CSR Report 2010 Full page PDF batch

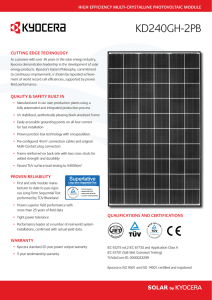

advertisement