MICROCRYSTALLINE SILICON OBTAINED BY HOT

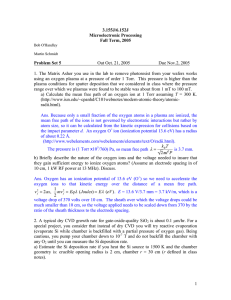

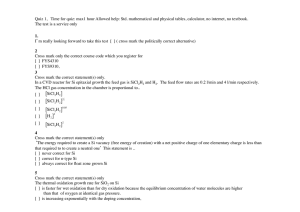

advertisement