Spectroscopic ellipsometry studies of II

advertisement

The University of Toledo

The University of Toledo Digital Repository

Theses and Dissertations

2010

Spectroscopic ellipsometry studies of II-VI

semiconductor materials and solar cells

Jie Chen

The University of Toledo

Follow this and additional works at: http://utdr.utoledo.edu/theses-dissertations

Recommended Citation

Chen, Jie, "Spectroscopic ellipsometry studies of II-VI semiconductor materials and solar cells" (2010). Theses and Dissertations. Paper

807.

This Dissertation is brought to you for free and open access by The University of Toledo Digital Repository. It has been accepted for inclusion in Theses

and Dissertations by an authorized administrator of The University of Toledo Digital Repository. For more information, please see the repository's

About page.

A Dissertation

entitled

Spectroscopic Ellipsometry Studies of

II-VI Semiconductor Materials and Solar Cells

by

Jie Chen

Submitted to the Graduate Faculty as partial fulfillment of the

requirements for the Doctor of Philosophy Degree in Physics

_____________________________________

Dr. Robert W. Collins, Committee Chair

_____________________________________

Dr. Patricia Komuniecki, Dean

College of Graduate Studies

The University of Toledo

December 2010

Copyright 2010, Jie Chen

This document is copyrighted material. Under copyright law, no parts of this document

may be reproduced without the expressed permission of the author.

An Abstract of

Spectroscopic Ellipsometry Studies of II-VI Semiconductor Materials and Solar Cells

by

Jie Chen

Submitted to the Graduate Faculty as partial fulfillment of the

requirements for the Doctor of Philosophy Degree in Physics

The University of Toledo

December 2010

The multilayer optical structure of thin film polycrystalline II-VI solar cells such as

CdTe is of interest because it provides insights into the quantum efficiency as well as the

optical losses that limit the short-circuit current.

The optical structure may also

correlate with preparation conditions, and such correlations may assist in process

optimization.

A powerful probe of optical structure is real time spectroscopic

ellipsometry (SE) that can be performed during the deposition of each layer of the solar

cell.

In the CdCl2 post-deposition treatment process used for thin film polycrystalline

II-VI solar cells, the optical properties of each layer of the cell change during the process

due to annealing as well as to the elevated temperature.

In this case, ex-situ SE before

and after treatment becomes a reasonable option to determine the optical structure of

CdCl2-treated CdTe thin film solar cells.

CdTe solar cells pose considerable challenges for analysis by ex-situ SE.

iii

First, the

relatively large thickness of the as-deposited CdTe layer leads to considerable surface

roughness, and the CdCl2 post-deposition treatment generates significant additional

oxidation and surface inhomogeneity. Thus, ex-situ SE measurements in reflection from

the free CdTe surface before and after treatment can be very difficult. Second, SE from

the glass side of the cell is adversely affected by the top glass surface which generates a

reflection that is incoherent with respect to the reflected beams from the thin film

interfaces and consequently depolarization if collected along with these other beams.

In

this research, the first problem is solved through the use of a succession of Br2+methanol

treatments that smoothens the CdTe free surface, and the second problem is solved

through the use of a 60° prism optically-contacted to the top glass surface that eliminates

the top surface reflection. In addition, the succession of a Br2+methanol treatment not

only smoothens the CdTe surface but also enables CdTe etching in a layer-by-layer

fashion.

In this way, it has been possible to track the optical properties of the CdTe

component layer as a function of depth from the surface toward the CdS/CdTe interface

in order to gain a better understanding of the film structure.

In this study, ex-situ spectroscopic ellipsometry was applied first to investigate the

optical properties of the TEC-15 glass substrate, and then to extract the optical properties

of thin film CdTe and CdS both as-deposited and CdCl2-treated.

After obtaining all the

optical properties of the solar cell component layer materials, a comprehensive ex-situ SE

analysis has been applied to extract the optical structure of a single thin film of

CdCl2-treated CdTe, and finally to obtain the optical structure of the CdCl2

iv

post-deposition treated CdTe solar cell.

Based on the fundamental studies in this thesis, various aspects of the solar cell

structure after the complicated CdCl2 treatment have been determined.

In future work

the role of the key parameters of CdCl2 post-deposition treatment process will be

explored including: the temperature and treatment time. As a result, a correlation will

be established between solar cell performance and film structure.

Finally, an

understanding of how solar cell structure can be optimized to achieve the highest solar

cell performance may be possible through improved control of the CdCl2 post-treatment

process.

v

Table of Contents

Abstract

iii

Table of Contents

vi

List of Tables

ix

List of Figures

xii

1

Introduction to Spectroscopic Ellipsometry

1

1.1 History…………………………………...………………...………………..…....1

1.2 Purpose…… …………………………………………………………...…..…….2

1.3 Data measured by ellipsometry…………………………………………………..3

1.4 Mathematical derivation…..……………………………………………………..5

1.5 Spectroscopic ellipsometer used in the study…………………………………..10

1.6 Data analysis……………………………………………………………………12

2

Introduction to CdTe-based Solar Cells…………………………………………..18

2.1 CdTe-based solar cell structures ……………………………………………….18

2.2 Deposition method and process steps…………………………………………..21

2.3 Application of spectroscopic ellipsometry as an analysis technique …………..22

3

Optical Properties of TEC-15 Glass…….………………………………………...26

3.1 Introduction……………………………………………………………………..26

vi

3.2 Experimental details…...………………………………………………………..28

3.3 Data analysis and results…………………...…………………………………...29

4

Verification of the Chemical Etching Process for CdTe Depth Profiling………52

4.1 Introduction……………………………………………………………………..52

4.2 Structural evolution of CdTe during etching: experimental details…………….54

4.3 Structural evolution of CdTe during etching: results and analysis ......…….......57

4.4 Detection of a-Te on etched CdTe: experiment details…………………………59

4.5 Detection of a-Te on etched CdTe: results and analysis………………………..60

5

Optical Properties of Thin Film CdTe and CdS before and after CdCl2

Post-deposition Treatment………………………………………………………...71

5.1 Introduction……………………………………………………………………..71

5.2 Optical properties of as-deposited CdTe and CdS films deposited on c-Si

substrates……..…………………………………………………………………72

5.3 Optical properties of CdCl2 post-deposition treated CdTe and CdS……………78

5.4 Etch-back profiling of CdTe thin film structure after post-deposition treatments...

…………………………………………………………………………………. 84

6

Optical Structure of As-deposited and CdCl2-treated CdTe Superstrate Solar

Cells…………………………………………………………………………………94

6.1 Introduction……………………………………………………………..………94

6.2 Experimental details…………………………………………………………….96

6.3 Results and discussion: film side and prism side measurements…..…………...97

vii

6.4 Results and discussion: through the glass measurements……………………..113

6.5 Summary………………………………………………………………………119

7

RTSE Analysis of CdTe Solar Cell Structures in the Substrate Configuration…..

………………………………………………………………………………………120

7.1 Introduction……………………………………………………………………120

7.2 Analysis of CdTe deposition on rough molybdenum…………………………121

7.3 Ex situ spectroscopic ellipsometry analysis of a CdTe solar cell in the substrate

configuration…………….……………………………………………………138

8

Spectroscopic Ellipsometry Studies of II-VI Alloy Films………………...…….152

8.1 Introduction……………………………………………………………………152

8.2 Top cell material candidates: Cd1-xMnxTe and Cd1-xMgxTe…………………...154

8.3 Bottom cell material: Cd1-xHgxTe……………………………………………..172

9

Summary and Future Directions………………………………………………...178

9.1 Summary………………………………………………………………………178

9.2 Future directions………………………………………………………………183

References

196

Appendix

A

Dielectric functions

207

viii

List of Tables

4.1 Best fit parameters and confidence limits that define Eqs. (4.1) and (4.2) for the

dielectric function of a-Te. …..……………………………………………………..63

5.1 Fitting results for single crystal and thin film polycrystalline CdTe using an analytical

model

consisting

of

four

critical

points

and

one

T-L

background

oscillator. …...………………………………………………………………………74

5.2 Fitting results for single crystal and thin film polycrystalline CdS using an analytical

model

consisting

of

three

critical

points

and

one

T-L

background

oscillator…………………………………………………………………………….75

5.3 Best fit dielectric function parameters comparing single crystal, CdCl2-treated, and

as-deposited CdTe samples. ………………………………………………..……….79

5.4 Best fit dielectric function parameters for as-deposited CdS on a fused silica prism,

CdCl2-treated

CdS

on

the

prism,

and.

as-deposited

CdS

on

c-Si. ……………………………………………………………….………….……..83

ix

6.1 Dielectric function library used in spectroscopic ellipsometry data analyses for CdTe

solar cells. ……………………………………………………………………..……98

6.2 Best fitting parameters added step by step to improve the mean square error (MSE) in

modeling

through-the-glass

SE

measurements

of

a

CdTe

solar

cell. ………………………………………………………………………………..116

6.3 Multilayer stack thicknesses, non-uniformity, and compositions, the latter expressed

in terms of volume fractions, along with parameter confidence limits for the best fit

to SE data obtained through the glass. …………………………………………….118

7.1 CdTe bulk and surface roughness layer thicknesses for the top four CdTe bulk

layers. ……………………………………………………………………………..126

7.2 Five models used to evaluate the Mo overlayer thickness using reference dielectric

functions from the literature. ……………………………………………………...134

7.3 Best fit critical point and Tauc-Lorentz oscillator parameters describing the inverted

dielectric function of polycrystalline ZnTe:Cu. The exponents µn are fixed at the

single crystal values of Table 7.4. ………………………………………………...143

x

7.4 Best fit critical point and Tauc-Lorentz oscillator parameters for single crystal ZnTe.

……………………………………………………………………………………..144

7.5 Best fitting parameters added step by step to improve the standard mean square error

(MSE) in the ellipsometric analysis of a CdTe solar cell in the substrate

configuration. ……………………………………………………………………..150

8.1 Deposition parameters used to prepare the CdxMg1-xTe and CdxHg1-xTe thin

films. ………………………………………………………………………………155

8.2 Critical point parameters of transition energy and width obtained in the fits to the

dielectric functions of Fig. 8.9. ……………………………………………………167

8.3 Critical point energies and E0 broadening parameters for two as-deposited

Cd1-xMgxTe alloys from spectroscopic ellipsometry.

Also shown are corresponding

results for as-deposited and CdCl2-treated CdTe. …………………………………172

8.4 Energy position and width of the critical point generating the strongest peak in ε2 for

as-deposited thin film Cd1-xHgxTe. ………………………………………………..174

xi

List of Figures

r

1-1 Schematic representation of the electric field vector trajectory E (rr0 , t ) for an elliptically

r

polarized light wave at a fixed position r0 versus time. Q is the tilt angle between the

ellipse major axis a and the p-axis, measured in counterclockwise-positive sense

when facing the light source.

χ is the ellipticity angle given by tan-1(b/a). …...........

……………………………..…………………………………………………………7

1-2 Reflection of a polarized light wave at an interface between two media. ……….…..9

1-3 Spectroscopic ellipsometer used in this research mounted in the ex-situ mode of

operation. …………………………………………………………………………...11

1-4 Simplified flow chart of the data analysis procedure. …………...…………………13

1-5 Optical model and physical structure of a c-Si wafer used as a substrate. .……...........

………………………………...………………………..…...………………...…….14

2-1 The substrate structure for CdTe solar cells. ……………………………………….19

xii

2-2 The superstrate structure for CdTe solar cells. ……………………………………..19

3-1 The multilayer structure of the TEC-15 glass substrate. …………………………...28

3-2 Simple model deduced from the analysis of the transmittance and ellipsometric (ψ, ∆)

spectra of Figs. 3-3 – 3-5 for the soda lime glass substrate. The surface roughness

is obtained in a best fit of the (ψ, ∆) spectra. …………………..…………………..31

3-3 Best fit simulated and experimental normal incidence transmittance spectra T vs.

photon energy for an uncoated soda lime glass substrate used in the fabrication of

TEC glasses. ………………………………………………………………………..31

3-4 Best fit simulated and experimental ellipsometric angle ψ = tan−1 (|rp/rs|) vs. photon

energy for an uncoated soda lime glass substrate used in the fabrication of TEC

glasses.

The angle of incidence is 60˚. …………………………………………..32

3-5 Best fit simulated and experimental ellipsometric angle ∆ = δp − δs vs. photon energy

for an uncoated soda lime glass substrate used in the fabrication of TEC glasses.

The angle of incidence is 60˚. ……………………………………………………...32

3-6 Index of refraction (left) and extinction coefficient (right) vs. wavelength for the

xiii

uncoated soda lime glass substrate.

The index of refraction results are derived from

the ellipsometric ψ spectrum whereas the extinction coefficient results are derived

from the transmittance spectrum.

The data values are tabulated in Appendix A. ......

………………………………………………………………………………………33

3-7 Model with best fitting parameters obtained in the analysis of the transmittance and

ellipsometric (ψ, ∆) spectra of Figs. 3.8 and 3.9 for the soda lime glass substrate

coated with a single layer of undoped SnO2. ……………………………………….34

3-8 Normal incidence transmittance T vs. photon energy for a soda lime glass substrate

coated with a single layer of undoped SnO2, the first layer in the fabrication of TEC

glasses. Experimental data (broken line) and a best fit simulation (solid line) are

shown. ………………………………………………………………………………35

3-9 Ellipsometric angles ψ and ∆ vs. photon energy for a soda lime glass substrate coated

with a single layer of undoped SnO2. Experimental data (broken lines) and best fit

simulations (solid lines) for an angle of incidence of 60˚ are shown. ………………..

………………………………………………………………………………………35

3-10 (a,b) Real and imaginary parts of the dielectric function ε1 and ε2 vs. photon energy

for undoped SnO2 that forms the first layer of TEC glasses; (c) analytical expression

xiv

for the complex dielectric function of (a,b) along with the best-fit free parameters

and their confidence limits. ………………………………………………………...36

3-11 Model adopted for the analysis of the transmittance and ellipsometric (ψ, ∆) spectra

of Figs. 3.12 and 3.13 obtained on the soda lime glass substrate coated with a single

layer of SiO2. ……………………………………………………………………….37

3-12 Normal incidence transmittance T vs. photon energy for a soda lime glass substrate

coated with a single layer of SiO2, which is used as the second layer in the

fabrication of TEC glasses; experimental data (broken line) and a best fit simulation

(solid line) are shown. ……………………………………………………………...38

3-13 Ellipsometric angles ψ and ∆ vs. photon energy for a soda lime glass substrate

coated with a single layer of SiO2, which is used as the second layer in the

fabrication of TEC glasses; experimental data (broken lines) and a best fit simulation

(solid lines) are shown. ……………………………………………………………..38

3-14 (a) Real (solid line) and imaginary (broken line) parts of the dielectric function ε vs.

photon energy for SiO2 that forms the second layer of the TEC glasses.

The

imaginary part of the dielectric function vanishes; (b) mathematical expression for

the dielectric function in (a) along with the best fitting parameters and their

xv

confidence limits. ……………………………………………………..……………39

3-15 Real and imaginary parts of the dielectric function ε vs. photon energy for the SiO2

that forms the second layer of the TEC glasses (solid lines) for comparison with the

reference data of a thermally-grown SiO2 on crystalline silicon. ………………..……

………………………………………………………………………………………..39

3-16 Best fit sample structure for a soda lime glass substrate coated with a two layer stack

of undoped SnO2 and SiO2, which are the first two layers used in the fabrication of

TEC glasses. ………………………………………………………………………..40

3-17 Ellipsometric angles (ψ, ∆) at an angle of incidence of 60˚ and transmittance T at

normal incidence plotted versus photon energy for a soda lime glass substrate coated

with a two layer stack of undoped SnO2 and SiO2, which are the first two layers used

in the fabrication of TEC glasses. …………………………………………………..41

3-18 Best fit multilayer stack for a complete TEC-15 glass sample.

The layered

structure includes thin undoped SnO2, thin SiO2, and thick doped SnO2:F with

surface roughness on top.

The previously-determined dielectric functions were

used for the soda lime glass and the two thin layers. ………………………………43

xvi

3-19 Normal incidence transmittance T vs. photon energy for a complete TEC-15 glass

sample consisting of a soda lime glass substrate coated with layers of undoped SnO2,

SiO2, and top-most doped SnO2:F.

Experimental data (broken line) and a best fit

simulation (solid line) are shown. ………………………………………………….43

3-20 Ellipsometric angles ψ and ∆ at a 60˚ angle of incidence plotted vs. photon energy

for a complete TEC-15 glass sample consisting of a soda lime glass substrate coated

with layers of undoped SnO2, SiO2, and top-most doped SnO2:F. The broken lines

indicate experimental spectra and the solid lines indicate the best fit

simulation. ………………………………………………………………………….44

3-21 Real and imaginary parts of the dielectric function ε1 and ε2 vs. photon energy for

doped SnO2:F that forms the top-most layer of TEC-15 glass.

These results are

obtained as a best fit analytical expression at low energies where the film is

semitransparent and by an inversion of (ψ, ∆) data at high energies where the film is

opaque. ……………………………………………………………………………..44

3-22 (a) The analytical equation for the dielectric function of the top-most SnO2:F layer

of TEC-15 that holds below 4.4 eV; also shown is (b) a table of the best fit

parameters in the equation and their confidence limits. ……………………………45

3-23 Multilayer structure with best-fit parameters for a complete TEC-7 glass sample.

xvii

The layered structure includes thin undoped SnO2, thin SiO2, and a thick layer of

doped SnO2:F with surface roughness on top.

The previously determined dielectric

functions for TEC-15 glass were used here for this TEC-7 glass sample. ……………

………………………………………………………………………………………47

3-24 Multilayer structure with best-fit parameters for a complete TEC-8 glass sample.

The layered structure includes thin undoped SnO2, thin SiO2, and a thick layer of

doped SnO2:F with surface roughness on top.

The previously determined dielectric

functions for TEC-15 glass were used here for this TEC-8 glass sample. ……………

………………………………………………………………………………………47

3-25 Transmittance T vs. photon energy for a complete TEC-7 glass sample; experimental

data (broken line) and simulated results based on the ellipsometric model (solid line)

are shown (left). The difference between the two data sets is shown at the

right. ………………………………………………………………….…………….49

3-26 Normal incidence transmittance T vs. photon energy for a complete TEC-8 glass

sample; experimental data (broken line) and simulated results based on the

ellipsometric model (solid line) are shown (left).

The difference between the two

data sets is shown at the right. ……………………………………………………...50

xviii

3-27 For TEC-7 glass, the normal incidence scattering results predicted by combining

ellipsometry and normal incidence specular transmittance are shown in comparison

with experimental normal incidence integrated scattering data from a diffuse

transmission experiment.

Different TEC-7 samples were used for the two different

data sets. ……………………………………………………………………………51

3-28 For TEC-8 glass, the normal incidence scattering results predicted by combining

ellipsometry and normal incidence specular transmittance are shown in comparison

with experimental normal incidence integrated scattering data from a diffuse

transmission experiment.

Different TEC-8 samples were used for the two different

data sets. ……………………………………………………………………………51

4-1 A schematic of optical models used to evaluate a CdTe film by optical depth profiling

during both deposition and etching processes. ……………………….…………….56

4-2 The evolution of void volume fraction within the top 100 Å of the bulk layer as a

function of CdTe bulk layer thickness obtained during the deposition and etching

processes. …………………………………………………………………………...58

4-3 Schematic of the sample structural changes that occur in the last three etching steps

for a CdTe film on c-Si.

The starting thickness of this CdTe film is 3500 Å. ………

xix

…………….…………………………………………………………………………60

4-4 Ellipsometric spectra for a smoothened CdTe film on a c-Si wafer measured at angle

of incidence of 63°.

The broken lines represent data measured before the first

additional Br2+methanol etching step, and the solid lines represent data measured

after the 6th additional Br2+methanol etching step.

the two is 18 seconds.

The total etching time between

The starting CdTe thickness before any etching was 3 µm. ...

.………………………………………………………………………………………61

4-5 Ellipsometric spectra for a CdTe thin film on a crystalline Si substrate after the 36th

and 37th etch steps for comparison.

The starting CdTe film thickness was 3500 Å. ..

.………………………………………………………………………………………64

4.6 Ellipsometric spectra for a CdTe thin film on a crystalline Si substrate with a starting

thickness of 3500 Å measured after the 37th (left) and 36th (right) etching steps (data

points). Also shown are their best fits (broken lines). ………………………..……..

.………………………………………………………………………………………64

4-7 Model and best-fit parameters used for the analysis of the ellipsometric spectra of Fig.

4.6 (left panel) collected after the 37th etching step applied to a CdTe film on a

crystalline Si substrate.

Because the CdTe film is completely removed, this

xx

analysis provides the structure of the c-Si substrate.

MSE indicates the mean

square error in the fit. ………………………………………………………………65

4-8 Model and best fit parameters used for the analysis of the ellipsometric spectra of Fig.

4.6 (right panel) collected after the 37th etching step applied to a CdTe film on a

crystalline Si substrate.

c-Si substrate.

This analysis yields the structure of the a-Te layer on the

The void volume fraction in the a-Te layer has been obtained by

expressing the a-Te layer in this study of polycrystalline CdTe as a mixture of the

a-Te obtained in a previous study of single crystal CdTe along with a void

component. …………………………………………………………………………65

4-9 Real and Imaginary parts of the dielectric function ε1 and ε2 vs. photon energy for

a-Te generated through Br2+methanol etching of a polycrystalline CdTe film. ………

.………………………………………………………………………………………65

4-10 A comparison of the a-Te optical properties deduced in this study (see Fig. 4.9) with

the literature reference optical properties of a-Te from 1.5~6 eV, the latter obtained

by etching single crystal CdTe. …………………………………………………….66

4-11 Ellipsometric spectra for a CdTe thin film on a crystalline Si substrate with a starting

thickness of 3500 Å measured after the 35th etch step (left panel).

xxi

Also shown is

the best fit and associated model deduced in the analysis of the ellipsometric spectra

in order to extract the a-Te/CdTe/c-Si structural parameters (right panel). …………...

.………………………………………………………………………………………68

4-12 Experimental and best fit spectra (left panel) along with the best fit parameters and

model (right panel) for comparison with the results of Fig. 4.11, but without

introducing an a-Te component into the model. Such a model leads to a higher

MSE. ………………………………………………………………………………..68

4-13 Ellipsometric spectra and the best fit (left panel) for a smoothened CdTe film with a

starting thickness of 3 µm obtained before the first additional etch after smoothening.

Also shown is the model and best fit parameters used in the analysis of the

ellipsometric spectra over the energy range of 2 to 6 eV in order to deduce the a-Te

volume fraction in the surface roughness layer (right panel). ………………………...

.………………………………………………………………………………………69

4-14 Experimental and best fit spectra (left panel) along with the best fit model and

parameters (right panel) for comparison with the results of Fig. 4.13, but without

introducing an a-Te component into the model.

This ellipsometric analysis is

associated with a 3 µm thick smoothened CdTe film before the first additional etch

after smoothening. ………………………………………………………………….69

xxii

4-15 Ellipsometric spectra and the best fit (left panel) for a smoothened CdTe film with a

starting thickness of 3 µm obtained after the 6th additional etch after smoothening.

Also shown is the model and best fit parameters used in the analysis of the

ellipsometric spectra over the energy range of 2 to 6 eV in order to deduce the

surface roughness thickness and the a-Te volume fraction in the CdTe structure (right

panel). ………………………………………………………………………………70

4-16 Experimental and best fit spectra (left panel) along with the best fit model and

parameters (right panel) for comparison with the results of Fig. 4.15 but without

introducing an a-Te component into the model.

This ellipsometric analysis is

associated with a 3 µm thick smoothened CdTe film after the 6th additional etch. …...

…….…………………………………………………………………………………70

5-1 The room temperature dielectric functions of single crystal CdTe (broken lines) and a

CdTe film deposited at 188°C (solid lines). The downward arrows point to the

energy values of the four critical point transitions E0, E1, E1+∆1, and E2. ……………

……………………….………………………………………………………………73

5-2 Band structure of CdTe. …...………………………………………………………..74

xxiii

5-3 The room temperature ordinary dielectric functions of single crystal (wurtzite) CdS

(broken lines) in comparison with the polycrystalline thin film CdS deposited on c-Si

at 225 °C (solid line). The three downward arrows point to the energy values of the

critical point transitions. ……………………………………………………………75

5-4 (left) Best fit analytical models of the room temperature dielectric functions for two

CdTe films of thickness approximately 1000 Å, obtained from the same deposition

but with different post-deposition processing:

as-deposited (no treatments; broken

line) and CdCl2-treated for 5 min at 387°C (solid line); (right) a comparison between

the CdCl2-treated CdTe film (solid line) and single crystal CdTe (broken line). ……..

.………………………………………………………………………………………78

5-5 A schematic of the sputtering chamber for CdTe/CdS deposition on a fused silica

prism. ……………………………………………………………………………….81

5-6 (left) Best fit analytical models for the room temperature dielectric functions of a CdS

film as-deposited on a fused silica prism measured from the prism side and on a c-Si

wafer measured from the ambient side;

(right) best fit analytical model for the

room temperature dielectric functions of CdS measured from the prism side before

and after a 30 min CdCl2 treatment at 387°C. ……………………………………...82

xxiv

5-7 Resonance energies En (upper panel) and linewidths Γn (lower panel) for the critical

point transitions in single crystal CdTe (broken lines) and in db ~ 1000 Å thick CdTe

films sputter-deposited at different temperatures (points), all measured at 15°C. ……

………………………………………………………………………………………85

5-8 Critical point energies (upper panel) and widths (lower panel) as functions of CdTe

bulk layer thickness during etching by Br2+methanol for co-deposited CdTe films

processed in three different ways: (i) as-deposited, (ii) annealed in Ar for 30 min,

and (iii) CdCl2 treated for 5 min. The deviations at low thickness are due to the onset

of semi-transparency at the E1 critical point energy. ……………………………….86

5-9 Relative void volume fractions as functions of CdTe bulk layer thickness during

etching by Br2+methanol for co-deposited CdTe films processed in three different

ways: (i) as-deposited, (ii) thermally annealed in Ar for 30 min, and (iii)

CdCl2-treated for 5 min.

For the as-deposited and annealed films, the void fraction

is scaled relative to the observed highest density film.

For the CdCl2-treated film,

the void volume fraction is scaled relative to single crystal CdTe. …………………...

.………………………………………………………………………………………88

5-10 Energy of the E1 transition (upper panel) and its width ΓE1 (lower panel) as

functions of CdTe bulk layer thickness in successive Br2+methanol etching steps for

xxv

~3000 Å thick CdTe films. The two films were processed under identical conditions

including fabrication on c-Si wafer substrates and annealing in Ar at 387°C for 30

minutes. The data for experiment #1 are the same as those depicted in Fig. 5.8. …….

.………………………………………………………………………………………90

5-11 Energy of the E1 transition (upper panel) and its width ΓE1 (lower panel) as functions

of CdTe bulk layer thickness in successive Br2-methanol etching steps for ~3000 Å

thick CdTe films.

The two films were processed under similar conditions including

fabrication on c-Si wafer substrates and CdCl2 treatment for 5 minutes.

The data

for experiment #1 are the same as those depicted in Fig. 5.8. .......................................

.………………………………………………………………………………………90

5-12 Void volume fraction as a function of CdTe bulk layer thickness in successive

Br2-methanol etching steps for ~3000 Å thick CdTe films in a second experiment for

comparison with the results in Fig. 5.9.

Two different post-deposition processing

procedures were used: (i) an anneal in Ar for 30 min, and (ii) a CdCl2-treatment for 5

min.

For the Ar annealed films, the void fraction is scaled relative to the depth at

which the highest density is observed.

For the CdCl2-treated film, the void volume

fraction is scaled relative to single crystal CdTe. The void structure for the film

annealed in Ar is attributed to structure in the as-deposited film (as in Fig. 5.8).

In

contrast, the void structure for the CdCl2 treated film is associated with extensive

xxvi

near-surface roughness. …………………………………………………………….92

6-1 Evolution of the surface roughness thickness and a depth profile of the void volume

fraction plotted versus bulk layer thickness obtained in successive Br2+methanol

etching steps that reduce the bulk layer thickness of an as-deposited CdTe

component of a solar cell. …………………………………………………………..99

6-2 (a, left) Evolution of the surface roughness thickness and a depth profile of the void

volume fraction plotted versus bulk layer thickness obtained in successive

Br2+methanol etching steps that reduce the bulk layer thickness of the CdCl2-treated

CdTe component of a solar cell; (b, right) a schematic structure suggested from (a). ..

.……………………………………………………………………………………..100

6-3 (left) Depth profiles of the critical point energies of the E1, E1+∆1 and E2 transitions

in the as-deposited CdTe layer of a solar cell, plotted versus bulk layer thickness

obtained in successive Br2+methanol etching steps that reduce the bulk thickness;

(right) depth profiles of the linewidths of the E1, E1+∆1 and E2 transitions obtained in

the same experiment. ……………………………………………………………...103

6-4 (a, top left) Depth profiles of the critical point energies of the E1, E1+∆1 and E2

transitions in the CdCl2-treated CdTe layer of a solar cell, plotted versus the bulk

xxvii

layer thickness obtained in successive Br2+methanol etching steps that reduce the

bulk thickness; (b, top right) depth profiles of the linewidths of the E1, E1+∆1 and E2

transitions obtained in the same experiment; (c, bottom) a schematic structure

suggested from (b). ………………………………………………………………..104

6-5 Energies of the E1, E1+∆1, and E2 transitions as functions of CdTe bulk layer

thickness in successive etches of a CdCl2 treated CdTe solar cell that reach within

0.1 µm of the CdS/CdTe interface. ………………………………………………..106

6-6 Broadening parameters ΓE1, ΓE1+∆1, and ΓE2 as functions of CdTe bulk layer thickness

in successive etches of a CdCl2 treated CdTe solar cell that reach within 0.1 µm of

the CdS/CdTe interface. …………………………………………………………...106

6-7 Experimental pseudo-dielectric function spectra for the CdTe solar cell of Figs. 6.2

and 6.4 after the 15th etching step; also shown is the best fit using the structural

model of Fig. 6.8. …………………………………………………………………109

6-8 Structural model for the CdTe solar cell after the 15th etch step that provides the best

fit in Fig. 6.7. ……………………………………………………………………...109

6-9 Ex situ SE spectra in (ψ, ∆) (symbols) (a) from the free CdTe surface after 8

xxviii

Br2+methanol etching steps and (b) from the prism/glass side without etching. The

best fit results (solid lines) yield the structural parameters in Figs. 6.10 and 6.11,

including the thicknesses of the CdTe roughness, CdTe bulk, CdTe/CdS interface,

and CdS bulk layers, as well as the volume fractions of CdS/CdTe in the interface

layer and void in the CdS bulk layer. ……………………………………………..110

6-10 The best fit results from the free CdTe surface after 8 Br2+methanol etching steps

yielding the thicknesses of the CdTe roughness, CdTe bulk, CdTe/CdS interface, and

CdS bulk layers, as well as the volume fractions of CdS/CdTe in the interface layer

and void in the CdS bulk layer. ……………………………………………………111

6-11 The best fit results from the prism/glass side without etching yielding the

thicknesses of the CdTe roughness, CdTe bulk, CdTe/CdS interface, and CdS bulk

layers, as well as the volume fractions of CdS/CdTe in the interface layer and void in

the CdS layer. ……………………………………………………………………...111

6-12 CdS and CdTe/CdS interface layer thicknesses deduced from spectra collected

through the prism/glass (solid line) and from spectra collected from the CdTe surface

in successive etches (points, dotted line extrema). ………………………………..113

6-13 Multilayer stack used to model the thicknesses and compositions of the individual

xxix

layers of the CdTe solar cell.

The SE beam enters through the glass, and the

reflection from the top surface is blocked since it is incoherent with respect to the

reflection from the glass/film interface. …………………………………………..114

6-14 Step-by-step MSE reduction by adding one fitting parameter at a time.

Starting

with the CdTe thickness as a variable, each additional parameter was subsequently

fitted.

It was found that fitting the SnO2:F thickness provided the greatest

improvement in MSE among all 2-parameter attempts.

Similar methodology was

used for all 12 parameters. Circular points indicate the best n-parameter fit with n

given at the top and the added parameter given in Table 6.2. …………………….115

6-15 Ellipsometric spectra (points) in ψ (top) and ∆ (bottom) at an angle of incidence of

60° as measured through the glass at a single point on a 3 x 3 cm2 CdTe solar cell

sample. The solar cell was treated with CdCl2 but no back contact processing was

performed.

Also shown is a best fit (lines) using the model structure of Fig. 6.13

with the parameters listed in Table 6.3. …………………………………………...118

7-1 Time evolution of (ψ, ∆) at 5 photon energies selected from 706-point spectra

acquired during sputter deposition of CdTe on a Mo coated glass slide. The full

spectral acquisition time was 2 s and the angle of incidence was 65.68°. ………..122

xxx

7-2 Flow chart of the three-iteration <MSE> minimization procedure for CdTe film

growth on a rough Mo film substrate. …………………………………………….127

7-3 The schematic structure describing the final optical model for deposition on rough

Mo. ………………………………………………………………………………..128

7-4 The schematic structures describing the interface filling (left) and bulk layer growth

(right) models for the first interface layer. ………………………………………...129

7-5 (Left) MSE, which is a measure of the quality of the fit to RTSE data, for the

complete CdTe deposition using optical models for the CdTe film consisting of one

bulk layer (broken line) and four bulk layers (solid line).

In both cases a one-layer

model for surface roughness was employed; (right) the MSE for the model with four

bulk layers is shown on an expanded scale. ………………………………………130

7-6 Evolution of the surface roughness thickness versus deposition time determined using

a four-layer model for CdTe film growth on rough Mo.

The spikes in the surface

roughness thickness result from the consideration of each bulk layer individually

with an independent surface roughness layer.

In this case, the surface roughness

layer on the underlying layer is instantaneously transformed into an interface layer at

the vertical broken lines upon initial growth of the overlying layer, whose roughness

layer starts from zero thickness. …………………………………………………..132

xxxi

7-7 Time evolution of the CdTe overlayer volume percent during interface filling of the

underlying CdTe roughness layer for CdTe growth on Mo. ………………………132

7-8 (Left) Evolution of the individual bulk layer thicknesses versus deposition time

determined using a four-layer model for CdTe film growth on Mo; (right) evolution

of effective thickness of CdTe, including all bulk, interface, and surface layer

components. ……………………………………………………………………….133

7-9 Mo dielectric function at a nominal temperature of 200 °C acquired by inversion

assuming a Mo substrate roughness thickness of 79.6 Å (solid line).

For the

overlying CdTe, four bulk layers and a roughness layer are used to describe the best

fit model.

For the first bulk layer, the Mo/CdTe interface roughness, the CdTe bulk,

and CdTe surface roughness layer thicknesses di, db, ds, respectively, are determined

in a dynamic analysis, in which case the criterion is the minimum average MSE.

The Mo/CdTe interface roughness thickness di is taken to be the same as the Mo

substrate film roughness thickness. Also shown is the Mo dielectric function at room

temperature before heating to the deposition temperature as determined by inversion,

again assuming a Mo surface roughness layer thickness of 79.6 Å (broken line). …...

………………………………………………………………………………………134

7-10 Real (top panel) and imaginary (bottom panel) parts of the dielectric functions of the

xxxii

four layers [(a)-(d)] of a CdTe thin film deposited on rough Mo. These results are

determined from inversion, after determining the CdTe roughness and bulk layer

thicknesses through minimization of the average MSE obtained throughout the layer

analysis; (e) also shown is a comparison of the first layer dielectric function of CdTe

deduced in this study with that of CdTe deposited on a smooth c-Si substrate at a

nominal temperature of 200 °C.

In (b)-(d) comparisons are provided between the

dielectric function of a given layer and that of the layer underneath it. ………………

.……………………………………………………………………………………..137

7-11 Comparison of the surface roughness thickness at the end of the deposition for a

1496.5 Å thick CdTe film on Mo as deduced by RTSE with the relative surface

height distribution and rms roughness from AFM. ……………………………….138

7-12 A comparison of measured pseudo-dielectric functions (solid lines) for Mo thin

films deposited by sputtering (a) on glass and (b) on Kapton. Also shown are the

fits (broken lines) using a reference dielectric function for dense Mo determined

separately, and the multilayer models depicted in the insets. ……………………..140

7-13 Ellipsometric spectra (solid lines) and best fit (broken lines) using the structural

model and best fit parameters shown in the inset.

The dielectric function is

determined simultaneously using a model assuming a sum of critical point structures.

xxxiii

The resulting dielectric function is shown in Fig. 7.14. …………………………..142

7-14 Dielectric function of thin film ZnTe:Cu prepared by magnetron sputtering with 1

wt.% Cu in the ZnTe target (solid lines).

A model consisting of four critical points

in the band structure has been used in this analysis.

The data points are literature

results for single crystal ZnTe. ……………………………………………………144

7-15 Step-by-step MSE reduction by adding one fitting parameter at a time. Starting with

the CdTe thickness as a variable, each additional parameter was subsequently fitted.

It was found that fitting the CdS thickness provided the greatest improvement in

MSE among all 2-parameter attempts. Similar methodology was used for all 14

parameters. Circles connected by the solid line indicate the best n-parameter fit with

n given at the top and the added parameter given in Table 7.5. …………………..147

7-16 Ellipsometric spectra for a CdTe solar cell deposited on Mo in the substrate

configuration (points).

measurement.

The cell was exposed to a CdCl2 treatment before this

The top contact of the solar cell is not incorporated over the area

probed, leading to the structure: ambient/CdS/CdTe/ZnTe:Cu/Mo.

The solid line

depicts the optical model shown in Fig. 7.17. …………………………………….148

7-17 Optical model for a CdTe solar cell in the substrate configuration (excluding the top

xxxiv

contact) deposited on a Mo film surface.

This model and the best fit parameters

provide the solid line results in Fig. 7.16. ………………………………………...151

8-1 Current-voltage and normalized quantum efficiency spectra for a champion 16.5%

efficient CdTe/CdS thin-film solar cell. …………………………………………..152

8-2 Two-terminal tandem cell based on Cd1-xMgxTe and Cd1-xHgxTe absorbers. …………

.……………………………………………………………………………………..154

8-3 Real (a) and imaginary (b) parts of the pseudo-dielectric functions of RF sputtered

CdTe (Eg = 1.50 eV), Cd1-xMnxTe (Eg = 1.63 eV) and Cd1-xMgxTe (Eg = 1.61 eV)

films all in the as-deposited state; (c) Pseudo-dielectric function of as deposited

Cd1-xMnxTe samples after different storage times in laboratory ambient: (1)

immediately after Br2/methanol etch; (2) 3 weeks after deposition; and (3) 1.5 years

after deposition. …………………………………………………………………...158

8-4 Best fit (lines) to the second derivative of the experimental pseudo-dielectric function

(points) for the as-deposited Cd1−xMnxTe film of Fig. 8.3 (c: immediately after etch).

The three CP transitions, E1, E1 + ∆1, and E2, are indicated by arrows with best fit

energies of 3.352, 3.884, and 5.033 eV, respectively.

The composition of x=0.06

can be estimated by the empirical relationship between E1, the strongest CP in this

xxxv

case, and the composition. ………………………………………………………...160

8-5 Variation of the pseudo-dielectric function of as deposited Cd0.94Mn0.06Te with time

after Br2/methanol etching, measured in situ at room temperature during exposure to

laboratory ambient. ………………………………………………………………..161

8-6 Pseudo-dielectric functions of as-deposited and one-step and two-step CdCl2 treated

Cd0.94Mn0.06Te samples. …………………………………………………………...161

8-7 Index of refraction and extinction coefficient of amorphous TeO2. ……………….162

8-8 Pseudo-dielectric functions of as-deposited and CdCl2 treated Cd1-xMgxTe samples. ...

.……………………………………………………………………………………..163

8-9 Approximate dielectric functions, i.e., optical properties deduced with a best attempt

to eliminate surface effects, for as-deposited films and CdCl2-treated films obtained

by SE after Br2+methanol etching that improves the surface quality (points); (a)

CdTe; (b) Cd1-xMnxTe; (c) Cd1-xMgxTe; the solid lines show the results of fits to

extract critical point energies and widths.

The result for the CdCl2-treated

Cd1-xMnxTe could not be fit with a critical point parabolic band model. ……………..

.……………………………………………………………………………………..166

xxxvi

8-10 Pseudo-dielectric function obtained directly from experimental (ψ, ∆) data using a

single interface conversion formula for a Cd1-xMgxTe sample prepared from a target

of CdTe (80 wt.%) + MgTe (20 wt.%) (CGT42).

The solid line describes

experimental data and the dashed line describes the best fit result.

The deduced

bulk and surface roughness layer thicknesses are shown. ………………………...169

8-11 Best fit analytical dielectric function obtained from an analysis of the experimental

(ψ, ∆) data for the Cd1-xMgxTe sample of Fig. 8.10 prepared from a target of CdTe

(80 wt.%) + MgTe (20 wt.%) (CGT42). …………………………………………..169

8-12 Pseudo-dielectric function obtained directly from experimental (ψ, ∆) data using a

single interface conversion formula for a Cd1-xMgxTe sample prepared from a target

of CdTe (60 wt.%) + MgTe (40 wt.%) (CGT92). The solid line describes

experimental data and the dashed line describes the best fit result.

The deduced

bulk and surface roughness layer thicknesses are shown. ………………………...170

8-13 Best fit analytical dielectric function obtained from an analysis of the experimental

(ψ, ∆) data for the Cd1-xMgxTe sample of Fig. 8.12 prepared from a target of CdTe

(60 wt.%) + MgTe (40 wt.%) (CGT92). …………………………………………..171

xxxvii

8-14 Band gap of as-deposited thin film Cd1-xHgxTe as a function of the substrate

temperatures over the range from 23°C to 153°C. ………………………………..174

8-15 Dielectric functions from mathematical inversion and from the corresponding

analytical model fit for as-deposited Cd1-xHgxTe films prepared with different

substrate temperatures. ……………………………………………………………175

8-16 Comparison of the real (left) and imaginary (right) parts of the pseudo-dielectric

function of as-deposited and CdCl2 treated CdxHg1-xTe films, including results (a)

before and (b) after a single Br2/methanol etching step. ………………………….177

xxxviii

Chapter One

Introduction to Spectroscopic Ellipsometry

1.1 History

The very first ellipsometric studies were performed by Professor Paul Drude (1863~

1906), even though the term “ellipsometry” was not used at that time

[1-1]

.

Drude was

the first to derive the equations of ellipsometry, and was also the first to perform

experimental studies on both absorbing and transparent solids. The optical properties

determined in these ellipsometry studies were found to be quite accurate. In fact, when

Palik compared Drude’s results with those obtained 100 years later, the results were

amazingly close [1-2]. Because of the absence of fast computation methods made possible

by the modern computer, Drude obtained the optical properties of solids at only a few

selected wavelengths [1-1].

After Paul Drude’s tremendous impact on ellipsometry development, very little

progress was reported in the succeeding 70 years. One exception was a 1945 article

authored by Alexandre Rothen who described the half-shade method to detect the

polarization state change of light upon reflection from a specular surface, and coined the

term “ellipsometry”[1-3].

When laboratory computers became prevalent in the 1960s and

1

1970s, automated ellipsometers for diverse purposes were developed

[1-4]

. Among the

different types of automated ellipsometers developed at that time, two major types are

still widely used in the spectroscopic mode of operation: (i) the rotating element

ellipsometer

[1-5],

and (ii) the phase modulation (PM) ellipsometer

[1-6]

.

The photon

energy range of spectroscopic ellipsometry has increased significantly over the years

since D. E. Aspnes and A. A. Studna developed the first rotating analyzer spectroscopic

ellipsometer covering the full (near-infrared)-to-(near-ultraviolet) range

[1-7]

.

At the

same time, the instrument development focus was also placed on increasing the speed of

full spectroscopic measurement by incorporating a multichannel detection system in the

ellipsometer in order to acquire the entire spectral range essentially simultaneously

[1-8]

.

As a result of this effort, the technique of real time spectroscopic ellipsometry (RTSE)

arose for analysis of thin film growth and materials processing.

1.2 Purpose

Spectroscopic ellipsometry is used to obtain the optical properties of materials of

interest in optical and electronic applications

[1-9]

. Once optical properties of materials

are available, thin film thicknesses can be measured using optical models for single thin

film and multilayer samples.

Advanced data analysis often enables measurement of

thickness and optical properties simultaneously

[1-10, 1-11]

.

The measurable thickness

range for ellipsometry varies from submonolayer to several microns.

For spectroscopic

ellipsometry measurements of thickness, a wide spectral range is important since the light

must penetrate through the thin film, reflect from an underlying interface, return through

2

the film, and proceed to the detector.

In studies of semiconductors, lower energy gap

materials such as CuInSe2 can be analyzed for thickness when the spectral range extends

deeper into the infrared.

For energies below the semiconductor band gap, the light

remains unabsorbed and reflects from the bottom interface of the film, enabling wave

superposition and phase shifts that allow thickness to be determined.

This demonstrates

the advantage of spectroscopic ellipsometers with an extended near-IR spectral range,

even below the 1.1 eV band gap of the most common Si diode detectors used in

ellipsometers.

A similar advantage exists for spectroscopic ellipsometers with an

extended ultraviolet spectral range when characterizing the thickness of metal thin films.

In addition to thickness, other properties of a film can be determined through

ellipsometric measurements performed in real time during the deposition process

[1-12]

.

These include roughness thickness on the surface of the film and the optical properties of

the film.

From the latter, the film density deficit (represented by a volume fraction of

voids in the layer), film crystalline quality (represented by a defect density or average

grain size), alloy composition, and temperature may be determined.

In fact, real time

measurements may also provide a depth profile of the film structure and properties, and

even area uniformity of the film.

1.3 Data measured by ellipsometry

An ellipsometric measurement provides the angles (ψ, ∆), corresponding to the

relative amplitude ratio (tanψ) and phase shift difference (∆) between the complex

3

r

r

amplitude reflection coefficients for E p and Es , the orthogonal linear electric field

components of a polarized light wave [1-13].

These electric field components are parallel

r

r

( E p ) and perpendicular ( Es ) to the plane of incidence.

(The overline arrow denotes a

complex vector in which case each vector component has a real amplitude and phase.)

r

r

The nature of E p and Es for a light wave will be further elucidated in the next section.

Thus, the quantity measured by ellipsometry is the ratio ρ% of the complex amplitude

reflection coefficients for the p-polarized field component ( R% p ) to that for the s-polarized

field component ( R% s ):

ρ% =

R% p

= tanψ ei∆ ;

%

R

(1-1)

s

where

E% p ref

R% p = inc = R% p exp ( iδ p ) ,

E%

(1-2)

E% ref

R% s = s inc = R% s exp ( iδ s ) .

E% s

(1-3)

p

Here, the notational style of these equations will be summarized.

Generally, the

subscripts p and s identify the wave characteristics for vector components parallel and

perpendicular to the plane of incidence, respectively.

For example, δp and δs represent

the phase shifts of each orthogonal electric field component upon reflection.

On the

other hand E% p ( s ) denotes the p (s) orthogonal component of the electric field amplitude.

The superscripts “ref” and “inc” in Eqs. (1-2) and (1-3) refer to the electric field

components of the reflected and incident light waves.

4

As a result, the angles ψ and ∆ are defined by:

tanψ =

R% p

,

R%

(1-4)

s

∆ = δ p − δs .

(1-5)

R% p ( s ) are also called the complex Fresnel coefficients.

As a complex variable, R% p ( s )

provides information on the amplitude change and phase shift of the p (s) field

components of the wave upon its reflection from the sample.

In fact, the complex

Fresnel coefficients provide the reflected-to-incident amplitude ratio and the

r

reflected-minus-incident phase shift for each orthogonal electric field component E p (or

r

Es ) of the polarized light wave.

1.4 Mathematical derivation

In order to understand the derivation of optical properties from the ellipsometric

angles (ψ, ∆), it is necessary to understand first the mathematics of polarized light.

When the most general state of elliptically polarized light wave transmits through or

reflects from one or more interfaces between media at a non-normal angle of incidence,

the polarization change can be defined in terms of a change in tilt angle and ellipticity

angle of the general polarization ellipse. This change depends on the angle of incidence

and the optical properties and thicknesses of the media.

The elliptically polarized state

of monochromatic light in any medium assumed to be isotropic can be described by

r

decomposing the beam into two orthogonal components which are linear and parallel ( E p )

5

r

as well as linear and perpendicular ( Es ) to the plane of incidence.

Both components are

plane waves and a superposition of such components is described by [1-14]:

r r

r

r r

E ( r , t ) = E0 exp [i (q ⋅ r − ω t ) ] ;

where

r

q

(1-6)

is the complex propagation vector,

ω

is the wave frequency,

r

and E0 determines the polarization state of the wave. In this linear p-s basis,

r

r

r

iγ

E0 = E p + Es = E p e p pˆ + Es eiγ s sˆ .

(1-7)

r

For this general polarization state of the light wave, the endpoint of the vector E0

r

traces an ellipse as a function of time t during propagation at a fixed position r0 .

complete cycle is made in a time τ =

phase velocity of v =

ω

Re(q% )

2π

ω

A

. The plane wave also travels in space with a

, and the endpoint of the field vector traverses one full

ellipse after a distance equal to the wavelength λ =

2π

.

Re(q% )

r

%ˆ.

complex magnitude of the propagation vector: q = qq

6

Here is q% defined as the

s

b

Q

r r

E (r0 , t )

χ a

p

r r

r = r0

r

Figure 1-1 Schematic representation of the electric field vector trajectory E (rr0 , t ) for an

r

elliptically polarized light wave at a fixed position r0 versus time. Q is the tilt angle

between the ellipse major axis a and the p-axis, measured in counterclockwise-positive

sense when facing the light source. χ is the ellipticity angle given by tan-1(b/a).

r

In Equation 1-6, the wavevector q defines the propagation direction.

If one

r

assumes q is parallel to the z-axis, the wave becomes:

r r

% − ωt ) ] ;

E ( r , t ) = E0 exp [i ( qz

(1-8)

where

ω

q% =

c

2

2

2

4πσ r ω % 2

ε r + i ω = c N ,

(1-9)

or

ω

q% = N% .

c

Here c is the speed of light in vacuum. At the light wave frequency ω, εr and σr denote

the real dielectric function and real optical conductivity of the medium in which the wave

7

travels, and N% is its complex index of refraction, where [1-15]

4πσ r

N% = n + ik = ε r + i

ω

.

(1-10)

Here n is the (real) index of refraction, and k is the extinction coefficient of the medium.

It should be noted that Re(q% ) =

wavelength is λ =

ω

c

n , so the phase velocity of the wave is v =

c

and the

n

2π c 2π

=

v as expected. Next q% and N% are substituted into

nω

ω

Equation 1-8 to give

r r

r

ω nz

ω kz

E (r , t ) = E0 exp −

− ωt .

exp i

c

c

(1-11)

In addition to the complex index of refraction N% , the complex dielectric function ε%

is another commonly used quantity to describe the macroscopic optical properties of

solids [1-15], where:

ε% = ε1 + iε 2 = N% 2 ,

(1-12)

ε1 = ε r = n 2 − k 2 ,

(1-13)

4πσ r

(1-14)

ε2 =

ω

= 2nk .

Ellipsometry measures the change in polarization state of the incident light caused by

reflection from one or more interfaces. When an incident linearly polarized light wave

reflects from a single interface between two media (see Fig. 1.2), the state of polarization

of the reflected beam can assume an elliptical state with the tilt and ellipticity angles

depending on the optical properties of the sample.

8

reflected wave

incident wave

p

p

.

s

Medium 0

Medium 1

.

s

θi

p

θi

s

θ% t

Plane of sample

.

Plane of incidence

p

s

transmitted wave

Figure 1-2

Reflection of a polarized light wave at an interface between two media.

For the ideal situation of a perfectly planar interface on the atomic scale with no

roughness, the optical properties of the reflecting medium can be derived from the

ellipsometric angles (ψ, ∆) as long as the optical properties of the incident medium and

the angle of incidence are known [1-13]. In the simplest case of reflection and transmission

at the perfectly planar interface between two isotropic media (see Fig. 1.2), the ratio of

the complex Fresnel reflection coefficients can be written:

N% s cos θi − na cos θ%t

R% p na cos θ%t + N% s cos θi

ρ% =

=

R% s na cos θi − N% s cos θ%t

%

%

na cos θi + N s cos θt

,

(1-15)

where na is the assumed real refractive index of Medium 0 (ambient, see Fig. 1.2), N% s is

the complex index of refraction of Medium 1 (substrate, see Fig. 1.2), θi is the angle of

incidence and θ%t is the complex angle of refraction. cos θ%t can be obtained from sin θ i ,

9

na , and N% s by using a complex form of Snell’s Law:

cos θ%t = ±

N% s 2 − na 2 sin 2 θi

.

N%

(1-16)

s

Then, eliminating cos θt from Equation 1-15 yields:

(

(

N% s 2 cos θi m na N% s 2 − na 2 sin 2 θi

R% p

ρ% =

=

R% s

N% s 2 cos θi ± na N% s 2 − na 2 sin 2 θi

ρ% =

)( n cosθ ±

)( n cosθ m

) , (1-17)

sin θ )

a

i

N% s 2 − na 2 sin 2 θi

a

i

N% s 2 − na 2

2

i

na sin 2 θi m cos θi N% s 2 − na 2 sin 2 θi

,

n sin 2 θ ± cos θ N% 2 − n 2 sin 2 θ

a

i

i

s

a

(1-18)

i

and solving for N% s 2 yields:

1 − ρ% 2

2

2

2

2

%

N s = na sin θi 1 +

tan

θ

i.

1 + ρ%

(1-19)

As a result, by using the dielectric function definition in Equation 1-12, ε%s can be

obtained from

1 − ρ% 2

ε%s = ε a sin θi 1 +

tan 2 θi .

1 + ρ%

2

(1-21)

Therefore, if one knows (i) ε a the dielectric function of the ambient; (ii) θi the angle

of incidence, and (iii) (ψ, ∆) the measured ellipsometric angles, then one can determine

the dielectric function of the reflecting medium.

1.5 Spectroscopic ellipsometer used in the study

The spectroscopic ellipsometer used for the study described in this thesis was

manufactured by J. A. Woollam Company

[1-16]

. The specific model used here was the

M-2000DI, which is a rotating-compensator multichannel ellipsometer.

10

This

ellipsometer covers the photon energy range from 0.74 to 6.50 eV. One complete set of

spectra in the ellipsometric angles (ψ, ∆) (0.74~6.5 eV) can be collected as an average

over a minimum of two optical cycles in a time of (30.7 Hz)-1 = 32 ms; thus, the single

optical period is 16 ms. Here 30.7 Hz is the mechanical rotation frequency of the

compensator. In the case of real time SE applications, specifically for monitoring the

CdTe or CdS deposition process, acquisition times from 1 to 3 seconds were chosen. In

the case of the ex-situ SE applications, the data acquisition time of 10 seconds was

chosen to ensure a higher precision in the measured (ψ, ∆) spectra. As a result of the

multichannel detection capability, this spectroscopic ellipsometer is ideal for in-situ

process monitoring and quality control, and specifically for studies of the CdTe-based

solar cells as described in this thesis.

Figure 1-3 Spectroscopic ellipsometer used in this research mounted in the ex-situ

mode of operation.

The angle of incidence is adjustable for this ellipsometer.

For ex-situ studies, the

ellipsometer is set at angles of incidence ranging from 45° to 75° at 5° intervals.

11

Measurements at different angles of incidence enable one to extract optical properties of

unknown materials with greater confidence. Analyses of all spectra apply either

numerical inversion or least-squares regression algorithms, or even combinations of these

two methods.

1.6 Data analysis

As described in Section 1.4, the ellipsometry measurement provides two angles

(ψ, ∆), which quantify the change in the state of polarization of the light wave upon

oblique reflection from the sample. Ellipsometry does not directly measure the optical

properties and thickness of a thin film; however, ψ and ∆ are functions of these

characteristics, which require data analysis for extraction [1-17]. The starting point for such

analysis is an optical model for the sample.

A general schematic of the analysis

procedure is illustrated in Fig. 1.4.

The first step in building an optical model for the sample requires identifying the

physical sequence of layers of the sample, including each layer’s thickness and optical

properties, the latter either as fixed functions, analytically defined functions with variable

parameters, or even continuously variable functions point by point.

For each such

thickness and optical property variable, it is necessary to provide an estimated value to

begin the iteration. As an example, an optical model for a simple silicon substrate

sample is shown in Fig. 1.5.

In general, building an optical model begins with the

simplest structure; however, complexities such as surface and interface roughness layers

12

can be added as required in order to improve the fit to the data and to conform with any

previously established understanding of the nature of the sample.

Measurement

(ψ, ∆) versus E

(ψ, ∆) versus θi

Construct optical

model

Assign initial

values to variables

Fit, compare

data and model

results

Results:

n, k versus E

thicknesses

Figure 1-4

Simplified flow chart of the data analysis procedure.

13

n, k, (surface roughness)

ds

n, k, (film)

db

n, k, (interface)

di

n, k, (substrate)

Figure 1-5

SiO2/void

ds

SiO2

db

SiO2/c-Si

c-Si

di

Optical model and physical structure of a c-Si wafer used as a substrate.

Calculated (ψ, ∆) spectra are first generated using the optical model with the initial

values assigned to the unknown parameters. Then these spectra are compared with the

experimental (ψ, ∆) spectra and iterative adjustments of the unknown parameters are

performed in a regression analysis intended to minimize the difference between the two

pairs of spectra. If the initial values of the unknown parameters differ substantially from

the overall best fit solution, however, then the regression algorithm may fail. The role

of this algorithm is to compute the corrections to the initial estimates that yield improved

agreement between the calculated and experimental spectra and ultimately the overall

best fit.

What can occur instead is the identification of a local minimum in the quality

of fit when plotted in the space of the unknown free parameters, and as a result the

calculated spectra may differ substantially from the experimental spectra. In contrast, if

the initial estimates are close enough to the overall best fit solution, then through iterative

corrections, the algorithm can identify the global minimum in the quality of the fit, and as

14

a result improved agreement between the calculated and experimental data is possible.

For this reason, the flow chart in Fig. 1.4 shows an iteration step not only in the

construction of the model but also in the variation of the initial values typically over a

grid in parameter space.

In addition to the simplest case of thicknesses as unknown parameters, the

least-squares regression method is commonly used to extract the complex dielectric

function of one or more materials in the model

[1-17]

.

When an unknown complex

dielectric function can be expressed as an analytically-defined function of several

wavelength-independent parameters such as electronic resonance energies (band gaps),

resonance amplitudes (oscillator strengths), and broadening parameters (inverse

excitation lifetimes), then the fitting procedure is similar to that of fitting simply

thicknesses. All the known values of the parameters are fixed in the model, and the

wavelength independent unknown parameters are estimated, including the thicknesses

and the optical property parameters. The (ψ, ∆) spectra associated with these initial

estimates are calculated and compared with the experimental (ψ, ∆) spectra. Then, the

least-squares regression algorithm is used to adjust the unknown parameters iteratively so

as to minimize the difference between the calculated and experimental ellipsometric

spectra. A mean square error (MSE) function is used as the criterion; the iterations are

terminated when MSE attains its minimum.

If the initial estimates of the unknown

parameters are close enough to the correct values, then the global minimum can be

reached; if not, a local minimum can lead to erroneous parameter results.

15

In such analyses, the least-squares regression algorithm uses the weighted mean

square deviation given by [1-17]:

1

MSE =

2N − M

ψ cal −ψ exp

i exp i

∑

σ

i =1

ψ

N

2

2

∆ ical − ∆ iexp

+

σ exp

∆

(1-22)

where N is the number of (ψ, ∆) data pairs versus wavelength or photon energy, and M is

the number of unknown free parameters determined in the analysis.

Thus, the squares

of the differences between each pair of calculated and experimental data (ψ cal ,ψ exp ) and

( ∆ cal , ∆ exp ) at a given wavelength or photon energy indicated by the subscript i are

summed and divided by the standard deviations of the experimental data σψexp and σ ∆exp ,

respectively, for the associated wavelength.

As a result, spectral points that exhibit a

lower signal to noise ratio, typically at the highest photon energies (6.0~6.5 eV) are

weighted less heavily.

Once the fit for a given model is successful, a number of various models need to be

tested in order to improve the global fit to the data.

These models generally start with

the simplest structure, e.g., a single film on a substrate, and then progress to more

complicated ones that include surface and interface roughness.

Some complications

may be expected based on an understanding of how thin films grow.

unexpected and provide new insights.

Others may be

In particular for complicated models with many

parameters, the overall best fit parameters must be evaluated for their confidence limits

and possible pair-wise or multiple correlations.

In addition, the best fit parameters must

be physically meaningful; obviously there should be no zero or negative thickness values.

16

For an intrinsic semiconductor, the index of refraction n must decrease smoothly with

increasing λ at wavelengths longer than that associated with the band gap.

In this range,

k should remain at zero, because of the lack of absorption at photon energies below the

band gap.

Obviously, k cannot be negative; otherwise, the light would be amplified in

traversing the material.

17

Chapter Two

Introduction to CdTe-based Solar Cells

2.1 CdTe-based solar cell structures

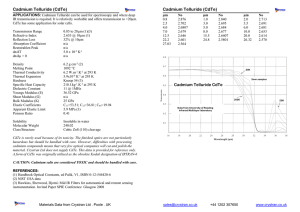

CdTe-based solar cells can be fabricated in both substrate and superstrate

configurations [2-1, 2-2, 2-3].

In the substrate configuration, sunlight enters the active layers

of the cell before reaching the underlying substrate, and thus the substrate need not be

transparent.

A typical substrate-type deposition process would follow the sequence,

Mo/CdTe/CdS/In2O3:Sn.

Indium-tin-oxide (ITO), denoted by the chemical formula

In2O3:Sn whereby Sn is the dopant, is a transparent conducting oxide (TCO) thin film

that functions as an electrical contact as well as a window layer through which sunlight is

transmitted

[2-1]

.

In the superstrate configuration which is the configuration used by

industry, the sunlight enters the substrate first, and the substrate must be selected for low

absorption over the solar spectrum.

Typically there will be a trade-off between low

absorption and low cost in module manufacturing.

A typical deposition sequence in this

case is glass/SnO2:F/CdS/CdTe/Cu/Au. A common superstrate for the CdTe solar cell is

TEC glass manufactured by Pilkington.

TEC glass is a soda-lime glass coated with

successive layers of undoped SnO2, SiO2, and F-doped SnO2, SnO2:F, to achieve the

18

desired sheet resistance, optical properties, and chemical stability.

Another TCO used in

place of In2O3:Sn and SnO2:F in both substrate and superstrate solar cells is ZnO:Al,

aluminum-doped zinc oxide.

Schematic examples of the substrate and superstrate

configurations are shown in Figs. 2-1 and 2-2.

Ambient

front contact

ITO

CdS

CdTe

back contact

Figure 2-1

Mo

The substrate structure for CdTe solar cells.

Ambient

Cu/Au back

contact

CdTe

CdS

front

contact

SnO2:F

SiO2

TEC-15

SnO2

Soda lime glass

Figure 2-2

The superstrate structure for CdTe solar cells.

In this thesis, results for both substrate and superstrate solar cells will be presented;

however, the focus has been on solar cells using TEC-15 glass as the superstrate. This

glass has been used in module manufacturing and will be described in detail in Chapter 3.

The TEC-15 glass is ~ 3 mm thick and serves as a support for the active layers of the

solar cell.

It is transparent, rigid, and inexpensive, and has the widest applications for

ground mounted PV systems. The critical component is the TCO layer, SnO2:F, which

19

is the top-most layer of the TEC-15 glass and acts as the front contact electrode of the

solar cell.

The polycrystalline cadmium sulfide (CdS) layer is invariably an n-type

semiconductor, and serves as one side of the p-n heterojunction solar cell

[2-1]

. As a

material with a wide band gap of 2.43 eV at room temperature, CdS is transparent to

optical wavelengths as short as 510 nm.

Because its thickness is relatively small

compared to that of CdTe, typically ~1000 Å, some fraction of the photons with energy

above 2.43 eV will still pass through the CdS layer to reach the CdTe layer.

The polycrystalline cadmium telluride (CdTe) is the active absorber layer and serves

as the p-type semiconductor of the heterojunction.

It is an ideal absorber material

because its 1.5 eV band gap is very close to the theoretically calculated optimum value

for a single junction solar cell

[2-4]

under unconcentrated AM1.5 sunlight.

It is an

efficient absorber above its band gap, and its high absorption coefficient results from the

direct nature of the band gap transition. Typically, the thickness of the CdTe layer in the

solar cell ranges from 2 to 4 µm in order to absorb a larger fraction of the light between

633 nm and 832 nm.

CdS layer.

The p-n junction consists of the CdTe layer in contact with the

Because the doping level in CdTe is much lower than that in the CdS, most

of the depletion region of the device is located within the CdTe layer.

The back contact studied in this dissertation uses copper (~ 30 Å) and gold (~ 200 Å)

in forming the electrode. Due to its high conductivity, a large thickness is not needed for

the gold layer.

20

2.2 Deposition method and process steps

The deposition method pioneered at the University of Toledo utilizes the radio

frequency (RF) magnetron sputtering technique for fabrication of both the CdTe and CdS

thin films [2-5].

The CdTe or CdS sputtering target, serving as one electrode, is driven by

a RF power source.

This power source generates a plasma of ionized argon gas between

the target and the substrate platform, which serves as the second grounded electrode.

The RF potential drives the ions towards the surface of the target where they impact,