Ch20 Assembly and Packaging

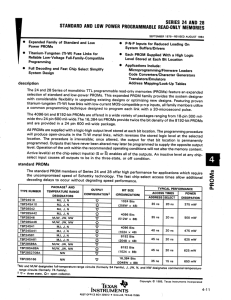

advertisement

1

Assembly and Packaging (Part 1)

Chapter 20 : Semiconductor Manufacturing Technology by M. Quirk & J. Serda

Saroj Kumar Patra,

TFE4180 Semiconductor Technology,

Norwegian University of Science and Technology ( NTNU )

TFE4180 Semiconductor Manufacturing Technology

2

Objectives

• Describe the general trends and design constraints of

assembly and packaging.

• State and discuss the traditional assembly methods.

• Describe the different traditional packaging options.

TFE4180 Semiconductor Manufacturing Technology

3

Introduction

• Final assembly and packaging, the back-end of the IC

manufacturing process

• Two distinct processes

TFE4180 Semiconductor Manufacturing Technology

4

Traditional Final Assembly and

Packaging Process (Encapsulation)

Wafer test and sort

Wire bond

Die Separation

Plastic packaging

Die Attach

Final packaging and test

TFE4180 Semiconductor Manufacturing Technology

5

Four Important Functions of IC Packaging

1.

2.

3.

4.

Protection from environment and handling damage

Interconnections for signals into and out of the chip

Physical support of the chip

Heat dissipation

TFE4180 Semiconductor Manufacturing Technology

6

Dual in-line package

(DIP)

Quad flat pack

(QFP)

Single in-line package

(SIP)

Plastic leaded chip carrier

(PLCC)

Thin small outline package

(TSOP)

Leadless chip carrier

(LCC)

TFE4180 Semiconductor Manufacturing Technology

7

Design Constraints for IC Packaging

TFE4180 Semiconductor Manufacturing Technology

8

Levels of IC Packaging

1st level packaging:

IC-packaging

Metal leads for mounting

onto printed circuit board

Leads

2nd level packaging:

Printed circuit board (PCB)

assembly

Surface

mount chips

are soldered

on top of

copper pads

ont the PCB.

Pins

Pins are

inserted into

holes then

soldered on

rear of PCB.

Edge connector plugs into main system

PCB subassembly

Final product assembly:

Final assembly of circuit

boards into system

Main electronics

assembly board

TFE4180 Semiconductor Manufacturing Technology

9

Traditional Assembly

TFE4180 Semiconductor Manufacturing Technology

10

Four Steps of Traditional Assembly

•

•

•

•

Backgrind

Die separation

Die attach

Wire bonding

TFE4180 Semiconductor Manufacturing Technology

11

Backgrind

Downforce

Rotating and

oscillating spindle

Wafer on

rotating chuck

Table rotates only during

indexing of wafers

TFE4180 Semiconductor Manufacturing Technology

12

Advantages of Thinning Wafers

•

•

•

•

Thinner wafers are easier to dice into chips

Improved thermal dissipation

Reduces thermal stresses in thin ULSI packages

Thinner chips reduce the size profile and weight of

the final IC package

TFE4180 Semiconductor Manufacturing Technology

13

Die Separation

Wafer

Stage

Blade

TFE4180 Semiconductor Manufacturing Technology

14

Die Attach

Lead Frame

Lead

Die

Plastic DIP

- Selected die is attached

- Automated process

http://www.youtube.com/watch?v=syMdS02P3_w

TFE4180 Semiconductor Manufacturing Technology

15

Different Methods of Die Attaching

• Epoxy attach

• Eutectic Au-Si attach

• Glass frit attach

15

TFE4180 Semiconductor Manufacturing Technology

16

Epoxy Attach

Chip

Epoxy

Lead Frame

TFE4180 Semiconductor Manufacturing Technology

17

Eutectic Au-Si Attach

Gold/Silicon

eutectic alloy

Silicon

Gold Film

Lead Frame

TFE4180 Semiconductor Manufacturing Technology

18

Glass Frit Attach

Mixture of silver and glass

particles suspended in an

organic medium

TFE4180 Semiconductor Manufacturing Technology

19

Wire Bonding

Electrical connection from chip surface to inner lead terminal

http://www.youtube.com/watch?v=VwOEQodkBrY

TFE4180 Semiconductor Manufacturing Technology

20

Wire Connection Between Bonding

Pad and Lead Frame

Die

Moulding compound

Bond wire

Bonding pad

Leadframe

Pin Tip

TFE4180 Semiconductor Manufacturing Technology

21

Different Methods of Wire Bonding

• Thermocompression bonding

• Ultrasonic bonding

• Thermosonic ball bonding

21

TFE4180 Semiconductor Manufacturing Technology

22

Thermocompression Wedge Bonding

Heat

Pressure

Leadterminal

Device Bond pad

Wedge bond

TFE4180 Semiconductor Manufacturing Technology

23

Ultrasonic Bonding

Ultrasonic energy

Tool moves upward

Wedge tool

Wire fed

Pressure

Wire

Al bonding

pad

Die

(1)

(3)

(2)

Ultrasonic energy

Pressure

Tool moves upward

Wire Breaks

Lead Frame

(4)

(5)

TFE4180 Semiconductor Manufacturing Technology

24

Ball Bonding

Gold Wire

Capillary tool

Pressure +

Ultrasonic energy

Bonding ball

on

pad

Die

H2 Torch

Die

Ball

(1)

(3)

(2)

Pressure and heat

Lead Frame

(5)

Tool moves

up

Wire Fed

(4)

Tool moves upward

Wire Breaks at

the bond

(6)

TFE4180 Semiconductor Manufacturing Technology

25

Comparison Among Methods

Type

Pressure Temperature

Ultrasonic

energy

Wire

Pad

Au,

Al, Au

Thermo

Compression

High

300-500 oC

No

Ultrasonic

Low

25 oC

Yes

Ball bonding

Low

100-150 oC

Yes

Au, Al Al, Au

Au

Al, Au

TFE4180 Semiconductor Manufacturing Technology

26

Wirebond Quality Measuring

• Visual inspection

• Pull test

TFE4180 Semiconductor Manufacturing Technology

27

Visual Inspection

•

Used to detect wirebonding failures

Wire broken

Wire missing

Ball short circuit

27

TFE4180 Semiconductor Manufacturing Technology

28

Pull Test

•

Quantitative assessment of wirebond quality

Hook

Terminal

Device

Chip under test

Holder

TFE4180 Semiconductor Manufacturing Technology

29

Traditional Packaging

• Metal packaging

• Plastic packaging

• Ceramic packaging

TFE4180 Semiconductor Manufacturing Technology

30

Metal Packaging

• Was common in early history of Semiconductor industry

• Still used today in special cases

Gold‐plated header

Die

Wirebonds

Leads

TFE4180 Semiconductor Manufacturing Technology

31

Transistor Outline (TO) Type Metal

Package

Laser diode

in TO39 package [1]

Voltage regulator

in TO3 package [2]

Used for packaging this type of devices:

•

•

•

•

Semiconductor lasers, solid-state lasers with a diode pumping

Photodetectors, matrix photodetectors (CCD, FPA)

X-Ray detectors

Transistors, operational amplifiers, etc.

TFE4180 Semiconductor Manufacturing Technology

32

Plastic Packaging

•

Industry mainstay since its introduction

•

Highly popular due to:

o flexibility of the lead shape (gull-wings, J-leads, PIH)

o high volume production techniques

Die

Leadframe

Leadframe [3]

Tie bar

Tie bar removal

lines

TFE4180 Semiconductor Manufacturing Technology

33

Plastic Packaging

Packaging procedure

•

•

•

•

Molding

Deflashing

Component lead forming

Lead finish

TFE4180 Semiconductor Manufacturing Technology

34

Plastic Dual In-Line Package (DIP)

A type of through-hole mount package with lead pins

protruding from both sides of the package.

DIP20 package [4]

DIP6 package [5]

Used for packaging this type of devices:

Microcontrollers, logic elements, memory, operational amplifiers,

buffers, optocouplers, timers, signal generators, etc.

TFE4180 Semiconductor Manufacturing Technology

35

Single In-Line Package (SIP)

A single row of leads protruding from the bottom of its body.

SIP's are often used in packaging:

• networks of multiple resistors

• single on chip amplifier solutions

• voltage regulators

Power controller in SIP package [6]

Audio power amplifier in SIP package [7]

Resistor network in SIP package [8]

TFE4180 Semiconductor Manufacturing Technology

36

TSOP with Gull Wings

TSOP - Thin Small Outline Package

Gull Wings – shape of the pins

•

•

•

•

Low profile

Tight lead spacing

High pin count

Used for surface mount

SDRAM [9]

DRAM [10]

TSOPs are often used in packaging memory modules

(SRAM, Flash memory, FSRAM and E2PROM)

TFE4180 Semiconductor Manufacturing Technology

37

QFP with Gull Wing and

Surface Mount Leads

• QFP – Quad Flat Pack

• Socketing such packages is rare and

through-hole mounting is not possible.

• Used for packaging memory, processors,

controllers, ASIC, DSP, etc.

80‐pin Microprocessor in TQFP package [12]

TQFP ‐ Thermally Enhanced

package [11]

TFE4180 Semiconductor Manufacturing Technology

38

PLCC with J-Leads

•

PLCC - Plastic Leaded Chip Carrier

•

Used for surface mount

•

Used for packaging memory, processors, controllers,

ASIC, DSP

PAL from TI

in 28 pin package [14]

EEPROM from ALTERA [13]

TFE4180 Semiconductor Manufacturing Technology

39

Leadless Chip Carrier (LCC)

•

Available in plastic and ceramic packaging

•

Used for packaging CMOS image sensors, MEMS,

crystal oscillator filters, antenna switch modules

LCC from Tektronics [15]

TFE4180 Semiconductor Manufacturing Technology

40

Ceramic Packaging

Used for the state of the art devices that require:

• maximum reliability

• high-power

• hermetic seal

Two main methods of ceramic packaging:

• Refractory ceramic (used for high performance IC packaging)

• Laminated ceramic (low cost approach used to create CerDIP package)

OpAmp from AD in CerDIP package for use in harsh environment [17]

CPGA [16]

TFE4180 Semiconductor Manufacturing Technology

41

g{tÇ~ lÉâ

TFE4180 Semiconductor Manufacturing Technology

42

References

[1] http://www.thorlabs.com/images/large/21973‐lrg.jpg

[2] http://media.digikey.com/photos/Texas%20Instr%20Photos/296‐TO‐3‐8.jpg

[3] http://www.ue.com.hk/index.php/SOIC_%28Small_Outline_Integrated_Circuit_Packages%29

[4] http://www.chinaicmart.com/uploadfile/ic‐doc/261‐20‐DIP.jpg

[5] http://media.digikey.com/photos/Fairchild%20Semi%20Photos/46‐6‐DIP%20WHITE.jpg

[6] http://www.infineon.com/cms/en/corporate/press/news/releases/2009/INFXX200906‐063.html

[7] http://sjostromaudio.com/pages/hifi‐projects/36‐hifi‐projects/82‐qrp01‐the‐gainclone‐high‐performance‐power‐

amplifier?showall=1

[8] http://www.emartee.com/product/41417/Resistor%20Network%2010K%20OHM%209P%208RES%20SIP

[9] http://rocky.digikey.com/weblib/Micron/Web%20photos/557‐86‐TSOP.jpg

[10] http://s.eeweb.com/resized/images/remote/http_s.eeweb.com/quizzes/2011/02/22/dram‐tsop‐

1298440075_500_327.png

[11] http://www.analog.com/en/technical‐library/packages/qfp‐quad‐flat‐pack/tqfp‐thermally‐enhanced/index.html

[12] http://en.wikipedia.org/wiki/File:PIC18F8720.jpg

[13] http://ca.digikey.com/1/1/1042179‐ic‐max‐7000‐cpld‐64‐68‐plcc‐epm7064lc68‐15.html

[14] http://media.digikey.com/photos/Texas%20Instr%20Photos/296‐28‐PLCC.jpg

[15] http://component‐solutions.tek.com/services/ic‐packaging/packaging‐tech/#leadless‐chip‐carrier

[16] http://www.interfacebus.com/ic‐package‐Ceramic‐PGA‐package‐dimensions.html

[17] http://www.analog.com/en/technical‐library/packages/dip‐dual‐inline‐package/cerdip‐side‐or‐bottom‐

brazed/index.html

42

TFE4180 Semiconductor Manufacturing Technology