section 16140 wiring devices

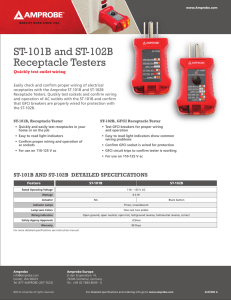

advertisement

CITY OF EDGEWATER FIRE STATION 55 50% CONSTRUCTION DOCUMENTS June 14, 2010 SECTION 16140 - WIRING DEVICES PART 1 - GENERAL 1.1 RELATED DOCUMENTS: The general provisions of the Contract and the requirements of Section 16050 apply to the Work specified in this Section. 1.2 SUMMARY: Provide a complete system of wiring devices properly wired, including a solid grounding connection. All devices shall be installed in outlet boxes of required size and volume. 1.3 1.4 QUALITY ASSURANCE: A. Underwriters Laboratories: Provide wiring devices which are listed and labeled by UL. Receptacles shall be listed per UL 498 including Supplement SA effective January 1, 1995. Speedwire terminals shall not accept AWG No. 12 solid wire. B. National Electrical Manufacturers Association: Wiring devices shall comply with NEMA Standards WD-1 and WD-6. C. Wet Locations: Wiring devices and their enclosures installed outdoors and in wet locations shall be approved for the purpose. SUBMITTALS: A. Provide submittals according to Section 16050. B. Product Data: 1. 2. 3. 4. 5. 6. Each device type, indicating, amperage and voltage rating, materials, NEMA designation, color and manufacturer's catalog sheet. Each device wall plate indicating material, thickness or gage, color and manufacturer's catalog sheet. Color approval: Submit manufacturer’s catalog page for each wiring device. Clearly mark item on catalog page to indicate color. Submit to Architect for approval of color. For wall switches, submit manufacturer’s features sheet to verify silver alloy contacts. For receptacles, submit manufacturer’s catalog page to verify one-piece backstrap with ground pin punched out of strap. Ground pin contacts that are a separate piece and riveted or otherwise affixed to the backstrap are unacceptable. Ground Fault Circuit Interrupter Receptacles: Submit evidence that GFCI receptacles are listed under UL Standard 943 with revisions effective January 1, 2003. proof of UL listing under Standard 514A. WIRING DEVICES 16140-1 CITY OF EDGEWATER FIRE STATION 55 50% CONSTRUCTION DOCUMENTS June 14, 2010 PART 2 - PRODUCTS 2.1 GENERAL: All devices shall be suitable for use intended, and have voltage and current ratings adequate for loads served. All receptacles shall have a grounding pole unless specifically indicated otherwise, and shall be self-grounding. All switches shall have a grounding terminal. 2.2 DEVICE COLORS: A. 2.3 Standard Device Color: White, unless otherwise noted. STANDARD DEVICES: A. Manufacturers: 1. 2. Acceptable: The following manufacturers will be acceptable providing they meet the project specifications: Cooper Wiring Devices (includes former Arrow-Hart brand), Woodhead Industries, Inc., Hubbell , Leviton , Pass & Seymour/Sierra/Slater . Source: Each type of wiring device shall be furnished by one manufacturer. B. Wall Switches: 20A_120_277V AC contacts. Toggle type, quiet action. Contacts shall be formed of silver alloy. Toggle switch shall have provisions for back wiring with screw actuated clamp type terminals, side wiring with captively held binding screws, and separate screw terminal for the grounding wire. Screwless push-in wiring terminals shall not be used. Provide single pole, single throw, unless drawings indicate 3_way, 4_way, double pole, key operated, SPDT momentary, or any other special features. Pass and Seymour 20AC Series. C. Switches for Special Purposes: Special switches used for disconnection purposes (small appliances, etc.) shall be rated as specified above for "Wall Switches". Where required provide 30A contacts (Pass and Seymour 30AC1 Series). Where motors are switched, the switch shall have a horsepower rating adequate for the motor. D. Switches with Pilot: Contacts as specified under "Wall Switches" above. Pilot light switches shall have red pilot indicator that "lights when ON". "Locator" switches shall have pilot that "lights when OFF". E. Standard Convenience Outlet: 20A/125V/2 Pole/3 Wire Duplex. NEMA 5_20R. Receptacle shall have provisions for back wiring from eight separate wiring openings with screw actuated clamp type terminals and side wiring with captively held binding screws. Receptacle face shall be high-impact resistant nylon. Body shall be thermoplastic polyester. Mounting strap shall be solid brass, one-piece design to wrap completely around receptacle body and have integral, no-rivet grounding contacts. The receptacle grounding contacts are formed directly out of the backstrap metal, they shall not be separate pieces riveted to the backstrap. Hubbell 5362, Leviton 5362A or Pass and Seymour 5362-A. WIRING DEVICES 16140-2 CITY OF EDGEWATER FIRE STATION 55 F. 50% CONSTRUCTION DOCUMENTS June 14, 2010 Power Receptacles: 1. 2. 3. 4. 5. 6. 7. 20A/125V: Single receptacle, NEMA 5-20R. Pass and Seymour Series 5361, Hubbell 5361 20A/250V: Single receptacle, NEMA 6-20R. Pass and Seymour Series 5871. 30A/125V: NEMA 5-30R. Hubbell 9308 (Standard Color) 30A/250V: NEMA 6-30R. Hubbell 9330 (Standard Color) 50A/250V: NEMA 6-50R. Hubbell 9367 (Standard Color) Range Outlet: 50A/125/250V. NEMA 14-50R Hubbell 9450A (standard black color) flush receptacle and wall plate. Special: Provide special power receptacles where indicated on the drawings. Special receptacles shall be similar to those specified above in quality. Determine NEMA pin configuration from the actual appliance to be installed. G. Locking Devices: Provide locking NEMA type receptacles which otherwise meet the specification above where required. H. Ground Fault Circuit Interrupters: 1. 2. 3. 4. 5. Provide U.L. listed ground fault circuit interrupter receptacles for personnel protection, which otherwise meet this specification, where required. GFCI receptacles shall be UL listed under UL Standard 943 including revisions effective January 1, 2003. Interrupters shall have a trip threshold of 5 + 1 mA; a trip time of .025 seconds, nominal, per U.L. Standard for Class A. GFCI shall have feed-through design to protect any receptacles installed downstream on same circuit. Refer to Part 3 for GFCI installation and testing. GFCI wiring device shall be entirely white plastic, including the Test and Reset buttons. I. Cords and Plugs: Provide a plug for special receptacles indicated on the drawings. Plugs shall mate with specified receptacle. Plugs shall be suitable for gripping the cord that is to be installed. Provide a cord of type and length required if so indicated on the drawings. J. Key Lock Switches: 1. 2. 3. 4. 5. 6. 7. 8. Provide key lock switches for corridor lighting and other locations indicated on Electrical Drawings. 20 Amp rated. 120/277 Volt ac rated Key-lock mechanism can only be turned ON or OFF using key. Key can be removed in both the ON and OFF positions. Nickel-plated key lock dome for rust-resistance. Single pole: Leviton 1221-2KL, Cooper Wiring Devices (former Arrow-Hart 119x Series), P&S Cat. No. PS20AC1-KL, or approved equal. 3-Way: Leviton 1223-2KL, Cooper Wiring Devices (former Arrow-Hart 119x Series), P&S Cat. No. PS20AC3-KL, or approved equal. 4-way: Leviton 1224-2KL, Cooper Wiring Devices (former Arrow-Hart 119x Series), P&S Cat. No. PS20AC4-KL, or approved equal. WIRING DEVICES 16140-3 CITY OF EDGEWATER FIRE STATION 55 9. 10. 2.4 Provide 302 Stainless Steel wall plate for each switch. Install with tamperresistant screws. Install flush mount unless surface mount indicated on Drawings. Provide shallow wall-box extender where required. Provide FD box for surface installations. WALL PLATES: A. General: Provide wall plates for all devices. Provide one-piece multi-gang plates where adjacently located outlet assemblies occur (includes multi-switch installation). Isolated ground receptacles shall be installed with individual cover plates and not grouped with other device types behind a multi-gang plate. Unless otherwise detailed or specified line voltage wall box dimmers and low voltage signal cable outlets shall be installed with separate cover plates and not combined with line voltage power outlets. B. Plate Finish: Smooth (no lines), similar to Hubbell wall plate. Screw heads shall have factory-applied paint finish to match colored wall plates. C. Flush Installations: 1. Standard device plates shall be type 302 satin stainless steel in public corridors, restrooms, kitchens and entrance lobbies; otherwise, plastic matching device color. Steel plates shall be complete with stainless steel cover screws. Provide type 302 satin stainless steel plates for all receptacles rated 30 amps or greater. Verify with Architect what type of plate, steel or plastic, to install in all areas with wood panel, stone, marble or other custom wall finishes. D. Surface Installations: Standard galvanized steel utility covers in dry areas. E. Narrow Mullions: In narrow mullions and similar locations where standard plate will not fit, install stainless steel or anodized aluminum to match mullion. Provide narrow design as required for application. F. Wet Locations: 1. 2. 3. 2.5 50% CONSTRUCTION DOCUMENTS June 14, 2010 A receptacle installed outdoors where exposed to weather or in other wet locations shall be in a weatherproof enclosure. Outlet cover shall be suitable for use whether or not the receptacle is in use (attachment plug cap inserted), per 2002 NEC 406.8(B) [former 1999 NEC 410-57(b) without Exception]. Provide single or double gang, horizontal or vertical, duplex of GFCI as required. Install on FS or FD box for surface raceway applications and standard box for flush applications. Outdoor outlet cover shall be Carlon E9Uxx Series “In-Use Weatherproof Cover, Hubbell Bell-brand Rayntite II series, Intermatic Guardian I WP1020 Series, WP1030 (extra depth) Series, or other approved equivalent. Indoor Locations: In indoor wet locations, or when noted “WP” on Drawings, provide cast aluminum weatherproof plate similar to Hubbell Bell 50xx-x Series, Intermatic WP10xxMC Series, or approved equal metal cover by TayMac. SPECIAL DEVICES: WIRING DEVICES 16140-4 CITY OF EDGEWATER FIRE STATION 55 A. 50% CONSTRUCTION DOCUMENTS June 14, 2010 Wall Box Timer Switch: Intermatic F5MH, F60MH, F12HH, or equivalent by M. H. Rhodes, Dayton, Paragon or Tork, 277 volt, 0-60 minute spring-drive timer unless indicated otherwise. PART 3 - EXECUTION 3.1 MOUNTING HEIGHTS: As indicated on the drawings or if not indicated in accordance with the Architect's instructions. When low-level outlets for different services occur adjacently on the same wall, height shall be set by duplex receptacle(s). All other telephone, data, TV etc. outlets shall be same as receptacle. Upper-level outlets such as line-voltage thermostats, call buttons, etc. shall be matched to light switch height. Locate outlets in exposed masonry walls such that only one CMU need be cut to fit around the outlet box. Notify Architect before rough-in of any areas where this would cause deviation from specified mounting heights. 3.2 APPLIANCE DISCONNECT: Where appliances or other utilization equipment are connected by cord-and-plug, and the cord-and-plug represents the NEC-required disconnecting means, then receptacle shall be installed in a location that is considered accessible as defined by the National Electrical Code. If this requirement necessitates deviation from the drawings, obtain Architect's approval of the new location prior to rough-in. 3.3 3.4 INSTALLATION: A. General: Install wiring devices and accessories as indicated, in accordance with U.L. listing, manufacturer's written instructions, applicable requirements of NEC and in accordance with recognized industry practices to fulfill project requirements. B. Preparation: Install wiring devices only in electrical boxes which are clean; free from building materials, dirt, and debris. C. Torque: Tighten connectors and terminals, including screws and bolts, in accordance with equipment manufacturer's published torque tightening values for wiring devices. Where manufacturer's torquing requirements are not indicated, tighten connectors and terminals to comply with tightening torques specified in UL Standard 486A. D. Alignment: Align and plumb all devices and wall plates. Plates shall fit flat against wall and tight against device surface without strain on plate. Plate edges shall be parallel to wall corners, doors, windows, etc. All switches and receptacles shall be installed vertical unless indicated otherwise on the drawings. FIRE-RESISTIVE WALLS AND PARTITIONS: Outlet boxes on opposite sides of fire-resistive walls and partitions shall be installed with horizontal separation of at least 24 inches. WIRING DEVICES 16140-5 CITY OF EDGEWATER FIRE STATION 55 3.5 3.6 GANGED SWITCHES: A. Install permanent barrier between all 277 Volt light switches ganged into one outlet box. B. Install ganged switches under a one-piece, multi-gang cover plate. DEDICATED OUTLET BOXES AND COVERS: A. Provide dedicated outlet box and cover for each outlet of types noted below. Outlets shall not be grouped into multi-gang outlet box with receptacles or other line-voltage devices. Wall plates shall cover only the dedicated outlet and not be part of larger common cover plate installed over receptacles outlets. Telecom cover plates shall not touch adjacent cover plates. B. Dedicated outlet box and cover: 1. 2. 3. 4. 5. 3.7 3.8 50% CONSTRUCTION DOCUMENTS June 14, 2010 Telecommunications outlet Computer cabling outlet Cable TV outlet Manual dimmer switch Isolated ground receptacle PROTECTION: A. General: Protect installed components from damage. Replace damaged items prior to final acceptance. B. Outlet Boxes: Protect outlet boxes from dry wall spackle compound, paint, litter, debris and other foreign material. FIELD QUALITY CONTROL: A. Testing: Prior to energizing circuits, test phase, neutral and ground wiring for electrical continuity and for short-circuits. Ensure proper polarity of phase and neutral connections is maintained. Subsequent to energizing, test wiring devices and demonstrate compliance with requirements. Operate each switch and other mechanical devices successfully at least three times. B. Ground Fault Circuit Interrupter for Personnel Protection: 1. 2. Test ground fault interrupter operation with both local and remote fault simulations in accordance with manufacturer instructions. GFCI receptacles shall be provided in all toilets, rooftop and kitchen as required per NEC 2002, Section 210.8 (B). END OF SECTION 16140 WIRING DEVICES 16140-6