micro-m-3

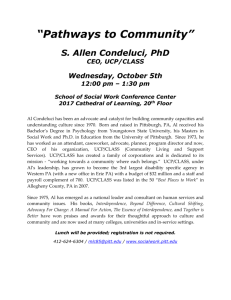

advertisement