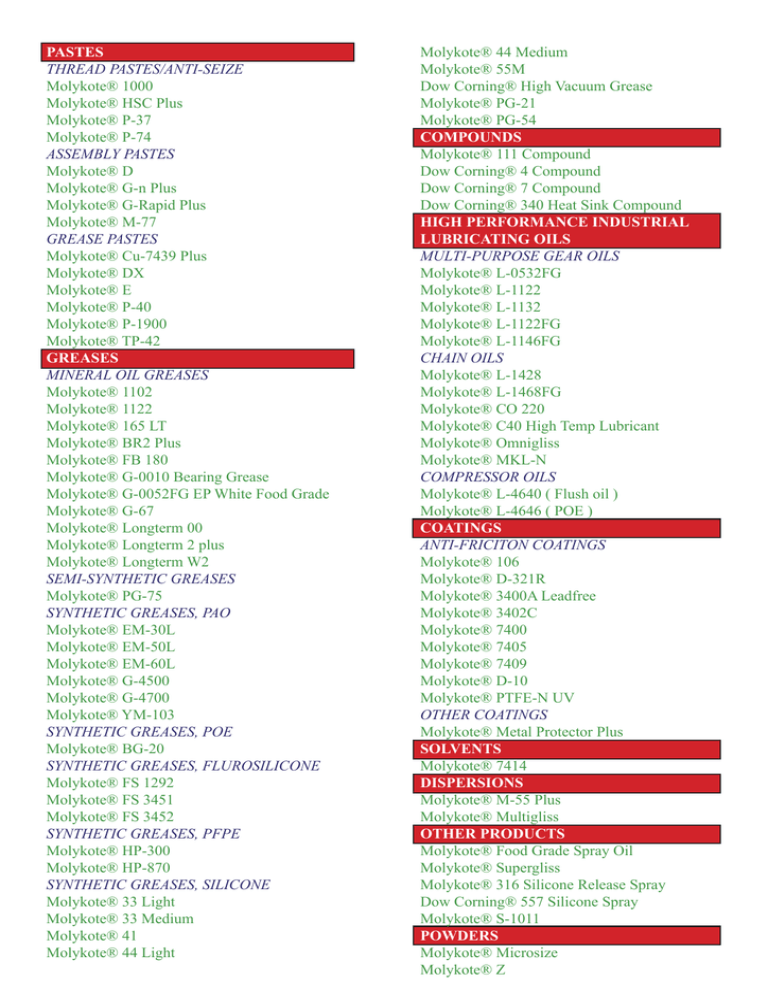

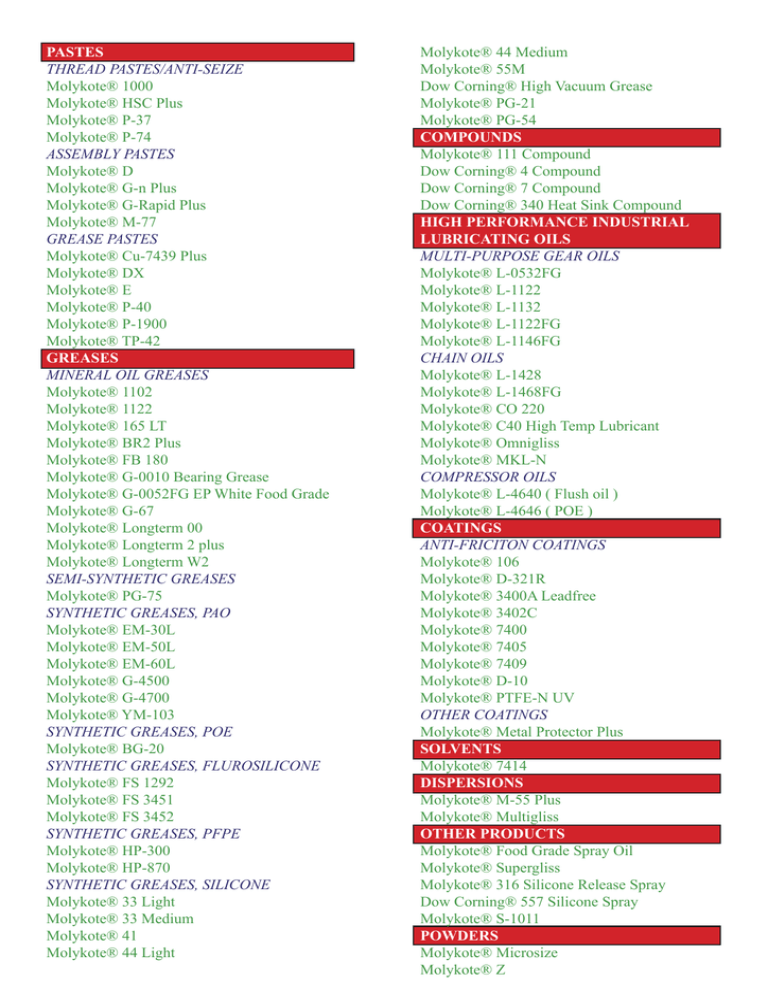

PASTES

THREAD PASTES/ANTI-SEIZE

Molykote® 1000

Molykote® HSC Plus

Molykote® P-37

Molykote® P-74

ASSEMBLY PASTES

Molykote® D

Molykote® G-n Plus

Molykote® G-Rapid Plus

Molykote® M-77

GREASE PASTES

Molykote® Cu-7439 Plus

Molykote® DX

Molykote® E

Molykote® P-40

Molykote® P-1900

Molykote® TP-42

GREASES

MINERAL OIL GREASES

Molykote® 1102

Molykote® 1122

Molykote® 165 LT

Molykote® BR2 Plus

Molykote® FB 180

Molykote® G-0010 Bearing Grease

Molykote® G-0052FG EP White Food Grade

Molykote® G-67

Molykote® Longterm 00

Molykote® Longterm 2 plus

Molykote® Longterm W2

SEMI-SYNTHETIC GREASES

Molykote® PG-75

SYNTHETIC GREASES, PAO

Molykote® EM-30L

Molykote® EM-50L

Molykote® EM-60L

Molykote® G-4500

Molykote® G-4700

Molykote® YM-103

SYNTHETIC GREASES, POE

Molykote® BG-20

SYNTHETIC GREASES, FLUROSILICONE

Molykote® FS 1292

Molykote® FS 3451

Molykote® FS 3452

SYNTHETIC GREASES, PFPE

Molykote® HP-300

Molykote® HP-870

SYNTHETIC GREASES, SILICONE

Molykote® 33 Light

Molykote® 33 Medium

Molykote® 41

Molykote® 44 Light

Molykote® 44 Medium

Molykote® 55M

Dow Corning® High Vacuum Grease

Molykote® PG-21

Molykote® PG-54

COMPOUNDS

Molykote® 111 Compound

Dow Corning® 4 Compound

Dow Corning® 7 Compound

Dow Corning® 340 Heat Sink Compound

HIGH PERFORMANCE INDUSTRIAL

LUBRICATING OILS

MULTI-PURPOSE GEAR OILS

Molykote® L-0532FG

Molykote® L-1122

Molykote® L-1132

Molykote® L-1122FG

Molykote® L-1146FG

CHAIN OILS

Molykote® L-1428

Molykote® L-1468FG

Molykote® CO 220

Molykote® C40 High Temp Lubricant

Molykote® Omnigliss

Molykote® MKL-N

COMPRESSOR OILS

Molykote® L-4640 ( Flush oil )

Molykote® L-4646 ( POE )

COATINGS

ANTI-FRICITON COATINGS

Molykote® 106

Molykote® D-321R

Molykote® 3400A Leadfree

Molykote® 3402C

Molykote® 7400

Molykote® 7405

Molykote® 7409

Molykote® D-10

Molykote® PTFE-N UV

OTHER COATINGS

Molykote® Metal Protector Plus

SOLVENTS

Molykote® 7414

DISPERSIONS

Molykote® M-55 Plus

Molykote® Multigliss

OTHER PRODUCTS

Molykote® Food Grade Spray Oil

Molykote® Supergliss

Molykote® 316 Silicone Release Spray

Dow Corning® 557 Silicone Spray

Molykote® S-1011

POWDERS

Molykote® Microsize

Molykote® Z

Product Information

Specialty

Lubricants MOLYKOTE® Omnigliss Spray

Quick-action penetrating agent

• Good penetration

Quick-action penetrating agent incorporating corrosion

protection, water-repellent and lubricating properties

• Water repellent

APPLICATIONS

FEATURES

• High pressure resistance

• Temporary corrosion protection

COMPOSITION

•

•

•

•

Mineral oil

Solid lubricants

Corrosion inhibitors

Stabilizer

• Suitable for frictional contacts, running at low to medium speeds, which are

not equipped with grease nipples or oiling holes.

• Used on joints, levers, chains and other components of transport and conveyor

equipment, textile machinery, automatic filling units and all types of packaging

equipment.

TYPICAL PROPERTIES

Specification writers: These values are not intended for use in preparing specifications.

Please contact your local Dow Corning sales representative prior to writing specifications

on this product.

Standard

Test

Unit

Color

Result

Light amber

Density

Density at 20°C

Viscosity at 40°C

g/ml

mm²/s

0.84

11.8

°C

-30 to +80

Temperature

Service temperature

Load-carrying capacity, wear protection, service life

Four-ball tester (VKA)

DIN 51 350 pt.4 Weld load

Weld scar under 800N load

HOW TO USE

How to apply

Shake before use. Can be applied with

brush, oil can, spray-can, hand-held or

compressed-air spraying equipment,

or by dipping. On badly corroded

parts, allow longer to react. Repeat if

necessary.

HANDLING PRECAUTIONS

PRODUCT SAFETY

INFORMATION REQUIRED FOR

SAFE USE IS NOT INCLUDED.

BEFORE HANDLING, READ

PRODUCT AND SAFETY DATA

SHEETS AND CONTAINER

LABELS FOR SAFE USE,

PHYSICAL AND HEALTH

HAZARD INFORMATION. THE

N

mm

2900

1.1

SAFETY DATA SHEET IS

AVAILABLE FROM YOUR LOCAL

DOW CORNING SALES

REPRESENTATIVE.

USABLE LIFE AND

STORAGE

When stored at or below 20°C in the

original unopened containers, this

product has a usable life of 60 months

from the date of production.

PACKAGING

This product is available in different

standard container sizes. Detailed

container size information should be

obtained from your nearest

Dow Corning sales office or

Dow Corning distributor.

LIMITATIONS

This product is neither tested nor

represented as suitable for medical or

pharmaceutical uses.

HEALTH AND

ENVIRONMENTAL

INFORMATION

To support customers in their product

safety needs, Dow Corning has an

extensive Product Stewardship

organization and a team of Health,

Environment and Regulatory Affairs

specialists available in each area.

For further information, please

consult your local Dow Corning

representative.

WARRANTY

INFORMATION - PLEASE

READ CAREFULLY

The information contained herein is

offered in good faith and is believed

to be accurate. However, because

conditions and methods of use of our

products are beyond our control, this

information should not be used in

substitution for customer's tests to

ensure that Dow Corning's products

are safe, effective, and fully

satisfactory for the intended end use.

Dow Corning's sole warranty is that

the product will meet the

Dow Corning sales specifications in

effect at the time of shipment. Your

exclusive remedy for breach of such

warranty is limited to refund of

purchase price or replacement of any

product shown to be other than as

warranted. Dow Corning specifically

disclaims any other express or implied

warranty of fitness for a particular

purpose or merchantability. Unless

Dow Corning provides you with a

specific, duly signed endorsement of

fitness for use, Dow Corning

disclaims liability for any incidental

or consequential damages.

Suggestions of use shall not be taken

as inducements to infringe any patent.

2

05/01/1998

Ref. no. 71-0173A-01

DC 3630

® MOLYKOTE is a registered trademark of Dow Corning Corporation.

©1997-2001 Dow Corning Corporation. All rights reserved.

Product Information

Specialty

Lubricants MOLYKOTE® 106

Anti-friction Coating

FEATURES

Heat-curing dry lubricant

• Low coefficient of friction

• High load carrying capacity

• Protection from corrosion

• Good adhesion

• Can be painted over

COMPOSITION

• Solid lubricants

• Organic binder

• Solvent

APPLICATIONS

• For smooth coating of metal/metal combinations.

• Maintenance-free, permanent lubrication of highly stressed friction

combinations with low speeds or oscillating operation.

• Used where design construction prevents the use of oil or grease or where the

risk of soiling is undesirable.

• This product is used successfully for the dry lubrication of locks, hinges, joints,

magnetic armatures and for the anti-seizure coating of engine and gear

components.

TYPICAL PROPERTIES

Specification writers: These values are not intended for use in preparing specifications.

Please contact your local Dow Corning sales representative prior to writing specifications

on this product.

Standard*

Test

Unit

Color

Result

Dark grey

Physical properties

DIN 53211/3

DIN 53217/2

CTM 0242 I

Viscosity at 20°C (DIN3 cup)

Density at 20°C

Non-volatile content

s

g/ml

%

42

1.16

41

Temperature

Curing time

Curing time

Service temperature range

minutes/°C 60/150

minutes/°C 30/180

°C

-70 to +250

Load-carrying capacity, wear protection, service life

ASTM-D2625

Falex load-carrying capacity¹

ASTM-D2714

LFW-1, rotating¹

F=2860N, n=72 minutesª¹,

v=7.9m/minutes

no. of revolutions x1000 to μ=0.1

LFW-1, oscillating¹

F=900N, frequency=89.5osc./minutes

no. of oscillations to μ=0.08

ASTM-D2714

N

p=13600*

s=11300*

p=187*

p=409*

Corrosion protection

ISO/R 1456

Salt spray test

h

1. * Surface:p = phosphatized, s = sand-blasted.

* CTM: Corporate Test Method, copies of CTMs are available on request.

ASTM: American Society for Testing and Materials.

DIN: Deutsche Industrie Norm

2

LIMITATIONS

HOW TO USE

Surface preparation

First clean and degrease the surface

which will be coated with

MOLYKOTE 106 Anti-Friction

Coating. Phosphatization or

sandblasting (180 grid) increases the

adhesion and service life.

How to apply

Stir the Anti-friction Coating

thoroughly before applying by

spraying, dipping, centrifuging or

brushing. Recommended dry film

thickness: 5 to 20μm.

Curing

60 minutes at 150°C,

30 minutes at 180°C

(Object temperature).

Solubility

Thinning can be carried out using

MOLYKOTE® L 13 Thinner.

HANDLING PRECAUTIONS

PRODUCT SAFETY

INFORMATION REQUIRED FOR

SAFE USE IS NOT INCLUDED.

BEFORE HANDLING, READ

PRODUCT AND SAFETY DATA

SHEETS AND CONTAINER

LABELS FOR SAFE USE,

PHYSICAL AND HEALTH

HAZARD INFORMATION. THE

SAFETY DATA SHEET IS

AVAILABLE FROM YOUR LOCAL

DOW CORNING SALES

REPRESENTATIVE.

USABLE LIFE AND

STORAGE

When stored at or below 20°C in the

original unopened containers,

MOLYKOTE 106 Anti-Friction

Coating has a usable life of 36 months

from the date of production.

PACKAGING

This product is neither tested nor

represented as suitable for medical or

pharmaceutical uses.

HEALTH AND

ENVIRONMENTAL

INFORMATION

To support customers in their product

safety needs, Dow Corning has an

extensive Product Stewardship

organization and a team of Health,

Environment and Regulatory Affairs

specialists available in each area.

For further information, please

consult your local Dow Corning

representative.

WARRANTY

INFORMATION - PLEASE

READ CAREFULLY

The information contained herein is

offered in good faith and is believed

to be accurate. However, because

conditions and methods of use of our

products are beyond our control, this

information should not be used in

substitution for customer's tests to

ensure that Dow Corning's products

are safe, effective, and fully

satisfactory for the intended end use.

Dow Corning's sole warranty is that

the product will meet the

Dow Corning sales specifications in

effect at the time of shipment. Your

exclusive remedy for breach of such

warranty is limited to refund of

purchase price or replacement of any

product shown to be other than as

warranted. Dow Corning specifically

disclaims any other express or implied

warranty of fitness for a particular

purpose or merchantability. Unless

Dow Corning provides you with a

specific, duly signed endorsement of

fitness for use, Dow Corning

disclaims liability for any incidental

or consequential damages.

Suggestions of use shall not be taken

as inducements to infringe any patent.

This product is available in different

standard container sizes. Detailed

container size information should be

obtained from your nearest

Dow Corning sales office or

Dow Corning distributor.

2

19/11/1998

Ref. no. 71-0154B-01

DC 2935

® MOLYKOTE is a registered trademark of Dow Corning Corporation.

©1997-2001 Dow Corning Corporation. All rights reserved.

Product Information

Specialty

Lubricants MOLYKOTE® 1102

Grease

FEATURES

• Highly resistant to water

• No drop point therefore no melting

or leakage from lubrication points

COMPOSITION

• Mineral oil

• Inorganic thickener

• Solid lubricants

For gas taps and cocks with metal, glass and plastic

combinations

APPLICATIONS

• Used successfully with natural gas stop-cocks of main and secondary lines in

domestic equipment, instantaneous water heaters and similar equipment.

• Lubrication of smaller taps made of metal, glass or plastic.

TYPICAL PROPERTIES

Specification writers: These values are not intended for use in preparing specifications.

Please contact your local Dow Corning sales representative prior to writing specifications

on this product.

Standard*

Unit

Test

Color

Result

Black

Consistency, density, viscosity

DIN 51 818

ISO 2137

ISO 2811

DIN 51 562

DIN 51 562

Consistency class, NLGI¹

Worked penetration

Density at 20°C

Base oil viscosity at 40°C

Base oil viscosity at 100°C

mm/10

g/ml

mm²/s

mm²/s

ca. 3

205-240

0.96

900

42

Temperature

ISO 2176

Service temperature range

°C

Drop point

°C

0 to +160

short term +220

None

Loading capacity, protection against wear

Four-ball tester

DIN 51 350 T.4 Weld load

DIN 51 350 pt.5 Wear scar under 800N load

Almen-Wieland machine

OK load

Frictional force with OK load

N

mm

2100

0.85

N

N

14500

1300

Resistance

DIN 51 807 T.1 Water resistance, static evaluation step

DIN 51 808

Oxidation resistance, pressure drop 100h, bar

99°C

0-90

1.3

Oil separation

DIN 51 817

Standard test

%

0.0

1. National Lubricating Grease Institute.

* ISO: International Standardisation Organisation

DIN: Deutsche Industrie Norm

HOW TO USE

How to apply

Clean the contact areas. As is usual

with lubricating greases, apply by

means of a brush, spatula, grease-gun

or automatic lubrication device. Can

be used in central lubrication systems.

If plastics or elastomers are present,

compatibility tests for swelling and

shrinkage, stress-crack formation,

changes in strength and hardness,

should be carried out because of the

difference in their qualities.

HANDLING PRECAUTIONS

PRODUCT SAFETY

INFORMATION REQUIRED FOR

SAFE USE IS NOT INCLUDED.

BEFORE HANDLING, READ

PRODUCT AND SAFETY DATA

SHEETS AND CONTAINER

LABELS FOR SAFE USE,

PHYSICAL AND HEALTH

HAZARD INFORMATION. THE

SAFETY DATA SHEET IS

AVAILABLE FROM YOUR LOCAL

DOW CORNING SALES

REPRESENTATIVE.

USABLE LIFE AND

STORAGE

When stored at or below 20°C in the

original unopened containers, this

product has a usable life of 60 months

from the date of production.

PACKAGING

This product is available in different

standard container sizes. Detailed

container size information should be

obtained from your nearest

Dow Corning sales office or

Dow Corning distributor.

WARRANTY

INFORMATION - PLEASE

READ CAREFULLY

The information contained herein is

offered in good faith and is believed

to be accurate. However, because

conditions and methods of use of our

products are beyond our control, this

information should not be used in

substitution for customer's tests to

ensure that Dow Corning's products

are safe, effective, and fully

satisfactory for the intended end use.

Dow Corning's sole warranty is that

the product will meet the

Dow Corning sales specifications in

effect at the time of shipment. Your

exclusive remedy for breach of such

warranty is limited to refund of

purchase price or replacement of any

product shown to be other than as

warranted. Dow Corning specifically

disclaims any other express or implied

warranty of fitness for a particular

purpose or merchantability. Unless

Dow Corning provides you with a

specific, duly signed endorsement of

fitness for use, Dow Corning

disclaims liability for any incidental

or consequential damages.

Suggestions of use shall not be taken

as inducements to infringe any patent.

LIMITATIONS

This product is neither tested nor

represented as suitable for medical or

pharmaceutical uses.

HEALTH AND

ENVIRONMENTAL

INFORMATION

To support customers in their product

safety needs, Dow Corning has an

extensive Product Stewardship

organization and a team of Health,

Environment and Regulatory Affairs

specialists available in each area.

For further information, please

consult your local Dow Corning

representative.

2

23/11/1998

Ref. no. 71-0146B-01

DC 2941

® MOLYKOTE is a registered trademark of Dow Corning Corporation.

©1997-2001 Dow Corning Corporation. All rights reserved.

c

d

Product Information

Specialty

Lubricants

FEATURES

" Particularly suitable for long-term

lubrication by virtue of its extremely low

tendency towards oxidation

" High drop point >250ºC (482ºF);

consequently reduced risk of melting and

run-out from lubrication point

" Wide service temperature range,

-40ºC to +200ºC (-40ºF to +392ºF);

for short periods, up to 230ºC (446ºF)

" High resistance to water and water

washout

" Resistant to mineral oil, fuels and many

chemicals

COMPOSITION

" Fluorosilicone oil

" Organic thickener

MOLYKOTE® FS 1292

Fluoro-Silicone Grease

APPLICATION

" Lubricating grease for metal/metal combinations with slow to medium-fast

movements and medium loads over a wide temperature range.

TYPICAL PROPERTIES

Specification writers: These values are not intended for use in preparing specifications.

Please contact your local Dow Corning sales representative prior to writing specifications on

this product.

Standard*

Test

Unit

Color

Result

Whitish

Consistency, density, viscosity

DIN 51 818

NLGI consistency class

1-2

ISO 2137

Worked penetration

mm/10

280-340

ISO 2811

Density at 20ºC (68ºF)

g/ml

1.28

DIN 51 562

Base oil viscosity at 25ºC (77ºF)

mm /s

1000

ºC

-40 to +200 (+230

for short periods)

ºF

-40 to +392 (+446

for short periods)

2

Temperature

Service temperature

ISO 2176

Drop point

ºC

>250

ºF

>482

Initial break-away torque

Nm

118x10-3

Torque after 20 minutes running time

Nm

41x10-3

Initial break-away torque

Nm

856x10-3

Torque after 20 minutes running time

Nm

56x10-3

N

3400

%

0.3

ASTM-D147880 Low temperature torque test

at -30ºC (-22ºF)

ASTM-D147880 Low temperature torque test

at -40ºC (-40ºF)

Load-carrying capacity

Four-ball tester (VKA)

DIN 51 350 pt.4 Weld load

Oil separation

DIN 51 817

Standard test

* ASTM: American Society for Testing and Materials.

ISO: International Standardisation Organisation.

DIN: Deutsche Industrie Norm.

HOW TO USE

How to apply

Clean bearing surfaces. Apply grease

in the normal way using a brush, grease

gun or automatic lubricating system.

MOLYKOTE FS 1292 Grease can be

used in centralised lubrication systems.

Do not mix with other greases.

HANDLING PRECAUTIONS

Product safety information required for

safe use is not included. Before

handling, read product and safety data

sheets and container labels for safe use,

physical and health hazard information.

The material safety data sheet is

available on the Dow Corning website

at www.dowcorning.com. You can also

obtain a copy from your local

Dow Corning sales representative or

Distributor or by calling your local

Dow Corning Global Connection.

USABLE LIFE AND

STORAGE

LIMITED WARRANTY

INFORMATION - PLEASE

READ CAREFULLY

The information contained herein is

offered in good faith and is believed to

be accurate. However, because

conditions and methods of use of our

products are beyond our control, this

information should not be used in

substitution for customer's tests to

ensure that Dow Corning's products are

safe, effective, and fully satisfactory

for the intended end use. Suggestions

of use shall not be taken as

inducements to infringe any patent.

When stored at or below 20ºC (68ºF) in

the original unopened containers, this

product has a usable life of 60 months

from the date of production.

Dow Corning's sole warranty is that the

product will meet the Dow Corning

sales specifications in effect at the time

of shipment.

PACKAGING

Your exclusive remedy for breach of

such warranty is limited to refund of

purchase price or replacement of any

product shown to be other than as

warranted.

This product is available in different

standard container sizes. Detailed

container size information should be

obtained from your nearest

Dow Corning sales office or

Dow Corning distributor.

LIMITATIONS

This product is neither tested nor

represented as suitable for medical or

pharmaceutical uses.

HEALTH AND

ENVIRONMENTAL

INFORMATION

To support Customers in their product

safety needs, Dow Corning has an

extensive Product Stewardship

organization and a team of Product

Safety and Regulatory Compliance

(PS&RC) specialists available in each

area.

DOW CORNING SPECIFICALLY

DISCLAIMS ANY OTHER

EXPRESS OR IMPLIED

WARRANTY OF FITNESS FOR A

PARTICULAR PURPOSE OR

MERCHANTABILITY.

DOW CORNING DISCLAIMS

LIABILITY FOR ANY

INCIDENTAL OR

CONSEQUENTIAL DAMAGES.

WE HELP YOU INVENT THE

FUTURE."

www.dowcorning.com

For further information, please see our

website, www.dowcorning.com or

consult your local Dow Corning

representative.

MOLYKOTE FS 1292 Fluoro-Silicone Grease

WE HELP YOU INVENT THE FUTURE. is a trademark of Dow Corning Corporation.

2

08/02/2002

Ref. no. 71-0165C-01

DC 2991

MOLYKOTE is a registered trademark of Dow Corning Corporation.

©0-2002 Dow Corning Corporation. All rights reserved.

Product Information

Specialty

Lubricants

FEATURES

" Extremely high load-carrying capacity

" Wear protection and reduction of existing

pitting in gear teeth flanks during

operation, due to the solid lubricants

incorporated in the grease. Extremely

adhesive due to build-in adhesion

improver

" Good protection against corrosion

(corrosion index 0 when tested using the

SKF-Emcor method)

" Contains no lead or nickel

COMPOSITION

"

"

"

"

"

"

Mineral oil

Lithium soap

Solid lubricants

Corrosion inhibitor

Adhesion improver

EP additives

MOLYKOTE® 165 LT

Gearwheel grease

c

d

Gearwheel grease for the lubrication of highly stressed open

gears and reducing gears made of metal, with a peripheral speed

of up to 2.5 m/s

APPLICATIONS

" Open gears that are subjected to high stresses and bad weather effects.

" Successfully used in crushing plants and in transmission gears and threaded

spindles of heavy, crank-driven presses.

TYPICAL PROPERTIES

Specification writers: These values are not intended for use in preparing specifications.

Please contact your local Dow Corning sales representative prior to writing specifications on

this product.

Standard*

Test

Unit

Color

Result

Black

Consistency, density, viscosity

ISO 2137

Unworked penetration

mm/10 240-270

ISO 2811

Density at 20ºC (68ºF)

g/ml

0.96

DIN 51 562

Base oil viscosity at 40ºC (104ºF)1

mm2/s

320

Service temperature range

ºC

-25 to +120

ºF

-13 to +248

Drop point

ºC

175

ºF

347

Break-away torque

Nm

880x10-3

Torque after 20 minutes running time

Nm

115x10-3

Temperature

ISO 2176

ASTMD147880 Low temperature torque test at -20ºC (-4ºF)

DIN 51 805

Kesternich method - flow pressure at -20ºC (-4ºF) mbar

1350

Loading capacity, protection against wear, service life

Four-ball tester

DIN 51 350 T.4 Weld load

N

4400

DIN 51 350 T.5 Wear scar under 800N load

mm

1.2

OK load

N

20000

Frictional force with OK load

N

2900

Almen-Wieland machine

Corrosion protection

DIN 51 802

SKF-Emcor method

Degree of corrosion

0

Resistance

DIN 51 807 T.1 Water resistance, static evaluation step

DIN 51 808

Oxidation resistance, pressure drop 100h,

99ºC (210ºF)

2-90

bar

0.2

TYPICAL PROPERTIES (continued)

Standard*

Test

Unit

Result

%

1.2

Oil separation

DIN 51 817

Standard test

1. Calculated viscosity value of base oil mixture.

* ASTM: American Society for Testing and Materials.

ISO: International Standardisation Organisation.

DIN: Deutsche Industrie Norm.

HOW TO USE

How to apply

Carefully clean the metal surfaces and

apply using a spatula or brush.

HANDLING PRECAUTIONS

Product safety information required for

safe use is not included. Before

handling, read product and safety data

sheets and container labels for safe use,

physical and health hazard information.

The material safety data sheet is

available on the Dow Corning website

at www.dowcorning.com. You can also

obtain a copy from your local

Dow Corning sales representative or

Distributor or by calling your local

Dow Corning Global Connection.

USABLE LIFE AND

STORAGE

When stored at or below 20ºC (68ºF) in

the original unopened containers, this

product has a usable life of 60 months

from the date of production.

LIMITED WARRANTY

INFORMATION - PLEASE

READ CAREFULLY

PACKAGING

This product is available in different

standard container sizes. Detailed

container size information should be

obtained from your nearest

Dow Corning sales office or

Dow Corning distributor.

LIMITATIONS

This product is neither tested nor

represented as suitable for medical or

pharmaceutical uses.

HEALTH AND

ENVIRONMENTAL

INFORMATION

To support Customers in their product

safety needs, Dow Corning has an

extensive Product Stewardship

organization and a team of Product

Safety and Regulatory Compliance

(PS&RC) specialists available in each

area.

For further information, please see our

website, www.dowcorning.com or

consult your local Dow Corning

representative.

The information contained herein is

offered in good faith and is believed to

be accurate. However, because

conditions and methods of use of our

products are beyond our control, this

information should not be used in

substitution for customer's tests to

ensure that Dow Corning's products are

safe, effective, and fully satisfactory

for the intended end use. Suggestions

of use shall not be taken as

inducements to infringe any patent.

Dow Corning's sole warranty is that the

product will meet the Dow Corning

sales specifications in effect at the time

of shipment.

Your exclusive remedy for breach of

such warranty is limited to refund of

purchase price or replacement of any

product shown to be other than as

warranted.

DOW CORNING SPECIFICALLY

DISCLAIMS ANY OTHER

EXPRESS OR IMPLIED

WARRANTY OF FITNESS FOR A

PARTICULAR PURPOSE OR

MERCHANTABILITY.

DOW CORNING DISCLAIMS

LIABILITY FOR ANY

INCIDENTAL OR

CONSEQUENTIAL DAMAGES.

WE HELP YOU INVENT THE

FUTURE."

www.dowcorning.com

MOLYKOTE 165 LT Gearwheel grease

WE HELP YOU INVENT THE FUTURE. is a trademark of Dow Corning Corporation.

2

28/01/2002

Ref. no. 71-0179C-01

DC 2939

MOLYKOTE is a registered trademark of Dow Corning Corporation.

©1997-2002 Dow Corning Corporation. All rights reserved.

Product Information

High Performance

®

Lubricants Molykote 33 Extreme

Low Temperature Bearing Grease,

Molykote® 41 Extreme High

Temperature Bearing Grease,

Molykote® 44 High Temperature

Bearing Grease

FEATURES

x

x

x

x

x

Resistance to oxidation, moisture and

corrosive atmospheres

Inertness

Good shear stability

Wide service temperature range:

33 Extreme Low Temperature

Grease: -100 to 400°F (-73 to 204°C)

41 Extreme High Temperature

Grease: 0 to 550°F (-18 to 288°C)

44 High Temperature Grease: -40 to

400°F (-40 to 204°C)

Compatible with many plastics

COMPOSITION

x

x

Lithium soap

Phenylmethyl silicone oil

Lubricants for antifriction bearings and plastic and rubber

parts

USES

All three Molykote® Bearing Grease are used to lubricate ball bearings operating

under light to moderate loads. These can be used for:

Molykote® 33 Extreme Low Temperature Bearing Grease

• Freezer cart casters and cold room conveyor equipment

• Utility disconnect switch contacts

• Plastic electric clock motors

• Maximum-demand meters, power-factor meters, watt-hour meters

• Windshield wiper motor gears

• Photographic, optical and surveying equipment

• Oscillographs, geophysical and light, low-torque instruments

• Starter clutch drives

Molykote® 41 Extreme High Temperature Bearing Grease

• Antifriction bearings of high-temperature equipment

• Oven conveyor bearings

• Wheel bearings of core oven carts

• Governor linkage of steam turbines

• Ball and socket connections of power insulators

Molykote® 44 High Temperature Bearing Grease

• Kiln preheater fans, oven fans, radiator cooling fans

• Textile slashers and driers

• Aircraft engine

• Conveyor systems

These greases do not soften or affect most plastics and are used to lubricate

plastic gears, bearings and cams, as well as metal and rubber parts. Because of

low torque requirements, Molykote® 33 Extreme Low Temperature Bearing

Grease is especially effective in equipment that must start in extreme cold.

Oxidation Resistance – Molykote® Bearing Greases are recommended for use in

units that must remain operable when subjected not only to low and high

operating temperatures, but also to severe weathering and oxidation.

TYPICAL PROPERTIES

Specification Writers: These values are not intended for use in preparing specifications. Please contact your local

Dow Corning sales office or your Global Dow Corning Connection before writing specifications on this product.

Method

DIN 51 562

ASTM D 217

Test

Results

33 Light

33 Medium

41 Grease

44 Light

44 Medium

Color

Off White

Off White

Black

Off White

Off White

Thickner

Lithium Soap

Lithium Soap

Carbon Black

Lithium Soap

Lithium Soap

Base Oil

Silicone

Silicone

Silicone

Silicone

Silicone

Base Oil Viscosity @ 25°C, mm2/s

100

100

316

125

125

Penetration, worked 60 strokes, mm

320

280

280

300

280

NLGI #

1

2

2

~1

2

1200 (122)

1200 (122)

1500 (152)

1100 (113)

1100 (113)

Max Dn Value (Bore Size in mm X rpm)

250,000

200,000

75,000

350,000

300,000

Service Temperature2 Degrees C (F)

-73 to 204

(-100 to 400)

-73 to 204

(-100 to 400)

-18 to 288

(0 to 550)

-40 to 204

(-40 to 400)

-40 to 204

(-40 to 400)

ASTM D 2265

Drop Point Degrees C (F)

226 (439)

226 (439)

>300 (>572)

220 (432)

220 (432)

Fed Std 791

Bleed after 24 hrs @149°C (300°F) %

2

1

4.8 3

2.5

2

DIN 51 817

Oil Separation (Standard Test, 7 days at 40°C) % 3.2

1.6

2.6

2.4

1.4

Specific Gravity @25°C (77°F)

0.97

0.97

1.14

1.05

1.05

Initial Break-away Torque, Nm

130 x 10 -3

164 x 10 -3

Torque after 20 minutes running time, Nm

13 x 10 -3

22 x 10 -3

DIN 51 350 pt4

4 ball weld load, N (kg)

1

ASTM D 1478-80

Low Temperature Torque @ -73°C

Low Temperature Torque @ -40°C

225 x 10 -3

Initial Break-away Torque, Nm

Torque after 20 minutes running time, Nm

DIN 51 808

DIN 51 821-02-A

60 x 10

Oxidation Resistance, pressure drop 100hr,

99°C (210°F) bar (psi)

0.4 (5.80)

FAG Rolling Element Bearing Tester, FE9,

1500/6000-150, F50, Hrs

-3

336 x 10 -3

124 x 10 -3

0

0.1 (1.45)

110

110

1

Maximum Dn values are approximations and will vary widely with temperature, load and bearing type.

Estimated service temperature range based on product formulation and laboratory testing. Actual service temperature range is dependent on other factors including the specific

application environment.

3

Values are at 392°F (200°C).

Specification Writers: Please obtain copies of the Dow Corning Sales Specifications for these products and use them as a basis for your specifications. They may be

obtained from any Dow Corning Sales Office, or from Dow Corning Customer Service in Midland, MI. Call (989) 496-6000.

2

Figure 1. Suggested Product Temperature Range Recommendations

Limitations of Typical Organic Greases

-100°F

-20°F

260°F

450°F

550°F

®

Molykote 33 Extreme Low Temperature Grease

®

Molykote® 33 Extreme Low Temperature Bearing Grease

Molykote® 41 Extreme High Temperature Bearing Grease

Molykote® 44 High Temperature Bearing Grease

Ref. No. 10-814C-01

Molykote 41 Extreme

High Temperature Grease

May 4, 2006,

®

Molykote

DIC164544

44 High Temperature

We help you invent the future is a trademark of Dow Corning Corporation.

Molykote is a registered trademark of Dow Corning Corporation.

Dow Corning is a registered trademark of Dow Corning Corporation.

Grease

2006 Dow Corning Corporation. All rights reserved.

DESCRIPTION

Molykote® 33 Extreme Low

Temperature Bearing Grease,

Molykote® 41 Extreme High

Temperature Bearing Grease and

Molykote® 44 High Temperature

Bearing Grease are silicone lubricating

oils with thickeners added.

Molykote® 33 Extreme Low

Temperature Bearing Grease and

Molykote® 44 High Temperature

Bearing Grease are thickened with a

special lithium soap; Molykote® 41

Extreme High Temperature Bearing

Grease is thickened with carbon black.

Molykote® 33 Extreme Low

Temperature Bearing Grease and

Molykote® 44 High Temperature

Bearing Grease are available in light

and medium consistencies – NLGI #1

and #2. Molykote® 41 Extreme High

Temperature Bearing Grease is

available in a medium consistency –

NLGI #2.

LISTINGS/

SPECIFICATIONS

Molykote® 33 Extreme Low

Temperature Bearing Grease is USDA

listed for use as a lubricant where there

is no possibility of food contact.

combinations, especially where sliding

friction is encountered.

3.6-kg cans, 5-kg pails, 18-kg pails,

25-kg pails, and 180-kg drums.

Molykote® 41 Extreme High

Temperature Bearing Grease –

Bearings operating at extremely high

temperatures need to be frequently

monitored to ensure that the grease has

not dried out. If this occurs, more

grease can be added, or the existing

grease rejuvenated by adding

Dow Corning® 710 Fluid.

HANDLING PRECAUTIONS

These products are neither tested nor

represented as suitable for medical or

pharmaceutical uses.

Product safety information required for

safe use is not included. Before

handling, read product and safety data

sheets and container labels for safe

use, physical and health hazard

information. The material safety data

sheet is available on the Dow Corning

website at www.dowcorning.com. You

can also obtain a copy from your local

Dow Corning sales representative or

Distributor or by calling your local

Dow Corning Global Connection.

HEALTH AND

ENVIRONMENTAL

INFORMATION

SHIPPING LIMITATIONS

None.

USABLE LIFE AND

STORAGE

When stored at or below 90°F (32°C),

Molykote® 33 Extreme Low

Temperature Bearing Grease,

Molykote® 41 Extreme High

Temperature Bearing Grease and

Molykote® 44 High Temperature

Bearing Grease have a shelf life of

60 months from date of manufacture.

Refer to product packaging for “Use

By” date.

To support Customers in their product

safety needs, Dow Corning has an

extensive Product Stewardship

organization and a team of Product

Safety and Regulatory Compliance

(PS&RC) specialists available in each

area.

For further information, please see our

website, www.dowcorning.com or

consult your local Dow Corning

representative.

HOW TO USE

Conventional grease application

methods – brushing, grease gun or

automatic application – are suitable for

use with these Molykote® Bearing

Greases. Laboratory tests and field

reports indicate that “heavy duty” guns

available from such manufacturers as

Lincoln-St. Louis are preferred.

Note: Extra care should be taken at all

times to prevent dirt from

contaminating the lubricant. These

greases should be packed with a clean

metal or ebonite spatula.

LIMITATIONS

These greases should not be applied to

surfaces that are to be painted. These

greases should not be used with highly

loaded ferrous metal bearing

Molykote® 33 Extreme Low Temperature Bearing Grease

Molykote® 41 Extreme High Temperature Bearing Grease

Molykote® 44 High Temperature Bearing Grease

Ref. No. 10-814C-01

PACKAGING

Not all sizes available in all

geographies.

Molykote® 33 Extreme Low

Temperature Bearing Grease is

supplied in 100-g tubes, 150-g tubes,

400-g cartridges, 1-kg cans, 3.6-kg

cans, 18-kg pails, 25-kg pails, 55-kg

drums, and 180 kg drums.

Molykote® 41 Extreme High

Temperature Bearing Grease is

supplied in 100-g tubes, 150-g tubes,

400-g cartridges, 1-kg cans, 3.6-kg

cans, 5-kg pails, 18-kg pails, 25-kg

pails, and 181.4-kg drums.

Molykote® 44 High Temperature

Bearing Grease is supplied in 100-g

tubes, 150-g tubes, 400-g cartridges,

May 4, 2006,

DIC164544

We help you invent the future is a trademark of Dow Corning Corporation.

Molykote is a registered trademark of Dow Corning Corporation.

Dow Corning is a registered trademark of Dow Corning Corporation.

2006 Dow Corning Corporation. All rights reserved.

LIMITED WARRANTY

INFORMATION - PLEASE

READ CAREFULLY

The information contained herein is

offered in good faith and is believed to

be accurate. However, because

conditions and methods of use of our

products are beyond our control, this

information should not be used in

substitution for customer's tests to

ensure that Dow Corning's products

are safe, effective, and fully

satisfactory for the intended end use.

Suggestions of use shall not be taken

as inducements to infringe any patent.

Dow Corning's sole warranty is that

the product will meet the Dow Corning

sales specifications in effect at the time

of shipment.

Your exclusive remedy for breach of

such warranty is limited to refund of

purchase price or replacement of any

product shown to be other than as

warranted.

DOW CORNING SPECIFICALLY

DISCLAIMS ANY OTHER

EXPRESS OR IMPLIED

WARRANTY OF FITNESS FOR A

PARTICULAR PURPOSE OR

MERCHANTABILITY.

DOW CORNING DISCLAIMS

LIABILITY FOR ANY

INCIDENTAL OR

CONSEQUENTIAL DAMAGES.

We help you invent the future.™

www.dowcorning.com

Molykote® 33 Extreme Low Temperature Bearing Grease

Molykote® 41 Extreme High Temperature Bearing Grease

Molykote® 44 High Temperature Bearing Grease

Ref. No. 10-814C-01

May 4, 2006,

DIC164544

We help you invent the future is a trademark of Dow Corning Corporation.

Molykote is a registered trademark of Dow Corning Corporation.

Dow Corning is a registered trademark of Dow Corning Corporation.

2006 Dow Corning Corporation. All rights reserved.

Product Information

Silicon-Based

Compounds Dow Corning ® 340

Heat Sink Compound

FEATURES

• High thermal conductivity

• Low bleed

• Stable at high temperatures

COMPOSITION

• Greaselike silicone fluid thickened

with metal oxide filler

Compound provides thermal coupling of electrical/electronic

devices to heat sinks

USES

Dow Corning ® 340 Heat Sink Compound is applied to the base and mounting

studs of transistors, diodes and silicon-controlled rectifiers. It can also serve as an

effective thermal coupler for many heat sink devices where efficient cooling is

required. It is also suitable for aircraft engines where heat sink properties are

required.

This product has also been used as a high-voltage corona suppressant, nonflammable

coating in connections for flyback transformers and TV sets and similar applications.

TYPICAL PROPERTIES

Specification Writers: Please contact your local Dow Corning sales office or your Global

Dow Corning Connection before writing specifications on this product.

Method

Test

Color

ASTM D 217 Consistency, Penetration

unworked

worked 60 strokes

worked 100,000 strokes

Fed. Std. 791, Bleed after 24 hr at 392°F (200°C)

Method 321.2

Fed. Std. 791, Evaporation after 24 hr at 392°F (200°C)

Method 321.2

ASTM D 2265 Drop Point

ASTM D 1475 Specific Gravity at 77°F (25°C)

Thermal Conductivity, K Factor

CTM1 0069

ASTM D 149 Dielectric Strength2

ASTM D 495 Arc Resistance

ASTM D 150 Dielectric Constant,

at 100 Hz

at 100 kHz

ASTM D 150 Dissipation Factor,

at 100 Hz

at 100 kHz

ASTM D 1169 Volume Resistivity

ASTM D 4049 Water Spray Off

Unit

Result

White

percent

300

275

245

0.05

percent

0.5

°F (°C)

570 (300)

2.1

cal/sec-cm-°C 0.0014

volts/mil

210

seconds

165

5

5

ohm-cm

percent

0.01

0.02

2 x 1015

1.3

1

CTMs (Corporate Test Methods) correspond to standard ASTM tests in most instances.

Measured using a sample thickness of 50 mils.

2

DESCRIPTION

Dow Corning 340 Heat Sink Compound

is a grease-like silicone material, heavily

filled with heat conductive metal

oxides. This combination promotes

high thermal conductivity, low bleed

and high-temperature stability.

The compound resists changes in consistency at temperatures up to approximately 350°F (177°C). In doing so, it

helps maintain a positive heat sink seal

to improve heat transfer from the

electrical/electronic device to the heat

sink or chassis, thereby increasing

overall efficiency of the device.

HANDLING PRECAUTIONS

PACKAGING

PRODUCT SAFETY INFORMATION

REQUIRED FOR SAFE USE IS NOT

INCLUDED IN THIS DOCUMENT.

BEFORE HANDLING, READ

PRODUCT AND MATERIAL

SAFETY DATA SHEETS AND

CONTAINER LABELS FOR SAFE

USE, PHYSICAL AND HEALTH

HAZARD INFORMATION. THE

MATERIAL SAFETY DATA SHEET

IS AVAILABLE FROM YOUR

DOW CORNING REPRESENTATIVE, OR DISTRIBUTOR, OR

BY CALLING YOUR GLOBAL

DOW CORNING CONNECTION.

Dow Corning 340 Heat Sink Compound is available in 5-oz (142-g)

tubes, 13.5-oz (383-g) weight/

5.75-fl oz (170-mL) volume Semco ®

cartridges, 20-lb (9-kg) pails, and

275-lb (124.7-kg) drums for production lines and large scale operations.

All weights, net.

USABLE LIFE AND

STORAGE

Dow Corning 340 Heat Sink Compound has a shelf life of 60 months

from date of manufacture. Refer to

product packaging for “Use By” date.

Printed in USA

Form No. 10-748B-01

LIMITATIONS

This product is neither tested nor

represented as suitable for medical

or pharmaceutical uses.

SHIPPING LIMITATIONS

None.

WARRANTY INFORMATION

The information contained herein is

offered in good faith and is believed

to be accurate. However, because

conditions and methods of use of our

products are beyond our control, this

AGP5223

information should not be used in

substitution for customer’s tests to

ensure that Dow Corning’s products

are safe, effective, and fully satisfactory

for the intended end use.

Dow Corning’s sole warranty is that

the product will meet the Dow Corning

sales specifications in effect at the time

of shipment. Your exclusive remedy

for breach of such warranty is limited

to refund of purchase price or replacement of any product shown to be other

than as warranted. Dow Corning specifically disclaims any other express or

implied warranty of fitness for a particular purpose or merchantability.

Unless Dow Corning provides you

with a specific, duly signed endorsement of fitness for use, Dow Corning

disclaims liability for any incidental or

consequential damages. Suggestions of

use shall not be taken as inducements

to infringe any patent.

Dow Corning is a registered trademark of Dow Corning Corporation.

©1997, 1999, 2000 Dow Corning Corporation. All rights reserved.

Product Information

Specialty

Lubricants MOLYKOTE® 3400 A

Thermosetting anti-friction coating

FEATURES

• Outstanding corrosion protection

• Excellent adhesion to metal

• Low friction coefficient

• High resistance to oil and fuels

• Prevents fretting corrosion

• Exceptionally wide service

temperature range

(-198 to +430°C)

• High abrasion resistance,

consequently long service life

• High compressive strength

COMPOSITION

•

•

•

•

Solid lubricants

Corrosion inhibitors

Organic binders

Solvents

Thermosetting anti-friction coating for metal/metal

combinations involving slow to medium-fast movements

and medium to heavy loads

APPLICATIONS

• Suitable for permanent lubrication, with simultaneous corrosion protection, of

friction contacts involving high compressive stress and low speeds, and

wherever oils or greases cannot be used for technical reasons or are

undesirable because of the risk of soiling.

• Used successfully on hinge pins, plain bearings, cams, keyways and dentate

couplings on aircraft, on pins, springs and bearing surfaces of motor-car

brakes, moving parts of locks, switches and regulators; on special chains and

on all types of magnetic armature.

TYPICAL PROPERTIES

Specification writers: These values are not intended for use in preparing specifications.

Please contact your local Dow Corning sales representative prior to writing specifications

on this product.

Standard

Unit

Test

Color

Result

Grey

Density

ISO 2811

Density at 20°C

g/ml

1.2

°C

-200 to +430

Temperature

Service temperature

Load-carrying capacity, wear protection, service life

ASTM-D2625

ASTM-D2714

Falex pressure resistance¹

LFW-1, rotating

F=2860, N,n=72 rpm, v=7.9 min, no.of

revolutions to μ=0.1¹

LFW-1, oscillating, load 900N,

frequency=89.5 os./min. no. of

oscillations to μ=0.08¹

N

p=20000*

p=85000*

p=42000*

1. * Surface: p = phosphatised

HOW TO USE

How to apply

Carefully degrease friction surfaces

with solvent and allow solvent to

evaporate completely. Stir the

anti-friction coating thoroughly and

apply by spraying, dipping, painting

or centrifuging (dilute with

MOLYKOTE® L 13 - approximately

10-20%). The friction surfaces should

be coated as evenly and thinly as

possible. Annealing: 2 hours at 150°C

or 1 hour at 200°C.

Diluting agent: L 13 thinners.

HANDLING PRECAUTIONS

PRODUCT SAFETY

INFORMATION REQUIRED FOR

SAFE USE IS NOT INCLUDED.

BEFORE HANDLING, READ

PRODUCT AND SAFETY DATA

SHEETS AND CONTAINER

LABELS FOR SAFE USE,

PHYSICAL AND HEALTH

HAZARD INFORMATION. THE

SAFETY DATA SHEET IS

AVAILABLE FROM YOUR LOCAL

DOW CORNING SALES

REPRESENTATIVE.

USABLE LIFE AND

STORAGE

When stored at or below 20°C in the

original unopened containers,

MOLYKOTE 3400 A Thermosetting

Anti-Friction Coating has a usable life

of 60 months from the date of

production.

effect at the time of shipment. Your

exclusive remedy for breach of such

warranty is limited to refund of

purchase price or replacement of any

product shown to be other than as

warranted. Dow Corning specifically

disclaims any other express or implied

warranty of fitness for a particular

purpose or merchantability. Unless

Dow Corning provides you with a

specific, duly signed endorsement of

fitness for use, Dow Corning

disclaims liability for any incidental

or consequential damages.

Suggestions of use shall not be taken

as inducements to infringe any patent.

PACKAGING

This product is available in different

standard container sizes. Detailed

container size information should be

obtained from your nearest

Dow Corning sales office or

Dow Corning distributor.

LIMITATIONS

This product is neither tested nor

represented as suitable for medical or

pharmaceutical uses.

HEALTH AND

ENVIRONMENTAL

INFORMATION

To support customers in their product

safety needs, Dow Corning has an

extensive Product Stewardship

organization and a team of Health,

Environment and Regulatory Affairs

specialists available in each area.

For further information, please

consult your local Dow Corning

representative.

WARRANTY

INFORMATION - PLEASE

READ CAREFULLY

The information contained herein is

offered in good faith and is believed

to be accurate. However, because

conditions and methods of use of our

products are beyond our control, this

information should not be used in

substitution for customer's tests to

ensure that Dow Corning's products

are safe, effective, and fully

satisfactory for the intended end use.

Dow Corning's sole warranty is that

the product will meet the

Dow Corning sales specifications in

2

03/03/1998

Ref. no. 71-0030A-01

DC 2995

® MOLYKOTE is a registered trademark of Dow Corning Corporation.

©1998-2001 Dow Corning Corporation. All rights reserved.

Product Information

MOLYKOTE® 3402 C

Anti-friction Coating

FEATURES

Air-curing dry lubricant

• Excellent corrosion protection

• Excellent lubricity

• Air-curing

• Strong pressure and wear resistance

COMPOSITION

•

•

•

•

Solid lubricants

Organic binder

Corrosion inhibitor

Solvent

APPLICATIONS

• Excellent combination of corrosion protection and lubrication.

• Used on main axle threads of drill hammers, spindles.

TYPICAL PROPERTIES

Specification writers: These values are not intended for use in preparing specifications.

Please contact your local Dow Corning sales representative prior to writing specifications

on this product.

Standard*

Unit

Test

Color

Result

Grey

Physical properties

DIN 53211/3

DIN 53217/2

CTM 0242 I

Viscosity at 20°C or 68°F (DIN3 cup)

Density at 20°C (68°F)

Non-volatile content

Storage life

s

g/ml

%

years

47

1.08

34.5

5

minutes

minutes/°C

minutes/°F

°C

°F

15

120/20

120/68

-200 to +310

-328 to +590

Temperature

Drying time at 20°C (68°F)

Curing time

Curing time

Service temperature range

Service temperature range

Load-carrying capacity, wear protection, service life

ASTM-D2625

ASTM-D2714

ASTM-D2714

Falex load-carrying capacity¹

LFW-1, rotating¹

F=2860N, n=72 minutesª¹,

v=7.9m/minutes

no. of revolutions x1000 to μ=0.1

LFW-1, oscillating¹

F=900N, frequency=89.5osc./minutes

no. of oscillations to μ=0.08

N

s=10700

s=45

s=25

Resistance

Radiation resistance

rad

10¶

1. Surface pretreatment: s = sand blasted.

* CTM: Corporate Test Method, copies of CTMs are available on request.

ASTM: American Society for Testing and Materials.

DIN: Deutsche Industrie Norm

HOW TO USE

Surface preparation

First clean and degrease the surface

which will be coated with

MOLYKOTE 3402 C Anti-Friction

Coating. Phosphatization or

sandblasting (180 grid) increases the

adhesion and service life.

How to apply

Stir the Anti-friction Coating

thoroughly before applying by

spraying, dipping, centrifuging or

brushing. Recommended dry film

thickness: 5 to 20μm.

Curing

120 minutes at 20°C (68°F).

Solubility

Thinning can be carried out using

MOLYKOTE® L 13 Thinner.

HANDLING PRECAUTIONS

PRODUCT SAFETY

INFORMATION REQUIRED FOR

SAFE USE IS NOT INCLUDED.

BEFORE HANDLING, READ

PRODUCT AND SAFETY DATA

SHEETS AND CONTAINER

LABELS FOR SAFE USE,

PHYSICAL AND HEALTH

HAZARD INFORMATION. THE

SAFETY DATA SHEET IS

AVAILABLE FROM YOUR LOCAL

DOW CORNING SALES

REPRESENTATIVE.

USABLE LIFE AND

STORAGE

When stored at or below 20°C (68°F)

in the original unopened containers

MOLYKOTE 3402 C Anti-friction

Coating has a usable life of 60 months

from the date of production.

PACKAGING

Environment and Regulatory Affairs

specialists available in each area.

For further information, please

consult your local Dow Corning

representative.

WARRANTY

INFORMATION - PLEASE

READ CAREFULLY

The information contained herein is

offered in good faith and is believed

to be accurate. However, because

conditions and methods of use of our

products are beyond our control, this

information should not be used in

substitution for customer's tests to

ensure that Dow Corning's products

are safe, effective, and fully

satisfactory for the intended end use.

Dow Corning's sole warranty is that

the product will meet the

Dow Corning sales specifications in

effect at the time of shipment. Your

exclusive remedy for breach of such

warranty is limited to refund of

purchase price or replacement of any

product shown to be other than as

warranted. Dow Corning specifically

disclaims any other express or implied

warranty of fitness for a particular

purpose or merchantability. Unless

Dow Corning provides you with a

specific, duly signed endorsement of

fitness for use, Dow Corning

disclaims liability for any incidental

or consequential damages.

Suggestions of use shall not be taken

as inducements to infringe any patent.

This product is available in different

standard container sizes. Detailed

container size information should be

obtained from your nearest

Dow Corning sales office or

Dow Corning distributor.

LIMITATIONS

This product is neither tested nor

represented as suitable for medical or

pharmaceutical uses.

HEALTH AND

ENVIRONMENTAL

INFORMATION

To support customers in their product

safety needs, Dow Corning has an

extensive Product Stewardship

organization and a team of Health,

2

13/03/2000

Ref. no. 71-0041D-01

DC 3634

® MOLYKOTE is a registered trademark of Dow Corning Corporation.

©1997-2001 Dow Corning Corporation. All rights reserved.

P

Information About

MOLYKOTE® 3451

Chemical Resistant

Bearing Grease and

MOLYKOTE® 3452

Chemical Resistant

Valve Lubricant

R

O

D

U

C

T

I

DESCRIPTION

MOLYKOTE 3451 Chemical Resistant

Bearing Grease and MOLYKOTE 3452

Chemical Resistant Valve Lubricant are

fluorosilicone oils thickened with

fluorinated polymers. These lubricants:

Provide superior resistance to most

chemicals

Are compatible with most gaskets,

seals and packings

Resist washout by water, fuels, oils

and solvents

Type

Fluorosilicone greases

Special Properties

Chemical resistance; good loadcarrying ability, effective in high

temperatures

Primary Uses

–MOLYKOTE® 3451 Chemical

Resistant Bearing Grease –

NLGI #2

Exceptional antifriction

lubricant for bearings exposed to

harsh chemicals, solvents, high

temperatures, high speeds or

heavy loads

N

These greases lubricate over a wide

temperature range. MOLYKOTE 3451

Chemical Resistant Bearing Grease has

good life at temperatures from -40 to

450°F (-40 to 232°C);MOLYKOTE 3452

Chemical Resistant Valve Lubricant

has a serviceable temperature range

from -20 to 450°F (-29 to 232°C). Both

MOLYKOTE 3451 Chemical Resistant

Bearing Grease and MOLYKOTE 3452

Chemical Resistant Valve Lubricant

resist deterioration by solvents, acids,

chlorides and other severe chemicals

as well as low-pressure steam and

condensate. (See Table I.)

F

O

R

M

A

T

I

O

N

Bearing tests show MOLYKOTE 3451

Chemical Resistant Bearing Grease has

good life at varying high loads and

speeds.

USES

MOLYKOTE 3451 Chemical

Resistant Bearing Grease

MOLYKOTE 3451 Chemical Resistant

Bearing Grease is an exceptional antifriction bearing lubricant especially

designed for applications that experience

a wide range of temperatures, loads

and speeds. It is particularly useful in

bearings exposed to harsh chemicals

or solvents, bearings used at high

speeds and bearings subjected to heavy

loads. MOLYKOTE 3451 Bearing Grease

can be used on:

Chemical mixers

Needle bearings in circuit breakers

Pumps

Processing equipment

Fuel- and solvent-handling

equipment

Sealed-for-life bearings that must

operate at high speeds, heavy loads,

and high and low temperatures

– MOLYKOTE ® 3452 Chemical

Resistant Valve Lubricant –

NLGI #3

BL17877-1

Lubricant and sealant for valves,

shafts and packings exposed to

corrosive or aggressive chemicals

or high temperatures

Valves protected by MOLYKOTE 3452 Chemical Resistant Valve Lubricant show no evidence of

corrosion or degradation of lubricant.

TYPICAL PROPERTIES

These values are not intended for use in preparing specifications.

....................................................................................................

....................................................................................................

....................................................................................................

....................................................................................................

NLGI Consistency ......................................................................

Color ...........................................................................................

Thickener ...................................................................................

ASTM D 217 Penetration, worked, 60 strokes ................................................

Viscosity of fluorosilicone oil at 100°F (38°C), SUS ................

Service Temperature Range1, °F (°C) ......................................

Max. Dn Value2 ..........................................................................

Specific Gravity at 77°F (25°C) .................................................

Fed Std 791

Bleed, at 400°F (204°C), percent ..............................................

ASTM 2265

Evaporation, at 400°F (204°C), percent ...................................

Dropping Point, °F (°C) ............................................................

ASTM D 1264 Water Washout, at 175°F (80°C), percent ................................

Fed Std 791a3 4-Ball Weld Load,Kg ...................................................................

ASTM D 1478 Low-Temperature Torque

starting, g-cm at -40°F (-40°C) ...............................................

running, g-cm after 1 hr at -40°F (-40°C) .............................

Molykote

3451

Chemical Resistant

Bearing Grease

Molykote

3452

Chemical Resistant

Valve Lubricant

#2

White

Fluorinated polymers

275

2295

-40 to 450 (-40 to 232)

200,000

1.44

2.7

3.7

>536 (>280)

0.3

400

#3

White

Fluorinated polymers

270

46,000

-20 to 450 (-31 to 232)

75,000

1.50

1.2

1.1

>570 (>300)

0.1

400

2315

1960

1

Estimated service temperature range based on product formulation and laboratory testing. Actual service temperature range is dependent on other factors including the

specific application environment.

2

Dn value = shaft size of bearing in mm x rpm; based on estimate.

3

Method 6503.

Specification Writers: Please obtain a copy of the Dow Corning Sales Specification for this product and use it as a basis for your

specifications. It may be obtained from any Dow Corning Sales Office, or from Dow Corning Customer Service in Midland, MI.

Call (989) 496-6000.

Table I: Chemical Resistance of MOLYKOTE 3451 Chemical Resistant Bearing Grease and MOLYKOTE 3452 Chemical

Resistant Valve Lubricant

..........................................................................................................

..........................................................................................................

..........................................................................................................

After 24 hours at 77°F (25°C)1 ................................................................................................

Diesel ................................................................................................

Kerosene ..........................................................................................

Silicone Fluid ...................................................................................

Toluene ............................................................................................

Hexane .............................................................................................

Xylene ..............................................................................................

Isopropanol ......................................................................................

Methanol ..........................................................................................

VM&P Naphtha ...............................................................................

MOLYKOTE

3451

Chemical Resistant

Bearing Grease

Good3

Good

Fair

Good

Fair

Good

Good

Good

Good

MOLYKOTE

3452

Chemical Resistant

Valve Lubricant

Good

Good

Good

Good

Fair

Good

Good

Good

Good

Hydrocarbon

Grease2

Poor

Fair

Poor

Poor

Poor

Poor

Fair

Fair

Poor

1

Test method Federal Standard 791C-6.2.

A lithium-thickened petroleum grease.

3

Good no observable effect on grease [grease slightly soft; poor adhesion]; Fair

adhesion.

2

grease very soft; cracked and poor adhesion; Poor

grease hardened or dissolved; no

Volume Change, percent

Figure 1: Percent Volume Change of Various Rubbers in MOLYKOTE 3452 Chemical Resistant Valve Lubricant

MOLYKOTE 3452 Chemical

Resistant Valve Lubricant

MOLYKOTE 3452 Chemical Resistant

Valve Lubricant is an exceptional valve

lubricant and sealant product particularly suited for applications where corrosive or aggressive chemicals are used.

MOLYKOTE 3452 Valve Lubricant can

be used on:

Plug valves

Mechanical seals and packings

Slow-speed roller and journal

bearings

Moderate-speed ball bearings

Instruments in high vacuum, at high

temperatures and in corrosive

atmospheres

Rotary and reciprocating shaft seals

Flexible ball joints

LIMITATIONS

MOLYKOTE 3451 Chemical Resistant

Bearing Grease should not be applied

to surfaces to be painted.

MOLYKOTE 3451 Chemical Resistant

Bearing Grease and MOLYKOTE 3452

Chemical Resistant Valve Lubricant are

not recommended for use with highly

oxidative chemicals (liquid Cl2 or

liquid O2, for example).

These greases are soluble in ketones

such as acetone, methyl ethyl ketone

and methyl isobutyl ketone.

This product is neither tested nor

represented as suitable for medical

or pharmaceutical uses.

HOW TO USE

Application

MOLYKOTE 3451 Chemical Resistant

Bearing Grease and MOLYKOTE 3452

Chemical Resistant Valve Lubricant

can be applied using conventional

methods of grease application

brushing, grease gun or automatic

applicators.

SHIPPING LIMITATIONS

None.

STORAGE AND SHELF LIFE

When stored at or below 90°F (32°C),

MOLYKOTE 3451 Chemical Resistant

Bearing Grease and MOLYKOTE 3452

Chemical Resistant Valve Lubricant

have a shelf life of 60 months from

date of manufacture.

Note: In storage, a small amount of oil

may separate from MOLYKOTE 3451

Chemical Resistant Bearing Grease.

This separation does not materially

affect the lubricating qualities of the

grease. Simply stir fluid back into the

grease.

PACKAGING

MOLYKOTE 3451 Chemical Resistant

Bearing Grease is available in tubes

cartridges and pails

MOLYKOTE 3452 Chemical Resistant

Valve Lubricant is available in tubes,

cartridges, pails.

SAFE HANDLING INFORMATION

PRODUCT SAFETY INFORMATION

REQUIRED FOR SAFE USE IS NOT

INCLUDED. BEFORE HANDLING,

READ PRODUCT AND MATERIAL

SAFETY DATA SHEETS AND CONTAINER LABELS FOR SAFE USE,

PHY SICAL AND HEALTH HAZARD

INFORMATION. THE MATERIAL

SAFETY DATA SHEET IS AVAILABLE

FROM YOUR DOW CORNING REPRESENTATIVE, OR DISTRIBUTOR,

OR BY WRITING TO DOW CORNING

CUSTOMER SERVICE, OR BY

CALLING (989) 496-6000.

LIMITED WARRANTY –

PLEASE READ CAREFULLY

Dow Corning believes that the

information in this publication is an

accurate description of the typical

characteristics and/or uses of the

product or products, but it is your

responsibility to thoroughly test the

product in your specific application to

determine its performance, efficacy

and safety. Suggestions of uses should

not be taken as inducements to

infringe any particular patent.

Unless Dow Corning provides you with

a specific written warranty of fitness

for a particular use, Dow Corning s

sole warranty is that the product or

products, as supplied, will meet

Dow Corning s then current sales

specifications. DOW CORNING

SPECIFICALLY DISCLAIMS ANY

OTHER EXPRESS OR IMPLIED

WARRANTY, INCLUDING THE

WARRANTIES OF MERCHANTABILITY AND OF FITNESS FOR

USE. Your exclusive remedy and

Dow Corning s sole liability for breach

of warranty is limited to refund of the

purchase price or replacement of any

product shown to be other than as

warranted, and Dow Corning expressly

disclaims any liability for incidental or

consequential damages.

Dow Corning is a registered trademark of

Dow Corning Corporation.

©1994, 1998 Dow Corning Corporation.

All rights reserved.

Printed in USA

AGP3853A

Form No. 10-813-98B-01

Dow Corning Corporation

Midland, Michigan 48686-0994

c

d

Product Information

Specialty

Lubricants

FEATURES

" Low evaporation

" High oxidation resistance

" Wide service temperature range,

-30ºC to +230ºC (-22ºF to +446ºF)

" High resistance to water and water

washout

" Resistant to most solvents and chemicals

" Compatible with many plastics and

elastomers

COMPOSITION

" Fluorosilicone oil

" PTFE thickener

MOLYKOTE® FS 3452

Fluoro-Silicone Grease

Lubricating and sealing grease for metal/metal, metal/plastic

and metal/elastomer combinations involving slow movements

and heavy loadings over very wide temperature ranges,

particularly under unfavorable environmental influences

APPLICATIONS

" Suitable for the above friction contacts and service conditions.

" Successfully used on valves, mechanical seals and pumps, ball-and socket-joints,

bearings, on loading arms for ships and vacuum contained equipment.

TYPICAL PROPERTIES

Specification writers: These values are not intended for use in preparing specifications.

Please contact your local Dow Corning sales representative prior to writing specifications on

this product.

Standard*

Test

Unit

Color

Result

White

Consistency, density, viscosity

DIN 51 818

NLGI consistency class

2-3

ISO 2137

Worked penetration

mm/10

240-280

ISO 2811

Density at 20ºC (68ºF)

g/ml

1.47

Base oil viscosity at 25ºC (77ºF)

mm2/s

10000

ºC

-30 to +230

Temperature

Service temperature

ISO 2176

ºF

-22 to +446

ºC

>220

ºF

>428

Initial break-away torque

Nm

392x10-3

Torque after 20 minutes running time

Nm

94x10-3

Kesternich method - flow pressure

at -20ºC (-4ºF)

mbar

280

Drop point

ASTM-D147880 Low temperature torque test at -20ºC (-4ºF)

DIN 51 805

Load-carrying capacity, wear protection, service life

Four-ball tester (VKA)

DIN 51 350 pt.4 Weld load

N

4400

OK load

N

15500

Frictional force with OK load

N

3500

Almen-Wieland machine

Resistance

DIN 51 807 pt.1 Water resistance, static evaluation step

DIN 51 808

Oxidation resistance, pressure drop 100h,

99ºC (210ºF)

0-90

bar

0.0

TYPICAL PROPERTIES (continued)

Standard*

Test

Unit

Result

%

2.8

Oil separation

DIN 51 817

Oil separation - standard test

* ASTM: American Society for Testing and Materials.

ISO: International Standardisation Organisation.

DIN: Deutsche Industrie Norm.

HOW TO USE

How to apply

Clean bearing surfaces. Apply grease

in the normal way using a brush or

grease gun. Do not mix with other

greases. Due to variation in quality of

plastics and elastomers, compatibility

tests should be carried out for swelling

and shrinkage, stress-crack formation,

and changes in strength and hardness.

HANDLING PRECAUTIONS

Hands should be washed before eating,

drinking or smoking. Avoid contact

with the eyes and skin. Traces of toxic

trifluoropropionaldehyde may be

formed at temperatures of >150ºC

(>302ºF). Adequate ventilation must be

provided in enclosed spaces. At

temperatures above 290ºC (554ºF),

fluorine and hydrogen fluoride may be

evoked.

Product safety information required for

safe use is not included. Before

handling, read product and safety data

sheets and container labels for safe use,

physical and health hazard information.

The material safety data sheet is

available on the Dow Corning website

at www.dowcorning.com. You can also

obtain a copy from your local

Dow Corning sales representative or

Distributor or by calling your local

Dow Corning Global Connection.

LIMITED WARRANTY

INFORMATION - PLEASE

READ CAREFULLY

PACKAGING

This product is available in different

standard container sizes. Detailed

container size information should be

obtained from your nearest

Dow Corning sales office or

Dow Corning distributor.

LIMITATIONS

This product is neither tested nor

represented as suitable for medical or

pharmaceutical uses.

HEALTH AND