semiconductor material and process characterization using three

advertisement

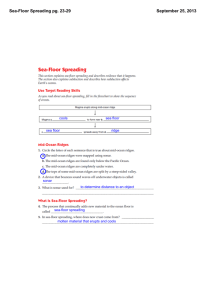

International Journal of Electrical & Computer Sciences IJECS-IJENS Vol: 12 No: 02 23 SEMICONDUCTOR MATERIAL AND PROCESS CHARACTERIZATION USING THREE PROBES Ateeq Ahmad Khan College of Engineering,Salman Bin Abdul Aziz University,Al Kharj, Saudi Arabia(ateeq@ksu.edu.sa) ABSTRACT One of the most powerful techniques of semiconductor material and process characterization is the use of three probes in spreading resistance configuration. The raw data thus obtained needs analysis for extracting profiling information. The problem of poor spatial resolution of Spreading Resistance measurements on shallow doped layers has been taken up. An analysis of the raw spreading resistance data is made and a technique is developed for the correction of these data and their utilization in profiling the doped samples. The technique includes both the areas of application, namely the lateral profiling across the surface of the doped samples and the depth profiling of the doped layers using beveled samples. The mathematical model developed for the analyses is in conformity with the physical set up of the experimental measurements. The results of the analysis in both the above stated cases are presented. The resulting corrected spreading resistance data are in good agreement with the values obtained by the other well established methods. KEYWORDS Spreading resistance, spatial resolution, semiconductor material, doping, and diffusion. pressed against the specimen surface. The measuring current is passed through the two outer probes and the voltage across the two inner probes is measured using basic voltmeter-ammeter circuitry. The method directly gives the sheet resistance, a measure of the carrier concentration per unit surface area of the sample. For depth profiling this technique is applied along with the successive layer removal. The technique however, has two drawbacks. Firstly it has a poor resolution and secondly it requires care and too much time for the accurately controlled oxide growth during successive layer removal. The Spreading Resistance technique which is the area of investigation in the present paper is particularly attractive compared to other well established methods due to its better resolution, accuracy, lesser time consumption and ease in its implementation. The technique has gained popularity in both the areas of application, namely the lateral profiling across the surface of the doped samples and the depth profiling of the doped layers using beveled samples. However, the technique is still under the process of development. Earlier workers in this field have already studied and attempted many of the relevant problems. The problem related to the resolution of the technique is dealt with in the present paper. 2. 1. THE MEASUREMENT TECHNIQUES INTRODUCTION Semiconductor material and process characterization are an integral part of the IC technology. The basic measurement made on a semiconductor is its sheet resistivity which is a measure of its impurity content or carrier concentration. The measurement is usually made on the check slices prepared simultaneously during each diffusion step of IC fabrication. The profile showing the lateral variation of resistivity along the surface or the variation of resistivity along the depth characterizes the specimen. With the advancement of technology, the importance of reliable, accurate and efficient measurement technique has considerably increased. The most widely used and probably the best known technique so far is the four point probe resistance technique in which four probes, equally spaced in straight line, are For a given semiconductor sample the spreading resistance at a point on its surface due to a given probe may be defined as the resistance appearing at the near tip of the probe when it is pressed against the surface at that point. Thus, if a small diameter probe, radius r, making a point contact with a sample surface, is kept at a potential V and a current I passed into the sample through the probe, then the quotient V/I gives the spreading resistance (Rs) at the contact point. It can very well be used to characterize a semiconductor sample as it has a definite relation with its conductivity. The measurements may be made with the usual voltmeter-ammeter circuitry. Several probe configurations have been suggested. In the 2-probe configuration, the voltage across the two current probes is measured and quotient V/I is the sum of the spreading resistances due to the two 123902-7575 IJECS-IJENS © April 2012 IJENS IJENS International Journal of Electrical & Computer Sciences IJECS-IJENS Vol: 12 No: 02 probes. The spreading resistance under each probe is to be separated which is often difficult in a practical set up. The difficulty is eliminated in the 3-probe configuration in which a third probe, the potential probe, is introduced to measure the potential difference between the sample and one of the current probes, designated as the critical probe. A remarkable advantage of the spreading resistance technique is the ease with which depth profiles are obtained. Here the much time consuming procedure of the successive removal of layers is not required. Instead, the sample surface is beveled at a shallow angle, usually less than one degree, and the spreading resistance measurements are made on the greatly magnified surface thus exposed. As the relation between the spreading resistance and the resistivity depends upon a number of physical conditions, it is necessary to calibrate the apparatus by measuring the spreading resistance of known resistivity samples. The calibration curve so obtained is unique for a given probe. The problem of reproducibility of measurements has already been taken up and necessary measures suggested. The error caused by variation of resistivity within the sampling depth has also been studied and the correction models suggested. In most of the cases, the potential distribution is determined by considering the non-uniform profiles of interest to be a multilayered structure of different resistivity values. The resulting computer routines are fairly complex and involve large CPU time. For very shallow layers, the spreading resistance has been shown to be related to the sheet conductivity as, ρ = (2-1) An attractive feature of the spreading resistance technique is its excellent spatial resolution as expected from the fact that practically all the voltage drop V from probe to specimen occurs within a distance of a few probe radii. But it was observed that, even with a uniform resistivity sample, the measured spreading resistance is much higher near an insulating edge. Typically, with a 2 micron diameter probe; an increase of 10% at a distance of 400 micron and of 60% at a distance of 10 micron from the insulating edge has been reported. It follows that the spatial resolution is poor, contrary to what was expected earlier. A theoretical analysis has therefore been made and a correction procedure is developed here. 3. 24 THE DATA ANALYSIS For both the uniform and non-uniform resistivity samples, the mathematical analysis of the spreading resistance technique is presented as a mathematical model which is in conformity with the physical set up of the experimental measurements. Figure 1 shows the arrangement of the probe on the sample surface and the co-ordinate system used in the analysis. The probes have a spacing ‘d’ and are at a distance ‘x’ from the insulating edge. Probes 1, 2 and 3 are located at (0,-d/2), (0, d/2) and (0, 3d/2) respectively the current I enters at probe 1 and leaves at probe 2, and the potential of probe 1, the critical probe, is sensed relative to probe 3. The spreading resistance measurement thus reduces to measuring the potential of the critical probe relative to probe 3 when the measuring current I flows through the former, the probe 2 being ignored. y Insulating Edge 3 d -I -I Image 2 X +I d +I 1 Figure 1: The Three Probe Arrangement Assuming a large semi-infinite sample, a lateral variation of sheet conductivity in the xdirection only is considered. Starting from first principle, the relevant equations are as follows. = . = −. ∇ ∇. = 0 Therefore,∇. −. ∇ = 0 (3-1) (3-2) (3-3) may be replaced by ,the two being directly related . So the equation 3-3 changes to 123902-7575 IJECS-IJENS © April 2012 IJENS IJENS x International Journal of Electrical & Computer Sciences IJECS-IJENS Vol: 12 No: 02 ∇. − . ∇ = 0 (3-4) This is the extended Laplace’s equation which can be expanded as ! ! + + ! " ! =0 + ! " ! =0 (3-6) = 0%& = −' (3-7) ( = −2*% . ∇; (3-8) V=0,y=0 (3-9) → ∞%0 → ∞%-, → ∞ ) (3-10) At, + , − - = % , Where V is the potential V(x,y) at any point P(x,y) and is the current density in x-direction. For a uniform resistivity sample with a constant sheet conductance , equation 3-6 is solved analytically as well as numerically. The analytical solution yields = 1 23 41 + ! ! relationship. (3-12) The numerical methods can, now, readily be applied. (3-5) Equation 3-6 is to be solved under the following boundary conditions #$ − the = 68 7-7 25 (3-11) The equation is solved numerically using the wellknown ‘Finite-Element’ method. The entire domain of integration is divided into a number of regions of finite dimensions, called finite elements. Each element has several nodes. The local solutions of the equation over each element to describe the local behavior of that region are written with the help of Galerkin’s method. Thus a matrix relationship between various problem variables at each node is established over each element. The system equations are then assembled from the contributions of the respective elements. The boundary conditions are then inserted into these equations which are subsequently solved numerically. The discussion so far refers to 2-dimensional problem. A conductivity variation (z) with respect to depth, however, makes the problem a 3-dimensional one which would be more difficult to solve. For a shallow junction and a small bevel angle, this difficulty is overcome by approximating the problem to a 2-dimensional sheet conductivity problem using 4. EXTRACTION OF CONDUCTIVITY FROM SPREADING RESISTANCE DATA Prior to applying any of the computational methods, a careful selection of the mesh of finite elements is necessary. The location of mesh points in the x and y directions are on the basis of equal potential difference rather than equal spacing. The potential variation being very near to logarithmic, the node spacing varied almost logarithmically. Secondly, a finer mesh gives more accuracy at the cost of an increased computation time and a compromise is made between these two factors. The accuracy of the numerical solution with a particular mesh is tested by obtaining the results numerically as well as analytically with a uniform conductivity of any assumed value (say, unity) and then comparing the two results. The discussions so far are related to determining the spreading resistance values 9 (x) if the conductivity variation is known. What is required in practice is the opposite of this, i.e. determination of variation from knowledge of 9 (x) data obtained experimentally rather than the other way round. As such there is no well-defined mathematical procedure for such a reverse calculation. Here a method using simple iterative technique is presented. A spreading resistance variation 9 (x) is first assumed and the corresponding sheet conductance variation is obtained from equation 2-1. Using this assumed , the voltage variation V(x,y) due to the critical probe is determined by solving numerically the extended Laplace’s equation under appropriate boundary conditions using finite element method and taking in to consideration various corrections required. The spreading resistance is then calculated as 9 (X) = [V (0,-d/2)-V (0, 3d/2)]/I (4-1) The spreading resistance values so obtained are then compared with the experimental values. Based on the errors so obtained, corrections are applied to the assumed Rs(x) values, and subsequently to the corresponding variation, using an optimization routine. The same procedure is repeated several times till the calculated spreading resistance 123902-7575 IJECS-IJENS © April 2012 IJENS IJENS International Journal of Electrical & Computer Sciences IJECS IJECS-IJENS IJENS Vol: 12 No: 02 0 26 values coincide with the experimental values within the required limits of accuracy, few iterations are usually sufficient. 160 DISCUSSION In the case of lateral profiling,, the data for the analysis is obtained from the spreading resistance measurements made on a boron diffused silicon wafer, up to a distance of 300 micron from the insulating edge. For the analysis in the case of depth profiling, g, the data used are obtained from the measurements on a phosphorus diffused pp-type substrate beveled at 0.5 degree, along a lateral distance of 210 micron corresponding to the depth from the surface to junction. In each case, the probe tip diameter and spacing acing are 2 micron and 635 micron respectively.. The meshes used for numerical solutions are optimized to give an error within 0.67% in the spreading resistance values with respect to the values obtained analytically, with a uniform resistivity.A comparison of the raw spreading resistance data (measured values) with the corrected data obtained from thee analysis in both the cases is demonstrated graphically in figures 5-11 and 5-2. SPREADING RESISTANCE(OHMS) 5. 150 RAW 140 CORRECTED 130 120 110 100 50 300 550 800 1050 DISTANCE FROM THE EDGE (MICRO METER) Figure 2:: Spreading Resistance Profiles (Lateral) RAW 370 CORRECTED 330 SPREADING RESISTANCE(OHMS) It is observed in the case of lateral profiling that the measured spreading resistance istance values do not give correct conductivity variation due to poor spatial resolution. They underestimate the surface concentration by more than 50% near the insulating edge. Thus the raw spreading resistance data are practically of no use and the appli application of the correction technique presented is essential. In the case of depth profiling on beveled sample, the resolution problem appears to exist more near the surface and near the junction than in the middle portion where the corrected values coincide with the measured values. This is because of the higher resistivity on one side and lower resistivity on the other side which bring the weighted average very near to the local value. The corrected profile is in good agreement with that obtained from the we wellestablished incremental al sheet resistance technique except near the junction. An explanation for the discrepancy near the junction has been given in terms of carrier depletion effect. 290 250 210 170 130 90 50 10 0 0.5 1 1.5 DEPTH FROM THE SURFACE(MICRON) Figure 3:: Spreading Resistance Profiles (Depth) 1233902-7575 IJECS-IJENS © April 2012 IJENS IJENS 2 International Journal of Electrical & Computer Sciences IJECS-IJENS Vol: 12 No: 02 27 REFERENCES [1] Leong, Choo, “Spreading Resistance Analysis with Carrier Spilling Correction”, Journal of Vacuum Science Technology B (1992) [2] A F Yaremchuk , “Analysis of the correction factor in the spreading-resistance technique for monitoring epitaxial silicon”, Applied Physics A Materials Science Processing (2003) [3] D.C.D Avanzo, R.D. Rung and R.W. Duttan, “Spreading resistance for impurity profiles”, Technical report no. 5013-2, Stanford University, Stanford, California, USA, 1977 [4] J. Phys. D, “An accurate calculation of spreading resistance”, Appl. Phys. 39, 1761(2006) [5] C.A. Brebbia and A.J. Ferrante, “Computational Methods for Solution of Engineering Problems”, Pentech Press, London, 1978 [6] Zhang Tanimoto, H. Adachi, K. Nishiyama, A, “1-nm Spatial Resolution in Carrier Profiling of Ultrashallow Junctions by Scanning Spreading Resistance Microscopy”, Electron Device Letters, IEEE , Volume: 29 Issue: 7 ,799 – 801(2008) [7] J. Lin-Kwang, S. Ramey, J.M. Reynes, R.J. Hillard, T. Thieme ,“The role of spreading resistance profiling in manufacturing control and technology development”, Microelectronics Reliability, Volume 40, Issues 8–10, 1497-1502,(2000) 123902-7575 IJECS-IJENS © April 2012 IJENS IJENS