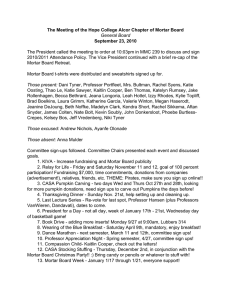

ATLAS CEMENT SCRATCH COAT scratch coat for 2- or 3

advertisement

PLASTERING MIXES ATLAS CEMENT SCRATCH COAT scratch coat for 2- or 3- coat plasterwork • improves plaster adhesion to substrate • recommended for cement and cement-lime plasters • reduces the material cost of plasterwork • the highest strength category • manual or machine application PRODUCT CONFORMS WITH THE EUROPEAN STANDARD Use Technical data Creates adhesion layer in two- or three-coat plaster systems – applied directly to the substrate before the application of top coat of cement or lime-cement plaster. Excellent compatibility with ATLAS plastering mortars: -- PLASTERING MORTAR, -- LIGHTWEIGHT CEMENT-LIME PLASTER -- KB-TYNK Reduces the cost of two- or three-coat plasterwork – replaces more expensive plaster types at the scratch coat stage. Hand or machine applied – the use of plastering units speeds up the application considerably. ATLAS CEMENT SCRATCH COAT is manufactured in the form of dry mix of highest quality cement binder, quartz fillers and modifiers improving the plasticity and workability of the material. Types of substrates – walls and ceilings of bricks, blocks, hollow blocks and other similar ceramic or silicate elements; concrete and aerated concrete; cement-bonded particleboard, cement and cement-lime plasters. Properties High strength – the highest standard-specified strength class CS IV (above 6.0 N/mm²) – the scratch coat is a suitable base for top coats, even those of high strength plastering mortars, as it is resistant to shrinkage stress occurring during the setting of mortars of that type. Excellent adhesion to substrate – especially recommended for smooth surfaces or substrates of low absorption capacity; bonds strongly to bricks, blocks etc. The mortar can be supplemented with so-called anti-frost additives allowing to carry out works at lowered temperatures, i.e. below +5°C – the new temperature range of mortar application, the way of its preparation (especially the adjustment of the amount of water added), principles of carrying out works and the mortar setting conditions must be accepted according to the guidelines of the manufacturer of the additive. The amount of the anti-frost agent depends on the content of cement in the mortar – the proportion of cement to fillers in ATLAS SCRATCH COAT is at 1:4. Note. The manufacturer of the mortar is in no way responsible for the effects and the quality of the anti-frost agents used. 150 CLASS OF REACTION TO FIRE ACC. TO THE EUROPEAN STANDARD www.atlas.com.pl Bulk density (of dry mix) ca. 1.57 kg / dm³ Wet density (after mixing) ca. 2.06 kg / dm³ Dry density (after setting) ca. 1.6 kg / dm³ Mixing proportions water / dry mix 0.22 l / 1 kg Scratch coat thickness ca. 4 mm Mortar preparation temperature, substrate and ambient temperature during work from +5°C to +25°C Maturing time ca. 5 minutes Pot life ca. 2 hours ca. 6.5 l / 30 kg Technical requirements ATLAS CEMENT SCRATCH COAT conforms to PN-EN 998-1 standard. EC Declaration of Performance No. 111/CPR. PN-EN 998-1:2012 (EN 998-1:2010) Factory made plastering mortar of specified properties, general-purpose (GP) For indoor and outdoor use Compressive strength ≥ 6.0 N/mm² Reaction to fire - class A1 Water absorption ≤ 0.40 kg/m2 min0,5 Adhesion 0.5 N/mm² - FP:B Water-vapour permeability coefficient μ 22 Thermal conductivity coefficient (average tabular value P=50%) 0.83 W/mK (λ10, dry) Durability. Compressive strength decrease after freeze-thaw cycles < 10 % Durability. Mass decrement after freeze-thaw cycles ≤ 3% Dry bulk density ≤1800 kg/m³ Content of hazardous substances See: Material Safety Data Sheet (MSDS) PLASTERING MIXES Application Substrate preparation The substrate should be dry, stable, flat and capable of load bearing, i.e. sufficiently sound, and cleaned of materials that might affect mortar adhesion, especially dust, dirt, lime, oil, grease, wax, residues of release agents or paint. Insufficiently bound substrate fragments should be hammered off, whereas all loose or crumbling particles should be removed using a steel wire brush. Contacting edges of particleboards should be reinforced prior to plastering using strips of stainless steel mesh. Corners and edges of window and door reveals should be protected using galvanised steel corner profiles. If necessary, substrates characterised by excessive absorption capacity should be primed with ATLAS UNI-GRUNT emulsion. Mortar preparation Pour the mortar from the bag into a clean container with the suitable amount of water (see Technical Data for proportions) and mix using a drill with a mixer (or in cement mixer) until homogenous. In the case of machine application - in a plastering unit. Leave the mortar to rest for 5 minutes and then remix. The mortar is ready to use directly after mixing and should be used up within ca. 2 hours. Application of scratch coat The mortar is applied to the prepared substrate manually or mechanically, in a uniform coat, to the thickness of ca. 4 mm. Do not smooth or float the material. Leave the mortar to set initially (ca. 12 hours). After initial mortar setting the top plaster coat can be applied. Maintenance Ensure appropriate room ventilation during drying. Protect external plasters from drying too quickly. Consumption Material consumption depends on the accuracy of surface covering. In the case of scratch coat covering the entire surface the material consumption is ca. 8 kg of dry mix for 1 m2. Important additional information • Adjust the ratio of added water experimentally, following the desired consistency of the mortar, type of substrate and weather conditions. Inappropriate amount of water for mix preparation results in deterioration of strength parameters of the scratch coat. • Tools must be cleaned with clean water directly after use. Difficult to remove residues of the set mortar can be removed with the ATLAS SZOP agent. • Irritant - contains cement. Irritating to respiratory system and skin. Risk of serious damage to eyes. May cause sensitisation by skin contact. Due to its form - powder, the product may cause mechanical irritation of eyes and respiratory system. Keep out of reach of children. Do not breathe dust. In case of contact with eyes, rinse immediately with plenty of water and seek medical advice. Wear suitable protective clothing, gloves and eye/face protection. If swallowed, seek medical advice immediately and show the container or label. Follow the instructions in the Material Safety Data Sheet. • The mortar must be transported and stored in tightly sealed bags, in dry conditions (most preferably on pallets). Protect against humidity. Shelf life in conditions as specified is 12 months from the production date shown on the packaging. Content of soluble chromium (VI) in ready-to-use mix - ≤ 0.0002%. Packaging Paper bags: 30 kg Pallet: 1080 kg in 30 kg bags The above information constitutes basic guidelines for the application of the product and does not release the user from the obligation of carrying out works according to engineering principles and OHS regulations. At the time of publication of this product data sheet all previous ones become void. Date of update: 2013-09-19 Product Data Sheets Catalogue 151