SILICON CONCENTRATOR CELLS IN A TWO

advertisement

SILICON CONCENTRATOR CELLS IN

A TWO-STAGE PHOTOVOLTAIC

SYSTEM WITH A CONCENTRATION

FACTOR OF 300x

Dissertation zur Erlangung des Doktorgrades der Fakultät für

Angewandte Wissenschaften der Albert-Ludwigs-Universität

Freiburg im Breisgau

vorgelegt von

Andreas Mohr

aus Stegen

Juni 2005

Freiburg im Breisgau

Dekan:

Prof. Dr. Jan G. Korvink

Datum der Promotion:

9.11.05

Erstgutachter: PD Dr. V. Wittwer

Zweitgutachter: Prof. Dr. O. Paul

Vorsitzender der Prüfungskommission: Prof. Dr. H. Zappe

Beisitzer: Prof. Dr. P. Woias

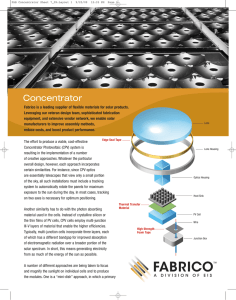

Photography: Silicon concentrator cell together with a loupe.

Abstract

Photovoltaic concentrators have a high potential to achieve cost reduction for solargenerated electricity. Different studies indicate that energy production cost of

photovoltaic concentrators can occur at a fraction of the energy production costs of flat

module plants in countries having high direct solar irradiation over the year.

This cost reduction is achieved by a reduction of the area of highly-efficient and quite

expensive solar cells using cheap optical elements concentrating the light. The fraction

of the solar cell cost of the concentrator system decreases with increasing concentration

factor, while the fraction of the costs of the optical elements and the tracking system

increase. A tracking system is needed in order to collect the direct sun light using

optical elements. The concentrator system cost goes up to a higher cost level if two-axis

tracking systems instead of one-axis tracking systems are used in order to allow a high

concentration factor. Two-axis tracking means usually a more complex mechanical

setup and is thus more complicated to control. One-axis tracking systems are usual

designed for relatively low concentration levels up to 50x.

Fraunhofer ISE developed an one-axis tracking PV concentrator system enabling a high

geometrical concentration of around 300x. This concentrator system was optimised and

realised in this work. The system uses a parabolic trough mirror and a three-dimensional

second stage consisting of compound parabolic concentrators (CPCs). Due to the two

stages of this system it is named BICON (BI ≡ Two stages; CON ≡ Concentrator)

system. The used CPCs are optimised for concentrating the sunlight by total internal

reflection up to a geometrical concentration ratio of 7.7x. Together with the first stage

concentration of 40.4x, a geometric concentration of around 300 suns can be achieved.

The three-dimensional second stage consisting of the dielectric CPCs has an acceptance

angle of +/- 23.5° allowing one-axis tracking from summer to winter solstice. The twostage system is tracked around a polar-oriented axis. For this linear concentrator system

and particularly for an easy mounting on the CPCs a rear-line-contacted (RLCC) silicon

concentrator solar cell was developed in this work.

In order to find an optimum cell structure, a set of masks was designed for processing

85 different RLCC cells on one single four-inch wafer. On this set of masks all the

important cell parameters are varied. Extensive data from these solar cells is presented

in order to display major trends in cell design and performance. As a result of this

optimisation study, a 25% efficient RLCC cell at around 100 suns at 25°C was

fabricated.

An analysis of the recombination effects in the RLCC cell shows that the carrier

recombination is dominated by the emitter recombination due to the highly doped cell

regions, which are still in low-level injection, while the base of the cell is in high-level

injection. At even higher injection the influence of the Auger recombination in the base

Abstract

becomes more and more important.

In investigating the RLCC cell, a shunting effect at the rear side of the cell and a nonideal diode characteristics become apparent. Both effects could be successfully

implemented in an one-dimensional numerical simulation model.

Utilising measurements from several runs of the solar cell, a two-dimensional model

was implemented in order to investigate physical effects due to the lateral current flow

in the RLCC cell. For this the complete cell is divided into three regions: The peripheral

bus bars and a inner cell element. Using network simulations of all three elements, the

measured cell performance could be represented precisely.

The optical performance of the compound parabolic concentrators (CPCs), which are

used as second stage in the concentrator, were analysed by using angular-dependent

measurements and a laser mapping system. With the laser mapping system twodimensional plots of all optical losses of the CPCs mounted on a RLCC cell are possible

including reflection losses at the front surface, absorption losses in the material, internal

reflectance losses and coupling out losses at the exit aperture. An averaged high optical

efficiency of over 81% of PMMA CPCs mounted on rear-contacted concentrator cells

could be realised. Additionally, the CPCs reach the acceptance angle condition (± 23.5°)

of the BICON system.

As the final part of this work, a complete cell receiver consisting of six rear-linecontacted concentrator cells and six CPCs was successfully integrated into the one-axis

tracking BICON system. A high system efficiency of 16.2% could be realised at around

800 W/m2 direct normal irradiance under realistic outdoor conditions (not temperature

corrected). This is around 4% absolute higher than system efficiencies of standard

commercial available flat-plate modules under PVUSA Testing Conditions (AM 1.5g,

1000 W/m2, 20°C ambient temperature, 1 m/sec wind speed). A detailed analysis of the

BICON component efficiencies indicates that the BICON system efficiency should stay

nearly stable all year through and efficiencies of over 17.0% may be realised in the near

future.

Contents

1

Overview of silicon concentrator cells and concentrator systems ...................... 1

1.1

Concepts for silicon concentrator solar cells ........................................................ 1

1.2

Concepts for concentrating sunlight onto the cells ............................................... 4

2

Basics of solar cells and concentrator systems ..................................................... 9

2.1

Characteristic parameters of solar cells ................................................................ 9

2.2

Operation mode of solar cells ............................................................................. 11

2.2.1

The output current....................................................................................... 11

2.2.2

The output voltage ...................................................................................... 14

2.3

Recombination processes in solar cells .............................................................. 15

2.3.1

Recombination in highly doped regions ..................................................... 15

2.3.2

Radiative recombination in the base........................................................... 16

2.3.3

Defect recombination in the base................................................................ 16

2.3.4

Auger recombination in the base ................................................................ 16

2.3.5

Surface recombination ................................................................................ 17

2.4

Current voltage characteristics of solar cells ...................................................... 17

2.5

Series resistance of the RLCC solar cell............................................................. 18

2.6

Concentrator systems .......................................................................................... 23

2.6.1

Optics of concentrators ............................................................................... 23

2.6.2

Tracking modes........................................................................................... 24

3

Cells at high concentration levels ........................................................................ 27

3.1

Recombination .................................................................................................... 27

3.2

Mobility and conductivity................................................................................... 31

3.3

Band gap narrowing............................................................................................ 32

3.4

Current crowding ................................................................................................ 33

i

Contents

3.5

Edge losses ..........................................................................................................33

3.6

Temperature coefficient ......................................................................................34

4

Design and technology of the rear-contacted silicon concentrator cell ............37

4.1

Design of the concentrator cell............................................................................37

4.2

Set of masks ........................................................................................................42

4.3

Fabrication process..............................................................................................43

4.3.1

Process flow ................................................................................................43

4.3.2

Technology..................................................................................................46

4.4

5

Mounting of the cells...........................................................................................49

Cell testing..............................................................................................................55

5.1

Standard measurement systems...........................................................................55

5.1.1

Dark and light IV curves .............................................................................55

5.1.2

Spectral response and external quantum efficiency ....................................56

5.1.3

Spectral mismatch correction ......................................................................57

5.1.4

Measurement errors at one-sun ...................................................................58

5.2

Determination of the series resistance versus the concentration.........................59

5.2.1

Measurement method ..................................................................................59

5.2.2

Analysis of the measurement error..............................................................60

5.3

Needle array measurement setup.........................................................................61

5.4

Cell testing under concentration..........................................................................63

5.4.1

Measurement setup (KoSim).......................................................................63

5.4.2

Measurement method ..................................................................................64

6

Simulation ..............................................................................................................67

6.1

Simulation process ..............................................................................................67

6.2

Two-dimensional simulation of the three-dimensional RLCC cells ...................68

6.3

Simulation parameters.........................................................................................69

ii

Contents

6.3.1

Doping profiles ........................................................................................... 70

6.3.2

Reflection losses and generation profile..................................................... 70

6.3.3

Surface recombination velocity .................................................................. 70

6.4

Simulated trends of the RLCC cell ..................................................................... 71

6.4.1

Variation of the cell thickness on a 1 Ω cm substrate................................. 71

6.4.2

Variation of the RLCC cell thickness on a 100 Ω cm substrate ................. 72

6.4.3

Variation of the contact window width....................................................... 72

7

Experimental trends ............................................................................................. 75

7.1

Position of the bus bars....................................................................................... 75

7.2

Grid geometry ..................................................................................................... 80

7.3

Finger distance and contact windows ................................................................. 81

7.4

Cell thickness...................................................................................................... 83

7.5

Base doping concentration.................................................................................. 86

7.6

Thermal performance of the RLCC cells............................................................ 89

7.7

Determination of the series resistance ................................................................ 92

7.7.1

Analytical calculation ................................................................................. 92

7.7.2

Experimental determination........................................................................ 94

7.8

Summary of the parameter study ........................................................................ 95

7.9

25% efficient RLCC cell..................................................................................... 97

8

Modelling of rear-line-contacted concentrator cells.......................................... 99

8.1

Determination of the injection level ................................................................... 99

8.2

Analysis of the recombination mechanism for different concentration levels . 100

8.2.1

Measurement method................................................................................ 100

8.2.2

Analysis .................................................................................................... 101

8.3

cell

One-dimensional model for implementing the Voc characteristics of the RLCC

105

8.4

Influence of the bus bars on the RLCC cell performance................................. 109

iii

Contents

8.5

9

Summary of the chapter ....................................................................................112

The BICON system..............................................................................................113

9.1

Assembly of the BICON concentrator system ..................................................113

9.2

The construction of the parabolic mirror and of the dielectric secondaries ......115

9.3

Fabrication and characterisation of the CPCs ...................................................120

9.3.1

Lateral homogeneity of the CPCs .............................................................120

9.3.2

Absolute optical performance as a function of incidence angle................123

9.3.3

Determination of the surface roughness....................................................125

9.4

Indoor characterisation of the system under concentration...............................126

9.5

Outdoor measurements of the BICON system ..................................................130

9.6

Summary of the chapter ....................................................................................134

10

Conclusions ..........................................................................................................135

10.1

Summary .......................................................................................................135

10.2

Outlook..........................................................................................................136

11

Appendix:.............................................................................................................139

11.1

Detailed fabrication flow of the RLCC cell ..................................................139

11.2

Shortcuts........................................................................................................144

11.3

Variables........................................................................................................145

11.4

Constants .......................................................................................................149

11.5

Publications ...................................................................................................150

11.6

Danksagung...................................................................................................151

12

Bibliography ........................................................................................................152

iv

1

Overview of silicon concentrator cells and

concentrator systems

Many basic concentrator cell and concentrator system concepts came off during the

seventies due to the 1973 oil crisis. At this time a lot of government efforts were funded

for concentrators in the United States of America. In Europe and Japan, concentrator

activities were viewed less favourably because of the low direct solar irradiation all year

through. During the eighties the oil crisis was overcome, the oil price and the urgency of

the energy crisis passed. So, the government efforts and the concentrator activities were

strongly scaled back and unfortunately, there was no commercial success in

concentrator PV.

Since the middle of the nineties the photovoltaic activities are reinforced world-wide.

This is again due the eventual spark of reduced availability of fossil fuel in the near

future and in contrast to 1973 this time not only the governments but also big oil

companies as e.g. Shell or BP are interested in renewable energies. Different

governments, especially in Germany and in Spain, push and fund photovoltaic energy

and thus the solar industry grew up very fast over the last years. Since the demand for

silicon in the PV market increased faster than expected, a lack of the feedstock of the

silicon base material between the producer and the PV industry came off and is now

present. Using the concentrator technology, less silicon material is needed and this

could be the reason why there is so much interest in innovative concentrator concepts

world-wide today.

1.1

Concepts for silicon concentrator solar cells

The concentrator cell concepts, which are developed over the last 20 years, are based on

four main cell designs briefly discussed in this chapter. All these cell concepts are

optimised in respect to at least one of the following demands.

•

Minimised shadowing losses at the front side.

•

Low series resistance losses in the grid structure.

•

Small resistance losses due to the lateral current flow in the diffused layer between

the grid lines.

•

Low lateral current in the base.

•

Low contact resistance and recombination current underneath the contacts.

•

Good light trapping for the optimal use of the incoming light.

One basic cell concept is the V-groove cell (Figure 1.1) [1]. This cell is optimised for

reducing the front reflection while keeping the series resistance losses low. The idea of

1

1 Overview of silicon concentrator cells and concentrator systems

this concept is to use highly reflective metal on one side of the grooves. The coverage of

this metal is unimportant since all incoming light is reflected by the metal to the

opposite side of the V-grooves. Due to the structured surface the light trapping of this

cell is increased. The fabrication can be easily realised by using metal evaporation at an

defined angle to the cell surface. Unfortunately, due to the high metal coverage of the

surface without any deep diffusion underneath the contact, the recombination at the

contacts and the contact resistance are high. A high resistance limits the cell

performance under high concentration levels. This disadvantage is hardly avoidable in a

simple process of the cell. Different other groups used similar concepts in order to

reduce shadowing losses. Due to the contact problems, the best application field for the

V-groove cell concept seems to be low-cost concentrator systems with a geometrical

concentration ratio in a range from 5x to 40x.

light

metal

diffusion

metal

Figure 1.1: A V-groove solar cell which allows all light, reflected from the top contact

metal, to impinge the other side of the grooved surface [1].

Another approach to design a cell for the use under concentration is the vertical multijunction cell [2]. The top contact is formed by grooving the surface with a laser or

scriber and plating metal into the grooves.

light

plating

p+-diffusion

n+-diffusion

plating

Figure 1.2: The plated vertical junction solar cell [2].

The principle of this cell is presented in Figure 1.2. Using the vertical junctions, the

2

1 Overview of silicon concentrator cells and concentrator systems

junction area is increased and all the carriers are generated next to the junctions

independent of their generation position. This leads to a high probability of collecting

the generated carriers. One disadvantage of this cell design is that the recombination at

the large metal semiconductor contact area is high, leading to low open-circuit voltages.

The cell may be used for a concentration of up to 40x. The BP Saturn cells are based on

this concept and are applied in the EUCLIDES power plant, which will be described in

the next chapter.

A useful one-sun solar cell design, which can be optimised for high concentration

levels, is the p++-n-n++ cell from the Sandia National Laboratories from 1982, which is

shown in Figure 1.3. Efficiencies of around 20% were reached from 40 to 200 suns [3].

The cell performance under concentration is limited due to series resistance losses in the

front grid, because the geometric dimensions of the front grid must be optimised for two

contrary effects. On the one hand the grid fingers must be small for low reflection losses

and on the other hand the front fingers must be broad for low series resistance losses. A

reasonable application of this cell concept seems to be possible up to 150x.

Ag

p++

n-doped substrate

n++

Ag

Figure 1.3: A conventional solar cell optimised for high concentration and developed at

the Sandia National Laboratories [3].

The interdigitated back-contact cell (see Figure 1.4) has both electrical contacts on the

rear side of the cell [4]. So, there are no shadowing losses at the front side. This design

uses alternating n++- and p++-diffusion lines on the rear side so that 50% of the back is

covered by diffusions. The lateral series resistance losses due to the current flow in the

diffused areas can be neglected. The metal semiconductor contact resistance losses are

very small due to the high doping concentration of the diffusion lines. One critical point

of this design is that most carriers are generated at the front side and have to diffuse to

the rear side of the cell. So, recombination losses in the bulk must be reduced in order to

collect most of the generated electron/hole pairs at the rear contacts. If 50% of the rear

side is covered by high doping diffusions the recombination losses are high at the rear

side. For high voltages the dopant coverage of the rear side must be decreased.

3

1 Overview of silicon concentrator cells and concentrator systems

SiO2

SiO 2

n++

p++

n++

p++

p++

n++

n++

metal

Figure 1.4: The interdigitated back contacted cell (IBC) has no metal on the front side

in order to reduce the reflection losses at the front side [4].

The back-junction point-contact silicon solar cell, developed at the University of

Stanford (see Figure 1.5) [5], has also both contacts on the rear of the cell side in the

same way as the interdigitated back-contact cell. The major difference between these

cell types is, that instead of broad line diffusion underneath the contacts, only small

local diffusion points underneath the contacts are used. This leads to high voltages and

low contact resistances. The back-junction point-contact cell scheme can be applied in

systems with a geometrical concentration of over 200 suns.

p++

n

n

n++

++

p

n

p++

p

Figure 1.5: A cross section of a textured point-contact solar cell of SUNPOWERTM,

which has point contacts at the rear side [5].

1.2

Concepts for concentrating sunlight onto the cells

Over the last 20 years the developed concentrator systems use either reflecting or

refracting cheap optical elements in order to concentrate light onto the solar cells.

Middle scaled concentrator power plants in the range of some 100 kilowatts peak were

built up in order to demonstrate the long time stability and reliability of concentrator

systems. A detailed overview of the concentrator activities all over the world is given in

[6]. In this work only the most important basic concentrator concepts are summarised

and examples are presented.

Concentrators with reflecting optical element work either with a parabolic mirror having

a focus line (Figure 1.6) or a parabolic dish mirror (Figure 1.8) focusing the light onto a

closed packed PV element.

4

1 Overview of silicon concentrator cells and concentrator systems

cell receiver

parabolic

mirror

Figure 1.6: Parabolic mirror reflecting the Figure 1.7: EUCLIDES TM concentrator

incoming sunlight onto a focus line.

plant in Tenerife.

Concentrator systems using parabolic mirrors reach a geometrical concentration from

2x up to 50x. The EUCLIDESTM concentrator plant (Figure 1.7) in the south of Tenerife

is a project of different solar research groups. It is one of the largest parabolic mirror

concentrator power plant world wide [7]. The plant is composed of 14 arrays each 84

meters long and its nominal output power is 480 kWp. The concentration of the system

is 38.2x, the modules are cooled with a passive heat sink and the system is one-axis

tracked. The used cells are Saturn cells from BP Solar, whose cell concept is based on

the vertical junction cell as already described before.

solar cell array

parabolic dish

mirror

light

Figure 1.8: Dish concentrator concept.

The light is reflected by a parabolic dish

mirror to a PV array at the focus.

Figure 1.9: Dish concentrator system of

the company SOLAR SYSTEMSTM in

Australia.

The company SOLAR SYSTEMSTM in Australia and SUNPOWERTM in the US are

developing two-axes tracked reflective dish concentrators and water-cooled close-

5

1 Overview of silicon concentrator cells and concentrator systems

packed PV arrays for use in the focus (Figure 1.9). The parabolic reflective dishes have

a geometrical concentration of around 340x. The receiver consists of a array of 16 PV

modules (each 6 cm x 6 cm) and a power plant of 14 parabolic concentrators was

outdoor tested reaching a high electrical system efficiency of around 20% under

PVUSA Testing Conditions, i.e. 850 W/m2 direct irradiation, 20°C ambient temperature

and 1 m/sec wind speed.

Concentrator systems with refractive optical elements work either with Fresnel lenses

(Figure 1.10) concentrating the sunlight onto one point or linear Fresnel lenses (Figure

1.12) having a focus line.

light

Fresnel lens

v-trough secondary

solar cell

Figure 1.10: The incoming light is

concentrated by using thin Fresnel lenses.

Figure 1.11: Five Mega Modules™ of

AMONIXTM assembled on a 20 kWp

generating system.

linear

Fresnel lens

cell receiver

Figure 1.13: ENTECHTM 100 kW PV

power plant

Figure 1.12: Linear Fresnel lens

concentrator concept.

Two-axes tracked point-Fresnel lens arrays are being developed by AMONIXTM, USA.

20 kWp power plants were built up and a system efficiency of 18% at a geometrical

6

1 Overview of silicon concentrator cells and concentrator systems

concentration of around 250x was reached. This system uses secondary optical elements

called V-trough secondaries in the centre of the lens in order to increase the acceptance

angle of the system and to homogenise the illumination on the cell level. V-trough

secondaries are hollow pieces with reflective surfaces using multi reflection.

The company ENTECHTM fabricates line-focus Fresnel concentrators operating at 20x.

100 kWp power plants are being under development in the US. Module efficiencies of

around 15% at 20x under PVUSA were reached.

7

2

Basics of solar cells and concentrator systems

In this chapter the theoretical basics of solar cells and concentrator systems

are summarised. The main focus is set on recombination effects and series

resistance losses, which are the limiting parameters in the concentrator solar

cell under high concentration levels. At the end of this chapter, the optical

basics of concentrator systems are introduced.

2.1

Characteristic parameters of solar cells

Short-circuit current

If V = 0 V, the short-circuit current Isc is determined by the division of the short-circuit

current density (Jsc ≈Jph) and the active cell area Acell. The active cell area is the region

of the silicon, where the solar cell process is applied.

I sc = J sc ⋅ Acell ≈ J ph ⋅ Acell

Equation 2.1

Open-circuit voltage

If Jout = 0 and the surface and SRH recombination are neglected, the open-circuit

voltage Voc can be approximated by

Voc ≈

kT J sc

kT J sc

,

ln

ln

+ 1 ≈

q J0

q

J

0

Equation 2.2

where k is the Boltzman´s constant, T is the absolute temperature, q is the elementary

charge and J0 is dark diffusion saturation current density.

Efficiency and the maximum power point

The efficiency η is the maximum output power divided by the incoming irradiance

G [W/m2].

η=

J mpp ⋅ Vmpp ⋅ Acell

G

Equation 2.3

Vmpp and Jmpp are the voltage and the current at the maximum power point of the IVcurve. The efficiency can also be expressed as

9

2 Basics of solar cells and concentrator systems

η=

J sc ⋅ Voc ⋅ FF ⋅ Acell

.

G

Equation 2.4

The fill factor FF is given by

FF =

J mpp ⋅ Vmpp

J sc ⋅ Voc

Equation 2.5

.

Cell parameters under concentration

In order to deliver a simple insight of the cell performance under concentration C, the

solar cell can be described by the illuminated one-diode current characteristics.

V − JRs ,total

J out = J 0 exp

VT

− 1 − CJ ph ,

Equation 2.6

where VT = kT/q and Rs,total is the area weighted total series resistance of the cell.

Equation 2.6 is only valid if the base is in low-level injection, which means that

Na >> ∆p in a p-doped base or Nd >> ∆n in a n-doped base. If the base is in high-level

injection the illumination-dependent changes of some parameters, which are discussed

in detail in Chapter 3, must be considered. For low-level injection the empirical cell

parameters in dependence of the concentration are listed in Table 2.1 [8].

J sc (C ) ≈ − CJ ph ,one − sun

Voc (C ) ≈ VT ln

C ⋅ J ph ,one − sun

J0

C ⋅ J ph,one − sun ⋅ Rs

FF (C ) ≈ (FFone − sun + 0.0035 ln C ) ⋅ 1 −

Voc (C )

η (C ) =

J sc (C ) ⋅ Voc (C ) ⋅ FF (C )

C ⋅ Gone − sun

VT

0.66Ωcm 2

≈

C max (η max ) ≈

R s ⋅ J ph ,one − sun

Rs

Table 2.1: Solar cell parameters in dependence of the concentration. The series

resistance Rs is weighted by the solar cell area and the one-sun parameters are the

values of P, Jph and Jsc at one-sun under Standard Test Conditions.

It can be seen that the efficiency of the solar cell increases with increasing concentration

due to the increase of the open-circuit voltage Voc with the natural logarithm. The

concentration level at which the cell efficiency peaks depends strongly on the series

10

2 Basics of solar cells and concentrator systems

resistance Rs. For Jph,one-sun = 40 mA/cm2 and VT = 26 mV at room temperature, a

maximum efficiency of around 100 suns can only be reached for Rs values smaller than

6.6x10-3 Ω cm2.

2.2

Operation mode of solar cells

2.2.1

The output current

An often shown way to analyse the current behaviour of silicon solar cells is to apply

the current density, the drift plus diffusion and the continuity equation. This is a good

approach to understand the transport processes in the pn-junction of a device. However,

the operation of high-efficiency solar cells is not mainly controlled by current transport

processes but by generation and recombination processes. So, Swanson and Sinton [9]

use another approach to describe highly-efficient solar cells. For this an integral

formulation of the continuity equation is applied describing the relationship between

generation and recombination of carriers and brings out the output current at the

contacts. Using this approach, high-injection effects, which are needed for describing

concentrator cells under high concentration, can be simply introduced. The integral

method of Swanson and Sinton is summarised in this chapter. The applied basics of

semiconductors and silicon solar cells can be found in [10],[11],[12].

For modelling the steady-state carrier transport in silicon, the standard equations are:

•

The current transport equations.

At a pn-junction an electric field is present in addition to a concentration gradient

leading to drift current and diffusion current flow.

v

v

v

J e = qµ e nE + qDe ∇n

Equation 2.7

v

v

v

J h = qµ h pE − qDh ∇p

Equation 2.8

v

where E is the electric field, µe,h are the mobilities of the carriers, De,h are the

diffusion coefficients and n, p are the hole and electron densities.

The total current density is the sum of Equation 2.7 and Equation 2.8.

v

v

v

J cond = J e + J h

Equation 2.9

•

The continuity equations.

The number of carriers flowing into a volume minus the carriers which recombine

and plus the carriers which are generated in this volume equals the number of

carriers flowing out of the volume.

11

2 Basics of solar cells and concentrator systems

v v

∇ ⋅ J e = − q ( Rrec − Gl )

v v

∇ ⋅ J h = q ( Rrec − Gl )

Equation 2.10

Equation 2.11

where Rrec and Gl are the recombination and generation rates.

•

The Poissson equation.

The constant Fermi level required at thermal equilibrum results in an unique space

charge distribution at the pn-junction. The unique space charge distribution and the

electrostatic potential are given by the Poisson equation.

v

q

∇ 2ψ = − ( p + N D+ − n − N A− )

ε

Equation 2.12

where Nd and Na are ionized doping densities and Ψ is the potential referenced to

the intrinsic level.

•

The carrier density equations.

The electron and hole densities are in terms of the intrinsic carrier concentration ni

and the intrinsic Fermi level Ei

E F , n − E F ,i

n = ni exp

kT

Equation 2.13

E F ,i − E F , p

p = ni exp

kT

Equation 2.14

where EF,i is the intrinsic Fermi level and EF,n and EF,p are the electron and hole

quasi-Fermi levels.

For determining the output current of a solar cell, the continuity Equation 2.10 and

Equation 2.11 are integrated over the device volume.

v v

Equation 2.15

∇

∫ ⋅ J e dv = q ∫ (Rrec − Gl ) dv

V

V

v v

∇

∫ ⋅ J h dv = − q ∫ (Rrec − Gl ) dv

V

Equation 2.16

V

With the Gauss divergence theorem the left-hand sides of Equation 2.15 and Equation

2.16 are converted to surface integrals over the complete device surface S.

v

Equation 2.17

J

∫ e ⋅ nˆ d s = q ∫ (Rrec − Gl )dv

S

V

v

J

∫ h ⋅ nˆ d s = − q ∫ (Rrec − Gl )dv

S

Equation 2.18

V

where n̂ is the normal vector directed outward of the device (see Figure 2.1).

12

2 Basics of solar cells and concentrator systems

The complete device surface S can be separated into three single surfaces. The region

around the p-contact should be S1, the region around the n-contact should be S2 and the

rest should be S3 as shown in Figure 2.1.

Iout1

n^

p-contact

Jp

Jn

S1

S3

S2

n^

Iout2

n-contact

Figure 2.1: Separation of the complete device surface into three single surfaces.

v

v

v

v

ˆ

ˆ

ˆ

J

⋅

n

ds

=

J

⋅

n

ds

+

J

⋅

n

ds

+

J

∫ e

∫ e

∫ e

∫ e ⋅ nˆ ds

S

S1

v

∫J

h

S2

Equation 2.19

S3

v

v

v

⋅ nˆ ds = ∫ J h ⋅ nˆ ds + ∫ J h ⋅ nˆ ds + ∫ J h ⋅ nˆ ds

S

S1

S2

Equation 2.20

S3

At the p contact the current is

v

v

I out1 = − ∫ J e ⋅ nˆ ds − ∫ J h ⋅ nˆ ds.

S1

v

J

∫ h ⋅ nˆds by Equation 2.20 and

Replacing

Equation 2.21

S1

S1

v

J

∫ h ⋅ nˆds by Equation 2.18 and inserting

S

this into Equation 2.21 it follows

v

v

v

I out1 = − q ∫ Gl dv + q ∫ Rrec dv + ∫ J h ⋅ nˆ ds + ∫ J h ⋅ nˆ ds − ∫ J e ⋅ nˆ ds .

V

V

S3

S2

S1

Since the total current is Iout = Iout1 = -Iout2 and if taking into account that

I ph = q ∫ Gl dv (photogenerated current),

V

I rec ,base = q ∫ Rc dv (recombination in the base),

V

v

I rec , surface = ∫ J h ⋅ nˆ ds (recombination at the surface),

S3

v

v

I rec ,contact = ∫ J h ⋅ nˆ ds − ∫ J e ⋅ nˆ ds (recombination at the contact),

S2

S1

13

Equation 2.22

2 Basics of solar cells and concentrator systems

it follows from Equation 2.22

I out = I b ,rec + I s ,rec + I cont ,rec − I ph = I rec − I ph .

Equation 2.23

Since a negative sign means a positive output power in a solar cell, the output current is

the photogenerated current minus the total recombination current which consists of the

recombination in the base material, the recombination at the surface and the

recombination at the contacts. This equation is valid independent of whether the base is

in high-level injection or in low-level injection.

2.2.2

The output voltage

A typical band diagram of a high efficient silicon solar cell is shown in Figure 2.2. Such

a solar cell consists of highly doped regions near the contacts (leading to an ohmic

contact and a reduction of the contact recombination) and a lightly doped base.

Taking EF,n and EF,p as constant through the n++- and p++-region and into the edge of the

quasi-neutral base near the contacts, then the output voltage as shown in Figure 2.2 is

given by

Vout = Vi ,n + Vi , p + Vb + Vc + Vm .

Equation 2.24

Vc, Vm and Vb are the voltage losses at the contact, in the metal and in the base and they

are all negative. Vc and Vm will be discussed in detail in Chapter 2.5. EF,n and EF,p can be

taken as constant through the n++- and p++-region, respectively, because these regions

are heavily doped leading to an abundance of majorities and to an independence of the

quasi-Fermi levels to the illumination. qVi,n and qVi,p are the differences between the

quasi –Fermi levels and the intrinsic Fermi level.

qVb

EF,n

EF,i

qVi,n

qVi,p

EF,p

metal

p++-doped

region

base

n++-doped

region

metal

Figure 2.2: Band diagram of a high efficient solar cell under illumination.

Using Equation 2.13 and Equation 2.14, qVi,n and qVi,p can be expressed as

14

2 Basics of solar cells and concentrator systems

n

qVi , n = E F ,n − E F ,i = kT ⋅ ln

ni

p

qVi , p = E F ,i − E F , p = kT ⋅ ln .

ni

Equation 2.25

Equation 2.26

If the base, contact and metal voltage losses are neglected and n and p are taken as

constant through the base it follows from Equation 2.24

Vout ≈

kT pn

ln .

q ni2

Equation 2.27

Thus, the output voltage is the separation of the quasi-Fermi levels and can be

determined by the pn-product in the base if transport losses are not considered. The

details of the high doped p++- and n++-contacts are not of interest for calculating the

output voltage.

Transport losses decrease the output voltage. These transport losses can be summarised

as

Vb + Vc + Vm ≈ I ⋅ R s ,total / Acell ,

Equation 2.28

where Rs,total [Ω cm2] is the area weighted series resistance.

Including transport losses, the output voltage is

Vout ≈

2.3

kT pn

ln − I ⋅ Rs ,total / Acell .

q ni2

Equation 2.29

Recombination processes in solar cells

In order to determine the current voltage characteristic of the solar cell, all the

recombination terms from Equation 2.23 must be defined. A detailed derivation and

description of these recombination terms is given in [11],[12].

2.3.1

Recombination in highly doped regions

The base recombination in Equation 2.23 involves the n++- and p++-doped regions at the

contacts, where no analytical solution for this recombination exists. Also no analytical

solution exists for the recombination at the semiconductor metal contact.

Del Alamo and others [13] found out that this problem can be solved by defining a new

arbitrary surface around the highly doped region and the contact area. In order to get the

total recombination current density into the highly-doped region and into the contact,

only the current density through this arbitrary defined surface must be considered. This

assumption is possible because the electrons and holes, which diffuse into the p-contact

15

2 Basics of solar cells and concentrator systems

and n-contact region, respectively, either recombines in the doped regions or at the

contacts. The complete minority carrier recombination current into a n-doped region can

be written as

pn

J rec ,n −contact = J 0n 2 − 1

ni

Equation 2.30

For the p-doped region it is

pn

J rec , p −contact = J 0p 2 − 1

ni

Equation 2.31

where J0n and J0p are temperature-dependent diffusion saturation currents. For the pnproduct the carrier densities at the edge of the space charge region in the neutral base

can be applied.

2.3.2

Radiative recombination in the base

The radiative recombination is proportional to the excess carrier densities and is given

by

(

Rrec ,radiative = B pn − ni2

)

Equation 2.32

where B is the radiative rate coefficient. Since silicon is an indirect semiconductor this

recombination process is improbable and can be neglected.

2.3.3

Defect recombination in the base

Defect recombination in the base can be modeled by using the approach of Shockley ,

Read and Hall [14],[15], so this recombination is called SRH recombination. Under

low-level injection conditions, the recombination rate is proportional to the excess

minority carrier density.

Rrec , SRH =

n − n0

Equation 2.33

τ SRH

where τSRH is the lifetime of the minorities.

Including the effects of the majorities a more complicated expression can be obtained.

Since FZ material is used for the silicon concentrator solar cells, the number of defects

in the bulk and the SRH recombination is very small.

2.3.4

Auger recombination in the base

The Auger recombination is a three particle process. The energy of an electron-hole

recombination pair is given to a free particle either an electron or a hole.

16

2 Basics of solar cells and concentrator systems

(

)

(

Rrec , Auger = C n n 2 p − n02 p0 + C p p 2 n − p02 n0

)

Equation 2.34

Cn is the n-type Auger coefficient if the free particle is an electron and Cp is the p-type

Auger coefficient if the free particle is a hole.

2.3.5

Surface recombination

The recombination at the surface of a solar cell can be described by using a minority

recombination current into the surfaces. The recombination current density can be taken

as proportional to the excess minority density.

J rec , surface = qS (n − n0 )

Equation 2.35

J rec , surface = qS ( p − p0 )

Equation 2.36

at a p-type surfaces.

at a n-type surfaces.

S is the surface recombination velocity which is in the range of 1 to 103 cm/sec for

passivated surfaces.

2.4

Current voltage characteristics of solar cells

For a simple analysis of the cell operation the electron and hole quasi-Fermi energies

are taken as constant through the base and the voltage drops along the base are ignored.

Using the recombination terms from Equation 2.30 to Equation 2.36, the recombination

current densities for every single recombination mechanism can be determined. For this

first of all the pn-product is expressed by using Equation 2.29

qV

pn = ni2 exp

.

kT

Equation 2.37

Under low-level injection and for a p-doped base it is then

qV

pn = ni2 exp

≈ N An .

kT

Equation 2.38

By replacing the pn-product in the recombination terms (Equation 2.30 to Equation

2.36) by Equation 2.38, the recombination current densities can be calculated.

•

Taking Equation 2.30, Equation 2.31 and Equation 2.38, the recombination currents

into highly doped regions are

qV

J rec ,n −contact = J 0n exp

− 1 ,

kT

17

Equation 2.39

2 Basics of solar cells and concentrator systems

qV

J rec , p −contact = J 0p exp

− 1 .

kT

•

Equation 2.40

The recombination current due to the SRH recombination is

I rec , SRH = q ∫

n − n0

τn

V

dv ,

Equation 2.41

what can be rewritten to

J rec , SRH

qt c ni2

=

N Aτ n

qV

exp

− 1 ,

kT

Equation 2.42

where A is the area of the device and tc is the thickness of the base.

•

The recombination current due to the surface recombination is

I rec, surface = qS

∫ (n − n )dA ,

0

Equation 2.43

Asurf

I rec, surface

qAsurf Sni2

qV

exp

=

− 1 .

NA

kT

Equation 2.44

The radiative recombination and the Auger recombination can be neglected under lowlevel injection conditions.

Inserting Equation 2.39, Equation 2.40, Equation 2.42 and Equation 2.44 in Equation

2.23, the current voltage characteristic is under low-level injection

J out

2

I out

qtc ni2 qAsurf Sni

qV

=

= J 0n + J 0 p +

+

⋅ exp

− 1 − J ph ,

A

N Aτ n

A ⋅ NA

kT ⋅ n

Equation 2.45

where the ideality factor n is 1.

Therefore, neglecting the recombination in the depletion zone, the ideality factor n of

the current voltage characteristics of a solar cell is 1 in low-level injection. The IVcharacteristics in high-level injection is considered in Chapter 3. In Chapter 3 the

ideality factors for the different recombination mechanism in low- and high-level

injection are summarised.

2.5

Series resistance of the RLCC solar cell

Besides the recombination losses in a solar cell, the cell performance is mainly limited

by the series resistance losses under concentration leading to a decrease of the fill factor

(see Table 2.1). The total series resistance Rs,total consists of the series resistance in the

base, in the emitter and in the metal as shown in Figure 2.3. In the following the

analytical expressions for the series resistance components of the RLCC cell are given.

The exact derivation can be found in [16].

18

2 Basics of solar cells and concentrator systems

γ

oxide

floating emitter (n +)

h e

base vertical

base lateral

p-silicon

emitter

n++

n+

p++

oxide

contact

metal

Figure 2.3: The different components of the series resistance of a rear-contacted solar

cell, which is described in detail in Chapter 4.1. γ are the incoming photons and e and h

are the generated electrons and holes.

Resistance in the base

In the RLCC cell the generated carriers must diffuse from the front side to the rear side

in order to be separated and collected at the contacts. The resulting series resistance is:

Rs*,base ,vertical = ρ base

tc

,

Acell

Equation 2.46

where ρbase is the specific resistance of the base, tc is the thickness of the cell and Acell is

the active area of the cell. In this work the series resistance R*s is given in Ω and the

series resistance weighted by the active cell area Rs is given in Ω cm2.

The vertical series resistance weighted by the active area of the cell is then

Rs ,base ,vertical = ρ base ⋅ t c .

Equation 2.47

The lateral component of the base series resistance is

Rs*,base ,lateral =

1 ρ base a f

,

6 tc l f

Equation 2.48

weighted by the active cell area, it results

Rs ,base ,lateral =

1 ρ base 2

⋅af ,

12 t c

Equation 2.49

where af is the distance between a p- and p-finger and lf is the length of a finger.

19

2 Basics of solar cells and concentrator systems

Resistance of the emitter

The series resistance of the emitter (n+-diffusion), which is locally diffused underneath

the n-fingers with a depth d, can be calculated by

Rs*,emitter =

1 ρ diffusion wd

,

6 d

lf

Equation 2.50

where ρdiffusion is the averaged specific resistance of the diffusion and wd is the width of

the n+-diffusion.

The area weighted emitter series resistance is

Rs ,emitter =

1 ρ diffusion 2

wd .

12 d

Equation 2.51

Contact resistance

1

2

3

4

metal

diffusion (n++ or p++)

contact area

Figure 2.4: Cross bridge resistor for measuring the contact resistance between the n++and p++-diffused semiconductor regions and the metal. While generating a constant

current between area 2 and 3, the voltage drop between area 1 and 4 is measured for

determining the contact resistance.

The resistance between the semiconductor and the metal can not be calculated

analytically. Therefore, cross bridge Kelvin resistor test structures [17] are integrated

into the set of masks allowing to measure the contact resistance by using a four-point

measurement method.

While generating a constant current between area 2 and 3 in Figure 2.4, the voltage drop

between area 1 and 4 is measured for determining the contact resistance. The contact

resistance is then

20

2 Basics of solar cells and concentrator systems

structure

Rstest

=

,contact

V1 4

I 23

test structure

Acontact

,

Equation 2.52

where Acontactteststructure is the contact area A of the test structure between the

semiconductor and the metal.

For the solar cell the contact resistance is

(

structure

test structure

Rs ,contact = Rstest

, contact , p + + + R s ,contact , n + +

) AA

cell

,

Equation 2.53

contact

where Acell is the active cell area and Acontact is the contact area between the metal and

the semiconductor.

Metal resistance

The ohmic losses due to the metallisation can be analytically described as

lf

1

ρ metal

,

3

hf ⋅ wf

Equation 2.54

l bus

1

ρ metal

,

3

hbus ⋅ wbus

Equation 2.55

Rs*, finger =

Rs*,bus =

where lbus and lfinger are the half of the length of the bus and the complete length of the

finger, wbus and wfinger are the width of the bus and the finger, hbus and hfinger are the

height of the bus and the finger and ρmetal is the specific resistance of the metal.

For the series resistance weighted by the area it is

Rs , finger

a f ⋅ l 2f

1

,

= ρ metal

3

hf ⋅ wf

Equation 2.56

Rs ,bus =

l ⋅A

1

ρ metal bus cell ,

3

h f ⋅ wbus

Equation 2.57

where af is the distance between two fingers.

In addition to the presented ohmic losses there are also so called “non-generation

losses”, which can not be described analytically [18]. The “non-generation losses” are

generated by the different path length of the current through the finger to the contacts.

Thereby, the voltage drops along the metal structure vary. Working at the maximum

power point of the complete cell, different local regions of the cell work at different

maximum power points leading to current losses. The “non-generation losses” can be

investigated by using circuit simulation.

21

2 Basics of solar cells and concentrator systems

Influence of the total series resistance on the cell performance under concentration

The total series resistance is the sum of the series resistance components.

Rs ,total = Rs ,base ,vertical + Rs ,base ,lateral + Rs ,emitter + Rs ,contact + Rs ,bus + Rs , finger

Equation 2.58

The total series resistance limits the fill factor at higher concentration levels. Some

simulated IV-curves for different total series resistances of a 65 µm thick rear-contacted

cell are plotted in Figure 2.5 at a concentration of 200 suns. It can be seen that with

increasing series resistance the fill factor is strongly reduced.

0.0

-0.2

-0.4

Current [A]

-0.6

-0.8

-1.0

concentration = 200 suns;

cell thickness = 65 µm;

Rs=0.005 Ω cm

Rs=0.01 Ω cm

2

Rs=0.02 Ω cm

2

Rs=0.03 Ω cm

2

Rs=0.04 Ω cm

2

2

-1.2

-1.4

FF losses

-1.6

-1.8

0.0

0.2

0.4

Voltage [V]

0.6

0.8

Figure 2.5: One-dimensional numerical simulation of a 65 µm thick rear-contacted

concentrator cell using PC1DTM.

22

2 Basics of solar cells and concentrator systems

2.6

Concentrator systems

2.6.1

Optics of concentrators

The optical and geometrical concentration (Cop, Cgeo) of a system are defined as

C op =

Gin

A

= η op ⋅ in = η op ⋅ C geo ,

Gout

Aout

Equation 2.59

where ηop is the optical efficiency of the system, Gin and Gout are the irradiances at the

entry aperture Ain and at the exit aperture Aout.

The efficiency of a concentrator system is defined as the product of the cell efficiency

ηcell and the efficiency of the used optics ηop.

η sys = η cell ⋅ η op .

Equation 2.60

In a two-dimensional space every ray entering through one point of the entry aperture

can be described by using a two-dimensional phase-space volume (Etendue) consisting

v

v

v

v

of x and p . Where x is the ray coordinate and p is the optical direction cosines at the

entry aperture. For a homogeneous light source (e.g. sun on earth) the Etendue in the

two-dimensional space can be described as

ε hom,2D = ∫∫ dpdx = ∫ dp ⋅ ∫ dx = n ⋅ 4a sin θ ,

Equation 2.61

where n is the refractive index of the surrounding medium, a is the half of the aperture

and θ is the half of the aperture angle [19].

Due to the theorem of Liouville [20] the Etendue at the entry aperture of an ideal

concentrator must be conserved at the exit aperture (εin = εout). This means for a twodimensional homogenous source using Equation 2.61.

ain ⋅ nin ⋅ sin θ in = a out ⋅ nout ⋅ sin θ out .

Equation 2.62

Therefore, the geometrical concentration of an ideal two-dimensional concentrator

system as shown in Figure 2.6 [20] is

C geo =

ain nout sin θ out

=

.

a out nin sin θ in

Equation 2.63

For the three-dimensional ideal concentrator the geometrical concentration is

n sin θ out

C geo = out

nin sin θ in

2

.

Equation 2.64

Taking Equation 2.63 and Equation 2.64 into account, the conservation of the Etendue

for an ideal concentrator means

•

concentrating light by decreasing the aperture results in an increase of the

divergence of the outgoing rays in contrast to the incoming rays,

23

2 Basics of solar cells and concentrator systems

•

the more parallel the incoming light is the higher the possible concentration is,

•

the maximum concentration can be reached if θout is 90°,

•

the maximum concentration for a two-dimensional ideal concentrator is 212x and

for a three-dimensional ideal concentrator around 45000x, where n = 1, θout = 90°,

θin = 0.27° (aperture angle of the sun).

θin

θout

pdirection

nin

2ain

nout

x

2aout

loss-free concentrator

Figure 2.6: Scheme of a loss-free two-dimensional concentrator.

An often used parameter to characterise a real concentrator system is the acceptance

angle θacc. θacc is defined as the angle of incident light at which 90% of the maximum

signal at the exit aperture is detected by the receiver.

Signal (θ acc ) ≥ 0.9 ⋅ Signal max

2.6.2

Equation 2.65

Tracking modes

Concentrator systems can only use the direct light of the sun. Thus, concentrator

systems have to be tracked with the sun. The two favourite tracking concepts are:

•

Two-axes tracked concentrator systems which have a vertical and horizontal

tracking axis. Because the aperture angle of the sun is θs = ± 0.27°, all the rays of

the aperture angle have to reach the solar cell and so, these systems need a minimal

vertical and horizontal acceptance angle θacc,v,h of ± 0.27°. Standard two-axes

tracking systems using e. g. lenses or dishes reach a high geometrical concentration

of 250x up to 500x.

•

One-axis tracked concentrator systems. These systems are tracked in most of the

cases around the polar axis which is tilted by the degree of latitude. Due to the

aperture angle of the sun, these systems have also a horizontal acceptance angle of

θacc,h = ± 0.27°, while the vertical acceptance angle θacc,v is ± 23.5° because the

angle of incident sun irradiation onto a polar tracked system changes between

± 23.5° from the summer to the winter solstice as illustrated in Figure 2.7. Standard

24

2 Basics of solar cells and concentrator systems

one-axis tracking systems using parabolic trough mirror or linear Fresnel lenses and

reach a geometrical concentration from 2x up to 50x.

Figure 2.7: All-season ecliptic of the sun at Fraunhofer ISE, Germany. The system is

tilted by the angle of latitude, which is 48° in Freiburg. The angle of incidence onto a

polar tracked concentrator system is 23.5° at the summer solstice and –23.5° at the

winter solstice.

A theoretical comparison between both systems shows that the annual irradiation

density is 980 kWh/m2a for the two-axes tracked system and is 930 kWh/m2a for a polar

tracked system at Freiburg (48° degree of latitude) [19].

25

3

Cells at high concentration levels

At high incident power densities the concentration of the generated carriers in

solar cells exceed the base doping concentration (∆n or ∆p >> ND or NA) and

the concentration of free electrons equals the concentration of free holes

(∆n = ∆p). In this case the cells are in high-level injection. In this chapter the

recombination losses, the conductivity and the band gap narrowing in the

highly injected case of the cell are presented, and the effects of high current

densities, edge losses and temperature losses on the cell performance are

discussed for high incident power densities.

3.1

Recombination

Taking the equation for the output current density Jout (Equation 2.23) and the output

voltage Vout (Equation 2.27) into account, the current voltage characteristics can be

derived under high-injection conditions.

If the base is in high-level injection, the number of free electrons equals the number of

the holes. This implies that

qV

pn = n 2 = ni2 exp

kT

1 qV

n = ni exp

2 kT

,

.

Equation 3.1

Equation 3.2

Under high-level injection conditions the number of light-generated free carriers n is

much larger than the number of thermal generated carriers n0, so that

n − n0 ≈ n .

Equation 3.3

SRH recombination in the base

In the base the SRH recombination rate is under high-level injection

R SRH =

n

τ SRH

.

Equation 3.4

The recombination current due to the SRH recombination is then by using Equation

2.41 and Equation 3.2

J rec , SRH =

q ⋅ t c ⋅ ni

τ SRH

1 qV

exp

.

2 kT

27

Equation 3.5

3 Cells at high concentration levels

Thus, the ideality factor for the SRH recombination is 2 under high-level injection

conditions.

Auger recombination in the base

The Auger recombination rate is in the base under high-level injection

R Auger = C n n 3 + C p n 3 = C A n 3 ,

Equation 3.6

where CA = Cn + Cp (ambipolar Auger coefficient).

Using Equation 3.2 and Equation 3.4, the Auger recombination current is

3 qV

J rec , Auger = q ⋅ t c ⋅ C A ni3 e

2 kT

.

Equation 3.7

Thus, the ideality factor for the Auger recombination is 2/3 under high-level injection.

Recombination in the highly doped regions

The recombination in the highly doped regions can be treated as the SRHrecombination in the base under low-level injection. This is due to the fact that the

highly doped regions are under low-level injection even for very high irradiation. So,

the ideality factor of the recombination in the highly doped regions is always 1

(see Chapter 2.4).

Recombination in the depletion region

In the depletion region the number of electrons equals nearly the number of holes. Thus,

the recombination in the depletion region can be seen (if the recombination centre is in

the middle of the band gap) as the SRH recombination in the base under high-level

injection. So, the ideality factor is 2.

Surface recombination

The surface recombination mechanisms vary along the rear side of the cell cause of the

different local carrier concentrations underneath the rear side. In the red and yellow

marked regions in Figure 3.1 the dopant concentration is larger than the concentration

of the generated carriers, if the cell is in low-level injection. This leads to an ideality

factor of 1 (see Chapter 2.3.5). In the yellow marked region, the surface is under lowlevel injection even for high concentration levels. This leads to an ideality factor of 1

independent of the concentration.

Under high-level conditions in the base the generated carrier density in the red marked

area exceeds the dopant concentration leading to high–level injection effects in this

region underneath the surface.

28

3 Cells at high concentration levels

ne>nh

ne~nh

ne<nh

oxide

n+

depletion region

p-silicon

Figure 3.1: Regions with different surface recombination behaviour underneath the

rear side of the cell.

Since the surface is under high-level injection, it is

I rec, surface = q ⋅ S

∫ n dA ,

Equation 3.8

S surface

which results in

1 qV

I rec, surface = q ⋅ S ⋅ Asurface ⋅ ni exp

,

2 kT

Equation 3.9

where Asurface is this part of the surface, which is red marked in Figure 3.1.

Therefore, the ideality factor of the surface recombination is 2 in the highly injected

case.

In the green marked region the depletion region intercepts the surface. In the depletion

region the number of electrons equals nearly the number of holes, so that this region can

be treated as it is under high-level injection at low and high incident irradiance. This

leads to an ideality factor of 2 under low- and high-level injection. Due to the

interdigitated pn-structure of the RLCC cell, a large area of the depletion region

intercepts the surface, so that the recombination of the depletion zone intercepting the

surface can not be neglected in investigating the recombination mechanism.

Summary of the recombination mechanism

The ideality factors of the different recombination mechanism in a solar cell at different

concentrations are listed in Table 3.1.

Recombination

Injection level in the base

Ideality factor

SRH-recombination in the

base

Low-level injection

1

29

3 Cells at high concentration levels

SRH-recombination in the

base

High-level injection

2

Radiative recombination

Low-level injection

1

Radiative recombination

High-level injection

1

Auger recombination

Low-level injection

1

Auger recombination

High-level injection

2/3

Recombination in the

diffused regions

Low- and high-level

injection

1

Recombination in the

depletion region

Low- and high-level

injection

2

Surface recombination of

the depletion region

Low- and high level

injection

2

Surface recombination

Low-level injection

1

Surface recombination

High-level injection

2

Table 3.1: Ideality factors for different recombination mechanism at different

concentration levels.

Current voltage characteristics under high level injection

If any voltage drop in the base is neglected and taking Equation 2.23, the complete

current voltage characteristics can be written as

q ⋅ S ⋅ Asurface q ⋅ tc ⋅ ni

1 qV

J out =

+

+ J 02 exp

τ hl

A

2 kT

qV

+ J 01 exp

kT

(

)

3 qV

3

+ q ⋅ t ⋅ C Ani exp

− J ph

2 kT

Equation 3.10

where tc is the thickness of the cell and S is the surface recombination velocity.

Therefore, the current voltage characteristics can be expressed by the photogenerated

current minus the recombination terms under high-level injection. This leads to a three

diode characteristic of the solar cell as shown in Figure 3.2.

30

3 Cells at high concentration levels

Rs

n=1

n=2

Iout

n=2/3

Iph

Rp

Figure 3.2: Three diodes characteristics of the cell in high level injection, whereby the

series resistance Rs and the parallel resistance Rp are taken into account. Rp can be

caused by leakage currents to the surface or in the junction.

3.2

Mobility and conductivity

In doped semiconductors in low-level conditions the mobility of the carriers is limited

by scattering effects with phonons and impurities. With increasing doping concentration

the impurity concentration increases leading to a lower mobility of the carriers. The e/hmobilities are fully presented in the Masetti model [21]. Due to the lower effective mass

of the electrons the mobility of the electrons is higher than the mobility of the holes.

Using the Einstein-relation, mobilities can be converted to diffusivities for a certain

temperature.

De , h =

kT

µ e,h ,

q

Equation 3.11

where µe,h are the mobilities.

If the solar cell is in high-level injection, the above mentioned scattering effects are

unimportant. The main scattering effect is the carrier-carrier scattering effect due to the

high concentration of both carrier types. In addition the interaction between a hole and

an electron depends not only on the concentration but also on the relative direction of

motion of both carrier types.

In rear-contacted concentrator cells most of the carriers are generated at the front side of

the solar cell and must diffuse from the front to the rear side of the cell. Therefore,

electrons and holes diffuse in the same direction. In this case the diffusivity of the

carriers can be calculated as [22]

Da =

2kT µ h µ e

,

q µh + µe

Equation 3.12

where Da [cm2/s] is the ambipolar diffusion coefficient. In order to calculate the carrier

mobilities, the generated carriers are equated the doping concentration in the Masetti

model.

The total conductivity of the carriers in the semiconductor is

31

3 Cells at high concentration levels

σ total = σ e + σ h = q(ne µ e + nh µ h ) .

Equation 3.13

In low-level injection and in a n-doped (p-doped) semiconductor is ne>>nh (nh>>ne),

thus the total conductivity is

low − injection

σ total

, n − doped = σ n = qn e µ e for a n-doped semiconductor and

Equation 3.14

low − injection

σ total

, p − doped = σ p = qn h µ h for a p-doped semiconductor.

Equation 3.15

Therefore, the total conductivity depends only on the number of majorities in low-level

injection.

Under high-level injection and if the motion of the electrons and holes is in the same

direction, the conductivity can be calculated by using Equation 3.11, Equation 3.12 and

Equation 3.13.

σ ehigh −injection = σ hhigh −injection = qne,h

high − injection

= σ ehigh −injection + σ hhigh −injection = 4qne

σ total

2µ e µ h

µe + µh

µe µh

µe µh

= 4qnh

µe + µh

µe + µh

Equation 3.16

Equation 3.17

From Equation 3.17 it follows that the total conductivity under high-level injection is

independent of the base doping concentration and depends only on the number of

generated carriers, where nh = ne.

3.3

Band gap narrowing

Due to the interaction between electrons and holes and the interaction between free

carriers and dopants, the band gap between the valence band and the conduction band is

reduced. This is the so called “band gap narrowing”(BGN). In order to take this effect

into account, the intrinsic carrier density ni is replaced by the effective carrier density

ni,eff.

ni ,eff = ni e

∆E g

2 kT

Equation 3.18

where ∆Eg is the decrease of the band gap due to the BGN.

Using the model of the “apparent BGN” [23] and using fits of measured data of ∆Eg, the

value of the intrinsic carrier density ni is 1x1010cm-3 at 300 K [24]. Thereby ∆Eg can be

calculated to

(

)

N A > N ref

E ln N a / N ref

if

∆E g = bgn

N A ≤ N ref

0

Equation 3.19

where Ebgn = 17.8 meV and Nref = 2.3x1017 cm-3.

32

3 Cells at high concentration levels

In simulating RLCC cells, BGN effects due to high-level injection in the base are

neglected, because the solving algorithm would be much more complex due to the

feedback of ni and ∆Eg. BGN effects due to high doping concentrations are taken into

account in simulating the cells.

3.4

Current crowding

High local current densities generate “current crowding” problems. High local current

densities are generated in conventional solar cells by [25]

•

a very high resistance of the diffused regions underneath the contact windows in

comparison with the metal resistance,

•

a small contact resistance between the metal and the semiconductor in comparison

with the resistance of the diffused region underneath the contact windows.

In the RLCC cells the “current crowding” problems are generated in the tips of the

fingers next to the bus-bars, because all the electrons (holes) generated above the p-bus

bars (n-bus bar) must diffuse into the tip of the n-finger (p-finger) (this is fully

discussed in Chapter 8.4).

The effect of the “current crowding” is similar to the effect of the “non-generation

losses”(see Chapter 2.5). Due to the local high current densities, different voltage drops

are generated locally in the solar cell. Working at the maximum power point of the

complete cell, local regions of the cell might work not at the global maximum power

point leading to fill factor losses of the complete cell.

3.5

Edge losses

For our rear-contacted cells FZ material is used. Due to the high lifetime τb of the

minorities in FZ material, the diffusion length L of the generated carriers is very long

(L = (D x τminority)1/2). This long diffusion length is needed, so that the carriers, which are

mostly generated at the front, can diffuse from the front to the rear side. Unfortunately,

some carriers diffuse into the edge area outside of the small-sized active cell area

(4.5 mm x 4.5 mm), recombine in the bulk or at the saw cut edge of the cell and are lost

for the cell. In order to minimise the recombination losses, the distance between the saw

cut edge, having a very high recombination velocity, and the active cell area should be

two times of the diffusion length of the minorities as shown in [26].

At one sun the generated minority density at the MPP in the cell is around 2x1014cm-3

(see Chapter 8.1) and a cell with a 1 Ω cm base material is in low-level injection. The

diffusion length can be estimated to

33

3 Cells at high concentration levels

− injection

L1low

33 cm 2 / s ⋅ 2000 µ s = 2.6 mm ,

Ωcm , p − doped ≈

Equation 3.20

where Dh is 33 cm2/s and the bulk lifetime of 2000 µs is taken from measurements in

[27].

In the concentrator system, the cells are illuminated with 200 suns. At 200 suns the

generated minority density is around 5x1016cm-3 and the 100 Ω cm cell is in high-level

injection. The diffusion length for a p-doped semiconductor in the highly injected case

can be estimated to

high − injection

2

L100

Ωcm , p − doped ≈ 17 cm / s ⋅ 400 µ s = 0.8 mm ,

Equation 3.21

where 17 cm2/s is the ambipolar diffusion coefficient from Equation 3.12.

For an application of the rear-contacted solar cell in the concentrator system, the

distance of the active cell area and the saw cut edge of the RLCC cell should be two

times of the diffusion length of the minorities. A distance of 1.5 mm is chosen for the

RLCC cells in order to minimise edge losses.