Aluminum Cable Tray

advertisement

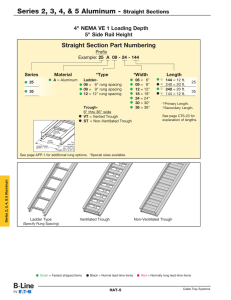

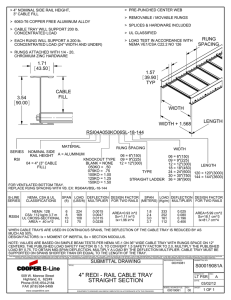

Aluminum Cable Tray Ladder — Extra wide aluminum rungs are welded to extruded aluminum I-beam siderails. Every second rung is reversed to allow for easy top or bottom mounting of cable ties and clamps. All edges and welds are rounded and smooth to prevent cable damage. Ventilated — A fabricated structure consisting of integral or separate longitudinal rails and a bottom having openings sufficient for the passage of air and utilizing 75% or less of the plan area of the surface to support cables. The maximum open spacings between cable support surfaces of transverse elements do not exceed 102 mm (4 in) in the direction parallel to the tray side rails (rung edge to rung edge). Solid Trough — A fabricated structure consisting of a bottom without ventilation openings within separate longitudinal side rails. Rungs are not perforated, and not alternated (up/down). However, Ty-Raps can be inserted diagonally between rung and bottom sheet for cable fastening. NOTE: Fast and easy snap-in splice plates are provided with each straight section. T&B aluminum cable tray is composed of two distinct systems H-Style and U-Style. These systems are interchangeable. 46 Straight Length Tray Bottom Types Available Ladder, Ventilated and Solid Trough Aluminum Cable Tray Straight Section Number Selection Straight Sections Aluminum Straights Straight sections utilize a 7” splice plate and the fittings have tangents at the extremities. This style offers enhanced aesthetics and rigidity system to the end-user. Straight Section Number Selection (AH16) 24L09144 Material A • Aluminum Style H • H-Beam Series Siderail Height Width Bottom Type Length ** 0 • Series 0 06 • (6") L06 • 6" rung spacing 144 •(12ft) *** 1 • Series 1 09 • (9") L09 • 9" rung spacing 288 •(24ft) 12 • (12") L12 • 12" rung spacing 3 •(3 meters) 18 • (18") * L18 • 18" rung spacing 6 •(6 meters) 2 • Series 2 3 • Series 3 4” 4 • Series 4 24 • (24") V • Ventilated 5 • Series 5 30 • (30") S • Solid Trough 36 • (36") 2 • Series 2 3 • Series 3 4 • Series 4 5” * 42 • (42") ** 0 • Series 0 1 • Series 1 2 • Series 2 3 • Series 3 6” 4 • Series 4 5 • Series 5 * ** *** 6 • Series 6 2 • Series 2 2C • Series 2C 3 • Series 3 Only upon request (consult factory for loading). Series 0 is not available in 288” or 6 meter lengths. Series AH1-4 is not available in 6 meter lengths. 7” T&B aluminum cable tray is composed of two distinct systems H-Style and U-Style. These systems are interchangeable. 47 4” Straight Sections Series 0-4, 1-4, 2-4 Ladder, Ventilated and Solid Trough Aluminum Cable Tray Straight Section Number Selection ( A H 0 4 ) 2 4 L 0 9 14 4 Material A • Aluminum Style H • H-Beam Series Siderail Depth Width Bottom Type Length 4 • (4") 06 • (6") L06 • 6" rung spacing 144 • (12ft) L09 • 9" rung spacing 288 • (24ft) L12 • 12" rung spacing 3 • (3 meters) * L18 • 18" rung spacing 6 • (6 meters) ** 0 • Series 0 09 • (9") *** 1 • Series 1 12 • (12") 2 • Series 2 18 • (18") 24 • (24") 30 • (30") V • Ventilated 36 • (36") S • Solid Trough * 42 • (42") * ** *** Only upon request (consult factory for loading). Series 0 is not available in 288”, or 6 meter lengths nor is it available in solid bottom Series 1 is not available in 6 meter lengths. Technical Specifications All calculations and data are based on 36" wide cable trays with rungs spaced on 12" centers with tray supported as simple spans with deflection measured at the midpoint. Continuous spans may reduce deflection by as much as 50%. Deflection factor For lighter loads, deflection at any length can be calculated by multiplying the load bythe deflection factor. For Fittings consult pages 60 to 99. SUPPORT SPAN 6 8 10 12 (Feet) 14 16 18 20 152 86 55 38 - - - - Deflection (in.) 0.265 0.472 0.737 1.062 - - - - Deflection Factor 0.002 0.006 0.013 0.028 - - - - 239 134 86 60 44 34 27 22 Deflection (in.) 0.318 0.565 0.884 1.272 1.732 2.262 3.863 3.534 Deflection Factor 0.001 0.004 0.010 0.021 0.039 0.067 0.108 0.164 358 202 129 90 66 51 40 32 Deflection (in.) 0.416 0.740 1.156 1.673 2.277 2.974 3.764 4.590 Deflection Factor 0.001 0.004 0.009 0.019 0.034 0.059 0.094 0.143 SERIES AH0-4 AH1-4 AH2-4 Load (lb/ft) Load (lb/ft) Load (lb/ft) T&B aluminum cable tray is composed of two distinct systems H-Style and U-Style. These systems are interchangeable. 48 4” Straight Sections Series 0-4, 1-4, 2-4 Ladder, Ventilated and Solid Trough Aluminum Straights Aluminum Cable Tray AH0-4 W (in.) 6 9 12 18 24 30 36 42 AH1-4 AH2-4 Wo (in.) Wi (in.) Wo (in.) Wi (in.) Wo (in.) Wi (in.) 7.35 10.35 13.35 19.35 25.35 31.35 37.35 43.35 4.93 7.93 10.93 16.93 22.93 28.93 34.93 40.93 7.46 10.46 13.46 19.46 25.46 31.46 37.46 43.46 4.88 7.88 10.88 16.88 22.88 28.88 34.88 40.88 8.38 11.38 14.38 20.38 26.38 32.38 38.38 44.38 4.88 7.88 10.88 16.88 22.88 28.88 34.88 40.88 Technical Specifications LOAD RATINGS 1.5 Safety factor. All tray sections will support an additional 200 lb concentrated load on any portion of tray (siderail, rung, etc.) above and beyond published load class. SIDERAIL DESIGN SERIES AH0-4 AH1-4 AH2-4 DIMENSIONS FACTORS • 1 PAIR Ix = 1.67 in4 Sx = 0.774 in3 Area = 0.742 in2 Ix = 2.19 in4 Sx = 1.05 in3 Area = 0.906 in2 Ix = 2.51 in4 Sx = 1.17 in3 Area = 0.986 in2 CLASSIFICATIONS NEMA 8B CSA – 12A, 8C C1 12B D1/3m UL UL Cross Sectional Area : 0.60 in2 UL Cross Sectional Area : 0.60 in2 UL Cross Sectional Area : 0.60 in2 Note: See appendix for information on “Heavy Load” bearing trays and spans beyond 6 m. T&B aluminum cable tray is composed of two distinct systems H-Style and U-Style. These systems are interchangeable. 49