WINDOWS AND DOORS

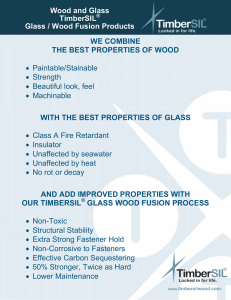

advertisement