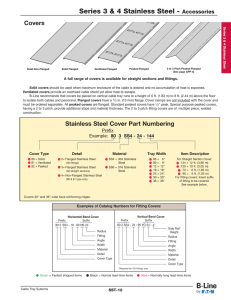

Cick here to the Cable Management Systems

advertisement