abc - AUT Scholarly Commons

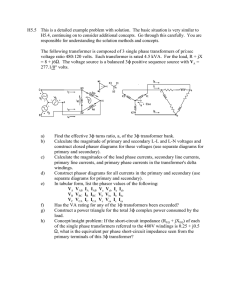

advertisement