division 28 - American Document Solutions Planroom

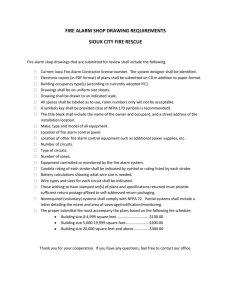

advertisement