HMDS - Padua@Research - Università degli Studi di Padova

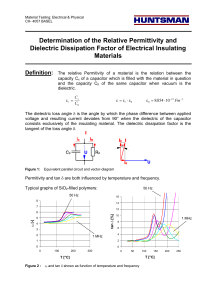

advertisement