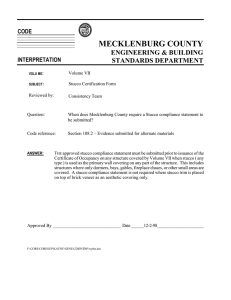

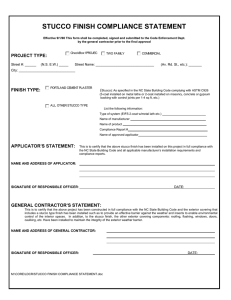

Victorian Stucco Part 2 (PDF, 1.3 MB, 95 pp.)

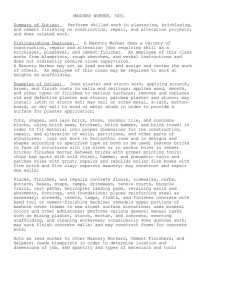

advertisement