1221 29th St. NW, Suite D

Auburn, WA 98001

(206) 529-4828

help@novinium.com

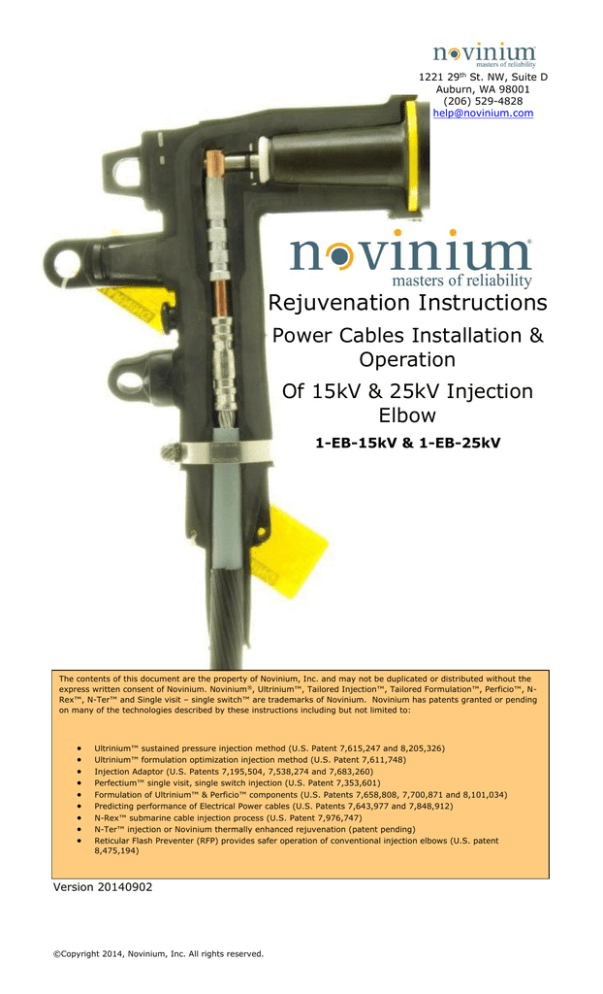

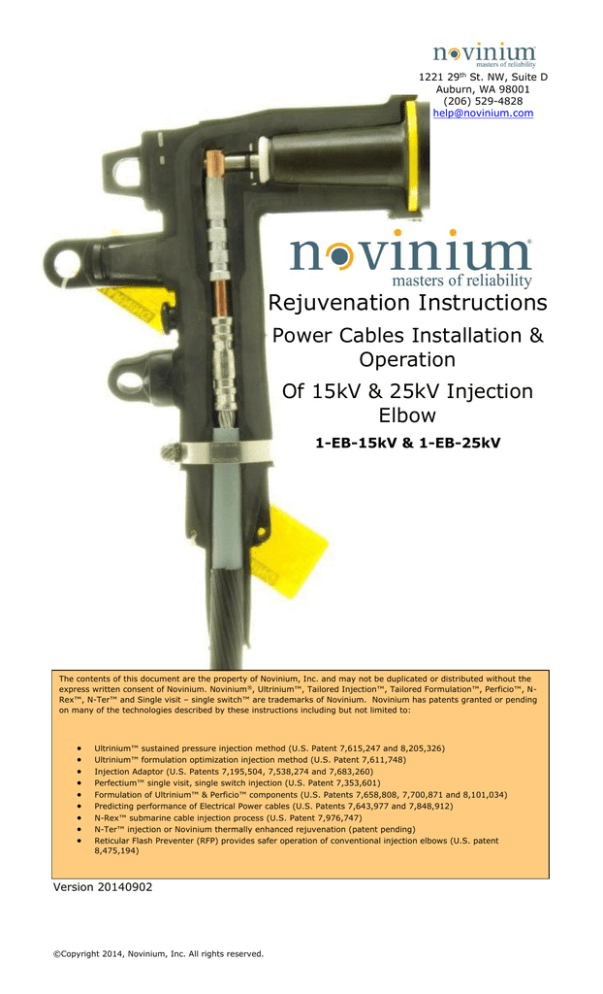

Rejuvenation Instructions

Power Cables Installation &

Operation

Of 15kV & 25kV Injection

Elbow

1-EB-15kV & 1-EB-25kV

The contents of this document are the property of Novinium, Inc. and may not be duplicated or distributed without the

express written consent of Novinium. Novinium®, Ultrinium™, Tailored Injection™, Tailored Formulation™, Perficio™, NRex™, N-Ter™ and Single visit – single switch™ are trademarks of Novinium. Novinium has patents granted or pending

on many of the technologies described by these instructions including but not limited to:

Ultrinium™ sustained pressure injection method (U.S. Patent 7,615,247 and 8,205,326)

Ultrinium™ formulation optimization injection method (U.S. Patent 7,611,748)

Injection Adaptor (U.S. Patents 7,195,504, 7,538,274 and 7,683,260)

Perfectium™ single visit, single switch injection (U.S. Patent 7,353,601)

Formulation of Ultrinium™ & Perficio™ components (U.S. Patents 7,658,808, 7,700,871 and 8,101,034)

Predicting performance of Electrical Power cables (U.S. Patents 7,643,977 and 7,848,912)

N-Rex™ submarine cable injection process (U.S. Patent 7,976,747)

N-Ter™ injection or Novinium thermally enhanced rejuvenation (patent pending)

Reticular Flash Preventer (RFP) provides safer operation of conventional injection elbows (U.S. patent

8,475,194)

Version 20140902

©Copyright 2014, Novinium, Inc. All rights reserved.

Installation & Operating Instructions

Novinium 1-EB-15kV & 1-EB-25kV

Loadbreak Injection Elbow Connectors

CONTENTS: Elastimold® Elbow, Probe with O-ring, Probe Wrench, Lubricant (Do Not Substitute),

Hose Clamp, Installation & Operating Instructions (NRI 36), templates (4), cable ties, Reticular Flash

Preventer™ (RFP), C-clip, retaining clip, and tags.

OTHER REQUIRED COMPONENTS: Copper-top compression lug, and, when extended length is

required, a Novinium specified splice compression lug and copper conductor.

The 1-EB-15kV and 1-EB-25kV injection elbows are designed to terminate underground distribution

cable having concentric neutral and extruded insulation shielding and provide an access port to

allow injection of Novinium® Ultrinium™ or Perficio™ rejuvenation fluid (Do not substitute). The

elbows provide operating interfaces for connecting respectively to 15kV class (8.3kV phase-toground and 14.4kV phase-to-phase) and 25kV class (15.2kV phase-to-ground and 26.4kV phaseto-phase) 200 ampere loadbreak bushing or accessory device with fault close ratings of 10,000

amperes RMS, symmetrical. 25kV class elbows may also be used on 28kV systems.

All apparatus must be de-energized during installation and removal of

part(s).

Do not energize this component before reading the entirety of this NRI 36.

DANGER

Do not touch or move energized products by hand.

Excess distortion of the assembled product may result in its failure.

Inspect parts for damage, rating and compatibility with mating parts.

All cable preparation must meet or exceed IEEE® P1816™ requirements.

This product should be installed only by qualified personnel trained in good

safety practices involving high voltage electrical equipment. These

instructions are not intended as a substitute for adequate training or

experience in such safety practices.

Direct contact with or close proximity to any of the following in an energized

system can result in electric shock, which will cause serious or fatal injury:

Uncovered elbow port, elbow with fluid access interface, fluid injection tube,

and fluid injection collection containers and fittings.

If fluid has been injected into elbow, there may be considerable pressure,

which will release when the fluid access injector or insulated cap is removed.

Always wear approved eye protection when installing or removing these

caps.

These instructions do not attempt to provide for every possible contingency.

Always exercise caution when working with electrical equipment.

Failure to follow these instructions could result in damage to the product and

serious or fatal injury

©Copyright 2014, Novinium, Inc. All rights reserved.

NRI-15-25kV (36) Page 2 of 14

Pre-Installation Instructions

IMPORTANT

1. Check Your Components

a) Check that the package is complete

and undamaged.

This component has the allowable

insulation diameter range in two units.

The top numbers are in millimeters

(mm) and the bottom numbers are in

inches.

b) Verify components properly fit the

cable and/or mating products.

If practical, the insulation diameter is

20 mils larger than the chosen elbow’s

minimum allowed insulation diameter

and less than or equal to the elbow’s

maximum allowed insulation diameter.

Refer to cable measurement

instructions in NRI 10.

The manufacturer’s allowable

insulation diameter range for this

component is .880-1.110”; Novinium

recommends an insulation O.D. range

of .900-1.110” to ensure a tight fit

c) Read this entire NRI before starting

work.

d) Have all required tools and supplies on

hand and maintain cleanliness

throughout the procedure.

CAUTION

The elbow access port provides

direct access to the cable

conductor. Contact with the

uncovered port or insertion of

objects other than the insulated

cap or fluid access interface fitting

can cause serious or fatal injury.

If the cable is energized during

injection, removal of the insulated

cap and the fluid access interface

must be done with a hot stick tool

following instructions in NRI 62.

2. Initial Inspection and Diagnosis

a) Remove the elbow or other

terminations to access the cable

strands.

Use a probe wrench to remove the

probe from the elbow.

With a back-and-forth twisting motion,

pull the elbow off the cable.

Save the elbow and probe for possible

re-use if the cable has to be replaced.

©Copyright 2014, Novinium, Inc. All rights reserved.

NRI-15-25kV (36) Page 3 of 14

b) Perform the inspection and diagnosis

procedures from NRI 10 and NRI 12.

NRI12: Electronic Cable

Diagnosis & Pinpointing

NRI 10: Visual Inspection &

Measurement

Choose an elbow and connector to match the

wire size and insulation diameter.

If the existing connector and cable

preparation quality are satisfactory

and meet IEEE® P1816™

requirements, the existing

connector may be kept with the

cutbacks modified per the nonextension, or standard templates.

If preparation is not satisfactory,

remove the existing connector

according to NRI 30 steps 1 and 2.

c) Determine if extending the cable

length is desirable and if a capacitive

test point is required.

Cut back the insulation shield and

insulation per the appropriate

template.

Existing

connector

Removal of existing

connector

Removal of existing

connector: see NRI 30

Use the non-extension

template on Page 16

Use the standard

template on Page 18

Use the #2-2/0 extension Use the 3/0 & 4/0 extension

template on Page 20

template on Page 22

d) If the existing connector was kept:

Rotate the connector 30 degrees

(or 1 full hour position on a clock)

in the opposite direction of the

strand lay.

Firmly tap the top of the connector

to open the strands and improve

flow.

Rotate the connector

to open strands

allowing flow

Tap old connector towards cable

If the original connector was removed:

Prepare the strands as instructed

in NRI 30, steps 8 through 13.

The insulation cut back must

include a 7/16” gap with strands

visible to allow a flow path into the

conductor strands.

7/16”

gap

Prepare new strands per

NRI 30 requirements

©Copyright 2014, Novinium, Inc. All rights reserved.

NRI-15-25kV (36) Page 4 of 14

3. Do a Flow Test

a) Perform a level 2 flow test with a CTA.

See NRI 50: Flow and Pressure

Testing.

You can perform an integrated flow

and pressure test using the injection

hardware by installing an injection

elbow (Steps 6 through 7).

b) If a termination using the original

connector does not flow, remove the

connector and prepare the strands as

required in step 1 for new connectors.

c) If a splice does not allow flow,

consider:

Using Sustained Pressure Injection

(SPR)

Replacing the blocked splice(s) per

NRI 33.

Recommend replacement of the

cable. See NRI 60, step 3.

4. Installing a New Compression Connector

If the existing connector was not kept,

install a new connector.

a) If a standard length connector can be

used, go to step 4d.

b) If extending the length is necessary,

install a coppertop extension and

splice connector according to the

appropriate template. (Step 2c

above)

Select the proper coppertop

extension and splice connector from

the table to the right.

c) Fully insert the copper conductor into

the splice connector and then slide it

completely onto the cable’s conductor.

AWG

Splice

#2, #1

1/0

2/0

3/0

4/0

ALCR9-8-NV

ALCR9-NV

ALCR10-9-NV

ALCR11-9-NV

ALCR12-9-NV

Extension Copper

Top

1-EC-EXTENSION-UPR

1-EC-EXTENSION-SPR

Pre-crimp length

must match template

Use the template to verify the precrimp length is correct.

d) Use the crimping tools and dies

specified for the connector. See this

NRI’s crimp table or NRI 30.

Fully insert cable and extension

conductors into splice connector

e) Crimp the standard length connector or

the splice connector for the extension.

The connector length should grow

about ¼” during crimping.

©Copyright 2014, Novinium, Inc. All rights reserved.

NRI-15-25kV (36) Page 5 of 14

f) Orient the cable to minimize cable

strain.

Assembled length matches template

Use the template to verify the length

of the connector assembly and 7/16”

gap to the insulation are shorter than

the maximum post-swage length.

5. Prepare the Termination

7/16” gap

a) Prepare and clean the cable

termination according to IEEE®

P1816™.

Necessary steps include:

Unwrap and bind concentric neutral

wires 1” away from end of elbow.

Remove insulation shield as in

template.

Bevel the insulation end if desired,

but no more than 1/8” max.

Thoroughly clean the insulation to

remove all conductive residue.

6. Prepare the Elbow

a) Remove the insulating cap and install

the retaining clip.

Unwrap and bind neutrals 1”

(25.4mm) from end of elbow.

1/8” MAX

insulation

taper

Remove

insulating

cap

Feed the warning tag and pulling eye

through the retaining clip slot.

Store the insulating cap assembly until

installation after injection completion.

b) Put the C-clip on the elbow, if it is not

already installed.

Place the C-clip in line with the

injection port on the opposite side.

Press on until fully seated.

If your injection elbow is an Elastimold®

elbow, go to step 7. Otherwise, skip to

step 8 on page 10.

7. Install a Reticular Flash

Preventer (RFP)

RFP – NPN: 1-UP-RFP,E

RFP Insertion Tool – NPN: 0-UP-RFPe-INSRT

Foam

a) Put the RFP, rigid disk first, into the

holder.

If a holder is not available, skip to

step 7d.

Rigid disk

©Copyright 2014, Novinium, Inc. All rights reserved.

Insert RFP with

rigid disk down

RFP Insertion

Tool Holder

NRI-15-25kV (36) Page 6 of 14

b) Press the RFP inserter into the holder

until the tip goes through the RFP, and

into the small hole in the holder on

the underside.

The RFP inserter is pushed

fully into holder; tip

inserts in small hole on the

underside.

c) Remove the RFP from the holder.

d) The RFP must be fully speared on the

RFP Inserter with the rigid disk facing

out.

Verify this is done correctly.

The RFP remains

on the inserter

Correct:

The RFP is on

the inserter,

with rigid

disk facing

out

Wrong:

The rigid disk faces

the inserter handle

e) Insert the RFP into the elbow’s fluid

access port using the RFP inserter.

Push the shoulder of the RFP inserter

firmly against the face of the fluid

access port.

The RFP inserter

is pushed fully

into the access

port.

The RFP will remain correctly installed

when the inserter is removed.

The RFP will stay in place

after the inserter is removed

f) Drip 5-10 drops of Novinium Fluid

from a bottle into the access port to

soak the RFP.

Flip Top Squeeze Bottle –

NPN:

0-FH-BTTL-40Z-FLIP

The RFP may also be wetted before

inserting into the access port.

The RFP must be saturated to function

properly.

©Copyright 2014, Novinium, Inc. All rights reserved.

NRI-15-25kV (36) Page 7 of 14

8. Install the Access Interface

(AI) or Fluid Injection Cap

(FIC)

AI installs on the fluid

access port and seals

with 2 O-rings

O-ring 1

If you are using an AI, continue

to step 8a. If you are using an

FIC, skip to step 8e.

O-ring 2

Release pin

with loop

a) Verify both AI O-rings are in place and

lightly lubricated with silicone grease.

Access Interface for 15 & 25kV –

NPN: 0-UP-AI-TUBE-QD

b) Press the release pin in until it is flush

with the open end of the dust cover.

c) Feed tie-wraps through the hole and

release slot on the dust cover in

opposite directions.

Feed

another

tie-wrap

into this

slot.

Feed a

tie-wrap

into this

hole

Tie-wrap heads should look like this:

Insert the tail of each tie-wrap around

the elbow and into the head of the

other tie-wrap. Don’t tighten yet and

don’t cross the wraps.

Head 1

Head 2

Tail 2 into

head 1

Heads

adjacent AI

d) Place the AI over the end of the

injection port.

Put the tie-wrap heads next to the AI

and evenly tight both wraps until the

body of the AI rests against the elbow

exterior.

Tail 1 into

head 2

Pull tails

Check that the AI is not tilted and

both ties are evenly tight. Trim the

excess from the tie-wraps.

Skip to step 9.

Using the FIC

Pull tails

Cinch tightly

and snip off

excess

Tie wraps

do not

cross

The FIC is very similar to the permanent cap.

It is advised to use the FIC retaining clip on

the FIC when available for increased safety.

The FIC retaining clip MUST be used when

required.

e) Slide the FIC in the Fluid Injection Cap

retaining clip if used. Similar to the

permanent cap and normal retaining clip.

f) Connect the FIC to your injection tank with

tubing, if not so already.

g) Fully install the FIC onto the injection

elbow.

AI is flush and

square to elbow

FIC

The retaining

clip must be

secured to the

C-clip

The FIC installs

similar to the regular

permanent cap

h) Secure the retaining clip, if used, to the Cclip on the elbow at this time. The C-clip

would have been installed in step 6b.

©Copyright 2014, Novinium, Inc. All rights reserved.

NRI-15-25kV (36) Page 8 of 14

FIC

Retaining Clip

AI or FIC, RFP, and

retaining clip are in

place before installing

9. Install the Elbow

a) Keep the strands free of grease.

Hose clamp here

DO NOT SUBSTITUTE THE

SUPPLIED GREASE!

Some components require a specific

grease to function properly. Changing

greases can cause a failure.

Avoid grease

on strands

Lubricate O-ring

Call Engineering to check if there will be

any problems using other grease.

b) Loosely position a hose-clamp on the

elbow body.

c) Slide the elbow onto the cable with a

back-sand-forth twisting motion.

Wipe off all excess grease.

d) Align the elbow with the compression

lug’s threaded hole.

e) Remove the protective cap on the

probe threads and lubricated the Oring on the probe.

Thread the probe into the lug by hand,

taking care not to cross-thread.

Tighten with the wrench until the

wrench bends.

10. Connect the Concentric Neutrals

a) Insert an end of No. 14 AWG (2.5mm)

copper wire or equivalent through the

ground eye on the elbow.

Twist tight but don’t damage the eye.

b) Twist the neutral wires and connect to

ground with the correct connector.

The bond wire is

attached to the

grounding eye

Provide adequate slack in wires for elbow

operation.

c) Check that all cable neutrals extend to within

1” of the elbow.

1” MAX

All neutral wires must extend to

within 1” of the elbow

©Copyright 2014, Novinium, Inc. All rights reserved.

NRI-15-25kV (36) Page 9 of 14

11. Final Elbow Prep

a) Tighten the hose clamp on the elbow snugly.

Tighten the hose

clamp until snug

The clamp is correctly tightened when the

outer clamp surface is even with the elbow

body.

Do not over tighten!

b) Attach your “Novinium Certified” craft tag to

the outside of the elbow.

Cover with 2-3 wraps of clear vinyl tape.

“Novinium Certified” Craft Tag –

NPN: 1-MI-CRAFT

Attach craft tag and

cover with vinyl tape

c) OPTIONAL: Connect the elbow and

bushing plug.

DO NOT HANDLE THE

BUSHING OR ELBOW

UNLESS THEY ARE KNOW

TO BE DE-ENERGIZED!

If possible, lubricate the receptacle of

the elbow and mating bushing on the

transformer with the supplied

lubricant.

Operate as shown.

DO NOT OPERATE BY HAND.

Use a hot stick to energize the elbow.

12. Inject the cable

Follow the instructions in:

NRI 62: Unsustained Pressure Rejuvenation

13. Disconnect the Injection Equipment

Remove the Access Interface (AI) or the

Fluid Injection Cap (FIC).

Be sure all pressure has been relieved

from the cable. See NRI 62.

©Copyright 2014, Novinium, Inc. All rights reserved.

NRI-15-25kV (36) Page 10 of 14

Removing the AI

Pull the yellow

loop

Pull the yellow loop on the release

pin with a hot stick and bring the

AI away from the elbow.

Gently nudging the pull ring from

side-to-side while pulling will ease

removal.

Pulling the pin allows the ties to fall

away from the AI, which releases it

from the elbow.

Pull AI

If the ties do not release, nudge it

with the end of the hot stick.

Removing the FIC

…then move AI

away from elbow

With the hot stick, grab the eye of

the FIC.

Twist the FIC and retaining clip up

to 90 degrees, until the retaining

clip comes free from the C-clip.

Grab the eye

with a hot stick

and twist to

unhook the

retaining clip

Pull the FIC and retaining clip free

from the elbow.

14. Install the Permanent Cap

a) Tightly secure the cap to the hot stick.

The hot stick’s metal ring presses

against the retaining clip during

installation.

b) Push the permanent cap onto the

elbow’s injection port.

Check that the retaining clip’s wings

are engaging the barbs of the C-clip.

If so, the cap is fully seated now.

The cap displaces the RFP into the

conductive insert of the elbow.

Pull cap tight to

hot stick with

retaining clip

Push cap onto

injection port

Retaining clip wings must

engage barbs of the C-clip

Cap pushes RFP

into conductive

insert.

©Copyright 2014, Novinium, Inc. All rights reserved.

NRI-15-25kV (36) Page 11 of 14

OPERATING INSTRUCTIONS

Before Loadmake or Loadbreak Operation:

Loadbreak connectors must be operated with an eight-foot long, fully-insulated “hotstick”

type of tool.

Remove fluid access interface and install Elbow Cap before operating elbow. For Injection

use, the AI is always installed before the elbow is put onto the bushing.

Area must be clear of obstructions or contaminants that can interfere with connector

operation.

Area should allow establishing firm footing and a secure grasp of the hotstick tool.

Maintain positive control over the movement of the loadbreak connector before, during,

and directly after the operating sequence.

Certain operating positions are more advantageous, because of the control, speed, and

force required to engage or disengage the elbow.

If there are questions on proper operating position, it is recommended that the connectors

be operated de-energized.

Do not connect two different phases of a multiple-phase system.

Before closing a single-phase loop, make certain both ends of the loop are the same phase.

LOADMAKE OPERATION:

Check appropriate accessory device operating instructions to be sure that the device is rated

for energized operation.

1. Area must be clear of obstructions or contaminants that can interfere with connector

operation.

2. When preparing the elbow connector bushing, attach the hotstick tool to the Bushing Cap

pulling eye. Following the instructions for this accessory, remove the cap from bushing.

3. Securely fasten a hotstick to the loadbreak connector pulling eye.

4. Establish firm footing and positive control of the elbow connector. Withdraw the elbow with

a fast, straight, firm motion from the accessory device on the apparatus parking stand. Be

careful not to place the elbow connector near a ground plane.

5. Place the elbow connector receptacle area over the bushing plug. Insert the elbow male

contact (arc follower portion) into the bushing until the first slight resistance is felt.

Resistance is felt when the arc follower portion of the male contact first meets the female

contact of the bushing (the contacts are approximately 2” apart).

NOTE: DO NOT HOLD IN THIS POSITION BUT IMMEDIATELY PUSH THE ELBOW

HOME WITH A FAST, FIRM, STRAIGHT MOTION, which will engage the internal lock on

the elbow and bushing interface. Apply sufficient force to engage the internal lock on the

elbow connector and bushing interface.

Fault Close:

1. It is not recommended that operations be made on known faults.

2. If a fault is experienced, both the elbow connector and the bushing must be replaced.

LOADBREAK OPERATION:

1. Place desired accessory device on apparatus parking stand. NOTE: Refer to

appropriate operating instructions for accessory device to be used. Be certain it is

rated for energized operation.

2. Firmly tighten a hotstick to the loadbreak connector pulling eye.

3. Without exerting any pulling force, slightly rotate the connector in order to break

surface friction prior to disconnection.

4. Withdraw the connector from the bushing with a fast, firm, straight motion, being

careful not to place the connector near a ground plane.

Place connector on appropriate accessory device, following the operating instructions

for that accessory.

©Copyright 2014, Novinium, Inc. All rights reserved.

NRI-15-25kV (36) Page 12 of 14

VOLTAGE TEST ON Novinium 1-EB-15kV and 1-EB-25kV:

The elongated versions of the Novinium 1-EB-15kV and 1-EB-15kV loadbreak elbow

connectors manufactured by Elastimold are equipped with integral capacitance test points

that can be used to establish whether or not the circuit is energized. All test instruments,

equipment, and accessories must be the appropriate type and rating for the application

they will be used. Proper functionality must be verified before and after an absence of

voltage test, per the individual equipment instructions. When using the test point,

complete the following steps:

1. Remove the test point cap with a hot stick. When removing the cap, PEEL OFF AT AN

ANGLE rather than pulling directly in line with the test point assembly.

2. Using a suitable sensing device, proceed to determine if cable is energized.

DO NOT USE CONVENTIONAL VOLTAGE MEASURING EQUIPMENT.

WARNING: THE VOLTAGE TEST POINT IS A CAPACITANCE DEVICE;

IT IS NOT DIRECTLY CONNECTED TO THE CONDUCTOR.

CONTAMINATION (MOISTURE, DIRT, ETC.) AROUND THE TEST POINT, OR USE

OF THE WRONG MEASURING EQUIPMENT CAN PROVIDE A FALSE "NO

VOLTAGE" INDICATION ON AN ENERGIZED ELBOW.

TO PREVENT SERIOUS OR FATAL INJURY TREAT THE ELBOW AS ENERGIZED

UNTIL THE "NO VOLTAGE" TEST POINT INDICATION IS CONFIRMED BY

OTHER MEANS.

3. After voltage detection has been made, clean the test point and then lubricate the

inside surface of the cap with silicone grease and replace it on the test point.

INJECTION APPLICATION SUPPLEMENT:

1. The elbow is deadfront only when the following conditions exist:

• The access port is covered with the insulated cap, and

• All shields are properly grounded.

2. When the fluid access interface (AI) is installed, the AI, elbow, injection and collection

tubes and containers are not shielded and must be treated as energized when used to

inject cable rejuvenation fluid.

During the injection process, water within the cable may be forced out the collection

tube. This water may be a conductive path from the energized conductor through the

unshielded fluid collection system. The tubing must be isolated from any grounded

surface by a distance greater than 1 inch.

The elbow shall not be disconnected during the injection process with the access

interface installed. The fluid access interface was designed for non-submersible

application only. Water submersion can cause electrical failure of the injection or

collection system resulting in an arc to ground. Call Novinium engineering at (206)

529-4828 for information on submersible application.

3M® is a registered trademark of 3M, Cooper® is a registered trademark of Cooper Power Systems, and Elastimold® is

a registered trademark of Thomas & Betts. Novinium is an original equipment manufacturer and service provider, and

is not affiliated with Thomas & Betts, Cooper, or 3M.

©Copyright 2014, Novinium, Inc. All rights reserved.

NRI-15-25kV (36) Page 13 of 14

Recommended Die Types/Sizes May 19, 2014

6-ton dies

12-ton dies

Connector Size

Connector

Barrel O.D.

(inches)

Burndy W-dies

Husky HT58

dies

Greenlee Udies

Novinium

Swage

Coppertop #4 to

2/0

0.635

W-BG, W-243

HT58G, HT58DM

U-BG, U-243

-

#2 to 2/0

0.687

W-245

HT58DP

U-245, U26ART

-

3/0

0.760

W-247, W-166

HT58DT

U-247, U27ART

-

Coppertop 3/0

to 4/0

0.785

W-247, W-166

HT58DT

U-247, U27ART

-

4/0

0.850

W-247, W-660

HT58DT

U28ART

0742

250 MCM

0.910

W-249

HT58DW

U-249, U29ART

0742

300 MCM

1.095

W-251

HT58DY

U-251, U30ART

0942

350 MCM

1.125

-

-

U31ART

0995

400 MCM

1.135

-

-

U32ART

0995

500 MCM

1.320

-

-

U34ART

1152

600 MCM

1.405

-

-

U36ART

1262

750 MCM

1.590

-

-

S39ART

1382

800 MCM

1.635

-

-

S40ART

1382

1000 MCM

1.840

-

-

S44ART

1598

©Copyright 2014, Novinium, Inc. All rights reserved.

NRI-15-25kV (36) Page 14 of 14