Material Magic: Semiconductors

advertisement

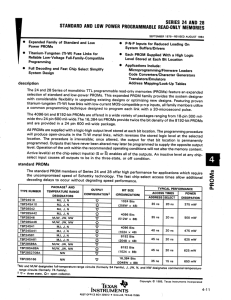

B쵆1 Materials Magic: Semiconductors Introduction Material Magic: Semiconductors 1 B쵆1 Materials Magic: Semiconductors Introduction Table of Contents An Introduction to Semiconductors and Their Use 3 Symbol List 6 Semiconductors: A Brief History of the Industry 8 2 B쵆1 Materials Magic: Semiconductors Introduction An Introduction to Semiconductors and Their Use Semiconductors have many unique properties that make them useful, especially in the manufacture of electronic and optical devices. During the last 40 years or so improvements in our understanding of the physics of semiconductors and developments in materials science have made possible electronic and optical devices that were inconceivable earlier. During this short period the semiconductor industry has grown into a multibillion dollar business and in the process changed the way we do science and engineering, the way we do business and even the way we learn. Of course, one could still ask, why has this incredible expansion in the semiconductor industry occurred? The answer to this question is that humankind has an insatiable desire for information and for energy. By employing semiconductor technology it has been possible to manufacture the extremely complicated electronic circuits necessary for high capacity computer, telecommunication and entertainment systems. Another contribution to this remarkable expansion of the semiconductor industry lies in the fact that semiconductor devices have been invented that are capable of generating electricity and light. In this short summary of semiconductor materials and technology, we will first be concerned with the basic properties of semiconductors (Chapter 1). The most important electrical, optical, thermal and magnetic properties will be reviewed first. Also, a short summary will be given of some important mechanical and acoustic properties. No attempt is made to give a rigorous mathematical treatment of the materials science of semiconductors here or discuss the properties of all the different types of semiconductors; there are almost 200 different semiconductors! Rather, the focus is on the physical principles involved, though every attempt is made to present accurate data in the text. Without the invention of the p-n junction all the electronic and optoelectronic devices that we have come to be so dependent on would not have been possible. Because of this, a chapter on the principles of semiconductor devices (Chapter 2) will follow. The principles of operation of electronic devices such as the bipolar transistor and the metal oxide semiconductor field effect transistor (MOSFET), as well as optical devices such as the light emitting diode (LED) and lasers are discussed. In addition, a short introduction to integrated circuits (microelectronics), sensors and actuators (microsystems) and finally a short discussion of what nanotechnology is, will be presented. By nanotechnology is meant the study of devices and systems having dimensions in the range 1 x 10-9 m, i.e. one billionth of a meter. Thereafter, a brief introduction to materials and device fabrication technology (Chapter 3 ) will be given. After discussing the very important subjects of the growth of semiconductor single crystals and basic device fabrication, integrated circuit technology will be reviewed. In fig. C1 a cross section through an advanced Complimentary Metal Oxide Semiconductor (CMOS) inverter circuit is shown [1]. As it can be seen it is very complicated and consists of many layers of different materials; a substrate of silicon, 3 B쵆1 Materials Magic: Semiconductors Introduction insulators such as silicon dioxide and silicon nitride, conductors such as aluminium and copper, as well as highly doped silicon are employed. It is then surprising to realize that this complicated device is actually made with the repetitive application of relatively few processes. How this is done will be explained in the discussion on device fabrication. Fig. 1 A cross sectional view of an advanced CMOS inverter circuit [1]. Also a very brief presentation of some of the important aspects of the fabrication of photonic devices, microsystems and, finally, nanoelectronic devices will be given. In addition to improving our understanding of advanced semiconductor processing technology, it will be shown that, "nanotechnology", is not new! It is just one more step on the road to the ultimate in smallness of devices and systems. What is new in this respect is all the unexpected new physics and chemistry we meet along the way! In order to illustrate the level to which the technology has risen, fig. C2 shows a photograph of a 200 mm diameter slice of silicon on which approximately 200 microprocessor chips have been fabricated. The total number of transistors on the slice is about 2 billion. It should also be mentioned that the perfection and purity of the silicon crystal slice used far exceeds any natural or synthesized material made until now. 4 B쵆1 Materials Magic: Semiconductors Introduction Fig. 2 On this 200 mm diameter slice of silicon approximately 200 microprocessor chips have been made. The total number of transistors on the slice is approximately 2 billion. Finally, some of the special measurement techniques used to characterize semiconductor materials and devices (Chapter 4) will be discussed. The reason why an extra chapter on material testing is included is that some of the methods employed for semiconductors are not found elsewhere. In order to make these chapters as useful as possible, the material of each section will include enough physical theory to give the reader an understanding of how semiconductor devices work and how they are manufactured. We will see that although integrated circuits can be very complicated, the manufacture of these is based on relatively few processes as stated above. It is hoped that this sort of presentation will help to make the basic principles more easily understood and, thus, give the reader a basis for a more quantitative study of semiconductors. Again it should be mentioned that for specific mathematical details, data, and advanced theory, reference should be made to the references cited. 5 B쵆1 Materials Magic: Semiconductors Introduction Symbol List Symbol Description Unit A B C C D E E EC EF Eg EV E Ec Em F F F(E) G H Ħ h I IC J Jth K K kT L Le m0 mn mp mi N N ni n0 NA NC ND NV p p0 P Lattice Constant Magnetic Induction Speed of Light in Vacuum Capacitance Diffusion coefficient Magnitude of Electronic Charge Energy Energy, bottom of conduction band Energy, Fermi level Energy, bandgap Energy, Top of Valance Band Electric Field Critical Field at Breakdown Maximum Field Frequency Force Fermi - Dirac Distribution Function Generation Rate Planck’s Constant =h/2 Photon energy Current Collector Current Current Density Threshold Current Density Boltzmann constant Wave Vector Thermal Energy Length Diffusion Length Electron Rest Mass Effective Mass, Electron Effective Mass, Hole Direction Cosines Index of Refraction Free Electron Concentration Intrinsic Carrier Concentration Equilibrium Electron Concentration Acceptor Impurity Concentration Effective Density of States, Conduction Band Donor Impurity Concentration Effective Density of States, Valance Band Free Hole Concentration Equilibrium Hole Concentration Pressure Å T cm / s F cm2/s C eV eV eV eV eV V/cm V/cm V/cm Hz (cps) N 6 pairs/cm2s J-s eV A A A/cm2 A/cm2 J/K eV cm or m cm kg kg kg cm-3 cm-3 cm-3 cm-3 cm-3 cm-3 cm-3 cm-3 cm-3 Pa B쵆1 Materials Magic: Semiconductors Introduction P R R Ri (n0,p0,T) ri (T) t T vn vs vth V Vbi VEB VB W WB Y 0 s ox s / 0 or 0 n p d s i Bn Bp e m c Power Resistance Reflection Coefficient Recombination Rate Recombination Rate Time Absolute Temperature Carrier Velocity Saturation Velocity Thermal Velocity Voltage Built in Potential Emitter - Base Voltage Breakdown Voltage Thickness Base Thickness Young’s Modulus Absorbtion Coefficient Linear Coefficient of Expansion Permittivity in Vacuum Semiconductor Permittivity Oxide Permittivity ox/ 0 Dielectric Constant Lifetime or decay time Angle Wavelength Frequency of Light Permeability in Vacuum Electron Mobility Hole Mobility Resistivity Specific Density Space Charge Density Stress Coefficients Schottky Barrier Height, semiconductor Schottky Barrier Height, semiconductor Metal Work Function Angular Frequency (2 f or 2 ) = eB/m = cyclotron frequency Ohm Extinction Coefficient 7 W cm-2 s-1 cm-2 s-1 s K cm/s cm/s cm/s V V V V cm or m cm or m cm-1 1/ C F/cm F/cm F/cm s rad m, nm, Å Hz H/cm cm2/V - s cm2/V - s - cm atoms/cm-3 cm-3 n-type V p-type V eV Hz Hz B쵆1 Materials Magic: Semiconductors Introduction Semiconductors: A Brief History of the Industry Today it is possible to manufacture semiconductors with a purity and perfection that was unheard of until a few years ago. However, the importance of semiconductors is not just based on perfection of the semiconductor crystals we can grow but, in large measure, on advances in the design of electronic and optical devices, as well as the tremendous advances that have been made in the area of semiconductor manufacturing technology. Thus, the history of semiconductors is not just the history of semiconductor materials manufacture, but also the history of the great strides made in the invention of new electronic and optical devices and integrated circuits. It is the interplay between semiconductor materials technology and the fantastic inventiveness of electronic and optical systems designers that has made possible the microelectronic revolution that has taken place during the last 50 years. For those who are interested in economics, it should also be mentioned, of course, that not only technology push but also market pull has been decisive in expansion of the semiconductor industry as we have already mentioned before. Today the semiconductor industry is the largest in the world, in terms of economy! From the very beginnings of the electronics and radio era in the early 1900's it was realized that to make complex electronic systems it would be necessary to find ways of interconnecting thousands or even millions of electronic devices in reliable and inexpensive circuits. Although the use of electron tubes was dominant all the way up through the 1950's, the vision was to somehow make a system of integrated electronic circuits that could be employed to make reliable electronic systems cheaply. This took more than 75 years to achieve and the solution was very much different than what scientists and engineers first envisioned. The era of semiconductors started in a modest way even before the turn of the 19th century with the discovery that a point contact to selenium exhibited rectifying properties and that the material was photosensitive. By the mid 1930's point contact selenium rectifiers and photodetectors, silicon carbide varistors, and lead sulfide (naturally occurring Galena) point contact diodes for radios were on the market [2]. During the second world war radio detection and ranging (RADAR) was developed to a high level and began to be used in a variety of distance and object identification applications. As a consequence, there arose a need for sensitive mixer and detector diodes for radar detection circuitry. Since silicon and germanium were the best materials for these applications, a great effort was established for the production of high purity silicon and germanium. This effort has continued to this day. Semiconductors Germanium, Silicon and III-V Compounds The element germanium was discovered by Winkler in 1886 in the mineral argyrodite. For half a century after it remained very much a scientific curiosity, although it's properties were studied extensively. In 1935 studies were begun at the Eagle Picher plant in the United States, on recovery of the element from zinc smelting operations. In 1941 a pilot plant production of 8 B쵆1 Materials Magic: Semiconductors Introduction 99.9% germanium oxide was achieved. At that time there was no commercial application for this material, but in 1942 the National Defense Research Council initiated a search for materials that could be used for microwave detectors in radar. Germanium and silicon were found to be well suited. Germanium occurs as a minor constituent of a number of ores. Argyrodite (4AgS-GeS2) occurs in Germany and contains about 6-7% of the metal. Germanite (7CuS-FeS-GeS2) containing 5-10% Ge and renierite (a complex of Cu, Fe, Ge and As) are both found in Africa in zinc ores . None of these minerals has been found in sufficient quantity to be of significance commercially. Most of the supply of germanium is obtained as a bi-product from other smelting operations. In contrast to germanium, silicon is one of the most abundant elements, second only to oxygen. Silica has been recognized from the earliest times and glass manufacture has been depicted in Egyptian frescoes from approximately 2000 B.C. However, the quartz form of silica was long believed to be the element and it was not until comparatively modern times that the element silicon was discovered. As is well known, early interest in silicon was generated by the use of silicon as an alloying element in the steel industry. Originally the element was prepared as ferrosilicon by heating a mixture of silica, carbon and ferric oxide in a blast furnace. Later electric arc furnaces were used in the refining of silicon and purities up to 99.8% were obtained. The III-V compounds are stoichiometric compounds prepared from elements of group IIIA in combination with elements of group VA. Although most of the combinations have been examined, only the gallium and indium compounds with arsenic, antimony and phosphor are of commercial significance. The III-V compounds are always grown as single crystals so that their preparation will be discussed later in the text. Highly purified elements must be used in the growth of crystals, of course. The Invention of the Transfer Resistor = Transistor! Moving over to the work on electronic devices, in December of 1947 a fantastic discovery was made. The first point contact bipolar transistor was made by a group of scientists at Bell Laboratories in the United States. The inventors were John Bardeen and Walter Brattain [3]. The first point contact transistor was made using polycrystalline germanium. Shortly after the transistor effect was demonstrated using silicon and by 1949 single crystal material was used instead of polycrystalline. This conversion from polycrystalline to single crystal material was primarily the work of Gordan Teal and Morgan Sparks, also from Bell Laboratories. They were also responsible for the fabrication of the first junction transistor, which W. Shockley invented [4,5]. The conversion from polycrystalline to single crystal source material has been one of the most significant advances in semiconductor materials technology, because without a source of large single crystals with uniform properties, the commercial production of small devices would had been difficult and the development of complex large area integrated circuits impossible. 9 B쵆1 Materials Magic: Semiconductors Introduction In spite of the fact that point contact transistors were relatively expensive and unreliable, they were in most respects superior to vacuum tubes. Because of the advantages they were put into production in 1951 as replacements for vacuum tubes in telephone exchanges. After that, the technological advances came rapidly and were followed by a gigantic expansion of the market. First came the grown junction transistor, then the germanium alloyed transistor. Silicon alloyed transistors were difficult to manufacture and never became a commercial success. The next important development in materials technology was the use of gaseous diffusion, again developed at Bell Laboratories [6]. This technique gave rise to the diffused, "mesa", transistors. These were commercially available using germanium substrates in 1957 and silicon substrates in 1958 [7, 8]. The mesa transistor represented a considerable improvement over the grown junction or the alloy junction transistor because higher operational frequencies and less expensive devices could be made due to the much narrower and more reproducible base widths that could be produced using diffusion. Since many transistors could be made at one time on each slice of semiconductor material and many slices could be cut from a crystal, mesa transistors were less expensive to manufacture. In spite of the fact that the development of these three types of transistor represented a great advancement in manufacturing, they all had the same serious flaw. The p-n junctions were exposed at the semiconductor surface. Many types of coatings were developed in order to reduce the electrical leakage at these surfaces, but none were completely successful. The Planar Process Fortunately, a solution to this serious problem was found in 1959 by Jean Hoerni at Fairchild Semiconductor Corporation [9, 10]. This was called the planar process and it solved this problem very effectively by terminating the p-n junctions under a thermally grown silicon dioxide layer on the surface of the silicon slice. There is no other semiconductor that has an oxide that can be grown in situ and that possess the near ideal electrical characteristics of silicon dioxide. The introduction of the planar process, which increased reliability and improved yields, along with the inherently better high temperature performance of silicon, marked the beginning of the decline of germanium devices. Thus, the four year period between 1957 and 1961 included first the introduction of large scale production with introduction of the mesa process and then the beginning of the conversion from germanium to silicon because of the advent of planar processing. Invention of the Integrated Circuit Until the invention of the integrated circuit, complete circuits, whether they used transistors or vacuum tubes, were made by individually connecting the various components, i.e. tubes or transistors, diodes, capacitors, resistors and inductors, together. Although, many improvements were introduced to increase packing density, simplify fabrication and increase reliability of the electronic circuits, they all continued to depend on the wiring together of discrete and separately packaged devices. During February of 1959 came the great breakthrough. Jack Kilby of Texas Instruments Corporation filed a patent application describing a concept that 10 B쵆1 Materials Magic: Semiconductors Introduction allowed, using relatively simple steps, the fabrication of all the necessary components of the desired circuit, both active and passive components, in a single piece of semiconductor and their interconnection in situ [11]. Because of the manner in which the integrated circuit (IC) construction was described in the Kilby patent, a separate patent on an IC using the planar process was awarded to Robert Noyce of Fairchild Semiconductor [12]. That award was the subject of a heated legal battle, but in the end both inventors were awarded a patent, each for a different aspect of the integrated circuit. Kilby was credited for conceiving and constructing the first working monolithic circuit in 1959 and Noyce for his sophistication of the monolithic circuit for more specialized use, particularly in industry. The Metal Oxide Semiconductor Transistor (MOST) In 1960 D. Kahng and M.M. Atalla presented a paper on the silicon insulated gate field effect transistor at the IRE-AIEE Solid State Device Conference in Pittsburg, Pennsylvania, U.S.A [13]. Three years later S.R. Hofstein and F.P. Heiman published a paper describing the fabrication of integrated circuits IC based on this device. Today, these devices are called Metal Oxide Semiconductor Transistors (MOST). The MOST is actually the same device described in O. Heil's British patent entitled, "Improvement in or Relating to Electrical Amplifiers and Other Control Arrangements and Devices", of 1939 [14]. It is interesting to note that the device that Bardeen, Brattain and Shockley were trying to make at Bell Laboratories when they almost by chance invented the bipolar transistor was the MOST [15]! The MOST is by far the most important semiconductor device since the vast majority of all integrated circuits manufactured today are based on this device. Semiconductor materials and processing technology In addition to the semiconductor devices mentioned above, which are only a small number of those actually invented, there have been great advances in semiconductor materials and processing technology. Around 1958 the primary wafer fabrication steps in the mesa process were 1) diffusion, 2) metallization, 3) silicon etching and 4) various cleaning procedures. It should be mentioned also that the first integrated circuits were made employing these steps. In the planar process invented in 1960 three more steps were introduced: 4) thermal oxidation of silicon, 5) lithographic printing of patterns in a photoresist layer on top of the surface of the wafer and 6) the etching of such patterns in the oxide and the contact metal. Since 1960 there have been only a few steps added that allow new types of structures or circuits to be fabricated. Probably the most important were the following: 7) the use of epitaxial layers in bipolar circuits to provide an easy method of device isolation. Epitaxial layers are also deposited over previously diffused areas of the circuit to reduce collector saturation resistance and switching time, thus resulting in higher speed circuitry, 8) the use of epitaxial overgrowth of silicon onto insulating substrates, such as sapphire, for the fabrication of thin film transistors, 9) the use of chemical vapour deposition (CVD) to deposit materials such as silicon nitride for protective films and as diffusion masking material and 10) the use of ion implantation for MOST threshold adjusting and as an alternate technique for diffusion. In addition to improving processing technology, great imagination has been used in increasing the achievable complexity of IC circuitry and in reducing 11 B쵆1 Materials Magic: Semiconductors Introduction the cost of each circuit element. However, these advances have been made possible through the use of more sophisticated equipment and through processes such as the use of plasma etching instead of wet etching and optical steppers and the use of electron beam writers or X-ray printing instead of contact printers. Fig. 3 illustrates how advances in microlithographic techniques has made possible the reduction of the size of semiconductor devices [16]. However, it must be admitted that the reduction in device size has required increasing complexity and cost of patterning equipment. Not surprisingly this trend is also typical for all the other fabrication processes as well. Fig. 3 The minimum line width that different lithographic exposure systems can be used to make versus the years they were in use. Notice that the minimum line width decreases during the system's lifetime [16]. In addition, to the advances in processing equipment the other areas of the industry have changed also. The increase in circuit complexity can be seen by comparing the first commercially available IC which consisted of a single flip-flop with two transistors, four diodes, four capacitors and six resistors with a MOST memory of today, such as the 1 megabit DRAM chip shown in fig. 4. This memory chip has an area of approximately 70 mm2 and contains over 2,200,000 components [17]. 12 B쵆1 Materials Magic: Semiconductors Introduction Fig. 4 a) A photograph of a 100 mm diameter silicon wafer on which 1 megabit DRAM have been fabricated. b) we see the DRAM itself mounted in a special ceramic package [17]. In the IC of the 1960 chip area was approximately 1 mm2; today chip area can be larger than 200 mm2. However, it should be mentioned that while chip size has increase tremendously, it has not increased commensurately with circuit complexity, i.e. while the area has increased 100 times circuit complexity has increased by more than 10 million times. In addition to all this, the slice diameter of silicon crystals has steadily increased from 25 mm to 200 mm due to advances in crystal growing techniques. Going back to device and circuit design again, it is clear that these have become much more sophisticated and much smaller. Two or three layers of interconnections between circuit components are common today, but the number of active devices required to perform a given function has decreased. For example, some of the early DRAM cells required six transistors, whereas today one transistor and one capacitor suffice. Also in the area of processing much more attention is necessary to make sure that designs are more tolerant of expected process variations. At the same time, process control has been continually tightened through better 13 B쵆1 Materials Magic: Semiconductors Introduction understanding of the processes and the introduction of microprocessor control of most of the equipment. With the recognition that most yield loss is associated with particulates on the wafer, extensive effort has been expended to provide better cleaning procedures, purer chemicals and a cleaner manufacturing environment. Moore's Law One way of showing the total effect of all of these improvements is to show the increase in the number of circuit elements in IC versus year from 1960 up until today as shown in fig. 5. Note that the increase in complexity of IC has increased exponentially, at first doubling every year and more recently roughly every 18 months. This curve is called Moore's Law, after Gordan Moore whom first noticed this relationship between chip complexity and the year that the IC was first introduced [18]. Moore was also one of the founders of Fairchild Semiconductor and Intel Corporations. To dramatize the effect of the original inventions and the subsequent improvements on our daily lives we can mentally eliminating all of the things around us that depend on transistors of one type or another for their successful operation. It is easy to see that our world would be very different indeed. Fig. 5 Device density and minimum feature size in a IC versus year. Until about 1975 the device density per chip doubled every year. Since then it has doubled every 18 months, approximately [18]. Photonics and the Semiconductor LASER Paralleling the developments in semiconductor electronics we have the field of Photonics. Here semiconductor materials technology also plays an important role. Lasing action in semiconductors was reported by several research groups in 1962 [19, 20, 21, 22]. The device used was a simple forward biased gallium arsenide (GaAs) p-n junction. Electron hole recombination in the depletion region of the p-n junction provided the optical gain and the polished facets perpendicular to the plane of the junction provided the optical feedback by forming a resonant cavity. Quite soon thereafter, lasing action was reported in other direct band gap semiconductor materials, among others: InP, InAs, InAsP, GaAsP, and GaInAs. However, the utility of these early devices was 14 B쵆1 Materials Magic: Semiconductors Introduction limited because, the large value of the threshold current density (Jth ≥ 50 kA/cm2 ) made continuous operation at room temperature impossible. The following year it was suggested that lasers might be improved if a layer of one type of semiconductor were sandwiched between two cladding layers of another semiconductor having a larger bandgap [23]. This configuration is commonly referred to as a heterostructure laser, in contrast to the homostructure lasers made of only one type of semiconductor material, mentioned above. In spite of the reduction in threshold current brought about by the use of heterostructure lasers, it wasn't until 1969 that a heterostructure laser that could be operated at room temperature was demonstrated [24]. For these devices the liquid phase epitaxial technique was employed for growing the GaAs and AlxGa 1-x As layers. Additional work resulted in heterostructure lasers operating contiuously at room temperature in 1970 [25]. By 1975 AlGaAs lasers having threshold currents as low as Jth 0.5 kA/cm2 were demonstrated using thin active layers approximately 0.1 m thick, i.e. about 100 nm thick! This represented a reduction of threshold current by more than two orders of magnitude over the simple homostructure lasers first fabricated in 1962. With these advances the semiconductor laser was changed from being a laboratory curiosity to a practical compact coherent light source useful for numerous applications. The room temperature operation of a InGaAsP laser operating in the pulsed mode at a wavelength of 1.1 m was also reported in1975. By changing the geometry of the laser to a very narrow stripe geometry continuous operation was achieved in 1976 [26] . In 1977 the wavelength was extended to 1.3 m. Since low loss dispersion free optical fibers were already available considerable effort was made to develop a practical InGaAsP laser for this wavelength. Around the same time, ultra low loss optical fibers having losses in the range of approximately 0.2 dB/km at the 1.55 m wavelength were being developed. As a consequence several groups changed the focus of their work and started to develop InGaAsP lasers operating at this wavelength. Since then the effort for developing InGaAsP lasers operating in the wavelength range of 1.3 to 1.6 m has proceeded very rapidly. The primary motivation for this is due to their application in fiber optical communications. Today the use of InGaAsP lasers in long haul optical communication systems is standard and has been so for several years. Another important area of photonics in which advances in semiconductor materials technology and device design has bought about impressive industrial growth, as well as, important advances in our understanding of the basic physics is that of photovoltaic devices or solar cells as they are often called. Photovoltaic Diodes Solar cells are employed in both space and terrestrial applications for the reliable generation of electricity. This device is unique in that it can convert sunlight directly into electricity with good efficiency. It has no moving parts, it can operate at room temperature and is virtually non-polluting. Some of the very earliest solar cell systems are still operational after 40 years of service. The solar cell is quite a simple device; actually it is just a large area diode. It 15 B쵆1 Materials Magic: Semiconductors Introduction was first described in a scientific paper by D.M. Chapin, C.S. Fuller and G.L. Pearson in 1954 [27]. The first devices had a conversion efficiency of 4%. Today, the most advanced structures are nearly 30% efficient, an efficiency that earlier was thought to be theoretically impossible! 16 B쵆1 Materials Magic: Semiconductors Introduction References Cited 1. J.D. Plummer, M.D. Deal and P.B. Griffin, "Silicon VLSI Technology, Prentice Hall, New Jersey (2000) Chapter 2 2. G. K. Teal, "Semiconductor Materials", Chapter 6 in "Material Processes", J.F. Yuong and R. Shane editors, Marcel Dekker, New York (1985) 3. J. Bardeen and W.H. Brattain, "The Transistor a Semiconductor Triode", Phys. Rev. 74, 230 (1948) 4. W. Shockley, M. Sparks and G.K. Teal, "p-n Junction Transistors", Phys. Rev. 83 pp 151 - 162 (1951) 5. W. Shockley, "The Theory of p-n Junctions in Semiconductors and the Junction Transistor", Bell Sys. Tech. J. 28, 435 (1949) 6. G.L. Pearson and C.S. Fuller, "Silicon p-n Junction Power Rectifiers and Lightning Protectors", Proc. IRE 42 760 (1954) 7. M. Tannenbaum and D.E. Thomas, "Diffused Emitter and Base Silicon Transistors", Bell Sys. Tech. J. 35 pp 1-22 (1956) 8. C.A. Lee, A High Frequency Diffused Base Germanium Transistor", Bell Sys. Tech. J. 35 pp 22 - 24 (1956) 9. J.A. Hoerni, "Method of Manufacturing Semiconductor Devices", U.S. Patent 3,025,589 March 20 1962 (filed May 1, 1959) 10. J.A. Hoerni, "Planar SiliconTransistors and Diodes", IRE Electron Devices Meeting, Washington D.C. Oct. 1960 11. J.S. Kilby, "Miniaturized Electronic Circuits", U.S. Patent 3,138,743 June 23, 1964 (filed Feb. 6 1959) 12. R.N. Noyce, "Semiconductor Device and Lead Structure", U.S. Patent 2,918,877, April 1961 (filed July 30, 1959) 13. D. Kahng and M.M. Atalla, "Silicon - Silicon Dioxide Field Induced Surface Devices", IRE - AIEE Solid State Device Conference, Pittsburg, Penn. 1960 14. O. Heil, "Improvement in or Relating to Electrical Amplifiers and Other Control Devices", British Patent 439,357 Sept. 26, !939 15. W. Shockley, "The Path to the conception of the Junction Transistor", IEEE Trans. Electron. Dev. ED 23 (1982) 16. S.M. Sze, "VLSI Technology Overview and Trends", Jap. J. Appl. Phys. 22, Suppl. 22 - 1, p3 (1983) 17 B쵆1 Materials Magic: Semiconductors Introduction 17. H.C. Kirsch, "A One Megabit DRAM", Digest IEEE International Solid State Circuit Conference, p256 (1985) 18. G.E. Moore, "Cramming More Components onto Integrated Circuits", Electronics 38114 - 117 (1965) 19. R.N. Hall, G.E. Fenner, J.D. Kingsley, T.J. Soltys,and R.O. Carlson, Phys. Rev. Lett. 9, 366 (1962) 20. M.I. Nathan, W.P. Dumke, G.Burns, F.H. Dill Jr. and G. Lasher,Appl. Phys. Lett. 1 62 (1962) 21. T.M. Quist, R.H. Rediker, R.J. Keyes, W.E. Krag, B. Lax, A.L. McWhorter and H.J. Zeiger, Appl. Phys. Lett. 1, 91 (1962) 22. N. Holonyak Jr. and S.F. Bevacqua, Appl. Phys. Lett 1, 82 (1962) 23. H. Kroemer, Proc. IEEE 51, 17882 (1963) 24. H. Kressel and H. Nelson, RCA Review 30 106 (1969) 25. I. Hayashi, M.B. Panish and P.W. Foy, IEEE J. Quantum Electron. QE 5 211 (1969) 26. J.J. Hsieh, J.A. Rossi and J.P. Donnelly, Appl. Phys. Lett. 28, 709 (1976) 27. D.M. Chapin, C.S. Fuller and G.L. Pearson, "A New Junction Photocell for Converting Solar Radiation into Power", J. Appl. Phys. 25 pp 676 - 677 (1954) 18