FTerm AF

I N S T A L L A T I O N

I N S T R U C T I O N

Aerial Re-enterable Fiber Optic Splice Closure

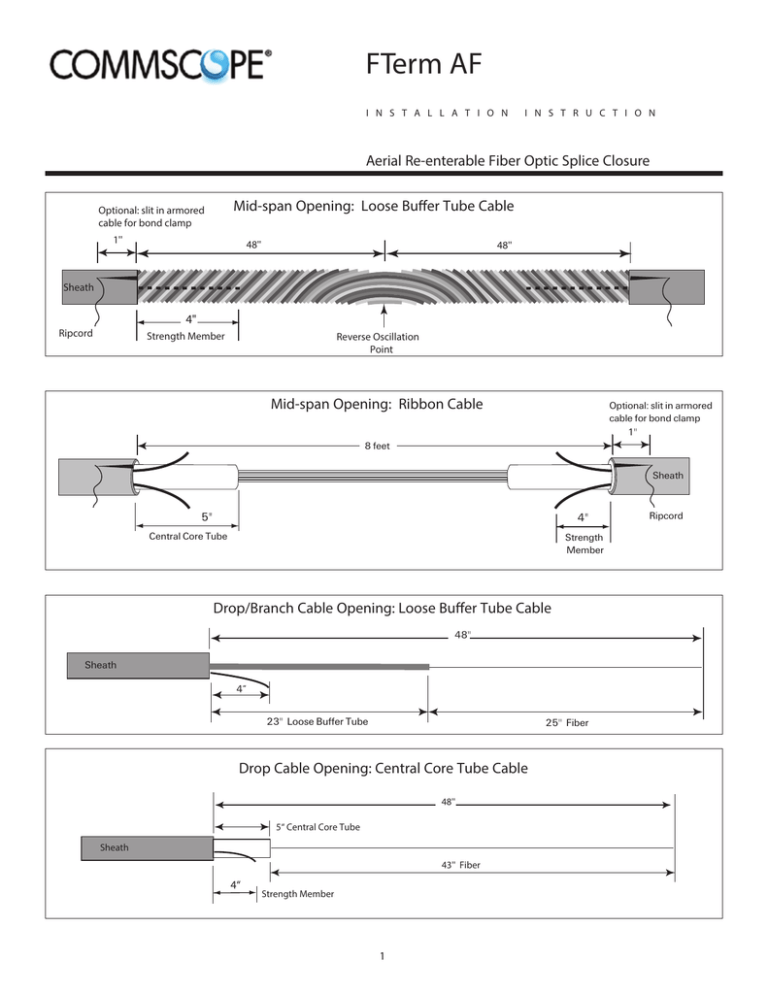

Mid-span Opening: Loose Buffer Tube Cable

Optional: slit in armored

cable for bond clamp

1''

48''

48''

Sheath

4"

Ripcord

Strength Member

Reverse Oscillation

Point

Mid-span Opening: Ribbon Cable

Optional: slit in armored

cable for bond clamp

1''

8 feet

Sheath

5"

4"

Central Core Tube

Strength

Member

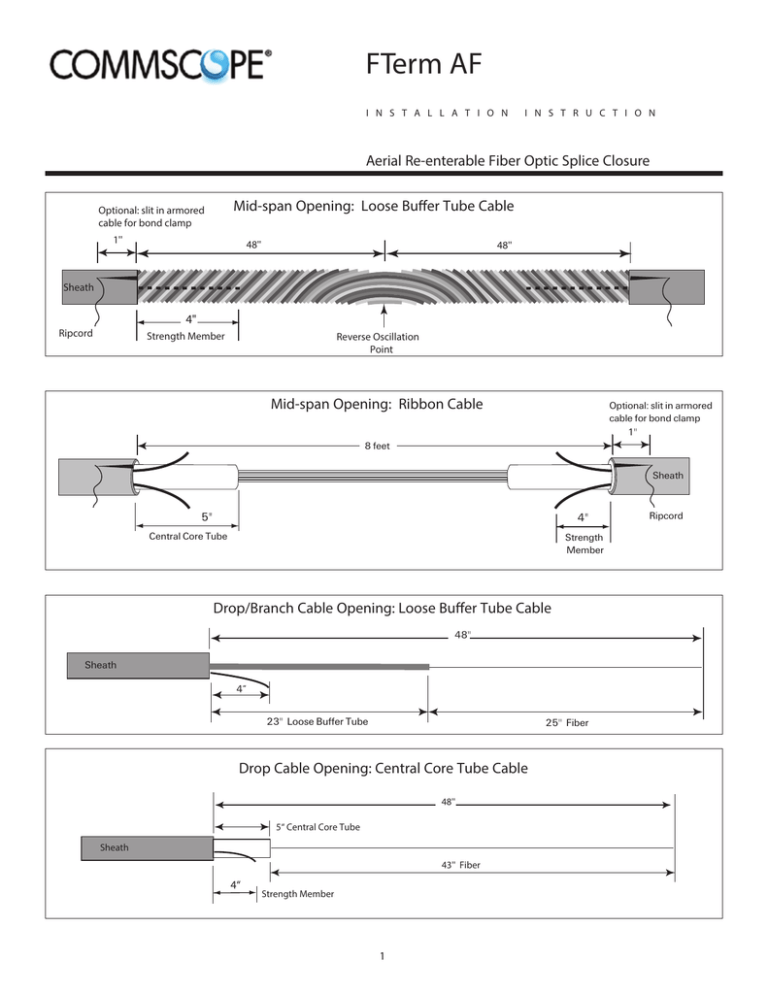

Drop/Branch Cable Opening: Loose Buffer Tube Cable

48''

Sheath

4“

23'' Loose Buffer Tube

25'' Fiber

Drop Cable Opening: Central Core Tube Cable

48''

5“ Central Core Tube

Sheath

43'' Fiber

4“

Strength Member

1

Ripcord

Table 1: Midspan Cable Opening Dimensions

Bonding & Grounding: B-Bonds

Main Cable

Fiber Count

24 - 144 fibers

2 8 8 fibers

Midspan Cable Opening Length

Loose Buffer

Central Core Tube

Tube Cable

(Ribbon) Cable

*6 ft. - 10 ft.

*6 ft. - 10 ft.

*6 ft. - 1 0 ft.

* 6 ft. min. when length is cut downstream.

8 ft. min. length when cut at midpoint.

Hose

clamp

Installation Instructions

3.0 Warnings and Safety Precautions

1.0 General Product Information

Use company-approved safety practices and equipment when

installing the FTerm AF closure.

The FTerm AF aerial re-enterable fiber optic splice closure is

designed for strand mounted applications. The FTerm AF closure

can accommodate shielded or unshielded loose buffer tube or ribbon cables. The closure combines CommScope’ GelGuard sealing gel technology and FOSC fiber management systems.

4.0 Required Tools

•

•

The FTerm AF closure can accommodate one cable up to 1.25” in

diameter and two additional cables or up to eight small drop cables

when grouped together up to .75” in diameter in each end of the closure.

Flat head screw driver

216 tool (can wrench)

5.0 Mark and Open Cables

Splice trays come with two SM12 splice modules which will hold up

to 24 splices, provided that SMOUV splice sleeves are used (purchased separately, kit SMOUV-1120-01-US).

5.1 Mid-Span Cable

Note: This closure is not recommended for load-bearing ADSS

cable.

Note: For loose buffer tube cable, it is beneficial to locate the

reverse oscillation point and position it at the center of the opening.

2.0 Kit Components

2.

Mark the cable 48” from the center in each direction. Ring cut

the cable, and remove the jacket and shield, if present.

•

•

•

•

•

•

•

•

•

•

•

•

•

•

3.

For loose buffer tube or ribbon cable, cut each strength member 4” from each sheath ring cut. (Figures 1, 2)

4.

For core tube cable, remove all but 5” of central core tube at

each end of the sheath opening. (Figure 2)

5.

Clean exposed ribbons or buffer tubes with a clean cloth and

company approved degreaser.

1.

Housing

Frame/hanger assembly

Splice organizer tray (not included in all kits)

Gel-filled end pieces

Small Tie wraps

Foam tape

Hose clamps

Velcro fastener strip

Loose buffer tube wrap 1”x12”

Perforated metal squares

Transport tubing 16” and 36”

Routing rings

Tray tabs

Diameter tape

Locate a loop of fiber optic cable roughly eight feet in circumference. Mark the center of the loop.

5.2 Grounding Shielded Cables

The FTerm AF closure kit can be ordered in a grounded or ungrounded configuration. If the grounded kit is ordered, the ground straps are

factory installed and ready to use. If the ungrounded kit is ordered

but grounding is later required, order the AIR FOSC closure grounding kit and follow the installation instructions included with that kit.

2

Place approved bond clamps 90° from the top of the cables. To prepare shielded cables for grounding, install a B-bond clamp. Open a 1”

slit in the sheath beyond the ring cut 90° from the top of the cables.

Insert the lower portion of the B-bond under the shield with the stud

protruding through the slit, and wrap with vinyl tape. Place the top

plate over the stud and tighten it down with the nut. Recommended

torque 40 in. lbs. Wrap the exposed area with vinyl tape. (Figure 3)

1''

Optional: slit in armored

cable for bond clamp

4"

6. Open Housing and Hang Frame

1.

1''

Open housing using a can wrench to loosen the 3 bolts. To

remove the frame grab the edge of the housing with your

hands and push up on the bottom of the frame with your

thumbs to release the frame from the housing. (Figure 4)

Figure 1

Optional: slit in armored

cable for bond clamp

NOTE: Terminal cables should be added to the housing before

re-attaching to the frame. This is best done while on the

ground. Refer to section 10.

4"

2.

Hang and secure the frame on the strand centering it over the

midspan cable opening.

5"

Figure 2

7. Attach Midspan Cable to Frame and Bond

1.

Loosen the top bottle cap.

Note: Do not use tape on cable sheath under hose clamp.

2.

Slide the strength member(s) under the bottle cap washer; and

continue pushing until the end of the strength member(s) is

trapped under the lip of the frame. Tighten the bottle cap.

(Figure 5)

Figure 3

Note: If strength member(s) contain an outer jacket, it may

need to be shaved off before fiberglass strength members will

fit under the lip of the frame.

Figure 4

Figure 5

3

3.

Front View

Place a large hose clamp around the cable and frame. Place a

perforated metal square between the cable and hose clamp.

(Figure 6) Tighten hose clamp to 40 in.lbs.

Repeat for opposite end of splice opening.

8. Prepare Midspan Fibers for Splicing

or Storage

8.1 Loose Buffer Tube (LBT) Cable

Figure 6

1.

Separate the buffer tube containing the fibers to be spliced

from any remaining buffer tubes. Remove clear plastic cover

from back of frame, or slide to one side. Push the unused loose

buffer tubes through the window in the frame; push one side

through first and let it “lead” the other side through so the

buffer tubes don’t kink.

2.

Coil and store the express buffer tubes using the 2” Velcro

pads and 1/2” strips as shown in Figure 7. Be careful not to

kink the tubes.

Note: If cable storage is too large, tie wraps can be used in

place of plastic cover. Do not overtighten the ties.

3.

Re-position the plastic cover on the back of the frame.

4.

Mark the buffer tube containing the desired fibers 23” from

each sheath opening. Remove the buffer tube from the fibers

between the marks per company-approved practice. Clean the

exposed fibers with a clean cloth and company-approved

degreaser.

5.

Route the buffer tube along the top of the frame and down to

the back side of the tray for attachment. Attach to upper holes

with tie wraps. Recommended that you wrap one layer of

loose buffer tube wrap around buffer tubes where tie wraps

are used. (Figure 8)

Back View

Figure 7

Note: If buffer tubes are too stiff to route to the tray, remove

the buffer tube and apply spiral wrap on the exposed uncut fibers

to protect them, and route them to a splice tray for storage.

6.

Cut a small piece of loose buffer tube wrap and wrap one layer

around the end of each buffer tube where it will enter the

splice tray. (Figure 8) Secure each buffer tube to the splice tray

with two tie wraps.

Note: Heads of tie wraps must face upwards on the tray.

7.

Figure 8

4

Cut the fibers to be spliced and store the remainder on the

tray. (See Figures 30A, 30B, and 30C for storage.)

8.2 Ribbon Cable

Note: When using a tie wrap to secure central core tube to the

frame, wrap the central core tube with LBT wrap first to prevent the tie wrap from crushing the core tube.

IMPORTANT: Instructions for storing ribbon cable on the FOSC

Ribbon Tray are included with the ribbon tray kit. The process

is not covered in these instructions.

1.

Secure the core tube to the frame with tie wraps through the

holes in the frame. (Figure 9)

2.

Identify the ribbon containing the fibers to be spliced, and separate it from the other ribbons. Remove clear plastic cover from

back of frame, or slide to one side. Push the unused ribbons

through the window in the frame and allow them to hang in a

loop behind the frame. Hint: push one side through first, and let

it “lead” the other side through so the ribbons do not kink.

3.

Organize, coil, and store the uncut ribbons in the back of the

frame using the 2” Velcro pads and 1/2” strips. Re-position the

plastic cover on the back of the frame. (Figure 10)

4.

Cut the ribbon containing the fibers to be spliced. If cutting the

fibers dead-to-the-field, cut the ribbon as close to the field side

(ONU side) of the splice opening as possible. If the fibers are

part of a loop architecture, cut them in the middle of the splice

opening. Transportation tubing must be used to route to tray

for straight splice applications.

5.

Figure 9

Back View

Use a 16” section of transportation tubing and use it to protect

the fibers from the selected ribbon. Route the encased fibers

from the top of the frame to the back of the splice tray. Secure

transportation tube to frame with tie wraps. (Figure 11)

Figure 10

Note: If necessary, wrap the end of the ribbon with vinyl tape to

make it easier to slide the ribbon through the spiral wrap.

9. Prepare Drop Cables for Splicing or Storage

9.1 LBT Drop Cables

1.

Remove 48” of cable jacket. Mark and remove 25” of buffer

tube.

2.

Cut each strength member 4” from the sheath ring cut. Install

bond hardware if applicable. See section 5.2.

9.2 Ribbon Drop Cables

1.

Remove 55” of cable jacket. Remove all but 5” of core tube.

2.

Cut strength members 4” from sheath ring cut.

3.

Slide a 16” piece of transportation tubing over the fibers,

extending 1” over the central core tube. Install bond hardware

if applicable. See section 5.2.

Figure 11

5

9.3 Attach Drops To Frame

1.

Wrap the drop cable with a perforated metal square where it

will be under the hose clamp. (Figure 12)

Note: For multiple cables see Figure 12 for placement of metal

square to prevent the cable jackets from slipping against each

other under the hose clamp.

2.

Slide cable and strength member(s) under the nearest bottle

cap washer. Continue pushing until the end of the strength

member is trapped under the lip of the frame, and tighten the

bottle cap.

3.

Place a small hose clamp around all drop cables and frame as

shown in Figure 12. Tighten the hose clamp.

4.

Cut a small piece of LBT wrap and wrap one layer around the

end of each buffer tube. Place the drop fibers to the front of

the splice tray. Figure 13 (see dotted line) depicts this procedure with loose buffer tube(s) cable. Secure the tube(s) to the

tray with two tie wraps.

5.

Attach the routing rings in any of the vertical holes shown in

Figure 14 to keep buffer tubes away from hinge area.

Figure 12

Figure 13

Figure 14

6

10. Connecting Termination Cables and

Installing Pigtails

1.

Unlatch and lift the terminal cover until it is in the locked position. (Figure 15)

2.

Insert the pigtail(s) into the fiber duct. (Figure 16)

3.

Plug in connectors 1 and 2 then adjust slack. (Figure 17)

4.

Plug in remaining connectors as shown in Figure 18.

5.

If needed readjust slack from the opposite side of the terminal.

Proceed to step 5, next page.

Figure 15

Figure 17

Figure 16

Figure 18

1

2

3

4

5

6

7

8

9

10

11

12

Figure 19

7

Figure 19a

1

2

3

4

5

6

7

8

9

10

11

12

Figure 19b

1

2

3

4

5

6

7

8

9

10

11

12

Figure 19c

1

2

3

4

5

6

7

8

9

10

11

12

Installing the Fanout

1.

Attach breakout box with fasteners provided as shown in

Figure 19a.

2.

Insert the 36” transportation tube into the duct. (Figure 19)

Insert fanout fibers into the transportation tube for routing to

tray.

3.

Plug in connectors . (Figures 19a, b, and c)

4.

If needed readjust slack from the opposite side of the terminal.

Drop 1

Drop 2

Figure 20

TracTape

Caution: Check connector bend radius on terminal side.

Note: If you have drop cables follow steps 5 and 6. If not,

continue with step 7.

5.

For a single drop cable apply a wrap of TRAC closure tape

around the drop cable jacket 4” from the sheath ring cut.

6.

For multiple drop cables that will share a port in the end piece,

wrap a layer of TRAC closure tape between the drop cables

and around them starting 4” from the sheath ring cut, as

shown in Figure 2. Do not exceed .75” total diameter in any

single port.

7.

Install the end pieces around the cables, with the end piece closure tab facing forward. (Figure 21) Install cable spacers per

company practice on either side of the closure so that the

cables are spaced properly and parallel to the strand as they

enter the end pieces.

8.

Wrap the closure housing around the frame with the bolts facing up. Place the body over the top two tabs of the frame, and

press the bottom two tabs into the opening of the housing until

they snap in place. (Figure 22)

Figure 21

Figure 22: Cutaway Side View

8

9.

On the front side place the bundle of pigtails or transportation

tubing under the pre-installed LBT or ribbon present on the

right side. (Figure 23) and over the pre-installed tubes

attached on the left side if present. (Figure 24)

10. Hold the pigtail bundle on the tray and mark the yellow tubing

one inch from the end of the tray. (Figure 25) From the mark,

measure out 22” for pigtails and fanout if de-ribbonized and cut

off evenly. Alternatively, if using ribbon tray, from the mark

measure out 35” for fanout.

Ribbon cannot be stored on a single tray, slack will have to be

pulled into the back of the frame.

Note: The length to the tray mark will be approximately 25”

from the fiber duct.

Figure 23

Figure 24

Figure 25

9

12. Cut and remove the yellow tubing and aramid fiber strands

from the mark. (Figure 26)

13. Wrap a piece of LBT wrap around the bundle of the pigtails or

transportation tube if using fanout. Remove tray and attach

pigtails or transportation tube with two tie wraps as shown in

Figure 27.

11. Splice Fibers and Store on Tray

Note: If kit contains a ribbon tray; follow ribbon tray instructions.

Fiber routing should follow the embossed arrows on the tray.

(Figure 28)

Figure 26

Do not store ribbon slack on single tray; pull ribbon slack from the

tray to the slack basket. See Figure 29 for routing and splicing ribbon

to ribbon cable.

Figure 27

Figure 28

Main

Drop

Figure 29

10

Figures 30a, 30b, and 30c illustrate examples of proper fiber

routing, though other arrangements are possible. Figure 30d

illustrates improper fiber routing.

Drop Cable Fibers

Main Cable Fibers:

Note: It is helpful to pre-organize your fibers on the tray prior

to splicing to determine the right configuration; routing

should match one of the diagrams in Figure 29 or 30a, b, or c.

Drop fibers

Figure 30A

Main cable fibers

Figure 30B

Figure 30C

WRONG! Both of these patterns will

cause signal attenuation!

Figure 30D

11

For easier splicing, remove tray from tray bracket, close bracket, cut

1” squares of both Velcro hook and eyes and join together. Remove

release paper from both sides and attach to frame. (Figure 31 )

Position tray over the top of the Velcro fastener and press in place.

(Figure 32)

When all splices have been completed and stored, install plastic tray

tabs on the arcs to help hold down the fibers. Replace the clear plastic tray cover.

12. Install Closure Body

1.

2.

Wrap the black Velcro fastener strap around the tray and tray

holder to keep the tray(s) in place. Lift the tray bracket so that it

hinges and snaps closed against the frame. Avoid pinching

ribbons, buffer tubes, transportation tubes, etc. in the bracket.

Figure 31

Close the housing, making sure the ends align properly with

the end pieces. Fasten the supplied bolts to secure the body in

place. (Figure 33)

Figure 32

Figure 33

AIR FOSC, FTerm, GelGuard, SMOUV, TRAC, CommScope logo, and CommScope are trademarks.

Other trademarks are the properties of their respective owners.

Technical Assistance Center (TAC)

Tel.: 800.830.5056

Email: TAC.Americas@commscope.com

www.commscope.com

The information given herein, including drawings, illustrations and schematics which are intended

for illustration purposes only, is believed to be reliable. However, CommScope makes no warranties as to its accuracy or completeness and disclaims any liability in connection with its use.

CommScope’s obligations shall only be as set forth in CommScope’s Standard Terms and

Conditions of Sale for this product and in no case will CommScope be liable for any incidental,

indirect or consequential damages arising out of the sale, resale, use or misuse of the product.

Users of CommScope products should make their own evaluation to determine the suitability

of each such product for the specific application.

©2005, 2007, 2008, 2009, 2016 CommScope Inc. All Rights Reserved PML 977921 F508.2/09