National Measurement System Programme for Engineering

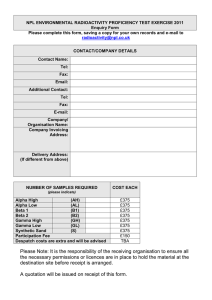

advertisement