to company

• Hard hat

the separate control drawing (sample standards. For switch and control

• Steel-toe work boots

hardware torque specifications, are

shown in Section 12).

• Appropriate eye protection per your

listed in Table 2-1.

Contact your factory representative if

company’s policy

• Other safety equipment as required by any parts are missing.

your company’s policies

Hardware

• 5⁄8 inch (16 mm) galvanized thru-bolts

(or equivalent) long enough to pass

through the center of the utility pole,

plus 3 inches (75 mm)

• Curved galvanized washers for the 5⁄8

inch (16 mm) thru-bolts

• Galvanized nuts for 5⁄8 inch (16 mm)

thru-bolts

• 1⁄2 inch (12 mm) and 5⁄8 inch (16

mm) galvanized lag screws (or equivalent)

• Flat galvanized washers for 1⁄2 inch

(12 mm) and 5⁄8 inch (16 mm)) lag

screws

• Extension links (if not ordered with

switch)

Electrical

• Terminal pad connectors (if not ordered with switch)

• Hubbell sealing paste (or equivalent)

• Surge arresters and wire (if needed)

• Pole grounding means

• Sensors, wire and connectors (if

needed)

Options

Required items such as additional

control pipe, surge arrester brackets,

terminal connectors, extension links

and crossarm braces not included

in the basic switch package must be

sourced separately. Contact your factory representative for ordering.

PSP8182074

Rev. B

Table 2-1 — Hardware Torque Specifications

User Supplied Hardware

Item

ft-lbs.N•m Notes

5⁄8 inch (16 mm) thru-bolts

N/A N/A Company standards apply

5⁄8 inch (16 mm) lag screws

N/A N/A Company standards apply

1⁄2 inch (12 mm) lag screws

N/A N/A Company standards apply

Terminal connectors

N/A N/A Company standards apply

Hubbell Supplied Hardware

Item

ft-lbs. N•m Notes

3/8 inch coupling spline bolts (locknuts)

25 34

3/8 inch adjustable guide bracket bolt

25 34

1/2 inch pole band bolts

60 81

1/2 inch pole band “J” bolts

60 81

Ground strap assembly

25 34 - 3/8 inch control pipe clamp

60 81 - 1/2 inch bracket clamp

25 34 - 3/8 inch parallel groove

ground wire clamp

5/8 inch handle clamp bolt

25 34

3/8 inch U-bolts 25 34 Apply star torque pattern

Control Insulator - 12 ft-lbs. (17 N•m) first pass

- 25 ft-lbs. (34 N•m) second pass

1/2 inch U-bolts 60 81 Apply star torque pattern

(Surge arrester brackets) - 30 ft-lbs. (40 N•m) first pass

- 60 ft-lbs. (81 N•m) second pass

1/2 inch terminal hardware

60 81

1/2 inch crossarm brace bolt

25 34 Steel and fiberglass crossarm

3/8 inch sensor bracket bolts

25 34

7

3 — Receiving & Handling

3a –

Inspect Packaging

Figure 3-1 – Switch in Crate

Step 1. — Perform Inspection

• Upon receipt, immediately inspect

packaging for signs of damage

• Start inspection with the packaging

material and proceed to the equipment

within

• Look for concealed damage

• If damage is found, note damage on

“Bill of Lading” prior to accepting

delivery, if possible

Note: Documentation of visible shipping damage can determine the outcome of any damage claim. Notifying

the carrier of concealed damage within

15 days is essential to resolving or

minimizing unsettled claims. Immediately file your claim and notify your

factory representative.

Figure 3-2 – Crate Opened

3b – Switch

Step 1. — Unpack Switch

• Place shipping crate on stable, level

surface near the utility pole

• Compare unitized switch with the illustration in Figure 3-1 and the parts list

on the separate control drawing to be

sure all items have been included

• Contact your factory representative if

any parts are missing

• Remove the top, ends, and one side

from the shipping crate as in Figure

3-2

• Remove hardware and straps holding

switch to crate as in Figure 3-3

• Leave unitized switch on its pallet until

ready to install

Figure 3-3 – Remove Straps

Unpack Controls:

• Swing Handle Control — 3c, Page 9

• Hook Stick Control - Factory Installed — Go to 4a, Page 10

8

PSP8182074

Rev. B

3 — Receiving & Handling

3c –

Swing Handle Control Figure 3-4 – Swing Handle Control & Mounting Components

Step 1. — Unpack Control and

Mounting Components

• Leave control pipe and handle on the

shipping pallet until ready to install

• Compare the control pipe and handle

components in Figure 3-4 with the

parts list on the separate control

drawing to be sure all items have been

included

• Compare hardware items shown in

Figure 3-2 with those listed on the

separate control drawing to be sure all

items have been included

• Contact your factory representative if

any parts are missing

Coupling

(Small Diameter)

Coupling

(Large Diameter)

3⁄8” Ribbed Neck Bolt and Hex Locknut

Ground Strap Assembly

Upper Guide Bracket

J-Hook Bolt

and Nut

1⁄2” Flat Washer

Handle Assembly

Adjustable Guide Bracket

1⁄2” Hex Nut

Pole Bands

1⁄2” x 1-1⁄2”

Hex Bolt

1⁄2” Lock Washer

Fiberglass or Steel

Top Universal Section

Steel

Control Pipe

Handle Guide Bracket

(Nameplate)

Install Switch:

• Switch Options — 4a, Page 10

PSP8182074

Rev. B

9

4 — Switch Installation

4a –

Switch Options

When ordered as an option, 3 brack- When ordered, two stainless steel

spline bolts are pressed into each

Hubbell makes available several opterminal pad. Nuts and lockwashers

tions to enhance installation and opare included.

eration of the Type AR unitized switch.

Note: Some of these options may have

been ordered with the switch.

ets are supplied for mounting 6 surge

Related Equipment

arresters (user supplied) for overIf the desired option(s) was not or- voltage protection.

Hubbell makes available other parts

dered with the switch, contact your

and equipment to further enhance

Crossarm Braces

factory representative.

installation or operation. These are

Crossarm braces may be ordered as not available as an option on the

Type AR switch and must be ordered

Options

separately.

Steel

Additional Control Pipe

Swing Handle

Control

The extra 7 foot (2.1 m) control pipe

section includes guide(s), coupling

and all necessary hardware for attachment.

Extension Links

Extension links must be used on

Type AR unitized overhead switch to

provide dead end clearance. When extension links are ordered as an option,

they are 14 inches (355 mm) long,

hot-dipped galvanized and REA accepted. A.B. Chance catalog number

C207-0112 (6 required per switch).

Control Insulators

A polymer insulator having a lightning

impulse withstand rating of 150 kV

Wood

an option in two versions:

• Steel — 1-3⁄4 inch (45 mm) hot-dip

galvanized steel angle

• Wood — 2 inch (50 mm) square

pressure-treated wood

Motor Operator

For motorized or remote operation of

the Type AR Switch, review Catalog

Section 14C or contact your factory

representative.

Other Items

Any other electrical and/or hardware

items used in the installation and

Terminal Connectors

maintenance of this switch can be

Tin-plated aluminum parallel-groove supplied by Hubbell. Contact your

factory representative for selection

and ordering.

clamps can be supplied as an option.

Cable range is from a minimum of No.

2 solid copper (0.258 inch/6.55 mm)

to a maximum of 500 kcmil (0.811

inch/20.6 mm) (6 per switch).

Sensor Bracket

Six channel formed galvanized steel

brackets and hardware are supplied

and 26 inches (660mm) of leakage for 3 inch (75 mm) bolt circle or 3/4

distance is supplied with all necessary inch (20 mm) center mounted voltage

and current sensors. Sensor hardware

hardware.

not included.

Swing Handle Control

Surge Arrester Brackets

10

Captive Hardware

PSP8182074

Rev. B

4 — Switch Installation

4b – Switch

Step 1. — Drill Holes and Install

Hardware

• Refer to the separate control drawing

and Figure 4-1

• Drill 2 — 11⁄16 inch (18 mm) holes on

the utility pole’s centerline according

to dimensions given on the separate

control drawing

• Install 2 — 5⁄8 inch (16 mm) thrubolts, washers and nuts (user supplied) with bolt heads on the side

of the utility pole the switch is to be

mounted on

• Leave bolt heads sticking out 1 inch

(25 mm)

Step 1. — Hoist Switch into

Position

• Refer to Figure 4-2

• Secure lifting sling to pull-off brackets

(30° minimum)

• Secure guide rope (not shown) as

required.

• Using your standard company practice,

hoist the switch into position

• Place unit so the upper bolt head

sticks out of the mounting bracket’s

upper key hole and the lower mounting bracket slot is over the lower

mounting bolt

• Lower switch until switch weight is

resting on the mounting bolts

• Torque nuts to specified value per

Table 2-1

• Remove lifting provisions used to hoist

the switch

Step 3.— Install Pole Band

• Assemble pole band halves with nut,

washer and bolt provided so band

approximates 1⁄2 of the utility pole’s

circumference, and allows for installing and tightening the J-hook bolts to

the switch mounting bracket

• Set pole band in position, insert

J-hook bolts into switch mounting

bracket and tighten to specified value

per Table 2-1

• Secure pole band to utility pole with

! WARNING

High voltage electric arc hazard.

Can cause death, severe personal injury or property damage.

Always hoist switch by the provisions that are provided. Hoisting by

“live parts” can bend switch blades, and mis-align parts, resulting in an

electrical arc.

Figure 4-1 - Mounting

Front View

Side View

Figure 4-2 - Hoisting

30° minimum

from horizontal

a 1⁄2 inch (12 mm) lag screw and

washer (user supplied)

Step 4. — Bracing

• Crossarm braces are recommended if:

1) the pole mounting bracket poorly

fits the pole curvature 2) the thruholes are drilled larger than recommended or 3) the switch asymmetry

causes excessive weight to be on one

side of the pole.

• Drill an 11⁄16 inch (18 mm) thru-hole

on center line of pole as shown on the

separate control drawing

• Secure crossarm brace to the utility

pole with a 5⁄8 inch (16 mm) thru-bolt

(user supplied) and to the crossarm

with the supplied hardware

• Torque nuts to specified values

per Table 2-1

Install Controls:

• Swing Handle Control — 5a, Page 12

• Hook Stick Control - Factory Installed — Go to Section 7, Page 17

PSP8182074

Rev. B

11

5 — Control Installation

5a –

Swing Handle Control Figure 5-1 — Swing Handle Control Installation Steps 1-3

Step 1.—Prepare Control Pipes

• Locate control pipes, universal section,

couplings, spline bolts and lock nuts

• Install a small-diameter coupling in

one end of each control pipe using the

spline bolts and lock nuts provided;

the large diameter coupling attaches to

the universal section

• Spline bolts may be tapped in to engage pipe and coupling

• Tighten lock nuts to specified value per

Table 2-1

Note: There will be one control pipe

without any coupling. This will be installed last.

Step 1 — Attach couplings to one end

of control pipes using spline bolts and

lock nuts. Note: One pipe will not have

a coupling, it will be installed last.

Step 2. — Connect Universal

Section To Switch

• Refer to Figure 5-1

• Connect universal section (steel or

fiberglass) to the switch drive shaft

using the larger dia. coupling, spline

bolt, and lock nut provided and tighten

to specified value per Table 2-1

Step 3. — Mount Upper Control

Pipe Guide Bracket

Note: The upper control pipe guide

bracket is fixed and its length cannot

be adjusted.

• Refer to Figure 5-1

• Position the lower end of top universal

section on the utility pole’s centerline

• Mark and drill on the utility pole’s centerline 6 inches (150 mm) below the

end of the universal section an 11⁄16

inch (18 mm) diameter thru-hole as

shown in Figure 5-1

• Mount the upper control pipe guide

bracket (fixed) to the pole with a

5⁄8 inch (16 mm) thru-bolt, curved

washer and nut (user supplied) placed

through the bracket’s round hole

• Place a 5⁄8 inch (16 mm) lag screw

with washer (user supplied) through

the bracket’s slotted hole

Step 2 — Attach universal joint to

switch drive shaft using large coupling, spline bolt, and lock nut.

6 inches

(150 mm)

Step 3 — Mount upper control guide

bracket on utility pole’s centerline 6

inches (150 mm) below the bottom of

the universal section.

12

PSP8182074

Rev. B

5 — Control Installation

5a –

Swing Handle Control Figure 5-2 — Swing Handle Control Installation Step 4

(continued)

Step 4. — Install Pipes and

Adjustable Pipe

Guide Brackets

Note: Pipe guide brackets must be a

minimum of 3 inches (75 mm) below

any control pipe coupling spline bolt.

• Refer to Figure 5-2

• Insert the end of the control pipe (with

out the coupling) up through the top

pipe guide bracket and connect it to

the universal section using the spline

bolt and lock nut provided; tighten to

specified value per Table 2-1

• Mark and drill on the utility pole’s

centerline an 11/16 inch (18 mm)

diameter thru-hole 6 inches (150 mm)

below the end of the control pipe just

installed

• Mount the next control pipe guide

bracket (adjustable) to the pole with

a 5/8 inch (16 mm) thru-bolt, curved

washer and nut (user supplied) placed

through the bracket’s slotted hole

• Place a 5/8 inch (16 mm) lag screw

with washer (user supplied) through

the bracket’s slotted hole

• Loosen the adjustment bolt in the control pipe guide bracket until Step 6

• Repeat the above procedures until all

adjustable control pipe guide brackets

and control pipe sections are installed

Step 4 — Bring end of first control

pipe section (end without coupling)

up through fixed guide and connect

to the bottom of the universal section.

Note: The last control pipe section may

need cutting to comply with your company’s control handle mounting height

specification/policy. If this is the case,

establish the handle height and cut

the last control pipe section to length

prior to mounting. See separate control

drawing for dimensions. Treat cut end

with zinc-rich paint.

Mount adjustable guide bracket on

utility pole’s centerline 6 inches (150

mm) below the bottom of the control

pipe just installed.

PSP8182074

Rev. B

13

5 — Control Installation

5a –

Swing Handle Control

(continued)

Step 5. — Mount Handle

Assembly, Handle

Guide Bracket and

Ground Strap Assembly

• Refer to Figure 5-3

• Measure and mark on the utility pole’s

center line 6 inches (150 mm) up from

the bottom of the last control pipe

• Drill an 11⁄16 inch (18 mm) hole

through the utility pole’s centerline

• Slide ground strap clamp (pipe clamp

end) up the control pipe approximately

24 inches (610 mm)

• Install handle assembly on control pipe

so the handle points down

• Slide handle assembly up the control

pipe approximately 18 inches (460

mm) and lightly tighten the clamp bolt

to keep the assembly from sliding off

— DO NOT set the piercing screw

• Slide the handle guide bracket (nameplate) up the control pipe and fasten it

to the pole with two 5⁄8 inch (16 mm)

thru-bolts, curved washers and nuts

(user supplied)

• Loosen handle assembly clamp and

slide it down the control pipe so the

lock hasp on the handle can swing

under the handle guide bracket with

minimum clearance

• Rotate handle assembly to the

“CLOSED” position and tighten handle

clamp bolt

• Slide grounding strap clamp on the

control pipe into position so it won’t

interfere with handle rotation/operation and tighten to specified value per

Table 2-1

• Mount parallel groove clamp end of the

grounding strap to the handle bracket

using the supplied hardware as shown

in Figure 5-3 detail

• Install a suitable earth ground wire in

clamp’s parallel groove and tighten to

specified value per Table 2-1

! WARNING

High voltage electric contact hazard.

Can cause death, severe personal injury or property damage.

Install control handle with appropriate safeguards to prevent unauthorized

switch operation, such as mounting out of reach or inside a fenced area, and

padlocking control handle according to your company’s standard operating

procedures.

Figure 5-3 — Swing Handle Control Installation Step 5

Step 5 — Drill holes for handle guide

bracket at desired height

Place the ground strap assembly

clamp, handle assembly and handle

guide bracket on control pipe before

bolting bracket to the pole.

Make sure lock hasp on handle

swings down and under the handle

guide bracket with minimum clearance.

Note: Grounding recommendations

may differ from those of your company.

Where differences exist, the operating

procedures of your company shall take

precedence.

14

PSP8182074

Rev. B

5 — Control Installation

5a –

Swing Handle Control Figure 5-4 — Swing Handle Control Installation Step 6

(continued)

Step 6. — Set Adjustable Control

Pipe Guides

• Refer to Figure 5-4

• Make sure all adjustable pipe guides

are loose

• Use the pipe guide adjustment mechanism to align the control pipes so they

form a straight line between the top

(fixed) guide and bottom handle lock

bracket

• Tighten adjustable pipe guides to

specified values per Table 2-1

Step 6 — Set adjustable pipe guide

brackets so control pipes don’t bind

and are straight between the top and

bottom fixed guides.

Adjust control pipe alignment by

moving guides in or out, and side to

side; then tighten carriage bolts per

Table 2-1.

PSP8182074

Rev. B

15

6 — Control Adjustment

6a –

Swing Handle Control

Note: The Type AR unitized switch is

shipped in the “CLOSED” position.

The correct amount of overtoggle for

positive switch closure is built into the

drive mechanism. If for some reason

the switch has been opened, return it

to its full “CLOSED” position before

proceeding.

Top View

Step 1. — Preparation

• Open and close switch several times

• Inspect entire installation for proper

and unrestricted operation

• If undue restriction is encountered,

readjust pipe guides and/or eliminate

source of obstruction as needed

Switch Closed

Position

Switch Open

Position

Step 2. — Set Control Handle in

Closed Position

• Refer to Figure 6-1

• Rotate control handle until the switch

is in the fully “CLOSED” position and

drive mechanism is overtoggled

• Inspect handle position to be sure it

rests in the center of the “CLOSED”

side of the handle bracket, and the

handle lock hasp freely swings down

into position under the handle bracket

• If needed, loosen handle clamp bolt

and adjust handle position; retighten

handle clamp bolt

Figure 6-1 — Swing Handle Control Adjustment

Step 2 — Make sure control handle is in the “CLOSED” position and the switch

drive mechanism is overtoggled to the “CLOSED” position.

Step 3. — Check Switch and Control Handle Operation

• Gently cycle control handle; observe

control pipe and switch operation

• Recheck control handle location relative to fully “CLOSED” and “OPEN”

positions

• If all settings are correct and switch

cycles freely, tighten handle clamp bolt

to specified torque per Table 2-1 and

set piercing screw

• If control mechanism or switch show

signs of undue binding, check control

guide alignment and make adjustments as required

• Pre-Operation Checks — Section 7, Page 17

16

PSP8182074

Rev. B

7 — Pre-Operation Checks

General

Figure 7-1 — Switch Sub-Assembly Components

Note: All switch contacts come

factory lubricated. DO NOT remove

this lubrication. If lubrication is

removed, immediately relubricate

with Dow Corning FS-1292 Silicone

grease or equivalent.

Interrupter

Interrupter Pick-up Lever

Deflector

The following pre-operation checks

apply to all Type AR configurations.

The Type AR unitized switch is fully

adjusted and function checked at the

factory. To determine if shipping or

installation damage has occurred,

perform the following operational

checks prior to placing the switch into

active service.

Shield

Stationary

Contacts

Terminal

Pad

Switch Blade

Blade Guide

Step 1. — Cycle Switch

• Slowly open and close the switch via

control handle or hook stick (whichever applies)

• Observe switch blades to see if all

three phases move together

• When fully closed, the control handle

or hook stick (whichever applies)

should overtoggle the operating arm

to the drive phase of the switch by

about 10° of rotation

• All three switch blades should now

be fully seated in their contacts and

against the back of the blade guide

• When fully open, the switch blades

should be from 80° to 90° of rotation

from the closed position

PSP8182074

Rev. B

17

7 — Pre-Operation Checks

Step 2 — Opening Sequence

Figure 7-2 — Switch Sequencing 1

• Refer to Figure 7-2

• When closed, the blade should touch

the back of the blade guide and completely engage all six of the stationary

contact fingers

• Refer to Figure 7-3

• Upon initial opening, the “V” on the

blade’s deflector should receive the

interrupter pick-up lever

Note: The exposed metal portion of the

deflector’s base should engage the interrupter pick-up lever’s exposed metal

surface prior to the blade leaving the

last set of contact fingers.

• Refer to Figure 7-4

• The interrupter must trip while the

metal portion of the deflector’s “V” is

in contact with the interrupter pick-up

lever’s exposed metal surface

• If the switch fails to operate as described, contact your factory representative

Figure 7-3 — Switch Sequencing 2

Step 3 —Closing Sequence

• The switch closing sequence is opposite the opening sequence except the

deflector passes under the interrupter

pick-up lever

• The interrupter pick-up lever then

drops to its normal position ready to

engage the deflector’s “V” upon switch

opening

• If the switch fails to operate as described, contact your factory representative

Figure 7-4 — Switch Sequencing 3

• Deadending & Wiring — Section 8, Page 19

18

PSP8182074

Rev. B

8 — Dead-Ending & Wiring

8a –

Dead-Ending

8b – Wiring

General

Step 1. — Jumper Conductors

Type AR switch has dead-ending

brackets as an integral part of the

cross arm. Located at the base of

each switch phase, the dead-end rating is 8,000 pounds (3630 kg) where

conductor pull-off forces are applied to

both sides of the switch. The dead-end

rating is 700 pounds (318 kg) where

conductor pull-off forces are applied to

only one side of the switch. Extension

links are required to dead-end from

the switch. Extension links may be

supplied with the switch if that option

was ordered. If not, extension links

must be supplied by the user.

• Using your company’s standard practices, jumper the conductors to the

switch terminal pads

• Use sufficient conductor length to allow for free switch movement

• Train jumpers from the high voltage line to the switch terminal pads

to avoid applying excessive bending

forces to the terminal pads

• Form/train jumpers such that minimal mechanical load is applied to the

terminal pads

• Excess mechanical forces may

bend terminal pads causing contact

misalignment - Refer to ANSI C37.30

series of standards for terminal pad

mechanical load ratings and line conductor application

! CAUTION

Excessive Terminal Pad

Mechanical Load

May cause arcing, improper operation

or switch damage

Minimize terminal pad mechanical

load by forming/training the jumper

connection to align with the terminal

pad before securing to the terminal

pad.

Note: If dead-ending on only one

side, install switch so mounting

bracket is on the side of the utility

Step 2. — Connect High Voltage

pole opposite the conductors.

Conductors

Using your company’s standard practices, connect the extension links, • Wire brush mating surface of the

switch terminal pads and terminal

insulators and conductors to the dead

connectors

end brackets.

• Wire brush connector surfaces where

conductors will be secured

• Wire brush conductor surfaces

• Apply a contact sealing paste to the

cleaned surfaces (Hubbell or equivalent)

• Assemble connectors, conductors and

hardware to the switch terminal pads

• Torque all hardware to specified values

per Table 2-1

Operation:

• Swing Handle Control — 9a, Page 20

• Hook Stick Control — 9b, Page 20

PSP8182074

Rev. B

19

9 — Operation

9a – Swing Handle/

Torsional Control

Note: Operate the switch quickly and

without hesitation to its fully “OPEN”

and/or “CLOSED” position. Slow switch

operation and partial opening and/or

closing must not be done. Fault closing rating requires less than 1⁄2 second

operation of the switch.

Step 1 —Opening/Closing Switch

• Unlock control handle

• Move control handle from its locked

position to a horizontal position

• Position feet and body in a manner

that provides good stability and allows

! WARNING

High voltage electrical contact hazard.

Can cause death, severe personal injury or property damage.

Visually inspect switch blades to be sure they are in the desired position. Control handle position may not indicate true open or closed

position of switch blades. Lock control handle according to your

company’s standard operating procedure.

for control handle to move without

losing a steady footing

• Under ice conditions, be prepared to

use greater force to overcome the additional resistance

• Quickly and firmly move the control

handle to its opposite position

• Move control handle into its locked

position

• Lock control handle in accordance with

your company’s policy

Review Maintenance Procedures — Section 10, Page 21

9b – Hook Stick Control

Step 2 — Lock Out/Tag Out

(If applicable)

• Use your company’s standard practices to apply a lock out/tag out device

into position utilizing provisions as

shown.

Note: Operate the switch quickly and

without hesitation to its fully “OPEN”

and/or “CLOSED” position. Slow switch

operation and partial opening and/or

closing must not be done. Fault closing rating requires less than 1⁄2 second

operation of the switch.

Step 1 —Opening/Closing Switch

• Position yourself below and slightly

to the front of the switch’s hook stick

mechanism

• Position feet and body in a manner

that provides good stability and allows

for hook stick use without losing a

steady footing

• Under ice conditions, be prepared to

use greater force to overcome the additional resistance

• From the front, insert hook stick (user

supplied) into the uppermost (highest)

operating “eye” of the hook stick lever

• Allow a minimum of 24 inches (610

mm) clearance from the bottom of the

hook stick to the ground

• Quickly and firmly pull the hook stick

down to rotate the hook stick lever to

its opposite position

• Remove hook stick from the operating

“eye” of the hook stick lever

Figure 9-1 - Opening

Figure 9-3 - Lock Out/Tag Out

Figure 9-2 - Closing

Review Maintenance Procedures — Section 10, Page 21

20

PSP8182074

Rev. B

10 — Maintenance

Maintenance

Prolong the life of the Type AR switch

with a periodic inspection and maintenance program. Although the switch

is designed for long-term exposure in

all weather conditions, certain environments may reduce its life without

periodic maintenance. Following these

minimum inspection and maintenance

procedures will help ensure long

service life.

Note: It is recommended that all switches go through a maintenance check at

least once a year; more frequently if

located in a contaminated area.

! DANGER

Hazardous voltage.

Contact with energized lines will result in death, personal injury or

property damage.

All maintenance work should be performed on de-energized switches. If work must be performed on live lines, follow your company’s

standard safe operating procedures.

! WARNING

Hazardous voltage.

Can cause death, severe personal injury.

Contact with the switch bases, hardware or crossarm could result in

For additional recommendations, refer

electrical shock. Ground the switch bases and mounting hardware

to ANSI C37.35 “IEEE Guide for the

prior to maintenance.

Application, Installation, Operation,

freely

And Maintenance of High Voltage Air • Make sure interrupters are operating

freely

Disconnection and Load Interrupter

Control Pipes & Handles

Step 3 — Check Switching Sequence

Switches.

Step 1 — Check Mounting Hardware

Inspection:

• Refer to Section 7 for details on switch

• Check and tighten all thru-bolts, lag

cycling

Insulators

screws and mounting hardware ac• Inspect the switch for proper operating

Step 1 — Inspect Insulators

cording to your company’s practices

sequence

Step 2 — Inspect Control Components

• Check all insulators for cracks, breaks

Step 4 — Inspect Switch Components

or burns

• Inspect all pins, rivets and bolted

• Inspect for eroded fault making conPower Conductors

connections for damaged or worn-out

tacts

parts

Step 1 — Inspect Conductors

• Inspect for alignment and corrosion of • Lubricate as needed all control com• Be sure all conductors are routed

the “live parts”

ponents with Hubbell silicone spray or

so they do not interfere with switch

•

Lubricate

all

contacts

with

Dow

equivalent

operation

Corning FS-1292 silicone grease or

• Inspect all conductors to be sure terReplacement:

equivalent

minations are tight and corrosion free

Parts & Parts Kits

• Inspect for erosion of the exposed

• Clean, retighten and apply contact

metal in the “V” of the deflector. ReTo repair damaged switches, Hubsealing paste as needed (Hubbell or

place if exposed metal is eroded down bell makes available replacement

equivalent)

to the plastic surround material.

parts and part kits. These are availSwitch

Step 5 — Inspect Moving Parts

able for individual components and

Step 1 — Check Mounting Hardware

sub-assemblies of the switch, and

• Inspect all interphase and moving

• Check and tighten all thru-bolts and

the controls. To secure replacement

parts for damaged or worn-out commounting hardware according to your

parts or part kits, contact your facponents

company’s practices

tory representative. Have the model

• Lubricate as needed all control com• Inspect all pins, rivets and bolted

ponents with Hubbell silicone spray or number, configuration and control

connections for damaged or worn-out

type information to assure securing

equivalent

parts

the correct part(s) or part kit(s).

Step 2 — Cycle Switch

Step 6 — Inspect Interrupter

• Open and close the switch several

times to clean the contact surfaces

and loosen moving parts

• Interrupters are sealed, non-serviceable units

• Make sure interrupters are operating

DO NOT mix parts or cannibalize

old switches. Use only Hubbell new

replacement parts.

Review Trouble Shooting Procedures — Section 12, Page 22

PSP8182074

Rev. B

21

11 — Trouble Shooting

The following table presents the

most common symptoms, their possible cause(s) and likely corrective

action(s). These do not cover all possible problems. If you are unable to

correct a problem using this trouble

shooting guide, contact your factory

representative

Table 11-1 – Trouble Shooting Guide

Symptom

Possible Cause(s)

Corrective Action(s)

Switch blade(s)

a) Drive lever not overtoggled

a) Adjust control handle for additional

will not fully close

rotation

b) Overtoggle out of adjustment

b) Consult factory representative

c) Interphase out of adjustment

c) Consult factory representative

Switch blade(s)

a) Inadequate rotation/travel in control handle

a) Adjust control handle for additional rotation

will not fully open

Switch blade(s)

a) Switch blade(s) not full closed

a) See first symptom above

will not pick up

b) Interrupter lever improperly aligned

b) Consult factory representative

a) Swing handle control pipes and a) Adjust alignment of guide brackets,

interrupter lever

Switch is hard to

operate

mechanism binding

b) Corroded or worn control mechanism

suppress arc upon

22

b) Inspect and replace worn parts, and

lubricate as needed,

Interrupter fails to a) Worn or damaged interrupter

switch opening

tighten loose hardware

a) Replace as needed with

factory authorized new parts

b) Improper switch/interrupter sequencing/

b) Consult factory representative

alignment

PSP8182074

Rev. B

PSP8182074

Rev. B

107 IN

2718 MM

32 IN

813 MM

24 IN

610 MM

9

NOTE-3

14

12 11

33 IN

838 MM

13 10

25 IN

635 MM

8.7 IN

221 MM

OPTION "L"

SURGE ARRESTER

BRACKETS

6.5 IN

165 MM

11/16 IN

17 MM DIA

THRU HOLES FOR

MOUNTING BOLTS

(NOTE-3)

8.7 IN

221 MM

DAY OF MFG

POSITIONS 4 THRU 11

----YR

DAY

22 IN

559 MM

OPTION "S" (STEEL)

OPTION "W" (WOOD)

CROSSARM BRACE

36 IN

914 MM

15-1/4 IN

387 MM

29 kV 26 IN

660 MM

17.1 kV 23 IN

584 MM

7

8

NAMEPLATE

15

DESCRIPTION

STEEL

OR

FIBERGLASS

OPTION "P"

EXTRA PIPE

(MOUNTING ARRANGEMENT)

83 IN

2108 MM

WITHOUT

1 NAMEPLATE

DETAIL "B"

STRODE

CHG BY

DATE

DISPOSITION OF MAT'L:

REASON (S) FOR CHANGE:

--

--

--

UPDATE, CLARITY OR NOTICE ONLY

USE STOCK

7

6

8

NOTE-3

DEW

AREAS AFFECTED

BY LATEST EC

Y N

_

S.P.C.

_

F.A.I.

_

TOOL/EQUIP

_

SUPPLIER

_

GAUGES

_

PRCS PROC

_

PKG/LABEL

_

INSP/TEST

RESP ENG

X

X

X

X

X

X

X

X

CONFIDENTIAL: THIS DRAWING AND ITS

CONTENTS ARE CONFIDENTIAL AND THE

EXCLUSIVE PROPERTY OF HUBBELL

POWER SYSTEMS. NO PUBLICATION,

DISTRIBUTION OR COPIES MAY BE MADE

WITHOUT THE WRITTEN CONSENT OF

HUBBELL POWER SYSTEMS.

HUBBELL POWER SYSTEMS UNPUBLISHED

ALL RIGHTS RESERVED UNDER THE

COPYRIGHT LAWS.

.X ± .060 FRAC ±1/16 ANGLES ±2°

.XX ± .030 ADD DRAFT (UNLESS NOTED)

.XXX ± .005 CASTING 3° FORGINGS 7°

CHANCE

1

TOLERANCE CHART

DETAIL "B"

5

2-1/4 IN

57 MM

HUBBELL

POWER SYSTEMS, INC

PSSAAR15

DRN BY

DWG NO.

D

DO NOT SCALE

THIS DRAWING

3

4

1

DATE

08-29-05

PSSAAR15

CAT / PART / ASSY NO.

ROBERTS

SHEET

2

1 OF 2

HUBBELL POWER SYSTEMS

DRAWING,

SWITCH CONTROL

SIZE

TITLE

CLOSED

OPEN

11 12

13 14

NOTE-6

NOTE-7

WITH NAMEPLATE

DETAIL "B"

90°

2

90°

1

NOTE-4

SECTION "A-A"

NOTE-5

"A"

"A"

3

1 P818-2002 GUIDE

2

2 E818-2007 HANDLE, ASSEMBLY

1

3 091697

STRAP, GROUND ASSEMBLY 1

4 P816-0122 PIPE

3

5 E818-2008 GUIDE, ASSEMBLY

2

6 P816-0006 COUPLING

2

7 P001-1907 BOLT, RIBBED NECK, RD HD 7

8 P001-1570 LOCKNUT, 3/8" HEX

7

S

9 P816-0721 BAND, POLE

2

AND 10 E816-0752 BOLT, J-HOOK ASSEMBLY 2

11 055635

NUT, 1/2" HEX

2

F 12 055869 BOLT, 1/2" X 1-1/2" HEX 2

13 055548

WASHER, 1/2" FLAT

3

14 055371

WASHER, 1/2" LOCK

2

15 P818-2041 COUPLING

1

S 16 E818-2042 CONTROL, STEEL UNIVERSAL 1

F 17 E818-2043 CONTROL, FIB UNIVERSAL 1

18 E818-1606 LEVER, ASSEMBLY

1

19 400177

CARR BOLT, 3/8" X 10" 2

20 P001-0749 NUT, FLANGED 3/8"

2

2

H 21 055584 WASHER, 3/8" FLAT

22 P001-1560 PIN

2

23 PSZ0012039 COTTER PIN

2

24 P818-1600 ROD, HORIZONTAL

1

25 P816-0721 BAND, POLE

2

26 E816-0752 BOLT, J-HOOK ASSEMBLY 2

27 055635

NUT, 1/2" HEX

1

28 055869

BOLT, 1/2" X 1-1/2" HEX 1

29 055548

WASHER, 1/2" FLAT

2

30 055371

WASHER, 1/2" LOCK

1

31 PSP8181661 BRACKET

1

32 P001-1969 BOLT, 3/8" X 4-1/2"

1

33 P001-1424 FLANGED LOCKNUT, 3/8" HEX 1

34 P001-1607 NUT, 3/8" ACORN

1

35 P818-1644 ROLLER

3

36 PSP8181659 SPACER

2

37 PSP8181660 SPACER

1

QUAN

POSITION 3 CONTROL

ITEM PART NUMBER DESCRIPTION

98 IN

4

2489 MM

W/INSULATOR

5

DETAIL "B"

(TYPICAL MOUNTING)

OPTION "C"

CONTROL INSULATOR

(REPLACES COUPLING)

4

83 IN

2108 MM

10/19/06

5

PSZ0012039, COTTER PIN ITEM 23, WAS 055902

DESC OF DWG:

EC #

19944

1. READ INSTALLATION INSTRUCTIONS FURNISHED WITH EACH SWITCH.

2. CONTROL SHOWN WITH SWITCH IN CLOSED POSITION.

3. MOUNTING BOLTS AND LAG SCREWS SUPPLIED BY USER.

4. GROUND CLAMP FOR #4 TO 4/0 CU. SUPPLIED WITH GROUND STRAP.

5. CONTROL MAY BE 90° EITHER WAY AROUND POLE FROM SWITCH MOUNTING.

6. LOCATION DETERMINED BY USER.

7. OPERATING SHAFT MAY BE CUT OFF TO SHORTER LENGTHS AS DESIRED.

8. DEADENDS STANDARD, EXTENSION LINKS ARE REQUIRED WHEN DEADENDING

TO THIS SWITCH, MIN LENGTH 14 IN (356 MM).

9. REFER TO SHEET TWO FOR HOOKSTICK APPLICATION AND OPTION ITEMS.

10. IF CROSSARM BRACE IS USED, DRILL HOLE IN POLE AT DIMENSION

SHOWN.

-INSTALLATION NOTES-

NOTE: 28 FT/8.5 M OF PIPE SUPPLIED

AS STANDARD WITH "S" OR "F" CONTROL.

FOR ADDITIONAL PIPE SEE OPTION P

QTY

B1 E818-1621 KIT, SENSOR MOUNTING 1

C1 E801-3397 INSULATOR, CONTROL

1

H1 P815-0025 BOLT, 1/2" CAPTIVE

12

H2 055634 NUT, 1/2" HEX

12

H3 058883 WASHER, 1/2" FLAT

12

L1 P801-3468 BRACKET, SA

3

L2 P816-0658 BOLT, MOUNTING

3

L3 055548 WASHER, 1/2" FLAT

6

L4 055371 WASHER, 1/2" SPRING LOCK 12

L5 055635 NUT, 1/2" HEX

12

L6 055545 BOLT, 1/2" X 2" HEX

6

P1 P816-0122 PIPE

1

P2 E818-2008 GUIDE, ASSEMBLY

1

P3 P816-0006 COUPLING

1

P4 P001-1907 BOLT, RIBBED NECK, RD HD 2

P5 P001-1570 NUT, 3/8" LOCK

2

S1 8705 BOLT, 1/2" X 5" W/SQ NUT 1

S2 055548 WASHER, 1/2" FLAT

2

S3 055371 WASHER, 1/2" SPRING LOCK 1

S4 P816-0175 BRACE, CROSSARM STEEL 1

T1 ATC1343 TERMINAL

6

W1 8705 BOLT, 1/2" X 5" W/SQ NUT 1

W2 055548 WASHER, 1/2" FLAT

2

W3 055371 WASHER, 1/2" SPRING LOCK 1

W4 P816-0194 BRACE, CROSSARM WOOD 1

X1 C207-0112 LINKS, EXTENSION

6

G1 SWL-025-B TERMINAL, BRZ BOLTED CABLE 6

G2 P815-0025 BOLT, 1/2" CAPTIVE

12

G3 055634 NUT, 1/2" HEX

12

G4 058883 WASHER, 1/2" FLAT

12

ITEM PART N0

OPTIONS "C" & "P" DO NOT APPLY WITH HOOKSTICK CONTROLS

G-TERMINAL CONNECTORS

X-EXTENSION LINKS

W-WOOD CROSSARM BRACE

T-TERMINAL CONNECTORS

S-STEEL CROSSARM BRACE

P-EXTRA PIPE

L-SURGE ARRESTER

BRACKETS

H-CAPTIVE HDWR

B -SENSOR BRKTS

C-CONTROL INSUL

POSITIONS 4 THRU 11 OPTIONS

CONTROL "S" AND "F" SHOWN

16

17

91 IN

2311 MM

14.00

356 MM

SWITCH MOUNTING

CROSSARM & INTERPHASE SHAFT

S - STEEL

F - FIBERGLASS

POSITION 2

SEE OPTION TABLE

CONTROLS

S - CONTROL WITH STEEL UNIVERSAL TOP

SECTION (AS SHOWN ON SHEET 01)

F - CONTROL WITH FIBERGLASS UNIVERSAL

TOP SECTION (AS SHOWN ON SHEET 01)

H - HOOKSTICK OPERATED CONTROL REPLACING

"S" AND "F" (AS SHOWN ON SHEET 02)

POSITION 3

OPTION "B"

SENSOR BRACKETS

INSULATION

1 - 110KV PORCELAIN (17.1KV)

3 - 110KV POLYMER (17.1KV)

4 - 150KV POLYMER (29KV)

6 - 150KV POLYMER (38KV GRD-WYE)

7 - 150KV POLYMER LONG LEAK (38KV GRD-WYE)

POSITION 1

INVERTED

CLOCKWISE

AR15___________

CATALOG NUMBER

REV

D

1:8

12 — Control Drawing Sample

Figure 12-1 – Sample Control Drawing

23

©

24

2010 Hubbell Incorporated, 210 North Allen Street, Centralia, MO 65240

1:4

B1

SENSOR BRACKETS

OPTION "B"

18 1/4"

463.6 MM

INSULATOR

7/8 DIA

22.2 MM

2 1/8"

53.9 MM

23 22 21

2 1/8"

53.9 MM

9/16 DIA

76.2 MM

(4-HOLES)

ON 3" B.C.

24

18

36

L4

L5

L6

L1

L2

19 20

CONTROL "H"

HOOKSTICK OPERATED

37

31

23 22 21

P4

P5

P3

OPTION "P"

P1

SURGE ARRESTER

BRACKETS

OPTION "C"

L3 L4 L5

EXTENSION LINKS

14IN/356MM

(TYPICAL 6-PLACES)

OPTION "X"

DATE

DISPOSITION OF MAT'L:

REASON (S) FOR CHANGE:

--

--

--

T1

OPTION "T"

P2

CHG BY

STRODE

AREAS AFFECTED

BY LATEST EC

Y N

_

S.P.C.

_

F.A.I.

_

TOOL/EQUIP

_

SUPPLIER

_

GAUGES

_

PRCS PROC

_

PKG/LABEL

_

INSP/TEST

RESP ENG

DEW

X

X

X

X

X

X

X

X

TERMINAL CONNECTOR

(PARALLEL GROOVE TERMINAL

ASSEMBLY FOR #2-500 KCMIL)

(TYPICAL 6 TERMINAL PADS)

UPDATE, CLARITY OR NOTICE ONLY

USE STOCK

10/19/06

UPDATED DRAWING FORMAT

DESC OF DWG:

EC #

19944

X1

CONTROL INSULATOR

(NOT AVAILABLE WITH

HOOKSTICK OPERATED CONTROL)

C1

ADDITIONAL 7 FT/2134 MM OF CONTROL

PIPE, COUPLING, GUIDE ASSEMBLY AND HARDWARE

(NOT AVAILABLE WITH HOOKSTICK OPERATED CONTROL)

OPTION "L"

19 20

26 29

27 28 30

OPTION "S"

OPTION "H"

G2 G3 G4

CHANCE

CONFIDENTIAL: THIS DRAWING AND ITS

CONTENTS ARE CONFIDENTIAL AND THE

EXCLUSIVE PROPERTY OF HUBBELL

POWER SYSTEMS. NO PUBLICATION,

DISTRIBUTION OR COPIES MAY BE MADE

WITHOUT THE WRITTEN CONSENT OF

HUBBELL POWER SYSTEMS.

HUBBELL POWER SYSTEMS UNPUBLISHED

ALL RIGHTS RESERVED UNDER THE

COPYRIGHT LAWS.

.X ± .060 FRAC ±1/16 ANGLES ±2°

.XX ± .030 ADD DRAFT (UNLESS NOTED)

.XXX ± .005 CASTING 3° FORGINGS 7°

TOLERANCE CHART

PSSAAR15

DRN BY

DWG NO.

D

DO NOT SCALE

THIS DRAWING

DATE

08-29-05

PSSAAR15

CAT / PART / ASSY NO.

ROBERTS

G1

SHEET

S1

2 OF 2

D

REV

W2

W1

S2

HUBBELL POWER SYSTEMS

DRAWING,

SWITCH CONTROL

SIZE

TITLE

POWER SYSTEMS, INC

HUBBELL

TERMINAL CONNECTOR

(BRONZE STRAIGHT BOLT TERMINAL

CABLE TO FLAT TYPE SWL)

OPTION "G"

H1 H2 H3

WOOD CROSSARM BRACE

(ONLY ONE SUPPLIED)

W3

S3

OPTION "W"

STEEL CROSSARM BRACE

(ONLY ONE SUPPLIED)

CAPTIVE HARDWARE

(TYPICAL 6 TERMINAL PADS)

W4

S4

POWER SYSTEMS, INC.

SWITCH BASE

(TYPICAL BOTH ENDS)

35 34 33 32

WASHER ASSEMBLED

BETWEEN PARTS

25

NOTE-3

®

PSP8182074

Rev. B