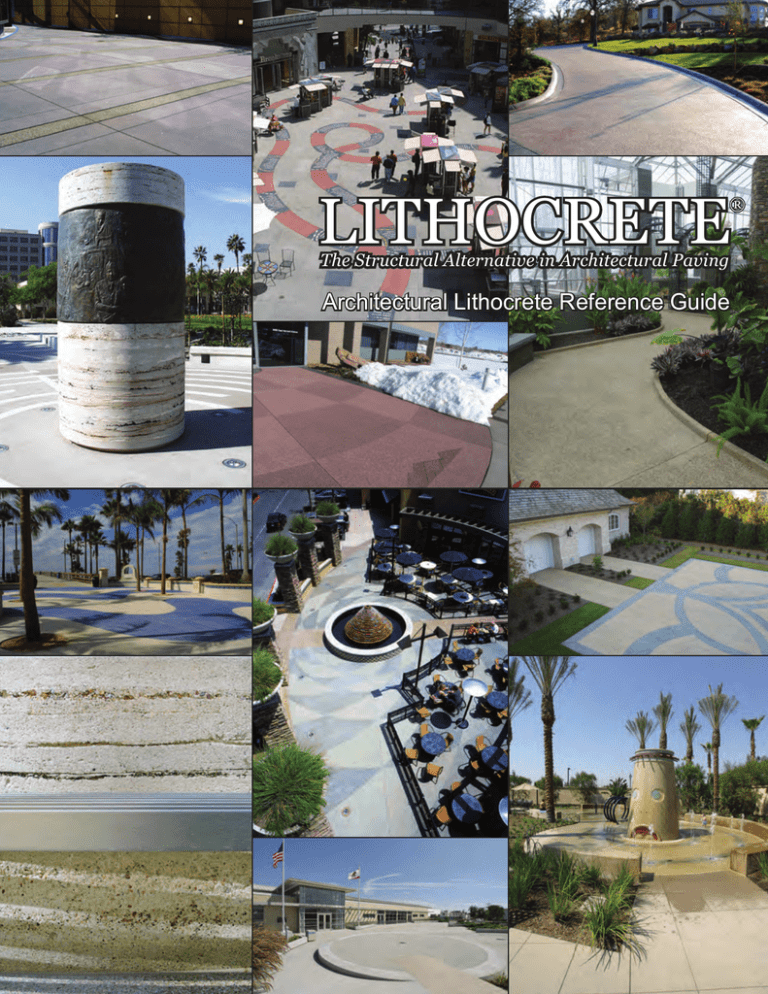

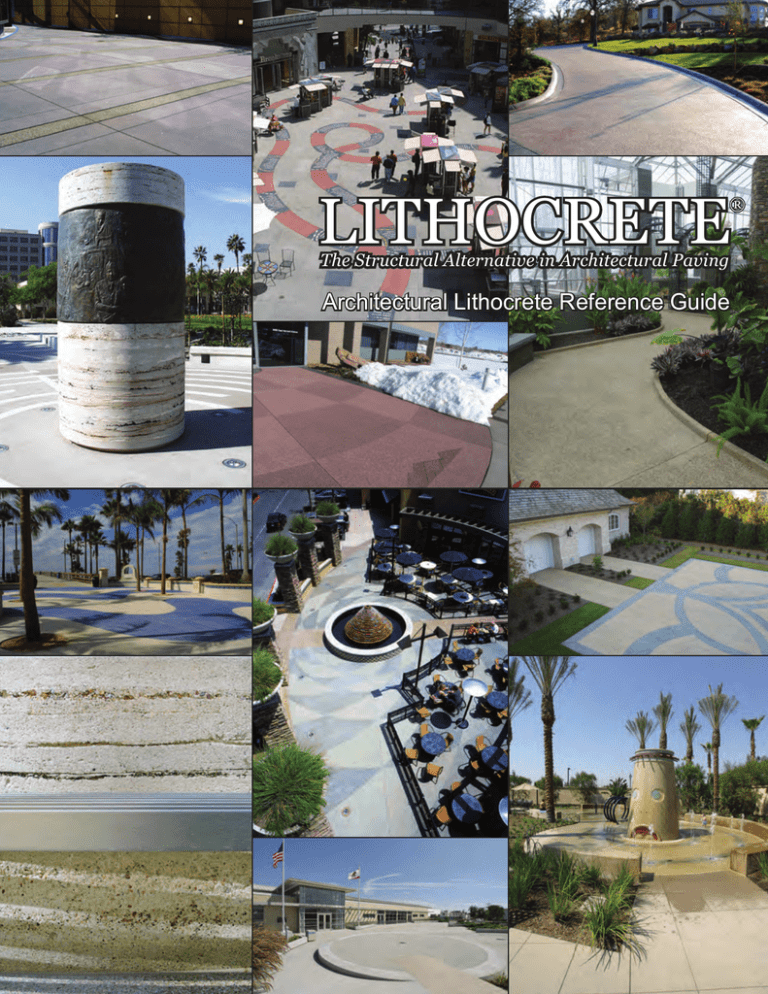

LITHOCRETE

®

Reference Guide Vol. 1

The Structural Alternative in Architectural Paving

Architectural Lithocrete Reference Guide

1

2

Copyright © 2008 Lithocrete, Inc.

All rights reserved. No part of this book may be reproduced, stored

in a retrieval system, or be transmitted in any form or by any means

without written permission from the publisher.

Lithocrete® is a registered trademark of Lithocrete, Inc.

Published by Lithocrete, Inc.

829 W. 17th Street, Costa Mesa, CA 92627

Authors, Ron Shaw & Jeff Counterman

Editor, Dan Carlsson

Graphic Design, Jeff Counterman

Main Photography, Ron Shaw

Printed in the USA

Index

3

Licensees

4

Introduction

6

®

Lithocrete Projects

Glass Lithocrete

®

®

Lithocrete Systems

12

34

44

3

Hollywood & Highland, Hollywood, CA

4

Opus Center / Koll Center, Irvine, CA (See pg. 11).

PROJECT LIST

REFERENCE INDEX

1800 Century Park East, Los Angeles, CA 51-52

2049 Avenue of the Stars, Los Angeles, CA 8, 56

Anaheim Veterans War Memorial, Anaheim, CA 48

Balboa Village, Newport Beach, CA 36-37

Bothell High School Performing Arts Center, Bothell, WA 32

California Endowment, Los Angeles, CA 54

Caltrans District Headquarters, San Diego, CA 30

Capital Group, Irvine, CA 9

Chapman College, Orange, CA 49

Chico City Plaza, Chico, CA 43

Colorado Hardscapes Corporate Office, Denver, CO 20

Constellation Place/MGM Corporate Headquarters, Century

City, CA 22-23, 46-47

Corporate Headquarters, Thousand Oaks, CA 12

Culver City’s City Hall, Culver City, CA 33

Daniel Stowe Botanical Gardens, Belmont, NC 16

Dayton Mall, Dayton, OH 29

El Dorado Pool, Scottsdale, AZ 40-41

Fenton Market Place, San Diego, CA 3

Fletcher Cove Park, Solana Beach, CA 10, 25

Forest Hills Residential Home, Wilmington, NC 17

Fox Studios, Century City, CA 18-19

Fremont Peak Park, Seattle, WA 32

Friant Foothills Residential Home, Fresno, CA 24

Hanna Fenichel Center, Solana Beach, CA 55

Hollywood and Highland, Hollywood, CA 1, 53

Huntington Bank, Columbus, OH 28

Innovative Concrete Corporate Offices, Round Rock, TX 49

Japanese American National Museum, Los Angeles, CA 26-27

Manhattan Fire and Police Station, Manhattan Beach, CA 44-45

National City Library, National City, CA 2, 31

Opus Center / Koll Center, Irvine, CA 2, 11

River Bluffs Residential Home, Fresno, CA 24

Rosa Street Bridge, Solana Beach, CA 38

Serendra, Manilla, Philippines 21

Shaw & Sons Corporate Offices, Costa Mesa, CA 6-7, 34-35, 51

Summit at Copper Square, Phoenix, AZ 39

T.B. Penick & Sons Corporate Office, San Diego, CA 50

The Atrium, El Segundo, CA 14-15

Theme Park, Hong Kong 10

Themed Retail/Entertainment District, Anaheim, CA 37, 48

Woodbury, Irvine, CA 37, 42

World Harvest Church, Columbus, OH 50

LITHOCRETE®:

Ascona Lithocrete® 6, 9, 13, 27, 51, 54

Bianco Nero Lithocrete® 6, 14-15, 17, 25, 33

Freeze-Thaw Conditions 20, 28-29, 32

Glass Black Lithocrete® 20, 32

Glass Blue Lithocrete® 2, 5, 10, 21, 34-43

Glass Green Lithocrete® 5, 41-42, 45

Glass Orange Lithocrete® 10, 38

Glass Purple Lithocrete® 37-38, 43

Glass Red Lithocrete® 25, 38, 41

Glass Yellow Lithocrete® 25, 37-39, 41-42

Guscio Shell Lithocrete® 10, 31, 36-37, 45

Mica Lithocrete® 1, 53

Public Works Projects 10, 25-27, 32-33, 36, 38,

43-45, 48

Pyrite Lithocrete® 2, 24, 31-32

Quartz Aggregate Hybrid Lithocrete® 20

Residential Lithocrete® 17, 24

Rosso Lithocrete® 6, 18

Rosso Nero Lithocrete® 6, 11, 27, 29, 36

Silica Carbide Lithocrete® 1, 22-23, 32, 53

Stained Lithocrete® 20, 30-31

Verde Lithocrete® 6, 22-23, 28

Verona Rosa Lithocrete® 6

Water Features & Pools 6, 15, 41-44, 48-49

White Aggregate Hybrid Lithocrete® 22

LITHOCRETE SYSTEMS:

System 1 - Original Lithocrete®

System 2 - Sedimentary Walls™ 23, 46-50

System 3 - Lithocrete Thin Tech™ 50

™

System 4 - Lithocrete Presto 12-13, 44, 51

System 5 - Presto Pneumatic Spray™ 1, 52-53

System 6 - LQS™ 25, 29, 54

System 7 - Lithocrete Litho Mosaics™ 55

COMING SOON:

System 8 - Monolithic Pour Joint System

System 9 - Monolithic Wall Joint 56

System 10 - Presto Wall Finish 56

System 11 - Non-Slip Ground Profile

System 12 - Structural Deck Pour System

System 13 - Monolithic Template Pour System

System 14 - Aquifer Replenishment System 51

System 15 - Slot Drain System 51

5

LICENSEES

ALL WEST ARCHITECTURAL, A DIVISION OF

ALL WEST CONSTRUCTION, INC.

Mike Carsten

2560 S. East Avenue

Fresno, CA 93706

TEL: 559.237.9600

FAX: 559.237.9607

www.awcfresno.com

ARCHITECTURAL STAINS, INC.

Mike Anderson

4301 S. Valley View #17

Las Vegas, NV 89103

TEL: 702.871.0045

FAX: 702.871.0038

www.architecturalstains.com

6

ARTISTIC CONCRETE SURFACES

Harvey Namm

4100 N. Powerline Suite Y-2

Pompano Beach, FL 33073

TEL: 888.567.8809

FAX: 954.970.7431

www.artisticsurfaces.com

BELARDE COMPANY, INC.

John F. Belarde

P.O. Box 684

Woodinville, WA 98072

TEL: 425.376.2500

FAX: 425.376.0332

www.belardeco.com

BEYOND CONCRETE

36 Industrial Drive

Keyport, NJ 07735

TEL: 800.972.0668

FAX: 732.441.3318

www.beyondconcrete.com

BOMANITE ARTISTIC CONCRETE

Aaron Echaniz

1860 W. Paisano Drive

El Paso, TX 79922

TEL: 915.533.6497

FAX: 915.542.4248

www.artistic-concretes.com

CAROLINA BOMANITE CORPORATION

Mike Bernath

4933 Chastain Ave.

Charlotte, NC 28217

TEL: 704.364.1854 • 800.522.6514

FAX: 704.527.7789

www.carolinabomanite.com

CHIEF CONCRETE, INC.

Matt Walker

6275 Stevenson Way

Las Vegas, NV 89120

TEL: 702.435.4038

FAX: 702.435.4075

www.chiefconcrete.com

COLORADO HARDSCAPES

John Buteyn

8085 E. Harvard Ave

Denver, CO 80231

TEL: 303.750.8200

FAX: 303.750.8886

www.coloradohardscapes.com

CREATIVE CONCRETE OF NEW MEXICO, INC.

Mary Jo Arrell

1749 Indian School NW

Albuquerque, NM 87104

TEL: 505.343.9067

FAX: 505.764.8780

www.ccnmi.com

CSOLUTIONS, A DIVISION OF MIDDLE GEORGIA

CONCRETE CONSTRUCTORS, INC.

Scott Truax or Tim Blankenship

3077 McCall Drive, Suite 15

Atlanta, GA 30340

TEL: 678.797.1901

FAX: 678.797.1822

www.csolutions.cc

CYPRESS BOMANITE

Ronnie Traballo

537 Edsa, Cubao

Quezon City, Philippines

TEL: 632.723.7719

FAX: 632.912.8491

www.cypressbomanite.com

HICKS CONCRETE CONSTRUCTION, INC.

Steven W. Hicks

7545 Commerce Street West

Corcoran, MN 55340

TEL: 763.420.7755

FAX: 763.420.6628

www.hicksconcrete.com

INNOVATIVE CONCRETE DESIGNS, LP - AUSTIN

Scott Carter

1 Roundville Ln., Suite 400

Round Rock, TX 78664

TEL: 512.218.3400

FAX: 512.833.6548

www.icondesignstx.com

INNOVATIVE CONCRETE DESIGNS, LP SAN ANTONIO

Mike Logsdon

#1 Bergmann Road

Boerne, TX 78006

TEL: 830.816.6670

FAX: 830.249.3113

www.icondesignstx.com

JEFFCO CONCRETE CONTRACTORS

George Henry

13414 Hwy. 69 South

Tuscaloosa, AL 35405

TEL: 205.345.3443 • 800.226.2668

FAX: 205.752.0973

www.jeffcoconcrete.com

JW SCHULTZ CONSTRUCTION

David Schultz

43 US Hwy. 51

Edgeton, WI 53534

TEL: 608.884.4720

FAX: 608.884.9349

www.jwschultzconstruction.com

QUALITY CONSTRUCTION SERVICES, S.A. de C.V.

Pablo Aviles

Alpes 1030-3

Lomas de Chapultepec

Mexico, D.F. 11000

TEL: 01 55 53 80 54 37

TEL: 01 800 639 6226

www.qcmex.com

ROBERT T. HILL & ASSOCIATES

Robert Hill

199. E. Shasta Ave

Chico, CA 95973

TEL: 530.891.4280

FAX: 530.891.0394

www.RobertTHill.com

T.B. PENICK & SONS, INC.

Frank Klemaske

9747 Olson Drive

San Diego, CA 92121

TEL: 858.558.1800

FAX: 858 558.1881

www.tbpenick.com

T.B. PENICK & SONS, INC. - OHIO

Bob Bennett

P.O. BOX 476

Grove City, OH 43123

TEL: 614.801.1844

FAX: 614.801.1877

www.tbpenick.com

7

Fenton Marketplace.

PROGRESSIVE CONCRETE WORKS, INC.

Mike Riggs

2136 W. Melinda Lane

Phoenix, AZ 85027

TEL: 623.582.2274

FAX: 623.582.1751

www.progressiveconcrete.com

SHAW & SONS

Ron Shaw

829 W. 17th St., Ste. 5

Costa Mesa, CA 92627

TEL: 949.642.0660

FAX: 949.642.0967

www.shawconstruction.com

Architectural

Concrete

F

or more than 56 years, Shaw & Sons

has been a leader in the production and

installation of architectural concrete.

Combining extensive knowledge of concrete

as a building material with artistic design, Shaw &

Sons created a unique architectural concrete product

called Lithocrete® which has been featured in numerous

public and private projects including many of Southern

California’s landmark buildings, institutions and public

places. These include the J. Paul Getty Villa Museum,

Griffith Observatory, a themed retail/entertainment

district in Anaheim, LA LIVE, Fox Studios, as well as

national museums, hospitals and local libraries.

Patent-protected Lithocrete® has been specified by

top-tier designers, architects, general contractors

and building owners in Southern California as their

architectural concrete of choice for the past 25 years.

8

Because of its popularity, Shaw & Sons is now making

Lithocrete® available to the design and construction

industries outside the Southern California area. Since

1993, Shaw & Sons has selected and licensed 20 wellrespected concrete construction companies throughout

the nation to install Lithocrete®.

As licensees, these companies have also been trained

to install Lithocrete® the “Lithocrete® Way,” which is

modeled after Shaw & Sons’ 56 years of experience

based on the installation of millions of square feet

of award-winning concrete product. It is important

to both Ron and Lee Shaw that each licensee be

capable of installing Lithocrete® to Shaw & Sons’

high standards of quality, design, and specifications.

To this end, each licensee spends numerous hours

of on-site training to learn how to properly install

Lithocrete®.

When you specify Lithocrete® for a project, you

are not only getting a unique architectural concrete

product, you are benefiting from Shaw & Sons’

proven methods and time-tested procedures which go

far beyond that offered by other concrete construction

companies.

Lithocrete’s® pristine Sample Garden.

Architectural Concrete

The Lithocrete® Way

PHASE III CONCRETE PLACEMENT AND FINISHING

Without the proper execution of Phase I, II and III, architectural concrete

paving will be substandard. Lithocrete prides itself as a leader in constructing

high-quality architectural concrete paving. Some, but not all, of the steps

Lithocrete implements in this zone are as follows:

• Thorough understanding of the design intent by the Owner, Designer and

General Contractor before starting project.

• Joint creation of a concrete mix design for each paving type on the project.

• Verification of approved mix design for each truckload delivered to the job

site.

• Adherence to “sole source” batch materials, i.e. sand, rock and cement,

throughout the duration of the project. Variations in batch material sources

will lead to unsightly “checkerboard” pours.

• Strict adherence to quality concrete mix design principles by Lithocrete

which include, same-source batch plant materials, 6-7 sack cement

content, 4” slump (+/-1”), 2,500 min. PSI strength, a water cement (W/C)

ratio between .62 and .67 use of admixtures such as shrinkage reducers,

integral colors and synthetic fibers.

• When installing Lithocrete, incorporate Lithocrete’s three patented concrete

additives: Lithocrete Conditioner, Lithocrete Etch Retarder and Litho-Seal.

• Placement, finishing and curing of concrete under strict adherence to ACI

standards, 2001 edition. Contraction and construction joints are precisely

laid out and saw cut straight and true to line and grade.

• After Lithocrete is installed, a final cleanup and a minimum of three coats

of clear, penetrating Litho-Seal paving sealer is applied to the surface to

reduce surface staining and ASR (alkali-silica reaction)

PHASE II FORMWORK AND REINFORCEMENT

Without proper formwork and reinforcing, concrete will not achieve its full

architectural and structural properties which designers demand today.

Some, but not all, of the steps Lithocrete implements during construction of

Phase II Formwork and Reinforcement are as follows:

• Layout, line and grades are checked and rechecked prior to beginning

construction.

• Layout is provided with digital equipment to an accuracy of +/- 1/8th of an

inch.

• Construction joints laid out to occur at predetermined locations placed

typically at 12-feet o.c.e.w. not to exceed 20-feet o.c.e.w.

• Placement of polystyrene foam isolation joint material at vertical surfaces,

i.e. walls, columns, steps, utilities lids, etc.

• Placement of steel rebar (not wire mesh) with proper clearances from

adjacent formwork, subgrade, and paving finish surfaces. Rebar is typically

installed as #4’s at 18” o.c.e.w. Rebar minimizes slab cracking and

significantly reduces vertical displacement should a crack occur.

• Adobe blocks are used to support rebar to the center of the slab.

• Form lumber is new, Grade #2 S4S Douglas Fir or better.

• Steel stakes are used in-lieu of wood.

• Installation of Speed Dowels, spaced typically at 18” o.c. or match rebar

schedule.

PHASE I SUBGRADE PREPARATION

On every project, Lithocrete ensures that proper subgrade procedures

have been executed prior to beginning work. Poor subgrade preparation

often leads to paving failure. Some, but not all, of the steps Lithocrete

implements during Phase I Subgrade Preparation are as follows:

• Placement of a minimum of 2” of a washed concrete sand base over

subgrade. Sand provides a “slip plane” for paving and allows for even

concrete hydration, which minimizes paving surface discoloration.

• Verification of precise and complete subgrade elevations. Inaccurate or

incomplete elevations lead to paving “bird-baths” and awkward cross

slopes, which may eventually lead to an unattractive paving product.

• Verification that utilities, i.e. sleeves and pipes, have been placed below the

sand base and that the utilities have been backfilled to proper compaction

standards. Utilities encased in concrete paving lead to stress cracks on the

paving surface and should be avoided at all times.

• Review of the Project Soils Report related to adequate compaction, base

materials and doweling/rebar requirements.

• Placement of geotextile fabric or aggregate base, if required, in the Project

Soils Report.

9

LITHOCRETE®

Lithocrete® is the original patented concrete system that has redefined fine plazas and other hardscape creations nationwide.

Lithocrete’s® unique colors and textures combine to create the perfect finish for large building plazas, museums, public

buildings and municipal projects. It is a natural granite and/or stone finish permanently imbedded into the surface of

structural concrete with Shaw & Sons’ own unique finishing process. Due to its small crushed size, Lithocrete® has become

a favorite for hospital entries where patients, handicapped people and visitors require a non-abrasive surface that remains

non-slip even when wet from inclement weather. Lithocrete® easily works over grade or on structure, and can configure

to variable grades and conditions. With System 1 Lithocrete®, there are also two additional patents that enable the use of

reactive materials including natural shells and heat-fractured, recycled glass, which has sustainable attributes.

Lithocrete® is currently the product of choice in Los Angeles’ world-renowned Century City mixed-use district. Five major

projects in 2007 on Century Park East have selected Lithocrete® for both new construction and hardscape renovations.

®

Although resilient and hardy, Lithocrete consists of a delicate balance of materials that require for optimum performance

use of special products such as Lithocrete Etch Retarder® that promotes flawless results of the finished product. Litho-Etch

Retarder® is an exclusive formula limited to use by Lithocrete® licensees and is the result of years of chemical analysis

based on Shaw & Sons’ research and development. Lithocrete® Conditioner enables a uniform finished product while LithoSeal Sealer is a one-time application that dramatically increases surface tension and protects Lithocrete® year-after-year

while greatly reducing maintenance.

10

Lithocrete Etch Retarder®.

Lithocrete Etch Retarder® application.

Capital Group Headquarters featuring Lithocrete® Ascona.

NO DELAMINATION

Delamination of the paving surface, common with other types of architectural concrete products, does not occur with

Lithocrete®. Lithocrete® is an integrated structural concrete and is not merely a “topping.” Common problems of exterior

toppings frequently result from irrigation and/or ground water that typically seeks horizontal joints between topping

and structural slabs, which in a short time can cause delamination. This will not happen with Lithocrete®. Lithocrete® is

similar to warehouse trap-rock slab construction made for high-traffic surfaces. The main difference is that Lithocrete®

exposes the surface materials and utilizes other procedures that allow Lithocrete to maintain its structural integrity much

longer than other architectural finishes. Esthetically, Lithocrete’s® granite and marble products have unique fine granite

or marble finishes, and unlike slab-set granite, they do not have to be flame-finished or sand-blasted to retain a non-slip

surface. By using crushed materials, Lithocrete® retains its natural beauty and ability to reflect small amounts of light.

11

MATERIALS

Almost any type of hard, durable aggregate can be used in the

preparation of Lithocrete® paving. Aggregates that have been

used successfully include: crushed rock (e.g. granite, obsidian,

quartz, serpentine, and marble), opaque or translucent

glass (predominantly recycled glass), gems and minerals

(e.g. turquoise, agate, obsidian, quartz, pyrite, jasper, and

serpentine), sea shells, beach pebbles, silica carbide, mica,

“Pixie Dust,” terra cotta, slate, tile, and brass insets.

In the past, keeping small ASR (alkali silica reaction) or

“reactive” aggregates embedded in the surface of concrete

paving was difficult, if not impossible. Lithocrete’s® patented

paving process permanently bonds “reactive” as well as

non-reactive aggregates with lithium quartz. Litho-Seal,

®

Lithocrete’s patented sealer, significantly reduces the reactive

condition that may exist between cement and aggregate. To

ensure minimal maintenance, a one-time application of LithoSeal should be used on Lithocrete® surfaces.

12

Theme Park, Hong Kong.

Fletcher Cove Park, Solana Beach, CA.

COLOR CONSISTENCY

Adding new Lithocrete® to existing Lithocrete® is performed seamlessly with perfect color matching. Lithocrete’s®

standard series of aggregates are from quarries that have good, long-term consistency characteristics. Projects installed

more than 25 years ago using Lithocrete® paving can be matched almost perfectly today. The Opus Center / Koll Center

pictured below and on page 2 features five separate phases of Lithocrete® installed over a span of nearly 25 years with

perfect color consistency.

13

Rosso Nero Lithocrete® is surrounded by tawny pink sandblasted band pattern and cast-in-place planter curb walls.

PATENTS

Three US patents protect Lithocrete®: #4,748,788; #6,016,635; #6,033,146; and U.S. Trademark #1,879,329. Lithocrete®

has a patent pending for power troweling which is used on any size surface-seeded aggregates encompassing a wide

variety of materials. Lithocrete® also has a patent pending for pneumatically applying surface-seeded materials that will

eliminate the common unevenness of applying silica carbide, mica, granites, sands, and other small surface-applied

materials. In addition to the aforementioned patents, Lithocrete® has patents pending for every individual system that is

introduced throughout this book, including System 8 - Monolithic Pour Joint System; System 9 - Monolithic Wall Joint;

System 10 - Presto Wall Finish; System 11 - Non-Slip Ground Profile; System 12 - Structural Deck Pour System; System

13 - Monolithic Template Pour System; System 14 - Aquifer Replenishment System; and System 15 - Slot Drain System.

Lithocrete® aggressively protects its patented products to ensure their proprietary status and market value.

14

Lithocrete® Projects

15

The Atrium

El Segundo, California

he Atrium office complex is the flagship property of

T

Continental Development’s Continental Park in El Segundo,

CA. The Atrium at Continental Park is the newest, most

prestigious business address in the South Bay area of Los

Angeles County. The two L-shaped, five-story buildings consist of

288,000 square feet of Class A office space, and incorporate the highest

technology and most advanced building systems available.

A concierge/security service and attached five-level parking structure

give business residents convenience and peace of mind. Tenants enjoy

an on-site gym complete with men’s and women’s shower facilities.

On-site restaurants – Fleming’s Prime Steakhouse & Wine Bar and

Romano’s Macaroni Grill – complement the rich array of amenities

within Continental Park. The Atrium serves as the Southern California

headquarters of Comerica Bank, one of the largest banking institutions

in the U.S.

16

To achieve the project’s high level of design, the materials and

workmanship had to be of the highest quality. A prime feature of the

project is the exterior landscaped courtyard framed by the placement of

the L-shaped buildings which also serves as an expansive outdoor space

for use by the tenants.

Flexibility was key for the exterior areas so they could be used as

semi-private space for individual use, but also be open enough to

accommodate large groups for informal receptions and gatherings.

It was necessary for the hard surface areas to be durable, easily

maintained, and yet have a rich, warm feel that will entice tenants and

®

visitors. Lithocrete was selected because it provided an integrally

colored aggregate finished concrete palette providing high esthetics and

low maintenance required by the architect and developer.

Plan view of Bianco Nero Lithocrete®

used throughout the Atrium.

Beginning construction subgrade.

Alternate pour plaza.

17

Cast-in-place wall fountains are surrounded by Bianco Nero Lithocrete®.

Fountain wall excavation.

Cast-in-place fountain walls.

Lithocrete® was selected to install the concrete

because of their reputation as one of the best

contractors for this kind of installation, which

requires a lot of skill and care to achieve a uniform

finish over a very large area. We didn’t have a

second chance at this and we knew we could

always trust Lithocrete® to do it right the first time.

Bruce DeJong, AIA

Gensler

Plaza pour complete.

Finished plaza.

Daniel Stowe Botanical Garden

Belmont, North Carolina

I

n 1989, Daniel J. Stowe, a retired textile

executive from Belmont, NC, reserved 400

acres of prime rolling meadows, woodlands

and lake front property and established a

foundation to develop a world-class botanical garden.

Curvilinear walkway meanders through tropical plants.

Geoffrey Rausch of MTR, Pittsburgh, PA, was

selected as the master planner for the land and the

first phase of the project included a visitor pavilion,

and 110 acres of cultivated land with 10 acres of

formal display gardens, all of which was completed

in 1999.

The second phase, which included the acclaimed

Orchid Conservatory, introduced the first public

conservatory in the region devoted to tropical

plants. The architects were looking for an aggregate

18

Close-up of granite monolithic curb and walkway.

walkway to match the local surroundings and

serve as a central feature of the structure. The

owners wanted a low maintenance walkway with

a monolithic curb to hold the mulch and moisture

off the walkway. Due to the design flexibility of the

aggregates and the dense low maintenance surface,

the answer for both the architects and the owners

®

was Lithocrete . Samples were made with various

blends of aggregates and color combinations until

the owners and architects settled on a mixture of four

different granites to blend with the natural stone,

brick, and slate used elsewhere on the project.

Curvilinear aggregate walkway provides a non-slip surface for

visitors.

®

By utilizing Lithocrete for the Orchid Walkway,

the planners achieved a non-slip surface for visitors

of all ages to walk on, with little work for the

maintenance crew in the moist, tropical environment.

Simultaneously, the architects achieved a color

scheme that is not only distinctive in its own right,

but blends beautifully with the natural surroundings.

Four granite aggregates in monolithic walkway and curb.

Forest Hills Residential Home

Wilmington, North Carolina

Constructed as a retirement home, this mansion is

nestled in the leafy neighborhood of Forest Hills

in Wilmington, North Carolina. The architecture

has a French provincial style and the driveway

was originally designed as a round about with a

planted circle. Luckily, we were able to convince

our clients that a traditional entry “courtyard”

was more appropriate. We reviewed several

different geometric patterns before settling on the

current design, which was based on a preliminary

wrought iron fence study that translated well to the

pavement.

Stanley tan granite blends with the house.

It was our original intent that the entry be

constructed using standard washed aggregate

concrete; however, the general contractor was not

comfortable constructing the geometric pattern

due to the sharp points the design created to which

we responded with a stained concrete to create

the complex pattern. Fortunately for the owner,

the landscape contractor, David Donahue, also a

landscape architect, introduced us to a new unique

approach to traditional concrete, Lithocrete®.

Bianco Nero Lithocrete® design from entry porch.

We conducted our own research on Lithocrete® and

agreed that Lithocrete® was in fact the perfect surface

for the project. Considering that this was the first

driveway in Wilmington to use Lithocrete®, we all

kept our fingers crossed that it would turn out well.

The end product was a beautiful finish, the perfect

color with excellent execution and the owner is

thrilled with their decision to select Lithocrete®.

John Nartowicz

Landscape Architect

Symmetrical design made with contrasting aggregate.

19

Fox Studios

Century City, California

A

t the southern edge of ultra modern

Century City, one of Los Angeles’ most

visible urban icons, are what remains of

the grand old studios of the 20th Century

Fox. Century City, with its tony array of hotels, shopping

centers, entertainment venues and towering skyscrapers,

was built on what was once the backlot of the 20th

Century Fox movie studio. Understanding the historic

value of this site, the developers named the commercial

complex “Century City.” Most of the studio’s facilities

have been relocated elsewhere to make room for the

Century City shopping center. But a significant part of the

old Fox Studios has survived and still remains active with

production of movies and TV dramas.

Avenue “D” fire lane.

Located on the landmark Fox Studios lot, the new

20

Fox Network Center and Executive Building combine

operation of Fox and its parent company, News

Corporation of America. The two adjacent buildings are

five-story structures built over a three-story underground

parking structure. Fox Network Center consolidates the

multiple Fox broadcasting activities previously scattered

throughout the LA area. The center is a 24-hour, fully

digital television broadcast facility for the nation’s fourth

largest network. It houses the technical operations of Fox

cable channels. The new Executive Building is the West

Coast headquarters for the executive and administrative

offices of the multimedia entertainment conglomerate.

Amenities include a 10,000 square-foot restaurant, a

65-seat private screening room and a large “blue sky”

®

media laboratory, and Lithocrete auto court and adjoining

hardscape.

Plan view of Rosso Lithocrete® and saw cut joint pattern.

21

Lithocrete® auto court constructed on waterproofed structural deck.

Lithocrete® has a distinctly elegant appearance in stark contrast to the asphalt pavement used throughout

Fox Studios. It helped us create promenades and plazas, each with a unique character. With the patterning we

saw cut into the Lithocrete®, “Avenue D” has a far richer quality to it, more like cut stone. It has become the

studio’s central gathering point for eating, casual business meetings and socializing. Using contrasting colors

in the Newscorp logo, Lithocrete® helped create the drama of the building’s entry.

Michael Tegnell

Senior Designer for Fox Studios

Colorado Hardscapes Design Center

Denver, Colorado

ithocrete® licensee Colorado

L

Hardscapes moved into a new facility

at 8085 E. Harvard Ave. in Denver,

CO, in September of 2001. Responding

to the ever-growing marketplace for architectural

grade concrete, Colorado Hardscapes transformed

the former medical space into a 14,680 squarefoot Concrete Design Center, which includes a

showroom, an outdoor sample courtyard, office

space, conference rooms, a plan room, and an R&D

facility.

Colorado Hardscapes’ Design Center is the only

Quartz aggregate hybrid Lithocrete® and saw cut scoring draw

together the alternating panels.

concrete design center in the state of Colorado.

As the leader in decorative concrete in the region,

Colorado Hardscapes spared no expense when

22

creating a design center for its product resources and

sales and marketing programs. The Design Center

is a hands-on learning center for architects, general

contractors, engineers and home owners where

they can see and feel not only the possibilities of

concrete, but can walk on, touch and learn the “back

story” behind the different concrete processes.

During the design phase of the new design center,

Alternating panels stained with diluted black chemical stain.

Colorado Hardscapes realized it needed an entrance

that would not only showcase the company’s

ability as concrete contractors, but also its desire

to provide one of the best decorative concrete

®

options available, patent-protected Lithocrete .

For the entrance, Colorado Hardscapes chose a

quartz aggregate hybrid Lithocrete® with alternating

panels stained with diluted black chemical stain and

borders of Lithocrete® with black concrete and black

glass. The safety, durability, and esthetics of the

Lithocrete® surface have made it a great marketing

entrance for Colorado Hardscapes’ Design Center

any season of the year.

Black Glass Lithocrete® with black concrete borders.

Serendra

Manila, Philippines

L

ocated just minutes away from

Makati’s Central Business District

is the Serendra master-planned

community. Developed by Serendra

Inc., a joint venture of Ayala Land Premier

Main water feature at center of open-air mall.

and Community Innovations, Serendra defines

the highest esthetics and quality standards of

community planning and development. The

12-hectare (29.6 acres) development sets the pace

for luxurious and serene living in suburban Manila.

Serendra’s design is a distinct mix of European

inspiration and Filipino flair. The master plan is

reminiscent of European residential villages which

are designed to be spacious with curvilinear and

multi-level housing units. However, the façade

resonates of native motifs used in ancestral “bahay

na bato” or literally translated “house of stone”

Alternating aqua blue glass Lithocrete® bands.

homes.

With approximately 7.5 hectares dedicated to wide

open spaces, themed gardens, and courtyards,

Serendra allows residents to enjoy an urban

sanctuary in the middle of the city. Seven custom

®

Lithocrete finishes are incorporated throughout

the project. Designers used vibrant Lithocrete®

interconnected colored pathways to promote a

pedestrian friendly community featuring glacier

green, brick red and sunburst yellow aggregates

in the Chinese-themed garden, and obsidian and

Gobi white aggregates in the Philippine courtyard.

Lithocrete® featured at store entrance in open-air mall.

At the heart of it all is the Piazza Serendra, the

development’s retail district, which features glass

Lithocrete® finishes seeded with recycled cobalt

blue, red, and green glass.

23

Constellation Place/MGM Corporate Headquarters

Century City, California

24

White aggregate hybrid Lithocrete® with Verde Lithocrete® bands and black with silica carbide bands. Prior to final clean up, sealing and

caulking, 3-inch stone inlay was saw cut into existing finishes and mortar-set into place. Three different but very specific hardscape patterns

encompass the building’s structure from the front entry to the porte cochere to the public area and gardens between the parking structure

and the building.

The Lithocrete® paving on this project is terrific. Its consistent and

looks substantial, and for us is an interesting material to match or

inlay with other kinds of pavers, such as natural stone.

Scott Johnson

Johnson, Fain Architects

Private entry patio for MGM screening previews. Verde bands complements the silica carbide

field panels and architectural saw cuts.

25

Verde Lithocrete® with silica carbide black bands in porte cochere with travertine stone inlay.

Constellation Place used various Lithocrete® color and patterns as displayed in the street entry

plaza, walkways and the Sedimentary Plaza (pp. 46-47).

River Bluffs Residential Home

Fresno, California

A home remodeled using earth tone and

natural aggregate rock with pyrite accents

complement the red roof structure and

Grecian columns. With the use of Lithocrete®

in Palm Springs Gold brings warmth and

Parking area featuring natural aggregate rock

with pyrite accents.

character to this Mediterranean home and its

architecture.

26

Friant Foothills Residential Home

Fresno, California

The architectural team worked closely

with a local landscape architect to

create a picture perfect frame for this

Mediterranean home nestled in the Friant

Foothills.

Detail of Lithocrete® driveway and entryway

bordered with a stained and rolled curb.

A Lithocrete® driveway poured on a 20% slope, bordered with

a stained and rolled curb.

Fletcher Cove Park

Solana Beach, California

O

cean-themed Fletcher Cove Park was carved from a

2-acre asphalt parking lot, giving the visitors and the

surrounding community a livelier, more inviting, and

esthetically pleasing place to enjoy the fresh breeze,

the sun, and the ocean view.

The transformation from parking lot to seaside park was the result

of a collaboration between Mike Peltz of M.W. Peltz & Associates,

landscape architects and urban planners, artist Betsy Schultz, and

®

®

Lithocrete . Embracing ideas from previous Lithocrete projects,

Peltz chose Lithocrete® as the best method to achieve the look he

Amphitheater, flatwork, and seating all utilize

LQS™ process.

wanted for the nautical park. Peltz introduced the ocean theme

concept into the park design and it was Lithocrete® that provided

the design solutions and materials to transform Peltz’s dream

into reality. Sand-like Lithocrete Quarry Stone™ (LQS™) was

juxtaposed with Lithocrete® shell aggregates that include mother

of pearl, course puka, coquina shells, and silver Mexican abalone

shells. The aggregates were hand seeded over shell imprinted

Lithocrete® to create a finish that is rich in texture and yet subtle

and elegant. Lithocrete® allows great flexibility and control of

aggregates; therefore a larger range of shell sizes were incorporated

into the design. The result is a natural and beautiful walkway that

complements the more colorful marine life art designed by Betsy

Schultz.

Fletcher Cove Park is an instructive and creative way to utilize and

maximize limited space. The seat walls throughout the park both

integrate and distinguish the different parts of the park in such a

way that the playground, basketball court, amphitheater, and green

lawn could all be incorporated into the design. Further, the detail

®

of the various walkways created with Lithocrete and the artist’s

meticulous on-going art installation for the walls, make this park an

ocean gem. And for the city and designers, this project was a great

success not only because of the esthetic achievement, but due to the

effective and professional collaboration between the artist, designer,

and Lithocrete®, the park was completed within budget.

Bianco Nero, yellow, and red glass Lithocrete® at

park entry poured into a sun-shape.

27

Japanese American National Museum

Los Angeles, California

28

T

he Japanese American National Museum is the only museum in the

United States dedicated to sharing the experience of Americans of

Japanese ancestry through images, documents and oral histories.

The new Japanese American National Museum pavilion is designed

to emphasize maximum flexibility and adaptability to allow the museum to

grow in an incremental and harmonious fashion. The architecture is bold and

contemporary, creating a dialogue between the new museum and the beautifully

restored former Buddhist temple that shares the museum site.

A part of the museum complex, the temple’s ceremonial entrance was rebuilt by

artisans who restored oak floors, reglazed and painted walls, stenciled original

designs on ceiling panels, and replicated delicate lanterns in what was once the

sanctuary. In the new museum, time-honored materials such as stone and wood are

juxtaposed with perforated stainless steel and high-performance glazing. In awardwinning fashion, the stone, steel and glass structure accented by Lithocrete®,

bridges East and West esthetic traditions.

Rosso Nero Lithocrete® alternating

with Ascona bands naturally

diminishes radial cast-in-place

stairs.

29

As design professionals, we look at each project as a unique opportunity to create something special. For

the Japanese American National Museum, we wanted the landscape design to be a seamless extension of the

building design. Our approach was based on minimal, but finely articulated forms that required a high level of

craftsmanship. The people at Lithocrete® have provided that level of craftsmanship and professional expertise

necessary to effectively realize our design intent. Their collaborative, service-oriented approach made them

an invaluable member of our team. We believe that their passion for quality, ingenuity, and understanding of

good design sets them apart when it comes to making concrete paving an effective medium expressing original

ideas.

Ann Cutner

Senior Associate/Landscape Architect

Huntington Bank

Columbus, Ohio

Thank you for an excellent installation project

with the sidewalks around the Huntington

Bank Building. At this time a year ago, we

were discussing the details of our project taking field samples, looking at schedules,

comparing product samples and colors,

discussing traffic control and responsibilities.

South view clearly reveals the clean lines of a quality

Lithocrete® project including a hidden E.J. System.

In less than six months after those meetings,

your company had installed approximately

9,400 square feet of Lithocrete® at the busiest

street corner in downtown Columbus and

through some very unusual autumn weather.

30

Now, one year later, we can just sit back,

admire the finished product, and smile. It is

easy to see that the maintenance of this surface

will be minimal compared to the pavers that

were replaced with the Lithocrete®. We no

longer worry about tripping hazards that

occurred with pavers moving and popping out

of place. The whole sidewalk appears cleaner

and neater. We regularly receive compliments

from tenants and passers-by.

The building owner is very pleased with the

decision to approve the project. As the Senior

Property Manager on site, I am proud to show

off the sidewalks and answer any questions

anyone might have about the project.

One of the four entrance where hundreds enter every day.

Bands of Florene Cream granite and fields of Verde granite

with green and amber-colored glass Lithocrete®.

Lynne B. Raduege

NAI Ohio Equities Realtors

Primary west entrance to Huntington Bank.

Dayton Mall

Dayton, Ohio

31

Primary intersection with a large pin wheel design showing alternating

fields of Lithocrete® and LQS™ finishes.

S

tarting with a traditional 1980’s style indoor mall

and a sense of adventure, the mall owner, Glimcher

Realty Trust of Columbus, OH, sought a fresh and

distinctive character for the new outdoor lifestyle

LQS™ finished natural concrete.

shopping experience which would evolve from the remodeling

of the existing retail facility. The key criterion for the exterior

hardscapes was to develop a look that would be distinctive, low

maintenance and meet or exceed safety requirements for slip

resistance.

The architect, FRCH of Cincinnati, OH, presented the owner with

®

the idea of using Lithocrete , noting its distinctive look, colorfast

nature and highly durable surface. On site mock-ups made the

final decision an easy one and now there are 60,000 square feet of

LQS™ finished Lithocrete® with 2,300 square feet of rose colored

granite Lithocrete® in the first of multiple phases of remodeling

planned for the facility.

Classic checkerboard of Rosso Nero Lithocrete® and

LQS™.

Caltrans District Headquarters

San Diego, California

T

he new 301,000 square-foot Caltrans

office campus is located on 10.8 acres

between Old Town State Park and the

San Diego River.

Designed by Wallace Roberts & Todd architects,

the campus landscape is a composition of entry

courts, pedestrian plazas, play areas and parking

lots. New trees along Taylor Street are species

that were introduced to Old Town during the

Mission, Mexican, American periods of historical

significance since 1769. These include Canary

Caltrans Headquarters, San Diego, CA.

Island palms, mission peppers, olive, oak,

eucalyptus, and jacaranda. The parking lot takes its

curved forms and native riparian materials from the

river. Bioswales in the parking lot are engineered to

32

collect storm water, which soaks into the ground.

®

Lithocrete was chosen for the flatwork because

of its durability and its monolithic and structurally

sound properties. WRT developed a custom blended

aggregate mixture named “Old Town Mix,” in

honor of the project’s location, to complement the

building’s design and colors.

Custom “Old Town Mix” created for the project.

Stained bands of Lithocrete® represent San Diego Freeway

system.

National City Library

National City, California

hen Carrier Johnson architects set out to find a flooring finish to complement the firm’s design for this

W

new library, the original choice was terrazzo. Terrazzo turned out to be too expensive for the library

budget. The criterion for the project was to find a finish with “durability in a civic presence.”

Durability was the main concern. The library is designed to last 50 years or more. Lithocrete® was

suggested as a cost alternative to terrazzo and the designers were ecstatic. The Lithocrete® alternative turned out to be

even better suited for the project than terrazzo. Lithocrete® has “a look that went along with the concept of the building.”

Carrier Johnson also discovered that they were able to customize the materials to complement their building design.

The designers chose a mixture of Indonesian green rock, tumbled beach glass, pyrite, and abalone shells. With decorative

®

®

Lithocrete bands on the exterior flatwork of the building, and Lithocrete on the inside, the architects were able to take

the same flooring they used on the exterior and continue their design within the interior of the library.

33

Monolithic 4 inch poured Lithocrete®.

Stained bands create illusion of separate

pours.

Minimized maintenance, no topical sealer required.

Highly reflective floor minimizes lighting

needs.

Bothell High School Performing Arts Center

Bothell, Washington

N

orth Shore Performing Arts Center, located at Bothell High

School in Bothell, WA, was recently expanded with the addition

of a state of the art theatre. This center is the region’s main

performing arts theatre and experiences a significant volume

of pedestrian traffic. Surrounding both the new gymnasium and theatre is a

beautifully designed, landscaped and highly used common area for students

and faculty during the day, and audiences and players during productions.

Lithocrete® was installed in a corded circular pattern in the common seating

®

area. The 1,450 square feet of Lithocrete was seeded with black glass, black

Lithocrete® was seeded with black glass, black

stone, iron pyrite, silica carbide, and set against

a black concrete background.

stone, iron pyrite, silica carbide, and set against a black concrete background.

Gray concrete walks lead out from the Lithocrete® into the two main entrances.

The additional decorative concrete touches throughout the seating area set a

pleasing tone and an artistic feel for visitors, players, students, and faculty.

34

Fresh snow on Lithocrete® showcasing the

durability of Lithocrete® under freeze-thaw

conditions.

Fremont Peak Park

Seattle, Washington

T

he people of Fremont,

WA, located in north

Seattle, believe that their

neighborhood is “The Center

of the Universe.” The entrance to their

new Fremont Peak Park, overlooking

Elliott Bay, incorporates this constellation

theory by designing the “27 Lunar Phases”

®

in black and white Lithocrete paving.

The shapes of the moon are formed with

metal bands, while the aggregate ranges

Twenty-Seven Lunar Phases

of the moon.

from white glass and stone to glow-in-the

dark stone and beads. The background

depicts the night sky with black glass,

stone, and silica carbide.

Plan view of white Lithocrete® glass and stone

aggregates in the phases of the moon.

Culver City’s City Hall

Culver City, California

C

ulver City is located in western Los

Angeles County with a population

of 38,816. Since the early 1900s,

Culver City has been home to many

motion picture production studios, in part because

it was the original home of MGM Studios. Today,

both National Public Radio West and Sony Pictures

Entertainment have headquarters in the city.

When Culver City was founded in the early 1900s,

the elected officials were called the Board of

Culver City’s City Hall.

Trustees and held their first meetings on the second

floor of the local theatre, which has since become

the Culver Hotel. By the end of the 1920s, the

trustees became the City Council, with the mayor

as the official spokesman for the city, and in 1928,

bond financing was passed to build the city hall

at its current location, 9770 Culver Boulevard.

Today’s city hall opened in 1995, and has a 3/4

replica of the 1928 city hall’s front facade at its

entry.

Bianco Nero Lithocrete® was specified for the front entry and the

entire surround area of Culver City’s City Hall.

I am pleased as Building Maintenance Supervisor; I

have not experienced any objectionable settlement,

displacement, aggregate “pop out” cracks or permanent

stains to the Lithocrete® paving. Considering the amount

of use this paving surface encounters, I feel that this

paving has definitely stood the test of time as well as

provided value to Culver City.

Steve Newton

City of Culver City

White cement concrete square inserts saw cut after Bianco

Nero field paving was installed.

35

36

Glass Lithocrete®

37

GLASS LITHOCRETE®

Due to the fact that its primary ingredient is recycled glass, as well as its other inherent resource conserving characteristics,

glass Lithocrete® is considered under LEED (Leadership in Energy & Environmental Design) to be a sustainable material

suitable for “green” building. As such, Lithocrete’s® heat fractured glass aggregate product line is ideal for projects that

are required to use recycled materials. Recycled glass provides a wide range of colors not typically found with other

paving materials, such as bright blues, yellows and reds. None of the glass aggregate colors will fade under sunlight; they

naturally reflect light and have less heat absorption. Sea shells and other natural materials can give a project a natural

appearance and textures, or as displayed at the Constellation Place/MGM headquarters buildings in Century City, a

uniform surface with a blend of coral sand and seashells.

Previously, glass in concrete was an unsuitable material due to ASR, in which the alkali in cement paste would react with

the silica in glass to produce harmful expansion. Replacing as little as 10% of natural stone aggregate with clear glass

produces a 14-day tested expansion that is twice the limit of 0.1% of A.S.T.M. C 1260 test. Lithocrete’s® patented product

includes two specific procedures that combat ASR and enable recycled, heat fractured glass to be used in concrete.

38

Rosso Nero Lithocrete® with beige integral color, white cement concrete, Guscio shell Lithocrete®, cobalt blue glass Lithocrete® and cast

in place walls.

Pathway edge with blue aqua glass.

Queensway Bay, Long Beach, CA.

Close-up of Themed Entertainment/Shopping District in

Anaheim, CA, featuring fountain with blue glass perimeter.

Lithocrete® helped us achieve a lot of special

effects at our Queensway Bay project. The

centerpiece of the project is Rainbow Harbor,

which provides docking for commercial boats

and historical vessels. We wanted a nautical

theme that takes design elements from the boats

and uses them throughout the entire length of

the harbor. With Lithocrete®, we were able to

incorporate sea shells into the concrete surface,

highlighted with colored glass pieces in specific

areas. We were impressed with Lithocrete’s®

unique method of blending the materials and

concrete together for added durability. Overall,

I’d say that Lithocrete® adds both quality

craftsmanship and variety to surface paving.

Robert J. Paternoster

City of Long Beach

Close-up of Balboa Peninsula in Newport Beach, CA, featuring

shells alternating with blue glass bands.

39

Rosa Street Bridge

Solana Beach, California

R

osa Street Bridge is a pedestrian and bicycle bridge that connects busy Highway 101 with the Cedros Design

District in Solana Beach, CA. Schmidt Design chose Lithocrete® to simulate the “green flash” phenomenon

seen when part of the sun suddenly changes color from red or orange to green or blue when it reflects

off the ocean. A patented process, Lithocrete® allows for the seeding of materials smaller than 3/8 of an

inch. The vibrant colors of this innovative design are achieved by seeding 15

different glass blends over 8-10 inches of natural gray concrete. The result is

a maintenance-free surface with the durability that spans 30 or more years.

Planks were extended across the bridge so that the concrete could be poured

and seeded with glass and gems. Inspirational quotes about the sun by

William Shakespeare, Helen Keller, and Walt Whitman are sandblasted along

the edges of the bridge walkway.

View of Rosa Street Bridge looking towards

Highway 101 in Solana Beach, CA.

40

Purple, blue, red, orange and yellow glass aggregate were selected to simulate the “green flash” phenomenon.

Summit at Copper Square

Phoenix, Arizona

Lithocrete® created a unique and dynamic look that added extravagance to

the Copper Square Project in Downtown Phoenix.

This streetscape and pedestrian plaza

were designed for intense pedestrian

traffic to create a vibrant, human

-scaled space appropriate to its

urban context. The glass and marbles

incorporated into the Lithocrete®

reference Copper Square, the nickname

for Downtown Phoenix. This makes the

design imageable as a symbol of the

revitalization of Downtown Phoenix,

while adding a dynamic and elegant

appearance to the project.

Laura Thelen

Urban Earth Design

41

The use of gold and copper gems, as well as amber glass aggregate in the

Lithocrete® process provides a unique look to the surface of the sidewalks.

Every design decision made for the Summit at Copper Square

was based on developing a unique, modern living experience

for Downtown Phoenix that would bring vibrancy to the

Copper Square neighborhood and a new cutting edge urban

lifestyle to its residents. The use of Lithocrete® as part of a

comprehensive streetscape and landscape design, provided

a level of detail, flexibility, elegance and whimsy which

complemented and furthered the design goals we were looking

for as architects and landscape architects.

Howard M. Hirsch AIA

Hirsch Associates

The decorative contrast of Lithocrete® illustrates the

benefit of hidden expansion joints that appear to

look like decorative saw cuts.

42

El Dorado Pool

Scottsdale, Arizona

43

Variety of selected

glass materials used.

Woodbury

Irvine, California

W

oodbury in the City of

Irvine, CA, is one of

The Irvine Company’s

new planned

communities. Patterned after classic

American small towns, Woodbury is

composed of smaller scaled neighborhoods

within several large districts. Each has

its own unique architectural character

Project fountain entry.

Spray bar fountain.

Lithocrete® shells at zero-edge pool entry.

Close-up of Lithocrete® shells at

zero-edge pool entry.

and central park, from which the districts

get their names. Parks are never farther

away than a five-minute walk. And at the

center of it all is The Commons, a spacious

®

central park featuring Lithocrete that is

a gathering place bisected by a historic

44

windrow of trees. The nearby Woodbury

Town Center provides residents with the

convenience of shopping and dining in

their own village.

Taking its cue from the traditional

neighborhoods of the past, Woodbury

connects five districts focused around

their own inviting squares and gardens.

Each district has its own architectural

flavor providing a smooth transition

from district to district and a refreshing

sense of place. Inside each district is a

diversity of neighborhoods encompassing

a mix of approximately 4,270 singlefamily attached and detached homes with

distinctive architectural styles ranging

from Cottage Style to Tuscan, Formal

Italian and Formal French, Spanish and

Santa Barbara.

Radial glass Lithocrete® rings were poured monolithically in typical A/B pour sequence.

Chico City Plaza

Chico, California

45

Chico City Plaza featuring a Lithocrete® glass world map with pop-jet fountain.

Unique chess boards were created with Lithocrete® glass enhancements.

46

Water feature with newly

developed System 10 Presto Wall Finish at the

Manhattan Fire & Police

facility in Manhattan

Beach, CA.

Lithocrete® Systems

SYSTEM 1 - ORIGINAL LITHOCRETE®

Original Lithocrete® with granite or reactive aggregates.

SYSTEM 2 - SEDIMENTARY WALL™

Sedimentary Walls™ display natural formations

representing the stratified characteristics of the Earth’s

geological layers.

Grey washed field paving is enhanced with a 30%

Lithocrete® glass stage.

SYSTEM 3 - LITHOCRETE THIN TECH™

Lithocrete Thin Tech™ is for interior floor finishes that use

self-level topping cementatious materials.

SYSTEM 4 - LITHOCRETE PRESTO™

Lithocrete Presto™ finish is the latest development in the

use of variable-sized (1/8 - 1-1/2 inch) aggregates in a

surface seeded application.

SYSTEM 5 - PRESTO PNEUMATIC SPRAY™

Lithocrete Presto Pneumatic Spray™ allows for the perfect

application of minerals such as silica carbide or spar to the

Upper plaza pedestrian paving creates an enhanced

land bridge. Etched concrete and areas of recycled glass

aggregate Lithocrete®.

surface of concrete.

47

SYSTEM 6 - LQS™

Lithocrete Quarried Stone™ (LQS™) is the preferred

system when the look of quarried stone is desired and cost

saving is a premium.

SYSTEM 7 - LITHOCRETE LITHO MOSAICS™

Lithocrete Litho Mosaics™ provides fascinating results

when you join Lithocrete® and mosaic artwork.

®

Lithocrete is the affordable way to enhance any public project.

A partial list of public specified projects:

Handicap walls intertwine with stairs and ramps leading

from street-level to plaza-level. The stair landings were

constructed with recycled green glass Lithocrete®.

Stair cheek walls were constructed to emulate ocean waves

and were seeded with recycled glass and sea shells to create

a unique texture and appearance.

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

Balboa Village, CA

Culver City Hall, CA

Hermosa Pier Avenue, CA

Bothell High School Performing Arts Center, WA

Griffith Observatory, CA

Brotham Hall, Cal State Long Beach, CA

Japanese American National Museum, CA

Superblock San Bernadino Courthouse, CA

Santa Monica Transit Mall, CA

Los Angeles Zoo, CA

Queensway Bay Rainbow Harbor, CA

Ahmanson Theatre, CA

L.A. County Museum of Art, CA

Virginia Park, CA

Chico City Plaza, CA

Fremont Peak Park, WA

48

Artist involvement: Anna Valentina Murch placing selected lenses of sedimentary materials with John Wills of Shaw & Sons. Materials

included pyrite, mica, silica carbide, quartzite, shells, granite and raw cement.

Hybrid Lithocrete® - Coral sand over white cement make up the hardscape and wall top finish.

SYSTEM 2 - SEDIMENTARY WALL™

Three US patents protect Lithocrete’s® System 2 Sedimentary Wall™. Sedimentary Walls™ display natural formations

representing the stratified characteristics of the Earth’s geological layers. These distinctive structures have been used in

many applications from water features to seat walls, and are adaptable to the spectrum of Lithocrete® projects ranging

from retail and colleges to Class A, high-rise office towers. Sedimentary Walls™ create special artistic interest in every

venue in which they exist and often are commissioned pieces of artwork that gain valuable recognition in the public and

corporate art arenas.

49

Sedimentary Walls™ artistically replicate the look of a natural, stratified crosscut of

the Earth’s geology.

Themed Retail/

Entertainment District,

Anaheim, CA

Anaheim Veterans War

Memorial,

Anaheim, CA

Close-up of obsidian vein and lens of pure white cement.

50

Large radius fountain basin and planted sedimentary fountain.

Patented Sedimentary Wall™ with curvilinear green seat wall

with medium sandblast finish.

Sedimentary column with white cement concrete and layers of

obsidian, pyrite and iron oxide pigments.

Innovative Concrete

Design Center,

Boerne, TX

Chapman University,

Orange, CA

Sedimentary Walls™ prior to back fill and final Lithocrete®

cleaning and sealing process.

End of lens detail, featuring Lampass stone, granite, river rock

and a palm frond.

Sample Sedimentary Wall™ with two different colored lenses

and nine different pigments.

Over 50 sedimentary features including seat walls, boulders

and columns over 10 feet high at Chapman University.

51

52

Lithocrete Thin Tech™ floor featured at T.B. Penick’s offices in San Diego, CA.

SYSTEM 3 - LITHOCRETE THIN TECH™

Lithocrete Thin Tech™ is for interior floor finishes that use selflevel topping cementatious materials. A US patent is pending for

the addition of select aggregates to the surface of self-leveling

topping materials used with Lithocrete Thin Tech™. There are no

limits to aggregate choices, as granite, glass and various minerals

can be utilized. The same aggregates used in Lithocrete® System 1

are broadcast onto the surface and are floated into the matrix. Once

the topping mix has solidified, the surface can be ground using

progressively sized diamond cups exposing the select aggregates.

Lithocrete Thin Tech™ featured in the World Harvest

Church in Columbus, OH.

The system is unique in that it can be constructed in less than ½

inch sections, allowing its application to areas that would be too

thin for stone or terrazzo. This process is a delight for designers,

architects and landscape architects who are engaged in retrofit

projects and are looking for a flooring material that is esthetically

enticing as well as economical.

Lithocrete Thin Tech™ featuring a palette of pale

grey, white, and cream custom mixed color and

aggregates.

SYSTEM 4 - LITHOCRETE PRESTO™

Lithocrete Presto™ finish is the latest

Shaw & Sons’ development in the use

of variable-sized aggregates in a surface

seeded application. Aggregates range

in size from 1/8 to 1-1/2 inch. Specially

designed concrete tools and techniques,

such as vibrating Bull Floats, either

mechanically or by hand, are required

to embed the aggregate into the surface.

Once floating of the surface is complete,

power toweling can begin. This is the

most important part, as the machine

aligns all the aggregates so they will

be flat. No other method is comparable

to this process and the results are

super-smooth walking surfaces never

Power troweling Lithocrete®.

before possible when using small- to

large-sized, crushed, surface-seeded

aggregates.

Shaw & Sons’ office includes newly developed Aquifer Replenishing System 14 that captures all surface run-off water and rain water

before entering the city’s gutter and storm drain systems. System 4 - Lithocrete Presto™ is suitable for such uses as vehicular drives and

parking for hospital entries that may serve pedestrians with bare feet.

53

SYSTEM 5 - PRESTO PNEUMATIC SPRAY™

Lithocrete® Presto Pneumatic Spray™ allows for the perfect application of minerals such as silica carbide or spar to the

surface of concrete. Hand broadcasting of minerals causes an uneven distribution, creating a splotchy looking surface. By

utilizing a pneumatic-powered materials sprayer, even distribution of the material is possible. The resulting finish is very

consistent and natural-looking. By using the pneumatic application, larger modules can be constructed since the materials

can be distributed over a greater distance with consistent coverage when compared to hand broadcasting.

54

Northrop Office Tower in Century City, CA.

A difficult design problem is remedied by using

durable Lithocrete® with mica in this vehicular

driveway that also serves as the front building

entry to Northrop’s office tower in Century City.

Presto Pneumatic Spray™ even distribution of material.

At the world renowned Hollywood &

Highland project, the utilization of

pneumatic material-spray equipment to

distribute silica carbide and mica chips,

which was specified for the Lithocrete®

architectural paving, created a uniquely

uniform aggregate surface never before

achieved in architectural concrete. With

over 70,000 square feet of pedestrian paving

and 8,600 lineal feet of concrete stairs, the

surface exposure and distribution of fine

aggregates were consistent throughout.

McCarthy congratulates Lithocrete® on this

new innovation in architectural concrete.

Greg Schoonover

McCarthy Building Companies, Inc.

Lithocrete® with mica and silica carbide.

55

Once again, Lithocrete® has contributed its

expertise and craftsmanship to a complicated

and challenging landmark project.

Hollywood & Highland has to be one of

the most difficult undertakings in recent

construction history, and it was pulled off to

perfection by your firm.

Jack Bousquet

Bousquet Dennis & Associates

Third floor promenade paving of Hollywood motion picture collection

at Hollywood & Highland where over 2.5 acres of various Lithocrete®

materials were used.

Close-up of Lithocrete® with mica and silica carbide.

SYSTEM 6 - LITHOCRETE QUARRIED STONE™ (LQS™)

Lithocrete Quarried Stone™ (LQS ™) is the preferred system when the look of quarried stone is required by designers.

Rather than the introduction of 100% coverage of select aggregates in System 1 - Lithocrete®, LQS™ takes a different

approach entirely by seeding the surface with 5% to 75% of select materials. This gives the appearance of inclusions and

veins normally found in quarried stone. Lithocrete Quarried Stone™ is an excellent alternative when the budget doesn’t

accommodate System 1. The LQS™ process results in a very distinctive, artistic appearance with characteristic random

patterns.

56

California Endowment in Los Angeles, CA featuring Ascona Lithocrete® and LQS™.

Plan view of Ascona Lithocrete® and LQS™ adjacent finish.

SYSTEM 7 - LITHOCRETE LITHO MOSAICS™

Lithocrete Litho Mosaics™ provides fascinating results when you join Lithocrete® with

mosaic artwork. This patent-pending process allows artists to pre-assemble their mosaic

artwork. Special paper is glued to the top side of the mosaic using water soluble glue.

Concrete is placed and floated, and then the mosaic patterns are placed on the concrete

surface. The patterns are then floated level with the surrounding Lithocrete®. The patterns

can be any artistic abstract expression. Other Lithocrete® systems can be employed in

the surrounding concrete. Lithocrete Etch Retarder® is sprayed on the entire surface, then

pressure-washed off along with the surrounding Lithocrete®. The results are beautiful

mosaics with the strength of a structural concrete matrix.

57

Hanna Fenichel Center

Solana Beach, California

T

he Hanna Fenichel Center for Child

Development is a non-profit organization

sponsored by The San Diego Psychoanalytic

Society and Institute and is the first public

project worldwide to showcase the patent-pending

Lithocrete Litho Mosaics™ process. The Hanna Fenichel

Center strives to build new creative areas both inside

Close-up of hop-scotch

Lithocrete Litho Mosaic™

pattern.

and out for children to learn and play. This mission is the

reason, during the center’s 2007 remodel, that Lithocrete

Litho Mosaics™ was specified rather than typical

concrete for the side-yard playground. The Lithocrete

Litho Mosaics™ project at the center features a handlaid, tile hop-scotch surrounded by inspirational words

such as Explore, Discover, Learn, Wonder, and Play for

the children to read, learn and play... A perfect place for

Hop-scotch Lithocrete Litho

Mosaic™ pattern at front entry.

children.

58

Finished wall with System 10 - Presto Wall Finish.

It was the decision of 2049 Century Park East’s

building’s owner, Tramell Crow Company, to

remove the existing travertine and the paving

of the auto court drop-off and replace it with

the Ascona Lithocrete® to match the new

building. Due to weight restrictions on the

three existing decks, up to 9 feet of high load

40, 2.4 lbs. styrofoam was used over a slurry

setting foundation over Mira drain over the

waterproofed structural deck.

Conical-shaped wall.

Inside formwork prior to the installation of reinforcing

steel.

Dedicated to Excellence

Shaw & Sons Concrete Construction is the research and development arm of Lithocrete®. At Shaw & Sons and Lithocrete®, our

position of industry leadership is maintained by our dedication to the following principles:

• Quality - Deliver each project within budget and ahead of schedule while maintaining the highest level of quality and product

integrity.

• Innovation - Continue education, research and development resulting in patented innovations that meet our clients’

requirements and challenges, and contribute to the structural and esthetic improvement of our industry on a national and

worldwide scale.

• People - Recognize talent and develop leaders from within our company. Reward those people who are committed to ethics,

craftsmanship, teamwork, discovery, and customer satisfaction.

• Clients - Build lifelong relationships with owners, designers, public agencies and general contractors who share our values,

offer us new challenges, and recognize our commitment to the continued improvement of our company and our products.

Conclusion

Through the past five decades and millions of square feet of successful installation of both horizontal and vertical concrete, Shaw

& Sons has created more than 35 patents and trademarks to date relating to structural and architectural concrete. We classify

concrete into four categories: “Structural” and “Architectural,” and “Vertical” and “Horizontal.” The difficulty begins when

architectural concrete requires structural properties and vertical concrete requires the look or esthetics of horizontal architectural

concrete. As previously discussed, Lithocrete® Architectural Concrete is very similar to “trap rock” warehouse slab construction,

except the seeded granite materials are revealed for architectural appeal.

By any measure, Lithocrete’s® granite series is the best structural-architectural hardscape material available. With our continued

quest to improve industry standards, we now have 15 unique Lithocrete® Systems, seven of which have already been released to

our selected licensees, and eight new Lithocrete® Systems that we are finalizing or perfecting.

Our new systems completely change the boundaries of what is possible with structural-architectural concrete and greatly

enhance both product types. For instance, Systems 9 and 10 have been used on the conical shaped, cast-in-place wall Shaw &

Sons constructed at 2000 Avenue of the Stars in Century City, CA. Using System 9 enabled us to pump the entire wall in one

continuous pour, yet the wall has complete isolation joints for expansion and contraction. System 10, our Presto Wall Finish

System, completely eliminates pour lines, entrapped air holes, and variable texture on vertical surfaces. It retains the smooth,

uniform finish and appearance of concrete that had only previously been achievable when constructed on flat or horizontal surfaces

®

(See pg. 56). Based on our licensees success with innovative uses of Lithocrete , we are completely committed to developing new

products and new uses for existing products.

Unlike typical product manufacturers that rely on untrained third parties to install their products and have no experienced, in-house

crews who actually do the installation, Lithocrete’s® systems are being continuously installed by Shaw & Sons and T.B. Penick,

allowing us to fully support all of our licensees . . . we consider them as our working partners. Workshops, company visits, “go to

meetings” and constant communication between our partners continue to rapidly grow as we pursue our mission with our licensees

of setting new product standards, quality levels, and customer satisfaction on every Lithocrete® project.

Ron D. Shaw

President/Lithocrete

59