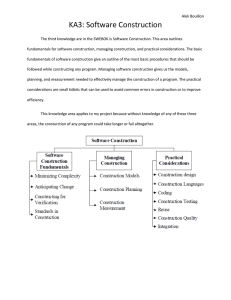

Introduction

Harmony™ 9001K/SK/KX

30 mm push buttons

Introduction

Schneider Electric’s Harmony™ 9001 30 mm push buttons, pilot lights, selector

switches and mushroom head operators provide robust and reliable solutions for a

wide range of heavy industry applications.

1

b 9001K operators are rugged and include chrome-plated bezels. (See page 5.)

b 9001SK operators include black plastic bezels for corrosion-resistant applications.

(See page 36.)

b 9001KX operators include chrome-plated square bezels and provide multi-function

operation. (See page 66.)

2

Product features:

b Heavy duty, oil-tight, dust-tight, and water-tight without boots. Most units are IP66

rated and are UL types 4, 4X and 13.

b FINGERSAFE™ contact blocks and light modules for improved safety

b Interchangeable light modules, contact blocks, color caps, pilot light lenses and

mushroom heads reduce inventory

b Integrated earth ground connection (no ground wires required)

b Easy installation with octagonal ring nut

b Metal or plastic legend plates

3

Contact block features:

4

b Clear window for status of contact operation and troubleshooting

b Color coded for easy identification

b Single screw mounting for quick installation

b Side-by-side and/or stacked mounting to minimize enclosure space requirements

Light module features:

b Low-cost incandescent lamps or energy-efficient, long-life LED lamps

b Wide range of voltages from 24V to 600V

5

All products are:

b UL listed and CSA certified

b CE declaration of conformity

b RoHS compliant

6

7

8

9

10

4

Harmony™ 9001K/SK/KX

30 mm push buttons

Specifications

9001SK

Environmental specifications

1

2

3

4

Conforming to standards

Marked

Product certifications

File E78403

CCN NKCR

Protective treatment

standard version

Ambient air temperature

around the device

EN/IEC 60947-1, EN/IEC 60947-5-1, EN/IEC 60947-5-4, JIS C 4520 and 852,

UL 508, CSA C22-2 n° 14, e marked, RoHS compliant

UL File E78403, CCN NKCR and CSA File LR25490, Class 3211-03

File LR25490

Class 3211-03

“TC”

Storage

°F (°C)

-40 to +158 (-40 to +70)

Operation

°F (°C)

-13 to +158 (-25 to +70)

Vibration resistance

Conforming to IEC 60068-2-6

Shock resistance

Conforming to IEC 60068-2-27

Frequency: 2 to 500 Hz: 7gn

Ford Standard EA-1

Half sine wave: 50 gn

Electric shock protection Conforming to IEC 61140

Class II

Degree of protection

Conforming to EN/IEC 60529

IP 66

Conforming to NEMA

Types 1, 2, 3, 3R, 4, 12 and 13

Push buttons, spring return

5

Illuminated push buttons

5

Selector switches and key switches

0.5

Mechanical life

(in millions of operating

cycles)

Mounting position

All positions

Electrical characteristics of contact blocks

5

Rated operational

characteristics

Rated insulation voltage

6

7

8

a AC-15

3 A, 240 V

c DC-13

0.55 A, 125 V

Conforming to EN/IEC 60947-1

Rated impulse withstand Conforming to EN/IEC 60947-1

voltage

Contact material

Normal environment and usage

V

Ui = 250 degree of pollution 3 (except pilot lights with incandescent bulb:

degree of pollution 2)

kV

Uimp = 2.5

Silver alloy

Contact operation

“N/C” ou “N/O”

Positive operation

Conforming to EN/IEC 60947-5-1

N

N/C contact(s) with positive opening operation

Short-circuit protection

Conforming to EN/IEC 60947-5-1

A

Cartridge fuse mounted upstream: 10

Cabling capacity

Conforming to EN/IEC 60947-1

(9001KA contact blocks and

9001KM light modules)

mm2

mm2

Screw clamp terminals (cross headedslotted screw)

Mini: 1 x 0.22

Maxi: 2 x 1.5

Recommended tightening torque: 0.8 N.m (10 in-lbs)

Thermal current

lth

A

10

Maximum operation

current

a.c. supply:

utilization category AC-15

NEMA A600

V

A

VA

Contact making capacity

120

240

60

30

7200

7200

480

15

7200

600

12

7200

V

A

VA

Breaking capacity

120

240

6

3

720

720

480

1.5

720

600

1.2

720

V

A

Contact making capacity and breaking capacity

125

250

600

0.55

0.27

0.1

9

d.c.supply:

utilization category DC-13

NEMA Q600

Slow break

10

Product range:

page 36

38

References:

page 41

Dimensions:

page 60

Mounting:

page 61

Specifications (continued)

Harmony™ 9001K/SK/KX

30 mm push buttons

9001SK

Basic Operators

(For Color Caps, Mushroom Buttons, Knobs, Se­lector Switch Cams, Contact Blocks, Light Modules and Legend Plates, see page 51.)

Description

UL Types/NEMA Types

4, 4X, 13

9001SKR1

9001SKR2

9001SKR3

9001SKR20

–

–

–

9001SKR8 (1)

9001SKR9 (1)

9001SK1L (2)

9001SK2L (2) (3)

–

9001SKP

9001SKS1 (1), 9001SKS2 (1), 9001SKS3 (1)

9001SKS4 (1), 9001SKS5 (1), 9001SKS6 (1), 9001SKS7 (1)

9001SKS8 (1)

9001SKR16 (1)

Non Illuminated Push Button (Full Guard)

Non Illuminated Push Button (Extended Guard)

Non Illuminated Push Button (No Guard)

Non Illuminated Push Button (Mushroom Button/screw on)

Non Illuminated Dual Push Button (Momentary)

Non Illuminated Dual Push Button (Momentary Interlocked)

Non Illuminated Dual Push Button (Maintained Interlocked)

Momentary Pull - Maintained Neutral - Momentary Push

Maintained Pull - Maintained Push

Illuminated Push Button (Full Guard - Plastic Top)

Illuminated Push Button and Push-to-test (No Guard)

Illuminated Push Button (Full Guard - Metal Top)

Standard Pilot Light

2-Position Selector Switch

3-Position Selector Switch

4-Position Selector Switch

Trigger-Action Emergency Stop

(1) Operator can be converted to an illuminated operator by removing the liner (6509704901) and adding a light module.

(2) Operator can be converted to a non-illuminated operator by adding liner (6509704901).

(3) Operator includes jumper wires for push-to-test conversion.

File

CCN

E42259

NKCR

File

LR25490

Class 3211 03

®

E10054

NOIV

File

LR26817

Class 3218 02

3

Marking

Hazardous Locations (Reed contact blocks, see page 53):

File

CCN

2

4

Non Hazardous Locations:

®

1

5

Marking

6

7

8

9

10

Product range:

page 36

References:

page 41

Dimensions:

page 60

Mounting:

page 61

39

Harmony™ 9001K/SK/KX

30 mm push buttons

Specifications (continued)

9001SK

1

2

3

4

5

6

9001SK Operator Materials:

Contact Block And Light Module Materials:

Push Button and Push-to-test Pilot Light

(9001SKR and 9001SKT)

Contact Block (9001KA)

Base – Thermoplastic Polyester

Stem – Acetal (non-illuminated push button)

Thermoplastic Polyester (illuminated push button

and push-to-test pilot light)

Seal – Nitrile

Gasket – Nitrile

Spring – 302 Stainless Steel

Spring Support – CRS

Lock Ring – Nylon

Trim Washer – Polypropylene

Locking Thrust Washer – Thermoplastic Polyester

Ring Nut – Thermoplastic Polyester

Color Insert – Polyethylene (non-illuminated push button)

Color Cap – Polycarbonate (illuminated push button and

push-to-test pilot light)

Mushroom Button – Acetal (non-illuminated push button)

Polycarbonate (illuminated push button)

Liner – Polypropylene (non-illuminated push button)

Selector Switch (9001SKS)

Base – Thermoplastic Polyester

Seal – Nitrile

Gasket – Nitrile

Seal Keeper – 302 Stainless Steel

Spring – 302 Stainless Steel

Cam Follower – Delrin 100

Bearing Washer – Polyester Film

Cam Carrier – Trogamid

Cam Profile – Delrin 100

Liner – Polypropylene (non-illuminated only)

Knob – Polycarbonate

Trim Washer – Polypropylene

Locking Thrust Washer – Thermoplastic Polyester

Spring Support – CRS

Housing – Amorphous Nylon

Contact Slider – Phenolic, Nylon or Acetal

Terminal – Steel

Saddle Clamp – Steel

Spring – Stainless Steel

Contacts – Silver and Copper

Blade – Beryllium Copper

Mounting Screw – Steel

Label – Paper

Light Module (9001KM)

Housing – Thermoplastic Polyester

Socket – Steel

Terminal – Steel with Tin Plate

Saddle Clamp – Steel

Translating Pin – Polycarbonate

Transformer – Thermoplastic Polyester, Steel, Copper,

Polyvinyl Chloride, Polytetrafluorethylene,

Acetate, Paper

Lamp Spring – Tin Plated Music Wire

Pilot Light (9001SKP)

7

Gasket – Nitrile

Base – Thermoplastic Polyester

Trim Washer – Polypropylene

Locking Thrust Washer – Thermoplastic Polyester

Ring Nut – Thermoplastic Polyester

Color Cap – Polycarbonate

8

9

10

Product range:

page 36

40

References:

page 41

Dimensions:

page 60

Mounting:

page 61

Harmony™ 9001K/SK/KX

30 mm push buttons

References (continued)

9001SK – Multi-function operators

Note: When ordering, add prefix “9001” to the reference.

30 mm Multi-function Operators — UL Types 4, 4X, 13/NEMA 4, 4X, 13

Non-Illuminated Push-pull Screw-on Mushroom Operators

Description Color

3-Position

Momentary PullMaintained NeutralMomentary Push

(2) (7)

2-Position (1)

9001SKR9R

Maintained PullNon-Illuminated

1-5/8 in Diameter Knob Maintained Push (2)

Includes 9001KN179WP

Legend Plate Marked

Pull To Start / Push To Stop

With 2 N.C.

Contacts

(1 KA3, 1 KA5)

With 1 N.O. / 1

Without

N.C.

Contacts (6)

Contact (1 KA1)

Red

SKR8RH25

—

SKR8R

Green

SKR8GH25

—

SKR8G

Other

SKR8bH25

—

SKR8b

Red

—

SKR9RH13

SKR9R

Green

—

SKR9GH13

SKR9G

Other

—

SKR9bH13

SKR9b

Positions for 9001SKR8RH1 or H13

(KA1)

KA3

KA2

PULL

x

O

CTR

O

O

Positions for 9001SKR8H25

PUSH

O

x

KA3

KA5

KA2

PULL

x

x

O

CTR

O

x

O

1

2

PUSH

O

O

x

3

O = contact open; x = contact closed

Non-Illuminated Turn-to-release Mushroom Operators

Description Color

2-Position Trigger-Action,

Turn-to-Release 1-5/8 in.

(40 mm) Non-Removal

Plastic Mushroom

9001SKR16H2

Red

With 2 N.O. / 2

N.C. Contacts

(2 KA1)

SKR16H2

4

Without

Contacts

SKR16

5

Complies with EN418/ISO13850

standards for Emergency Stop

push buttons when used with

circular Legend Plate 9001KN8330

(90 mm diameter) or 9001KN9330

(60 mm diameter). See page 56.

Illuminated Push-pull Mushroom Operators

Description Voltage

9001SKR9P1

1-5/8 in Diameter Knob

with “Pull To Start / Push

To Stop” 9001KN379

Legend Plate

With 1 N.O.

Contact

(KA1)

SKR16H13

With Red Knob

and 2 N.C.

Contacts

(1 KA3, 1 KA5)

3-Position

110–120 V, 50–60 Hz SKR8P1RH25

Momentary PullMaintained Neutral- Other—Transformer, SKR8PcRH25

Momentary Push

LED, Flashing (4)

(2) (3) (7)

Other—Full Voltage, SKR8PcRH25

Resistor, Neon (5)

Description

Voltage

With Red a Knob

and 1 N.O. & 1

N.C. Contact

(KA1)

2-Position

Maintained PullMaintained Push

(2) (3) (7)

For 1-3/8 in or 2-1/4 in

Diameter Knob (1)

With Other Color With Other

Knob and 2 N.C. Color

Knob Without

Contacts

Contacts (6)

SKR8P1bH25

SKR8P1b

SKR8PcbH25

SKR8Pcb

SKR8PcbH25

SKR8Pcb

With Other Color

Knob and 1 N.O.

& 1 N.C. Contact

(KA1)

With Other

Color

Knob Without

Contacts

110–120 V, 50–60 Hz SKR9P1RH13

SKR9P1bH13

SKR9P1b

Other—Transformer, SKR9PcRH13

L.E.D., Flashing (4)

Other—Full Voltage, SKR9PcRH13

Resistor, Neon (5)

SKR9PcbH13

SKR9Pcb

SKR9PcbH13

SKR9Pcb

(1) To obtain a red knob with “Push Emergency Stop” printed on the red

knob—substitute R05 in place of “R” .

(2) Replace b with the color code as chosen from the color code at right.

Example: SKR9b with a yellow knob = SKR9Y

(3) Replace c with the voltage assembly code as chosen from the

tables on page 54. Example: SKR8Pc with 277 V 50–60 Hz =

SKR8P8

(4) The knob must be the same color as the LED light module chosen;

e.g., for green LED, use green knob.

(5) On neon light modules, use clear knobs only.

(6) These operators can be ordered complete with contact blocks.

For maximum block usage, see page 51. Add the “H” number chosen

from page 51 to the end of the operator reference number and add

the cost of the “H” number to the operator cost.

(7) For positions, refer to the two tables below.

Color Codes

Color

Black (8)

Red

Green

Blue

Yellow

White

Orange (8)

Clear

Amber

Gray

SKR11, SKR12

B

R

G

L

Y

W

S

—

—

E

7

8

SKR8, SKR9

B

R

G

L

Y

W

S

C

A

—

9

10

(8) These colors are not available on illuminated push-pull operators.

To select and order Contact Blocks, Light Modules, Knobs, and Accessories, see pages 50 to 59.

Product range:

page 36

Specifications:

page 38

Dimensions:

page 60

6

Mounting:

page 61

43

Harmony™ 9001K/SK/KX

30 mm push buttons

References (continued)

9001SK – Contact blocks

Note: When ordering, add prefix “9001” to the reference.

Contact Block “H” Codes

The design of the 9001KA contact blocks allows them to be mounted side by side and/or in tandem. This enables you to specify an operator and

a particular arrangement of contact blocks (shipped completely assembled) with a single reference number. See page 50 for a description of

contact blocks.

Suffix No. (Add to

Operator Reference)

POS 2 POS 4 POS 6

POS 1 POS 3 POS 5

H1

H2

H3

H4

H5

H6

H7

H8

H9

H10

H11

H12

H13

H14

H15

H16

H17

H18

H19

H21

H23

H24

H25

Side 1 Side 2

Locating Notch

Example: A 9001KR1B push button with 2 9001KA1

contact blocks would be 9001KR1BH2.

1

KA1

KA1

KA1

KA1

KA2

KA3

KA2

KA3

KA4

KA4

KA1

KA2

KA2

KA2

KA1

KA3

KA1

KA2

KA1

KA1

KA5

2

KA1

KA1

KA1

KA2

KA3

KA1

KA5

KA1

KA3

KA1

KA3

KA3

KA3

KA1

KA1

KA1

KA3

KA1

KA2

KA3

Positions

3

4

5

6

KA1

KA1

KA1

2

KA2

KA1

KA3

3

KA2

KA3

KA2

KA3

KA1

KA1

KA3

KA1

KA1

KA1

KA1

KA1

5

2.10

(53)

6

1.60

(41)

0.56

(14)

1.66

(42)

2.63

(67)

.97

(25)

Standard Blocks

4

Note: For “H” Codes not shown in this table, contact your local Schneider Electric representative.

Dimensions When Using Contact Blocks

Panel Thickness

.25 max.

.06 min.

Panel Thickness

(2)

(6)

1/16 min.-1/4 max.

1

0.56

(14)

3.66

(93)

7

Reed Blocks

Maximum Contact Block Usage:

2 blocks mounted side by side only: Any 2, 3 or 4-Position spring return selector switch (non-illuminated, illuminated or keyed).

8

2 blocks mounted in tandem on one side only: Any 2 operator interlocked push button.

2 blocks mounted in tandem (total of four blocks): Any selector push button, keyed push button, 2, 3, or 4-Position maintained

selector switch (non-illuminated, illuminated or keyed), push pull operators (non-illuminated or illuminated), joy stick, dual

push button.

3 blocks mounted in tandem (total of six blocks): Single mo­mentary push buttons (non-illuminated or illuminated).

9

10

Product range:

page 36

Specifications:

page 38

Dimensions:

page 60

Mounting:

page 61

51

Harmony™ 9001K/SK/KX

30 mm push buttons

References (continued)

9001SK – Light modules

Note: When ordering, add prefix “9001” to the reference.

Standard Light Modules for 9001SK Control Units (1)

1

Voltage

Description

Light Module

Reference

All

Full Voltage

(without Bayonet Base Lamp)

Full Voltage

LED Red

LED Green

LED Yellow

Full Voltage

LED Red

LED Green

LED Yellow

Resistor

Full Voltage

LED Red

LED Green

LED Yellow

LED White

LED Blue

Full Voltage

LED Red

LED Green

LED Yellow

Transformer

Flashing

Resistor

Full Voltage

Neon

LED Red

LED Green

LED Yellow

LED White

LED Blue

Transformer

LED Red

LED Green

LED Yellow

LED White

LED Blue

Transformer

LED Red

LED Green

LED Yellow

LED White

LED Blue

Resistor

Neon

Transformer

Transformer

Neon

Transformer

6 Vac/Vdc

6 Vac/Vdc

6 Vac/Vdc

6 Vac/Vdc

12–14 Vac/Vdc

12–14 Vac/Vdc

12–14 Vac/Vdc

12–14 Vac/Vdc

18 Vac/Vdc

24–28 Vac/Vdc

24–28 Vac/Vdc

24–28 Vac/Vdc

24–28 Vac/Vdc

24–28 Vac/Vdc

24–28 Vac/Vdc

48 Vac/Vdc

110–120 V, 50–60 Hz

110–120 V, 50–60 Hz

110–120 V, 50–60 Hz

110–120 V, 50–60 Hz

110–120 V, 50–60 Hz

120 Vac/Vdc

120 Vac/Vdc

120 Vac/Vdc

120 Vac/Vdc

120 Vac/Vdc

120 Vac/Vdc

120 Vac/Vdc

120 Vac/Vdc

208–220 V, 50–60 Hz

208–220 V, 50–60 Hz

208–220 V, 50–60 Hz

208–220 V, 50–60 Hz

208–220 V, 50–60 Hz

208–220 V, 50–60 Hz

220–240 V, 50–60 Hz

220–240 V, 50–60 Hz

220–240 V, 50–60 Hz

220–240 V, 50–60 Hz

220–240 V, 50–60 Hz

220–240 V, 50–60 Hz

240 Vac/Vdc

240 Vac/Vdc

277 V, 50–60 Hz

380–480 V, 50–60 Hz

480 Vac/Vdc

550–600 V, 50–60 Hz

2

3

4

5

6

7

Replacement Lamp

Reference

KM40

Voltage

Rating

Assembly

Code

40

—

KM31

KM31LR

KM31LG

KM31LY

KM32

KM32LR

KM32LG

KM32LY

KM33

KM35

KM35LR

KM35LG

KM35LY

KM35LW

KM35LL

KM36

KM1LR

KM1LG

KM1LY

KM1

KMF1

KM38

KM38

KM11

KM38LR

KM38LG

KM38LY

KM38LW

KM38LL

KM3

KM3LR

KM3LG

KM3LY

KM3LW

KM3LL

KM7

KM7LR

KM7LG

KM7LY

KM7LW

KM7LL

KM25

KM12

KM8

KM5

KM14

KM6

31

31LR

31LG

31LY

32

32LR

32LG

32LY

33

35

35LR

35LG

35LY

35LW

35LL

36

1LR

1LG

1LY

1

F1

38

38

11

38LR

38LG

38LY

38LW

38LL

3

3LR

3LG

3LY

3LW

3LL

7

7LR

7LG

7LY

7LW

7LL

25

12

8

5

14

6

2550101020

6508805201

6508805203

6508805202

2550101037

6508805201

6508805203

6508805202

2550101037

2550101002

6508805210

6508805212

6508805211

6508805214

6508805213

2550101025

6508805201

6508805203

6508805202

2550101020

2550101036

2550101027

2550101027

2550101013

6508805210

6508805212

6508805211

6508805214

6508805213

2550101020

6508805201

6508805203

6508805202

6508805215

6508805216

2550101020

6508805201

6508805203

6508805202

6508805215

6508805216

2550101027

2550101013

2550101020

2550101020

2550101013

2550101020

.9 VA

1.2 VA

1.4 VA

1.2 VA

.28 VA

.28 VA

.28 VA

.28 VA

.28 VA

2.6 VA

2.4 VA

.85 VA

3.0 VA

3.0 VA

0.2 VA

1.4 VA

1.4 VA

1.4 VA

1.4 VA

1.4 VA

2.5 VA

2.0 VA

6.0 VA

0.3 VA

2.4 VA

2.8 VA

0.5 VA

2.5 VA

no lamp included

(1) For use with all operators except KX and remote test pilot.

Notes: Light modules are available in other voltages, as shown above. For use in hazardous locations, see page 53. With neon type light modules,

use a clear color cap only. With LED light modules, use either a clear color cap or a cap the same color as the LED.

8

Shallow Depth Light Modules For 9001SK Control Units (2)

9

Voltage

Description

24–28 Vac/Vdc

Full Voltage

LED Red

LED Green

LED Yellow

Full Voltage

LED Red

LED Green

LED Yellow

110–120 Vac/Vdc

Light Module Voltage

Reference

Assembly

Code

KM55

55

KM55LR

55LR

KM55LG

55LG

KM55LY

55LY

KM58

58

KM58LR

58LR

KM58LG

58LG

KM58LY

58LY

Rating

Replacement Lamp

Reference

1.2 VA

0.5 VA

2550101002

6508805204

6508805206

6508805205

2550101027

6508805204

6508805206

6508805205

3.0 VA

0.5 VA

(2) For use with all operators except KX and remote test pilot.

Notes: For use in hazardous locations, see page 53. Reduces the depth of illuminated push buttons with contact blocks by over 33%. With LED light

modules, use a cap that is the same color as the LED.

10

File

CCN

Product range:

page 36

54

Specifications:

page 38

E42259

NKCR

File

Class

Dimensions:

page 60

LR25490

3211 03

marked

Mounting:

page 61

Harmony™ 9001K/SK/KX

30 mm push buttons

References (continued)

9001SK – Replacement parts

Ring Nuts

Repair Parts

Used On

Reference

Description

Reference

SK1L

—

—

SK20, SK21, SK22, SK23

9001SK44

—

—

9001SK45

SK20, SK21, SK22, SK23 (3)

9001SK46

SK2L

—

—

SKP, SKTR

SKR1

SKR11

SKR12 (1)

SKR12 (2)

—

SKR2

—

—

SKR25

SKR3

SKR4

SKR5

—

—

—

SKR8

SKR9

SKS

SKS (3)

SKRU11

SKRU1,2,3,4,5,10

SKT

9001SK49

—

—

9001SK41

9001SK41

9001SK42

9001SK42

9001SK41

—

9001SK42

—

—

9001SK49

9001SK40

9001SK41

9001SK41

—

—

—

6509704401

9001SK41

9001SK45

9001SK46

9001SK41

9001SK40

9001SK49

E10 Key

Gray cap for 9001SKR11, or 9001SKR12

Clear plastic top (only) for 9001SK44 Ring Nut

Gasket for 9001K and 9001SK Push-pull Knob

Gasket for Plastic Illuminated Lens

Gasket for 9001SK selector switch knob

Black Compensating Gasket

Liner for Non-Illuminated Operators

Locking Thrust Washer

Nylon Spacer

Locking Thrust Washer (Std. 9001SK Operator)

Push-pull Mushroom Adapter (5)

Rubber Boot for Joystick

Knob on Joysticks without latch

Knob for SK Potentiometer

Fingersafe Cover for 9001KM

2941101100

3105217001

4487D63XI

6509701801

6509701901

3105406401

6509702001

6509704901

6512231201

6509705001

6512240601

9001K54

6512243201

4458D20X3

3105404408

6508804101

KU Replacement Ring Nuts

(Threaded Inside and Out)

Used On

Reference

KU1 through KU8, KU27, KU37, KU47

KU17, KU18

3105204101

3105205901

Interlock

3

Schneider Electric

Replacement Lamp Reference

—

2550101003

—

2550101003

—

—

—

—

2550101020

2550105014

2550105014

2550105014

2550105014

2550105014

2550105003

2550105003

2550105008

2550105005

2550105007

2550105003

2550105004

2550105008

2550105009

2550105010

2550105005

4

For mechanically interlocking two push buttons so that only one

button can be depressed at a time. A K3 attachment is

furnished with the 9001SKR11,SKR12, SKRU1 and SKRU11

operators. However, these are maintained operators and the

K3 interlock serves to release one of the buttons when the

other is depressed. When used with momentary contact

buttons, the K3 interlock does not hold the buttons in the

depressed position. It simply prevents pushing both buttons at

the same time.

The K3 interlock is mounted behind the operators. Operators

not included.

Replacement Lamps For Series A–F (black)

Light Modules

Lamp Number

(ANSI)

GE44 (4)

GE1490

GE44 (4)

GE1490

GE44 (4)

GE44 (4)

GE44 (4)

GE44 (4)

GE755

CMDK1A5

CMDK1A5

CMDK1A5

CMDK1A5

CMDK1A5

SYL12PSB

SYL12PSB

SYL28PSB

SYL120PSB

SYL6PSB

SYL12PSB

SYL24PSB

SYL28PSB

SYL48PSB

SYL60PSB

SYL120PSB

2

(5) Allows Type -20 and -21 mushroom color caps to be used on push-pull operators. Use of

9001K54 voids Type 6 rating.

(1) Maintained button of two button operator.

(2) Momentary button of two button operator.

(3) Secondary ring nut (holds knob on selector switch or potentiometer).

Light

Module Reference

KM1

KM2

KM3

KM4

KM5

KM6

KM7

KM8

KM9

KM11

KM12

KM13

KM14

KM15

KM21

KM22

KM23

KM25

KM31

KM32

KM34

KM35

KM36

KM37

KM38

1

Reference

Specifications:

page 38

Dimensions:

page 60

6

9001K3

Screwdriver

Reference

9001K69

Used to tighten mounting screws on contact blocks and light modules.

Wrenches

K95

7

K1

8

Where Used

9

Reference

For tightening ring nuts on 22 and 30 mm control units 9001K95

For protective cap kits

9001K1

10

(4) GE44 and GE755 are interchangeable (GE755 gives longer life). If a GE44 lamp is

ordered, a GE755 (2550101020) will be substituted. For a replacement lamp in a current

series light module see the light module listing on page 54.

Product range:

page 36

5

Mounting:

page 61

59

Push Buttons and Operator Interface - Type K and SK, 30 mm

Light Modules Type K, SK, KX, and T

Standard Light Modules for Types K, SK,. and KX Control Units ➃

For use in hazardous locations – See page 150.

• Neon type light modules — use CLEAR color caps only.

• LED light modules require the color cap color and the LED color be the same or use a clear color cap.

Voltage

2.78 in

70.61 mm

Standard

Duty

Shallow

Depth

1.75 in

44.45 mm

Dual Dimensions inches

mm

Description

For Use

With Single Lamp Ill.

Operators as

Indicated ➀

Light

Module

Type No. ➄

Voltage

Assembly

Code

Replacement Lamps ➂ ➃

Rating

Lamp

Number

(ANSI)

Lamp Part

Number ➄

6 Vac-dc

6 Vac-dc

6 Vac-dc

6 Vac-dc

Full Voltage

LED Red

LED Green

LED Yellow

All

All Except ➁

All Except ➁

All Except ➁

KM31

KM31LR

KM31LG

KM31LY

31

31LR

31LG

31LY

0.9 VA

0.65 VA

0.65 VA

0.65 VA

755

2550101020

6508805201

6508805203

6508805202

12-14 Vac-dc

12-14 Vac-dc

12-14 Vac-dc

12-14 Vac-dc

Full Voltage

LED Red

LED Green

LED Yellow

All

All Except ➁

All Except ➁

All Except ➁

KM32

KM32LR

KM32LG

KM32LY

32

32LR

32LG

32LY

1.2 VA

0.50 VA

0.50 VA

0.50 VA

756

2550101037

6508805201

6508805203

6508805202

18 Vac-dc

Resistor

All

KM33

33

1.4 VA

756

2550101037

24-28 Vac-dc

24-28 Vac-dc

24-28 Vac-dc

24-28 Vac-dc

Full Voltage

LED Red

LED Green

LED Yellow

All

All Except ➁

All Except ➁

All Except ➁

KM35

KM35LR

KM35LG

KM35LY

35

35LR

35LG

35LY

1.2 VA

0.50 VA

0.50 VA

0.50 VA

757

2550101002

6508805204

6508805206

6508805205

32 Vac-dc

Resistor

All

KM23

23

2.5 VA

757

2550101002

48 Vac-dc

48 Vac-dc

48 Vac-dc

48 Vac-dc

Full Voltage

LED Red

LED Green

LED Yellow

All

All Except ➁

All Except ➁

All Except ➁

KM36

KM36LR

KM36LG

KM36LY

36

36LR

36LG

36LY

2.6 VA

0.50 VA

0.50 VA

0.50 VA

48MB

2550101025

6508805204

6508805206

6508805205

60 Vac-dc

60 Vac-dc

60 Vac-dc

60 Vac-dc

Full Voltage

LED Red

LED Green

LED Yellow

All

All Except ➁

All Except ➁

All Except ➁

KM37

KM37LR

KM37LG

KM37LY

37

37LR

37LG

37LY

3.0 VA

0.50 VA

0.50 VA

0.50 VA

60MB

2550101026

6508805204

6508805206

6508805205

110-120 V, 25-30 Hz

110-120 V, 50-60 Hz

110-120 V, 50-60 Hz

Transformer

Transformer

Flashing

All Except ➁

All Except ➁

All Except ➁

KM2

KM1

KMF1

2

1

F1

2.2 VA

2.4 VA

0.85 VA

1490

755

267

2550101003

2550101020

2550101036

120 Vac-dc

120 Vac-dc

120 Vac-dc

120 Vac-dc

120 Vac-dc

120 Vac-dc

Resistor

Full Voltage

Neon

LED Red

LED Green

LED Yellow

All

All

All Except ➁

All Except ➁

All Except ➁

All Except ➁

KM38

KM38

KM11

KM38LR

KM38LG

KM38LY

38

38

11

38LR

38LG

38LY

3.0 VA

3.0 VA

0.2 VA

4.0 VA

4.0 VA

4.0 VA

120MB

120MB

NE51H

2550101027

2550101027

2550101013

6508805204

6508805206

6508805205

208-220 V, 50-60 Hz

Transformer

All Except ➁

KM3

3

2.5 VA

755

2550101020

220-240 V, 25-30 Hz

220-240 V, 50-60 Hz

220-240 V, 50-60 Hz

Transformer

Transformer

Flashing

All Except ➁

All Except ➁

All Except ➁

KM4

KM7

KMF7

4

7

F7

2.2 VA

2.0 VA

2.0 VA

1490

755

267

2550101003

2550101020

2550101036

240 Vac-dc

240 Vac-dc

Resistor

Neon

All Except ➁

All Except ➁ and KX

KM25

KM12

25

12

6.0 VA

0.3 VA

120MB

NE51H

2550101027

2550101013

277 V, 50-60 Hz

Transformer

All Except ➁

KM8

8

2.4 VA

755

2550101020

380 Vac-dc

Neon

All Except ➁ and KX

KM13

13

0.4 VA

NE51H

2550101013

380-480 V, 50-60 Hz

480 Vac-dc

Transformer

Neon

All Except ➁

All Except ➁ and KX

KM5

KM14

5

14

2.8 VA

0.5 VA

755

NE51H

2550101020

2550101013

550 Vac-dc

550-600 V, 50-60 Hz

Neon

Transformer

All Except ➁ and KX

All Except ➁

KM15

KM6

15

6

0.6 VA

2.5 VA

NE51H

755

2550101013

2550101020

Replacement lamps for Series G 120Vac LED Light Modules ➂

Voltage

Description

Lamp Part Number

120 Vac Only

LED Red

120 Vac Only

LED Green

6508805207

6508805209

120 Vac Only

LED Yellow

6508805208

Shallow Depth Light Modules For Types K and SK Control Units

For use in hazardous locations – See page 150. Reduces the depth of illuminated push buttons with contact

blocks by over 33%.

• LED light modules require the color cap color and the LED color be the same or use a clear color cap.

1.89

48.01

Side View

1.87

47.50

1.12

28.45

Side View

Shown with 9001 KA contact block

Voltage

Description

For Use With Single

Lamp Ill. Operators as

Indicated ➅

Light Module

Type No. ➄

Voltage

Assembly

Code

Rating

24-28 Vac-dc

24-28 Vac-dc

24-28 Vac-dc

24-28 Vac-dc

110-120 Vac-dc

110-120 Vac-dc

110-120 Vac-dc

110-120 Vac-dc

Full Voltage

LED Red

LED Green

LED Yellow

Full Voltage

LED Red

LED Green

LED Yellow

All Except ➁ and KX

All Except ➁ and KX

All Except ➁ and KX

All Except ➁ and KX

All Except ➁ and KX

All Except ➁ and KX

All Except ➁ and KX

All Except ➁ and KX

KM55

KM55LR

KM55LG

KM55LY

KM58

KM58LR

KM58LG

KM58LY

55

55LR

55LG

55LY

58

58LR

58LG

58LY

1.2 VA

0.5 VA

0.5 VA

0.5 VA

3.0 VA

0.5 VA

0.5 VA

0.5 VA

Replacement Lamps ➂ ➃

Lamp Number

Lamp Part

(ANSI)

Number ➄

757

120MB

2550101002

6508805204

6508805206

6508805205

2550101027

6508805204

6508805206

6508805205

➀ 9001 K, SK, KX.

➁ Do not use on any remote test version pilot light.

➂ LED lamps shown here will also function in Class 9001 Type J pilot lights.

➃ For Series A through F light modules – see page 158.

➄ All light modules with a LED above 12 V use a 14 V Bipolar LED.

➅ 9001K, SK, T

148

© 1999-2005 Schneider Electric All Rights Reserved

04/2005

Push Buttons and Operator Interface - Type K and SK, 30 mm

"H" Numbers

The design of the Class 9001 Type KA contact blocks allows

them to be mounted side by side and/or in tandem.

The system illustrated below has been set up to enable an operator and a particular arrangement of contact blocks to be

specified by a single type number. Operators and contact

blocks will be shipped completely assembled.

EXAMPLE: A Type KR1B push button with 2 Type KA1 contact

blocks would be Class 9001 Type KR1BH2.

Top View

For Types K and SK

Suffix No.

(Add to

Operator

Type No.)

H1

H2

H3

H4

H5

H6

H7

H8

H9

H10

H11

H12

H13

H14

H15

H16

H17

H18

H19

H21

H23

H24

H25

H26

H27

H28

H29

H31

H32

H33

H34

H36

H37

H38

H39

H40

H41

H42

H43

H44

H45

H46

H47

H48

H50

H51

H52

H53

H54

H55

H56

H57

H58

H59

H60

H61

H62

H63

H64

H66

H71

H72

H73

H74

H75

H76

H77

04/2005

Positions

1

KA1

KA1

KA1

KA1

KA2

KA3

KA2

KA3

KA4

KA4

KA1

KA2

KA2

KA2

KA1

KA3

KA1

KA2

KA1

KA1

KA5

KA1

KA3

KA1

KA1

KA2

KA1

KA5

KA3

KA3

KA5

KA1

KA3

KA1

KA2

KA3

KA1

KA2

KA5

KA1

KA5

KA5

KA3

KA4

KA4

KA1

KA2

KA5

KA1

KA1

KA2

KA1

KA1

KA3

KA3

KA3

KA3

KA1

KA1

KA1

KA1

KA1

2

KA1

KA1

KA1

KA2

KA3

KA1

KA5

KA1

KA3

KA1

KA3

KA3

KA3

KA1

KA1

KA1

KA3

KA1

KA2

KA3

KA1

KA3

KA3

KA4

KA2

KA1

KA3

KA1

KA2

KA2

KA2

KA1

KA1

KA2

KA1

KA2

KA2

KA2

KA2

KA3

KA1

KA3

KA3

KA1

KA2

KA5

KA2

KA2

KA4

KA5

KA2

KA2

KA2

KA2

KA2

KA1

KA3

KA5

KA1

KA2

KA3

KA2

3

KA1

KA1

KA2

4

5

6

KA1

KA1

KA3

KA2

KA3

KA2

KA3

KA1

KA1

KA1

KA1

KA3

KA1

KA1

KA1

KA4

KA3

KA1

KA1

KA5

KA1

KA3

KA1

KA3

KA3

KA2

KA2

KA3

KA3

KA4

KA3

KA2

KA3

KA4

KA2

KA2

KA3

KA2

KA2

KA5

KA4

KA3

KA4

KA3

KA3

KA2

KA2

KA2

KA1

KA1

KA5

KA3

KA3

KA2

KA3

KA3

KA3

KA5

KA3

KA2

KA1

KA1

KA2

KA3

KA5

KA1

KA3

KA5

KA3

KA2

KA3

KA2

KA3

Suffix No.

(Add to

Operator

Type No.)

H78

H79

H80

H81

H82

H83

H86

H87

H89

H90

H91

H92

H93

H94

H95

H97

H98

H99

H100

H101

H102

H103

H104

H105

H106

H107

H109

H110

H111

H112

H113

H114

H115

H116

H117

H118

H119

H120

H121

H122

H124

H125

H126

H127

H128

H129

H130

H131

H132

H133

H134

H135

H136

H137

H138

H139

H140

H141

H142

H143

H144

H145

H146

H147

H148

H149

H150

H151

H152

H153

H154

H155

H156

H157

H158

H159

H161

H162

H163

H164

H165

H166

H167

H168

H170

H171

H172

H173

H174

H175

H176

H177

H178

H179

Positions

1

2

KA1

KA3

KA4

KA1

KA12

KA35

KA3

KA3

KA3

KA1

KA1

KA1

KA3

KA1

KA2

KA1

KA1

KA2

KA1

KA2

KA1

KA1

KA1

KA31

KA31

KA3

KA3

KA3

KA4

KA33

KA1

KA21

KA3

KA3

KA2

KA1

KA1

KA3

KA3

KA1

KA2

KA3

KA4

KA1

KA12

KA33

KA2

KA2

KA1

KA1

KA2

KA2

KA2

KA1

KA1

KA3

KA1

KA2

KA3

KA2

KA3

KA1

KA1

KA5

KA42

KA43

KA41

KA2

KA2

KA2

KA2

KA3

KA3

KA3

KA3

KA45

KA3

KA5

KA44

KA43

KA1

KA3

KA51

KA53

KA53

KA51

KA71

KA71

KA1

KA53

KA4

KA42

KA1

KA1

KA1

KA1

KA52

KA2

K85

K85

KA55

KA22

KA54

KA53

KA23

KA54

KA1

KA6

KA4

KA3

K85

KA53

KA31

KA2

KA3

KA3

KA4

KA33

KA1

KA1

KA1

KA3

KA5

KA1

KA4

KA3

KA3

KA3

KA5

3

4

KA5

KA2

KA13

KA5

KA5

KA5

KA3

KA13

5

KA3

KA3

KA2

KA3

KA3

KA1

KA3

KA3

KA1

KA3

KA2

KA2

KA5

KA3

KA3

KA3

KA1

KA2

KA2

KA2

KA2

KA2

KA3

KA3

KA2

KA5

KA2

KA3

KA4

KA3

KA5

KA1

KA2

KA1

KA2

KA3

KA5

KA3

6

KA3

KA3

KA2

KA2

KA2

KA2

KA2

KA2

KA3

KA3

KA5

KA5

KA3

KA1

KA3

KA2

KA2

KA5

KA3

KA3

KA3

KA2

KA5

KA5

KA3

KA3

KA2

KA3

KA2

KA3

KA2

KA45

KA3

KA5

KA43

KA1

KA1

K85

KA2

KA3

KA3

KA2

KA2

KA2

KA5

KA44

KA2

KA3

KA2

KA2

KA44

KA2

KA41

KA5

KA4

KA52

KA51

KA71

KA71

KA2

KA52

KA5

KA43

KA1

KA2

KA53

KA2

KA1

KA2

KA1

KA1

KA3

KA3

K85

KA5

KA4

KA4

KA22

KA23

KA22

KA51

KA51

KA23

KA51

KA3

KA2

KA1

KA2

KA2

KA2

KA3

KA2

KA4

KA51

KA1

KA5

KA3

KA5

KA4

KA3

KA55

“H” Numbers not shown in their sequence are no longer used.

151

© 1999-2005 Schneider Electric All Rights Reserved