lighting upgrades for oak ridge public library

advertisement

project manual

lighting upgrades for oak

ridge public library

rca 14-010

contract # FY2015-177

construction documents | 2014 october 21

220 w. jackson ave. knoxville, tn v | 865.633.8058 f | 865.633.9059 w| redchairarchitects.com

oak ridge, tn

rca 14-010

lighting upgrades for oak ridge public library

10/21/14

SECTION 00 00 02 – PROJECT DIRECTORY

Owner:

City Of Oak Ridge

Municipal Building

200 South Tulane Avenue

Oak Ridge, TN 37830

Contact : Pat Fallon - V | 865.425.1847

Architectural:

Red Chair Architects

220 W. Jackson Avenue

Knoxville, TN 37902

V | 865.633.9058 F | 865.633.9058

Electrical:

I.C. Thomasson Associates

1114 Clinch Ave.

Knoxville, TN 37916

V | 865.525.3488.

END OF SECTION 00 00 02

PROJECT DIRECTORY

00 00 02 - 1

rca 14-010

lighting upgrades for oak ridge public library

10/21/14

SECTION 00 01 10 – TABLE OF CONTENTS

DIVISION 00

PROCUREMENT AND CONTRACTING REQUIREMENTS

Pages

00 00 01

00 00 02

00 01 10

00 01 15

00 30 00

00 30 00.1

00 30 00.2

Project Title Sheet .......................................................................................................................................... 01

Project Directory ............................................................................................................................................. 01

Table of Contents ........................................................................................................................................... 01

List of Drawings .............................................................................................................................................. 01

Available Information ...................................................................................................................................... 01

SESCO Lighting's Oak Ridge Library Lighting Submittal ................................................................................ 57

Prudential Lighting's Fixture D4, D6, SS, and F Installation Instructions ........................................................ 05

DIVISION 01

GENERAL REQUIREMENTS

01 11 00

01 29 00

01 29 73

01 33 00

01 40 00

01 50 00

01 73 00

01 73 29

01 74 00

01 74 19

01 77 70

01 78 23

01 78 39

01 79 21

Summary ........................................................................................................................................................ 03

Payment Procedures ...................................................................................................................................... 04

Schedule of Values ......................................................................................................................................... 02

Submittal Procedures ..................................................................................................................................... 10

Regulatory Requirements ............................................................................................................................... 01

Temporary Facilities and Controls .................................................................................................................. 06

Execution ........................................................................................................................................................ 05

Cutting and Patching ...................................................................................................................................... 03

Cleaning.......................................................................................................................................................... 03

Construction Waste Management and Disposal ............................................................................................. 03

Closeout Procedures ...................................................................................................................................... 05

Operation and Maintenance Data ................................................................................................................... 04

Project Record Documents ............................................................................................................................. 03

Demonstration and Training............................................................................................................................ 02

DIVISION 02

EXISTING CONDITIONS

02 41 19

Selective Structure Demolition ........................................................................................................................ 05

DIVISION 09

FINISHES

09 51 00

Acoustic Ceiling Tile ....................................................................................................................................... 05

DIVISION 26

ELECTRICAL

26 01 00

26 05 19

26 05 26

26 05 29

26 05 34

26 51 00

General Provisions For Electrical Systems ..................................................................................................... 05

Conductors - 600 Volt And Below ................................................................................................................... 02

Grounding And Bonding For Electrical Systems ............................................................................................. 01

Supporting Devices And Hangers ................................................................................................................... 02

Raceways And Conduit Systems .................................................................................................................... 04

Interior Lighting And Lamps ............................................................................................................................ 02

Pages

Pages

Pages

Pages

END OF SECTION 00 01 10

TABLE OF CONTENTS

00 01 10 - 1

rca 14-010

lighting upgrades for oak ridge public library

10/21/14

SECTION 00 01 15 – LIST OF DRAWINGS

GENERAL

G0.01

INDEX OF DRAWINGS, INFORMATION, SYMBOLS, LOCATION MAP, ABBREVIATIONS & KEY PLAN

ARCHITECTURAL DRAWINGS

AD1.10

MAIN AND UPPER LEVEL REFLECTED CEILING DEMOLITION PLANS, LEGEND AND NOTES

A1.10

MAIN AND UPPER LEVEL REFLECTED CEILING PLANS, LEGEND AND NOTES

A1.11

ENLARGED MAIN LEVEL REFLECTED CEILING PLAN, LEGEND AND DETAILS

ELECTRICAL DRAWINGS

E0.01

LEGEND, NOTES, DETAILS, AND SCHEDULES

E1.10

MAIN AND UPPER LEVELS LIGHTING PLAN

END OF SECTION 00 01 15

LIST OF DRAWINGS

00 01 15 - 1

rca 14-010

lighting upgrades for oak ridge public library

10/21/14

SECTION 00 30 00 – AVAILABLE INFORMATION

PART 1 - GENERAL

1.1

INFORMATION AVAILABLE TO BIDDERS

A.

The following submittals pertaining to this Project follow Specification Section 00 30 00.

1.

Section 00 30 00.1 – SESCO Lighting's Oak Ridge Library Lighting Submittal (57 pages) dated October 16,

2014.

2.

Section 00 30 00.2 – Prudential Lighting's Fixture D4, D6, SS and F Installation Instructions received from

SESCO Lighting (5 pages), no date.

B.

Cutsheets and selected manufacturer's installation instructions listed above are available to bidders. This

information was compiled for design purposes and is not part of the Contract Documents.

C.

The use and interpretation of the information listed above is entirely the responsibility of the using party.

PART 2 - PRODUCTS (Not Used)

PART 3 - EXECUTION (Not Used)

END OF SECTION 00 30 00

SUMMARY

01 11 00 - 1

SESCOSE Lighting We take the i ll out of i ll umination.™

702 Lindsay Pl.

Knoxville, TN 37919

865-633-9288 (Ph)

865-633-9278 (FX)

Knoxville

www.sescolighting.com

John Palk, General Manager

}}}}}}

DATE: 10/16/14

Prepared for: CITY OF OAK RIDGE

Prepared by:

SANDY BOBST

Contractor:

Contact Name:

DIANNA OSICKEY

Architect:

RED CHAIR ARCHITECTS

Phone Number:

Engineer:

IC THOMASSON

Number of Pages: 57

Project Name/Number: 0",3*%(&-*#3"3:

L ighting for a greener

tom orrow .™

LIGHTING

SUBMITTAL

3URMHFW2$.5,'*(/,%5$5<

&RQWHQWV2FWREHU

7\SH

$

&1

&1::

&5

&6

)DFWRU\

/'/7

,171

,171

,171

3%+

'

358'

'

(

*

:

66

75

;

;

358'

:,//

,167

),1(

358'

6,67

%(*+

%(*+

:$77

:$77

:$77

'HVFULSWLRQ

'67/%$6"""(

66*""",&+=6)

66*""",&+=6)

665*"""9,&+=6)

6721(/,*+7,1*&/)53&'2%

3/('/2):$70:6&819;1'02

'

3/('62&:$70:6&819;'0

/3+:*/('819

3/.+05(00::/

6/('9&)3)+2N"""

5/('+2

6$/<*:819685;1'

"""9

2//*"&&5

3&+*6$

/05&

/06::

/0&7

F

PRUD

STR-LED35-SO-20'-TMW-D1-SC-UNV-ND

6HVFR.QR[YLOOH

/LQGVD\3ODFH.QR[YLOOH71

S

6XEPLWWLQJ$JHQF\

'HVFULSWLRQ

3URMHFW

1RWHV

7\SH

'67/%$6"""(

$

2$.5,'*(/,%5$5<

)%&#%!

.#

!(*$) '!%#! *+!-!* )*''

%*(!+)(

(!";<

'%!)

&,&

)"%% GGG#

),

$%)(

'' $* '%*),&

'( %$

%$ *') %$

)/<=+9<7B

)%*'

&'

&>+8.+<.'<3.

&69>'<3.

3<%/>?<898

&>+8.+<.'<3.

3<%/>?<898

&69>'<3.

&' &>+8.+698/

*#$(

%

%

%

%

67

67

67

%*( $

&

&>+8.+<.1+

23-+19$6/8?7

' $

%")

-->

-->A$

-->A377381 )

)

)

' +'

&>+8.+<.

377381

%><8=0;E0;D4BF78C78=0A0=64

>=BD;C84B58;45>A4G02C2>;>AC4<?0=3;D<4=B>=BD;CF41B8C45>A2><?;4C4;8BC>5BC0=30A3F8A8=6>?C8>=B

&'(((%' ( ';40B48=3820C4F8C72742:<0A:

AHF0;;"8C*A8<

$>D=C

AHF0;;"8C*A8<;4BB

$>D=C

;4G-78?

E

983856345/$2363:=")%9C+6$2363:=66<312>=</=/<@/.

&:/-303-+>398=+</=?,4/->>9-2+81/A3>29?>89>3-/

AAA:2363:=-976?738+3</=

BBB :.0 :+1/ 90 $)')%$)'%"( ';40B48=3820C4F8C72742:<0A:

(4B?>=B40H;867C

)4=B>A)8=6;4/>=4

)

'78;8?B2C8;D<4

&22D?0=2H)4=B>A

&8=2;D34B584;3

2><<8BB8>=01;4

30H;867CB4=B>A

6XEPLWWLQJ$JHQF\

'HVFULSWLRQ

3URMHFW

1RWHV

7\SH

'67/%$6"""(

$

2$.5,'*(/,%5$5<

)%&#%!

.#

!(*$) '!%#! *+!-!* )*''%*(

!+)(

%)%#)',

8GCDA4?7>C><4CAH70B144=

2>=3D2C431H0=%,#'022A438C43

C4BC8=6;01>A0C>AH8=022>A30=24F8C7

!)%#$

'9>+6#?>:?>

67

003-+-C

67*

'

%

%

3=><3,?>398

(:

9A8

&:+-381<3>/<3+

F

0=34;08BCA81DC8>=

,4AC820;

=6;4

>A8I>=C0;=6;4

#D<4=<08=C4=0=24>5C74#B70B

144=C4BC431HC74<0=D502CDA4A8=

022>A30=24F8C7!)%#$

>4558284=CB>5+C8;8I0C8>=

/>=0;

#D<4=B

((

,4AC820;

=6;4

8:?>)96>+1/

)

)

8:?>$9A/<

*

*

8:?>?<</8>

$9A/<+->9<

'9>+6+<73=>9<>398

'/=>/.@+6?/=G-98>+->>/-283-+6=?::9<>09<<+>/.@+6?/=

#00=>+>/:9A/<D/<9?86/==-/<>+38-98><96=+</=:/-303/.

BBB :.0 :+1/ 90 48;8=6

-0;;

E6

#D<8=0=2423<

")' "& ) %$(

E

983856345/$2363:=")%9C+6$2363:=66<312>=</=/<@/.

&:/-303-+>398=+</=?,4/->>9-2+81/A3>29?>89>3-/

AAA:2363:=-976?738+3</=

!)58;4B5>AC78B0=3>C74A

?7>C><4CA82>?C8>=B20=14

3>F=;>0343>=;8=40C

FFF

;867C8=6?A>3D2CB

?78;8?B

2><

>A8I>=C0;=6;4

6XEPLWWLQJ$JHQF\

'HVFULSWLRQ

3URMHFW

1RWHV

7\SH

'67/%$6"""(

$

2$.5,'*(/,%5$5<

)%&#%!

.#

!(*$) '!%#! *+!-!* )*''%*(

!+)(

&) %$($) "(

%*$) $

%*( $

%*$) $

845>A<43?>BC?08=C4360D642>;3A>;;43

BC44;

-8A44=CA0=24F8C70338C8>=0;:=>2:>DC

0E08;01;4>=C>?B8345>A4;42CA820;2>==42C8>=B

(424BB43 8GCDA4B20=1450BC4=4338A42C;HC>C74

*10A6A830=3>AC843>55C>C741D8;38=6BCAD2CDA4

)DA5024 8GCDA4B20=14<>D=C43>E4AA424BB43

9D=2C8>=1>G0=3B8344=CAH0;B>0E08;01;4

)

")' "

$0G8<D<G;1G;1G;1

02C>AH?A4F8A43F8C73A8E4AB054CH38B2>==42C

&) ",()#

*74>?C820;5A0<40BB4<1;H2>=B8BCB>58=C46A0C43

#0AA0HB4364;867C8=60;867C6D834?0=4;8=>A34A

C>34;8E4AD=85>A<2>=CA>;;43;867CC7A>D670;>F4A

;4=B

*74>?C820;5A0<44=3B0A42>=BCAD2C435A><

3845>A<432>;3A>;;43BC44;0BB4<1;43C>64C74A

F8C74GCAD3430;D<8=D<?A>58;4B8=0BCDA3H5A0<4

*745A0<48B78=643B834<0A:43C>0;;>F40BH

0224BBC>C748=B834>5C7458GCDA4

$08=C4=0=2420=

14?4A5>A<435A><14;>FC74248;8=6

)$'' +'

,8<<8=6L

&DC?DC8B2;0BBA0C43

2>=C02C502C>AH5>A>C74A>?C8>=B

*#$ $)$$

C0=0<184=CC4<?4A0CDA4>5JC74#

;D<4=<08=C4=0=244G?42C0C8>=8B# :

:7

(4?>AC43022>A38=6C>!)*$334=3D<

<4C7>3>;>6H:#$C4BC3DA0C8>=

' $

(424BB43 &?C8>=0;5;4GF78?B0A4BD??;8438=M

;4=6C7B

)DA5024 )C0=30A3F8A8=62>=586DA0C8>=B0E08;01;4

&&'%+"(

4AC85843C>+#)#!))C0=30A3B

8CH

>578206>??A>E437>DB8=6>?C8>=

$ (

>DB8=60=3A0<4?08=C437867@D0;8CH?>F34A

2>0C43<0CC4F78C4>=;H

$+ '%$#$)

(0C435>A3AH30<?;>20C8>=B8=>?4A0C8=68=

0<184=CC4<?4A0CDA4B>5K

D4C>2>=C8=D8=6?A>3D2C8<?A>E4<4=CB'78;8?B#430;8C4A4B4AE4BC74A867CC>270=64C74B?4285820C8>=BF8C7>DC

=>C824

E

983856345/$2363:=")66<312>=</=/<@/.

&:/-303-+>398=+</=?,4/->>9-2+81/A3>29?>89>3-/

AAA:2363:=-976?738+3</=

BBB :.0 :+1/ 90 $2363:= 312>381

"9<>27/<3-+9<:9<+>398

<+85638&;?+</<3@/

&97/<=/>"

$298/

$2363:= 312>38197:+8C

36679?8>%9+.

!+<52+7#"+8+.+ &

$298/

6XEPLWWLQJ$JHQF\

'HVFULSWLRQ

3URMHFW

1RWHV

7\SH

66*""",&+=6)

&1

2$.5,'*(/,%5$5<

JOB NAME

SS6G2 / IC630

CATALOG NUMBER

6” Architectural LED Round Generation 2 / Open Reflector

NOTES

TYPE

7 1⁄2”

12 3⁄4”

1 5⁄16”

7”

DECORATIVE

13 1⁄2”

Cut-out: 6 1⁄2”

Order Matrix | Example: SS6G22000308-27-EM

A

B

C

A Series

SS6G2

B

1100

1500

2000

3000

C

278

308

358

408

D

D

6” LED Recessed Round

blank

-D10V1

-D10V

-ED10V1

-ED10V01

-LUT1

-LUT

-LUT5

-EDALI1

-EDALI01

Module Lumen Output

1100 Lumen

1500 Lumen

2000 Lumen

3000 Lumen

Color Temperature / CRI

2700K / 80 CRI

3000K / 80 CRI

3500K / 80 CRI

4000K / 80 CRI

E

E

Dimming

Non-Dimming

0-10V Dimming 1%

0-10V Dimming 10%

eldoLED 0-10V 1% 1

eldoLED 0-10V 0.1% 1

Lutron Hi-Lume 1%

Lutron EcoSystem 1%

Lutron EcoSystem 5%

eldoLED DALI 1% 1

eldoLED DALI 0.1% 1

Voltage

blank 120V

27 277V

E

-EM

-I100

-I200

-I400

Options

Emergency Backup

C-Channel Bar Hanger

Flat Bar Hanger

Wood Joist Bar Hanger

Notes:

1. eldoLED dimming not available for 3000lm module

A Series

IC630 6” Open Reflector

B

System Wattage *

Delivered Lumens **

SS6G21100358 / IC630C

SS6G21500358 / IC630C

SS6G22000358 / IC630C

SS6G23000358 / IC630C

15.89W

18.75W

24.58W

37.25W

1085lm @ 3500K

1462lm @ 3500K

1770lm @ 3500K

2618lm @ 3500K

* System wattage include driver and LED module consumption.

** Delivered lumen output will vary depending on CCT.

LED MODULE

- Powered by OSRAM PrevaLED® Cube LED Module

- 50,000 hours at 70% lumen maintenance

- No heat, mercury or UV

- Available in 1100, 1500, 2000 and 3000 lm

- CRI = 80 & CCT 2700K, 3000K, 3500K, 4000K

ELECTRICAL SYSTEM

- Thermal protection guard protects the LED module from overheating and will dim LED module if

necessary

- Power factor >.9, 50/60Hz

- Multiple dimming options available

OPTICAL SYSTEM

Specification grade reflector with 1.2mm thickness. Reflector available in clear specular, haze or

white. Architectural, discrete polished self flange standard. Optional painted white flange is available.

Meets RP-1 requirements with controlled light distribution at a 55° cut off.

FRAME CONSTRUCTION

Heavy duty galvanized steel frame with a large access junction box. ETL listed for through wiring. LED

light engine and driver are accessible from above or below ceiling.

INSTALLATION

The luminaire is type Non-IC. Insulation must be kept at a minimum of 3” away from fixture. Universal

mounting brackets included. Compatible with C-channel, flat bar, wood joist bar hanger and EMT. Bar

hangers must be ordered separately. C-channel are recommended for T-bar ceilings. Maximum ceiling

thickness is 1 1⁄4”.

Reflector Matrix | Example: IC630HZ-SF

A

Catalog Number

B

C

C

ACCESSORIES

Compatible with decorative drop and Infuz ™ accessories. See page 2 for options.

Trim

-SF Self Flanged

-SFW Self Flanged White

EMERGENCY BACKUP

Remote test switch included. Emergency driver operates LED load of up to 7.0 Watts at a nominal 450

lumens for a minimum of 90 minutes.

Reflector Finish

C Clear

HZ Haze

W White

LISTING/WARRANTY

- ETL listed to US and Canadian standards for damp locations.

- 10-Year Intense LED Limited Warranty

ARCHITECTURAL L/M-0911:14 P-16

Intense Lighting, LLC | 3340. E La Palma Ave. | Anaheim, CA 92806 | Phone: 1.800.961.5321 | Fax: 1.800.961.5322 | www.intenselighting.com

Note: Specifications and dimensions subject to change without notice.

6XEPLWWLQJ$JHQF\

'HVFULSWLRQ

3URMHFW

1RWHV

7\SH

66*""",&+=6)

&1

2$.5,'*(/,%5$5<

JOB NAME

6” Decorative Recessed Accessories

CATALOG NUMBER

NOTES

TYPE

Decorative glass and acrylic accessories are compatible with select reflectors. Customize and create your environment with the options below.

ORDERING INFORMATION:

Add accessory part number to the end of the reflector part number. (Example: IC630C-SF-D1R)

DECORATIVE

ORDERING INFO

DESCRIPTION

OD

ID

THICKNESS

-D1R

6” Red Acrylic Ring 1 3⁄8”

7 3⁄4”

5 1⁄2”

1⁄8”

-D2R

6” Red Acrylic Ring 2 3⁄8”

7 3⁄4”

3 1⁄2”

1⁄8”

-D1B

6” Blue Acrylic Ring 1 3⁄8”

7 3⁄4”

5 1⁄2”

1⁄8”

-D2B

6” Blue Acrylic Ring 2 3⁄8”

7 3⁄4”

3 1⁄2”

1⁄8”

-D1G

6” Green Acrylic Ring 1 3⁄8”

7 3⁄4”

5 1⁄2”

1⁄8”

-D2G

6” Green Acrylic Ring 2 3⁄8”

7 3⁄4”

3 1⁄2”

1⁄8”

-D5

6” Tempered Glass Decorative Drop

7 3⁄4”

NA

5⁄32”

-D6

6” Tempered Glass Decorative Drop

7 3⁄4”

NA

5⁄32”

-D7

6” Tempered Glass Decorative Drop

7 3⁄4”

NA

5⁄32”

-D8

6” Tempered Glass Ring 1 3⁄8”

7 3⁄4”

5 1⁄2”

5⁄32”

-D9

6” Sandblasted Tempered Glass Ring 2 3⁄8”

7 3⁄4”

3 1⁄2”

5⁄32”

Infuz decorative accessories may be used with select reflectors. Accessory kits are factory installed. Custom material

available by special order. Minimum order and lead times may apply. Consult factory.

How to Order:

1. Enter your specified reflector under section “A”.

2. Specify the Infuz adder on the reflector part number. (Example: IC630C-SF-IZDM-5-MO)

Flush Mount Recessed

B

A

B

D

D

Material

Specify Compatible

Reflector

-1

-2

-3

-4

-5

-6

Red Crush

Blue Crush

Tiger Thatch

Linea Vert

Bronze Weave

Fossil Leaf

Series

Type: Tiger Thatch

Item Code: 3

Order Matrix | Example: IC630C-SF-IFZDM-1

Reflector

-IFZFM Infuz Flush Mount

C

C

Type: Blue Crush

Item Code: 2

Drop Mount Recessed

Order Matrix | Example: IC630C-SF-IFZFM-W-1

A

Type: Red Crush

Item Code: 1

A

A

B

B

C

Reflector

C

Material

Specify Compatible

Reflector

-1

-2

-3

-4

-5

-6

Red Crush

Blue Crush

Tiger Thatch

Linea Vert

Bronze Weave

Fossil Leaf

Series

-IFZDM Drop Mount

Inner Reflector

-W White

-HZ Haze

ARCHITECTURAL L/M-0911:14 P-17

Intense Lighting, LLC | 3340. E La Palma Ave. | Anaheim, CA 92806 | Phone: 1.800.961.5321 | Fax: 1.800.961.5322 | www.intenselighting.com

Note: Specifications and dimensions subject to change without notice.

Type: Linea Vert

Item Code: 4

Type: Bronze Weave

Item Code: 5

Type: Fossil Leaf

Item Code: 6

6XEPLWWLQJ$JHQF\

3URMHFW

1RWHV

CATALOG NUMBER

NOTES

SS6G21100358 / IC630C

Luminaire Lumens: 1084.91 lm

80°

70°

346

RC

60°

691

50°

1037

1382

Room Cavity Ratio

Luminaire Watts: 16.06W

TYPE

Polar Curve

6” Architectural LED Round / Open Reflector

Reflector Finish: Specular Clear

40°

10°

20°

30°

Lumens Per Watt: 67.55

RW

1

2

3

4

5

6

7

8

9

10

70

113

108

102

97

92

87

83

79

75

72

Throw Distance

Color Temperature: 3300K

Spacing Criteria: 0.84

Beam Diameter

Throw Distance (d)

8’ (2.4m)

10’ (3m)

12’ (3.7m)

Beam Diameter

6.6’ (2m)

8.3’ (2.5m)

9.9’ (3m)

Illuminance (fc)

21.6

13.8

9.6

Illuminance (lux)

232

149

103

SS6G21500358 / IC630C

Polar Curve

6” Architectural LED Round / Open Reflector

Report #: L10135503

Reflector Finish: Specular Clear

Luminaire Watts: 18.75W

Luminaire Lumens: 1461.65 lm

80°

70°

437

RC

60°

874

50°

1311

1748

Room Cavity Ratio

Lighting Facts

Reg. #: L5DN-433BVD

40°

10°

20°

30°

Lumens Per Watt: 77.95

RW

1

2

3

4

5

6

7

8

9

10

70

113

107

102

96

91

87

82

78

74

71

Throw Distance

Color Temperature: 3310K

Color Rendering Index: 83.4

Spacing Criteria: 0.86

LED Product Partner

Lighting Facts

Reg. #: L5DN-N5DBMW

Beam Diameter

Throw Distance (d)

8’ (2.4m)

10’ (3m)

12’ (3.7m)

Beam Diameter

6.9’ (2.1m)

8.6’ (2.6m)

10.3’ (3.1m)

Illuminance (fc)

27.3

17.5

12.1

Illuminance (lux)

294

188

131

Coefficients of Utilization

Effective Floor Cavity Reflectance = .20

80

70

50

Wall Reflectance

50 30 10 70 50 30 10 50 30 10

110 108 106 111 108 106 104 104 102 101

103 98 95 105 101 97 94 98 95 92

96 91 86 100 94 90 86 92 88 84

89 84 79 95 88 83 79 86 81 78

84 78 73 90 83 77 73 81 76 72

78 72 68 86 78 72 68 76 71 67

74 68 63 82 73 67 63 72 67 63

69 63 59 78 69 63 59 68 63 59

66 60 56 74 65 59 56 64 59 55

62 56 52 71 62 56 52 61 56 52

Zonal Lumens and Percentages

Zone

Lumens %Fixture

0-30

769.83

71

0-40

970.39

89.4

0-60

1069.99

98.6

0-90

1084.91

100

40-70

105.29

9.7

60-80

10.32

1

90-180

0

0

0-180 1084.91

100

Color Rendering Index: 84.6

LED Product Partner

&1

2$.5,'*(/,%5$5<

JOB NAME

Report #: L10135501

7\SH

66*""",&+=6)

'HVFULSWLRQ

All testing was conducted in accordance with LM-79-08, Approved Method: Electrical and Photometric Measurements of Solid-State

Lighting Products as published by the Illuminating Engineering Society of North America (IESNA).

ARCHITECTURAL L/M-0911:14 P-18

Intense Lighting, LLC | 3340. E La Palma Ave. | Anaheim, CA 92806 | Phone: 1.800.961.5321 | Fax: 1.800.961.5322 | www.intenselighting.com

Note: Specifications and dimensions subject to change without notice.

50

100

95

89

84

79

75

71

67

63

60

30

99

92

86

80

75

70

66

62

59

55

0

10

98

90

83

77

72

67

63

59

55

52

0

93

86

80

75

70

65

61

57

54

51

Zonal Lumen Summary

Zone

CP

Lumens

0

1382

105.05

10

1310

334.24

20

1000

330.54

30

519

200.56

40

178

88.7

50

20

10.9

60

6

5.69

70

5

4.63

80

4

4.6

90

0

0

Coefficients of Utilization

Effective Floor Cavity Reflectance = .20

80

70

50

Wall Reflectance

50 30 10 70 50 30 10 50 30 10

110 108 105 111 108 106 104 104 102 100

102 98 95 105 101 97 94 97 94 91

95 90 86 100 94 89 85 91 87 84

89 83 79 95 88 82 78 85 81 77

83 77 73 90 82 76 72 80 75 72

78 72 67 85 77 71 67 75 70 66

73 67 62 81 72 66 62 71 66 62

69 62 58 77 68 62 58 67 62 58

65 59 55 73 64 58 54 63 58 54

61 55 51 70 61 55 51 60 55 51

Zonal Lumens and Percentages

Zone

Lumens %Fixture

68.9

1007.77

0-30

88.4

1292.7

0-40

98.6

1441.47

0-60

1461.65

100

0-90

156.83

10.7

40-70

14.24

1

60-80

0

0

90-180

100

0-180 1461.65

30

30

50

100

94

89

83

78

74

70

66

62

59

30

99

92

85

80

74

69

65

61

57

54

0

10

97

90

83

76

71

66

62

58

54

51

0

93

86

80

74

69

64

60

56

53

49

Zonal Lumen Summary

Zone

CP

Lumens

0

1748

133.33

10

1667

429.39

20

1308

445.05

30

727

284.93

40

264

132.74

50

30

16.02

60

9

8.06

70

6

6.18

80

5

5.95

90

0

0

6XEPLWWLQJ$JHQF\

3URMHFW

1RWHV

CATALOG NUMBER

NOTES

SS6G22000358 / IC630C

Luminaire Lumens: 1770.05 lm

80°

70°

574

RC

60°

1148

50°

1722

2296

Room Cavity Ratio

Luminaire Watts: 24.58W

TYPE

Polar Curve

6” Architectural LED Round / Open Reflector

Reflector Finish: Specular Clear

40°

10°

20°

30°

Lumens Per Watt: 72.01

RW

1

2

3

4

5

6

7

8

9

10

70

113

108

102

97

92

88

83

79

76

72

Throw Distance

Color Temperature: 3320K

Spacing Criteria: 0.82

Beam Diameter

Throw Distance (d)

8’ (2.4m)

10’ (3m)

12’ (3.7m)

Beam Diameter

6.5’ (2m)

8.2’ (2.5m)

9.8’ (3m)

Illuminance (fc)

35.9

23

15.9

Illuminance (lux)

386

247

172

SS6G23000358 / IC630C

Polar Curve

6” Architectural LED Round / Open Reflector

Report #: L10135507

Reflector Finish: Specular Clear

Luminaire Watts: 37.25W

Luminaire Lumens: 2618.14 lm

80°

70°

784

RC

60°

1568

50°

2351

3135

Room Cavity Ratio

Lighting Facts

Reg. #: L5DN-KHX3V5

40°

10°

20°

30°

Lumens Per Watt: 70.29

RW

1

2

3

4

5

6

7

8

9

10

70

113

107

102

96

91

87

82

78

74

71

Throw Distance

Color Temperature: 3250K

Color Rendering Index: 83.9

Spacing Criteria: 0.86

LED Product Partner

Lighting Facts

Reg. #: L5DN-OFR2VT

Beam Diameter

Throw Distance (d)

8’ (2.4m)

10’ (3m)

12’ (3.7m)

Beam Diameter

6.8’ (2.1m)

8.5’ (2.6m)

10.2’ (3.1m)

Illuminance (fc)

49

17.5

21.8

Illuminance (lux)

527

337

234

Coefficients of Utilization

Effective Floor Cavity Reflectance = .20

80

70

50

Wall Reflectance

50 30 10 70 50 30 10 50 30 10

110 108 106 111 108 106 104 104 102 101

103 99 95 105 101 97 94 98 95 92

96 91 87 100 94 90 86 92 88 85

89 84 80 95 88 83 79 86 82 78

84 78 74 91 83 77 73 81 76 73

79 73 68 86 78 72 68 76 71 68

74 68 64 82 73 68 64 72 67 63

70 64 60 78 69 64 60 68 63 59

66 60 56 74 65 60 56 64 59 56

62 57 53 71 62 56 53 61 56 53

Zonal Lumens and Percentages

Zone

Lumens %Fixture

0-30

1267.57

71.6

0-40

1591.31

89.9

0-60

1745.07

98.6

0-90

1770.05

100

40-70

163.72

9.2

60-80

17.68

1

90-180

0

0

0-180 1770.05

100

Color Rendering Index: 83.4

LED Product Partner

&1

2$.5,'*(/,%5$5<

JOB NAME

Report #: L10135505

7\SH

66*""",&+=6)

'HVFULSWLRQ

All testing was conducted in accordance with LM-79-08, Approved Method: Electrical and Photometric Measurements of Solid-State

Lighting Products as published by the Illuminating Engineering Society of North America (IESNA).

ARCHITECTURAL L/M-0911:14 P-19

Intense Lighting, LLC | 3340. E La Palma Ave. | Anaheim, CA 92806 | Phone: 1.800.961.5321 | Fax: 1.800.961.5322 | www.intenselighting.com

Note: Specifications and dimensions subject to change without notice.

50

101

95

89

84

79

75

71

67

64

60

30

99

92

86

80

75

71

66

62

59

56

0

10

98

90

83

77

72

67

63

59

56

52

0

93

86

80

75

70

65

61

57

54

51

Zonal Lumen Summary

Zone

CP

Lumens

0

2296

174.61

10

2179

554.44

20

1646

538.51

30

842

323.74

40

282

138.7

50

27

15.06

60

11

9.96

70

8

7.72

80

6

7.3

90

0

0

Coefficients of Utilization

Effective Floor Cavity Reflectance = .20

80

70

50

Wall Reflectance

50 30 10 70 50 30 10 50 30 10

110 108 105 111 108 106 104 104 102 100

102 98 95 105 101 97 93 97 94 91

95 90 86 100 94 89 85 91 87 84

89 83 79 95 88 82 78 85 81 77

83 77 72 90 82 76 72 80 75 71

78 71 67 85 77 71 67 75 70 66

73 67 62 81 72 66 62 71 66 62

68 62 58 77 68 62 58 67 62 58

65 59 54 73 64 58 54 63 58 54

61 55 51 70 61 55 51 60 55 51

Zonal Lumens and Percentages

Zone

Lumens %Fixture

1799.99

68.8

0-30

88.2

2309.92

0-40

2578.1

98.5

0-60

2618.14

100

0-90

40-70

284.78

10.9

60-80

28.95

1.1

0

0

90-180

0-180 2618.14

100

30

30

50

100

94

89

83

78

74

70

66

62

59

30

99

92

85

79

74

69

65

61

57

54

0

10

97

89

82

76

71

66

61

58

54

51

0

93

86

80

74

69

64

60

56

52

49

Zonal Lumen Summary

Zone

CP

Lumens

0

3135

239.05

10

2985

766.48

20

2329

794.46

30

1301

509.93

40

473

238.38

50

55

29.81

60

18

16.6

70

12

12.35

80

9

11.08

90

0

0

6XEPLWWLQJ$JHQF\

'HVFULSWLRQ

3URMHFW

1RWHV

7\SH

66*""",&+=6)

&1

2$.5,'*(/,%5$5<

DIMMING COMPATIBILITY

JOB NAME

CATALOG NUMBER

NOTES

0-10V DIMMING

TYPE

BLACK

- 120V or 277V

- Dims down to 1% or 10% light output

- Consult dimming manufacturer for installation instructions and power packs

INPUT

WHITE

RED - POSITIVE

DRIVER

GREEN

LED LIGHT

ENGINE

BLACK - NEGATIVE

COMPATIBLE DIMMERS

Manufacturer

HUNT

Leviton

Lightolier

Lithonia

Lutron

Synergy

Part Number(s)

PS-010-IV-120V, PS-010-WH-120V, PS-010-3W-IV-120,

PS-010-3W-WH-120V, PS-010-IV-277V, PS-010-WH-277V,

PS-010-3W-IV-277V, PS-010-3W-WH-277V,

FD-010: PS-IFC-010-IV, PS-IFC-010-WH-120/277V,

FD-010: PS-IFC-010-3W-IV, PS-IFC-010-3W-WH-120/277V,

FD-010-120V, FD-010-277V

Leviton Centura Fluorescent Control System,

IllumaTech™ IP7 Series, DPSPE-212

ZP600FAM120, MP1500FAM120, V2000FAMU

LEQ BC, LEQ LVBC, SLD LVBC, SQ1DC

DVTV, NTFTV

ISD BC 120/277

LUTRON ECOSYSTEM® DIMMING

- 120V or 277V

- Dims down to less than 1% or 5% light output

- Consult dimming manufacturer for installation instructions

0-10V

DIMMER

ECO

SYSTEM

CONTROL

(BY OTHERS)

VIOLET (+)

GREY (-)

BLACK

WHITE

RED - POSITIVE

DRIVER

GREEN

LED LIGHT

ENGINE

BLACK - NEGATIVE

COMPATIBLE DIMMERS

Product

EcoSystem

Part Number(s)

CS-1L-WM, CS-2L-WM, CS-1L-CM, CS-2L-CM,

EcoSystem ESN, Grafik Eye QS with EcoSystem, Quantum

LUTRON HI-LUME® DIMMING

- 120V or 277V

- Dims down to less than 1% light output

- Consult dimming manufacturer for installation instructions

ECO SYS

BUS

3-WIRE

CONTROL

(BY OTHERS)

VIOLET (E1)

VIOLET (E2)

BLACK

WHITE

ORANGE

GREEN

RED - POSITIVE

DRIVER

COMPATIBLE DIMMERS

Product

NovaT

Nova

Vareo

Skylark

Diva

Ariadni

Vierti

Maestro

Maestro Wireless

Spacer System

Lyneo

Radio RA 2

HomeWorks QS

Part Number(s)

NTF-10, NTF-103P, NTF-103P-277, NTF-10-277

NF-10, NF-103P, NF-103P-277, NF-10-277

VF-10

SF-10P, SF-12P-277, SF-12P-277-3, SF-103P

DVF-103, DVF-103P-277, DVSCF-103P, DVSCF-103P-277

AYF-103P, AYF-103P-277

VTF-6AM

MAF-6AM, MAF-6AM-277, MSCF-6AM, MCSF-6AM-277

MRF2-F6AN-DV

SPSF-6A, SPSF-6A-277, SPSF-6AM, SPSF-6AM-277

LXF-103PL, LXF-103PL-277

RRD-F6AN-DV

HQRD-F6AN-DV

ARCHITECTURAL L/M-0911:14 P-34

Intense Lighting, LLC | 3340. E La Palma Ave. | Anaheim, CA 92806 | Phone: 1.800.961.5321 | Fax: 1.800.961.5322 | www.intenselighting.com

Note: Specifications and dimensions subject to change without notice.

LED LIGHT

ENGINE

BLACK - NEGATIVE

6XEPLWWLQJ$JHQF\

'HVFULSWLRQ

3URMHFW

1RWHV

7\SH

66*""",&+=6)

&1::

2$.5,'*(/,%5$5<

JOB NAME

SS6G2 / IC635

CATALOG NUMBER

6” Architectural LED Round Generation 2 / Wall Wash Reflector

NOTES

TYPE

7 1⁄2”

12 3⁄4”

1 5⁄16”

7”

WET

LOCATION

13 1⁄2”

Cut-out: 6 1⁄2”

Order Matrix | Example: SS6G22000308-27-EM

A

B

C

A Series

SS6G2

B

1100

1500

2000

3000

C

278

308

358

408

D

D

6” LED Recessed Round

blank

-D10V1

-D10V

-ED10V1

-ED10V01

-LUT1

-LUT

-LUT5

-EDALI1

-EDALI01

Module Lumen Output

1100 Lumen

1500 Lumen

2000 Lumen

3000 Lumen

Color Temperature / CRI

2700K / 80 CRI

3000K / 80 CRI

3500K / 80 CRI

4000K / 80 CRI

E

E

Dimming

Non-Dimming

0-10V Dimming 1%

0-10V Dimming 10%

eldoLED 0-10V 1% 1

eldoLED 0-10V 0.1% 1

Lutron Hi-Lume 1%

Lutron EcoSystem 1%

Lutron EcoSystem 5%

eldoLED DALI 1% 1

eldoLED DALI 0.1% 1

Voltage

blank 120V

27 277V

E

-EM

-I100

-I200

-I400

Options

Emergency Backup

C-Channel Bar Hanger

Flat Bar Hanger

Wood Joist Bar Hanger

Notes:

1. eldoLED dimming not available for 3000lm module

Reflector Matrix | Example: IC635HZ-SF

A

A Series

IC635 6” Wall Wash Reflector

B

Reflector Finish

C Clear

HZ Haze

W White

B

C

C

Trim

-SF Self Flanged

-SFW Self Flanged White

Catalog Number

System Wattage *

Delivered Lumens **

SS6G21100358 / IC635C

SS6G21500358 / IC635C

SS6G22000358 / IC635C

SS6G23000358 / IC635C

15.75W

18.72W

24.57W

37.24W

784lm @ 3500K

1018lm @ 3500K

1287lm @ 3500K

1888lm @ 3500K

* System wattage include driver and LED module consumption.

** Delivered lumen output will vary depending on CCT.

LED MODULE

- Powered by OSRAM PrevaLED® Cube LED Module

- 50,000 hours at 70% lumen maintenance

- No heat, mercury or UV

- Available in 1100, 1500, 2000 and 3000 lm

- CRI = 80 & CCT 2700K, 3000K, 3500K, 4000K

ELECTRICAL SYSTEM

- Thermal protection guard protects the LED module from overheating and will dim LED module if

necessary

- Power factor >.9, 50/60Hz

- Multiple dimming options available

OPTICAL SYSTEM

Innovative optical lens directs light at a 20° angle towards wall achieving uniform and even light

distribution. Specification grade reflector with 1.2mm thickness. Reflector available in clear specular,

haze or white. Architectural, discrete polished self flange standard. Optional painted white flange is

available.

FRAME CONSTRUCTION

Heavy duty galvanized steel frame with a large access junction box. ETL listed for through wiring. LED

light engine and driver are accessible from above or below ceiling.

INSTALLATION

The luminaire is type Non-IC. Insulation must be kept at a minimum of 3” away from fixture. Universal

mounting brackets included. Compatible with C-channel, flat bar, wood joist bar hanger and EMT. Bar

hangers must be ordered separately. C-channel are recommended for T-bar ceilings. Maximum ceiling

thickness is 1 1⁄4”.

EMERGENCY BACKUP

Remote test switch included. Emergency driver operates LED load of up to 7.0 Watts at a nominal 450

lumens for a minimum of 90 minutes.

LISTING/WARRANTY

- ETL listed to US and Canadian standards for wet locations.

- 10-Year Intense LED Limited Warranty

ARCHITECTURAL L/M-0911:14 P-21

Intense Lighting, LLC | 3340. E La Palma Ave. | Anaheim, CA 92806 | Phone: 1.800.961.5321 | Fax: 1.800.961.5322 | www.intenselighting.com

Note: Specifications and dimensions subject to change without notice.

6XEPLWWLQJ$JHQF\

'HVFULSWLRQ

3URMHFW

1RWHV

7\SH

66*""",&+=6)

&1::

2$.5,'*(/,%5$5<

JOB NAME

CATALOG NUMBER

NOTES

TYPE

SS6G21100358 / IC635C

6” Architectural LED Round / Wall Wash Reflector

Report #: L10135502

Reflector Finish: Specular Clear

Distribution Curve

213

80°

70°

60°

426

Luminaire Watts: 15.75W

Luminaire Lumens: 783.67 lm

50°

639

40°

852

30°

Lumens Per Watt: 49.76

Color Temperature: 3290K

10°

Color Rendering Index: 84.3

LED Product Partner

20°

Lighting Facts

Reg. #: L5DN-A6MDI7

Distance

From

Ceiling

1’

2’

3’

4’

5’

6’

7’

8’

9’

10’

11’

12’

13’

14’

2’ From Wall

On 3’ Centers

3’ From Wall

On 3’ Centers

3’ From Wall

On 4’ Centers

3’

3’

4’

5

22

24

18

13

9

6

5

3

3

2

2

1

1

3

13

21

18

13

10

7

5

4

3

2

2

1

1

5

22

24

18

13

9

6

5

3

3

2

2

1

1

1

5

11

13

12

10

8

6

5

4

3

2

2

2

1

5

11

14

13

11

8

6

5

4

3

2

2

2

1

5

11

13

12

10

8

6

5

4

3

2

2

2

1

5

10

11

10

9

7

5

4

3

3

2

2

1

1

3

7

11

10

9

7

6

5

4

3

2

2

2

1

5

10

11

10

9

7

5

4

3

3

2

2

1

SS6G21500358 / IC635C

6” Architectural LED Round / Wall Wash Reflector

Distribution Curve

Report #: L10135504

288

80°

70°

60°

576

Reflector Finish: Specular Clear

50°

Luminaire Watts: 18.72W

Luminaire Lumens: 1018.05 lm

Lumens Per Watt: 54.38

863

40°

1151

30°

Color Temperature: 3290K

10°

20°

Color Rendering Index: 83

LED Product Partner

Lighting Facts

Reg. #: L5DN-RCC85P

Distance

From

Ceiling

1’

2’

3’

4’

5’

6’

7’

8’

9’

10’

11’

12’

13’

14’

2’ From Wall

On 3’ Centers

3’ From Wall

On 3’ Centers

3’ From Wall

On 4’ Centers

3’

3’

4’

7

30

33

25

17

12

8

6

4

3

3

2

2

1

4

19

28

24

18

13

9

7

5

4

3

2

2

1

7

30

33

25

17

12

8

6

4

3

3

2

2

1

All testing was conducted in accordance with LM-79-08, Approved Method: Electrical and Photometric Measurements of Solid-State

Lighting Products as published by the Illuminating Engineering Society of North America (IESNA).

ARCHITECTURAL L/M-0911:14 P-22

Intense Lighting, LLC | 3340. E La Palma Ave. | Anaheim, CA 92806 | Phone: 1.800.961.5321 | Fax: 1.800.961.5322 | www.intenselighting.com

Note: Specifications and dimensions subject to change without notice.

1

7

15

18

16

13

10

8

6

5

4

3

3

2

1

6

15

19

17

14

11

9

7

5

4

3

3

2

1

7

15

18

16

13

10

8

6

5

4

3

3

2

1

6

14

16

14

12

9

7

5

4

4

3

2

2

1

4

10

14

14

12

10

8

6

5

4

3

3

2

1

6

14

16

14

12

9

7

5

4

4

3

2

2

6XEPLWWLQJ$JHQF\

'HVFULSWLRQ

3URMHFW

1RWHV

7\SH

66*""",&+=6)

&1::

2$.5,'*(/,%5$5<

JOB NAME

CATALOG NUMBER

NOTES

TYPE

SS6G22000358 / IC635C

6” Architectural LED Round / Wall Wash Reflector

Distribution Curve

Report #: L10135506

365

80°

70°

60°

729

Reflector Finish: Specular Clear

Luminaire Watts: 24.57W

50°

1094

40°

1458

30°

Luminaire Lumens: 1287.38 lm

Lumens Per Watt: 52.4

Color Temperature: 3310K

10°

Color Rendering Index: 83.1

LED Product Partner

20°

Lighting Facts

Reg. #: L5DN-A2ZPBS

Distance

From

Ceiling

1’

2’

3’

4’

5’

6’

7’

8’

9’

10’

11’

12’

13’

14’

2’ From Wall

On 3’ Centers

3’ From Wall

On 3’ Centers

3’ From Wall

On 4’ Centers

3’

3’

4’

9

37

41

31

21

15

11

8

6

4

3

3

2

2

5

23

35

30

22

16

12

8

6

5

4

3

2

2

9

37

41

31

21

15

11

8

6

4

3

3

2

2

2

8

18

22

20

16

13

10

8

6

5

4

3

3

1

7

18

23

22

18

14

11

9

7

5

4

3

3

2

8

18

22

20

16

13

10

8

6

5

4

3

3

1

8

17

20

18

14

11

9

7

6

4

4

3

2

1

5

12

18

17

15

12

10

8

6

5

4

3

3

1

8

17

20

18

14

11

9

7

6

4

4

3

2

SS6G23000358 / IC635C

6” Architectural LED Round / Wall Wash Reflector

Distribution Curve

Report #: L10135508

537

80°

70°

60°

1074

Reflector Finish: Specular Clear

50°

Luminaire Watts: 37.24W

Luminaire Lumens: 1887.95 lm

Lumens Per Watt: 50.7

1611

40°

2148

30°

Color Temperature: 3250K

10°

20°

Color Rendering Index: 83.8

LED Product Partner

Lighting Facts

Reg. #: L5DN-2T7TZO

Distance

From

Ceiling

1’

2’

3’

4’

5’

6’

7’

8’

9’

10’

11’

12’

13’

14’

2’ From Wall

On 3’ Centers

3’ From Wall

On 3’ Centers

3’ From Wall

On 4’ Centers

3’

3’

4’

14

60

62

46

32

22

15

11

8

6

5

4

3

2

8

37

54

44

33

24

17

12

9

7

5

4

3

3

14

60

62

46

32

22

15

11

8

6

5

4

3

2

All testing was conducted in accordance with LM-79-08, Approved Method: Electrical and Photometric Measurements of Solid-State

Lighting Products as published by the Illuminating Engineering Society of North America (IESNA).

ARCHITECTURAL L/M-0911:14 P-23

Intense Lighting, LLC | 3340. E La Palma Ave. | Anaheim, CA 92806 | Phone: 1.800.961.5321 | Fax: 1.800.961.5322 | www.intenselighting.com

Note: Specifications and dimensions subject to change without notice.

3

14

29

34

30

24

19

15

11

9

7

6

5

4

1

6

15

19

17

14

11

9

7

5

4

3

3

2

3

14

29

34

30

24

19

15

11

9

7

6

5

4

2

13

27

30

27

22

17

13

10

8

6

5

4

3

1

8

20

27

26

22

18

14

11

9

7

6

5

4

2

13

27

30

27

22

17

13

10

8

6

5

4

3

6XEPLWWLQJ$JHQF\

'HVFULSWLRQ

3URMHFW

1RWHV

7\SH

66*""",&+=6)

&1::

2$.5,'*(/,%5$5<

DIMMING COMPATIBILITY

JOB NAME

CATALOG NUMBER

NOTES

0-10V DIMMING

TYPE

BLACK

- 120V or 277V

- Dims down to 1% or 10% light output

- Consult dimming manufacturer for installation instructions and power packs

INPUT

WHITE

RED - POSITIVE

DRIVER

GREEN

LED LIGHT

ENGINE

BLACK - NEGATIVE

COMPATIBLE DIMMERS

Manufacturer

HUNT

Leviton

Lightolier

Lithonia

Lutron

Synergy

Part Number(s)

PS-010-IV-120V, PS-010-WH-120V, PS-010-3W-IV-120,

PS-010-3W-WH-120V, PS-010-IV-277V, PS-010-WH-277V,

PS-010-3W-IV-277V, PS-010-3W-WH-277V,

FD-010: PS-IFC-010-IV, PS-IFC-010-WH-120/277V,

FD-010: PS-IFC-010-3W-IV, PS-IFC-010-3W-WH-120/277V,

FD-010-120V, FD-010-277V

Leviton Centura Fluorescent Control System,

IllumaTech™ IP7 Series, DPSPE-212

ZP600FAM120, MP1500FAM120, V2000FAMU

LEQ BC, LEQ LVBC, SLD LVBC, SQ1DC

DVTV, NTFTV

ISD BC 120/277

LUTRON ECOSYSTEM® DIMMING

- 120V or 277V

- Dims down to less than 1% or 5% light output

- Consult dimming manufacturer for installation instructions

0-10V

DIMMER

ECO

SYSTEM

CONTROL

(BY OTHERS)

VIOLET (+)

GREY (-)

BLACK

WHITE

RED - POSITIVE

DRIVER

GREEN

LED LIGHT

ENGINE

BLACK - NEGATIVE

COMPATIBLE DIMMERS

Product

EcoSystem

Part Number(s)

CS-1L-WM, CS-2L-WM, CS-1L-CM, CS-2L-CM,

EcoSystem ESN, Grafik Eye QS with EcoSystem, Quantum

LUTRON HI-LUME® DIMMING

- 120V or 277V

- Dims down to less than 1% light output

- Consult dimming manufacturer for installation instructions

ECO SYS

BUS

3-WIRE

CONTROL

(BY OTHERS)

VIOLET (E1)

VIOLET (E2)

BLACK

WHITE

ORANGE

GREEN

RED - POSITIVE

DRIVER

COMPATIBLE DIMMERS

Product

NovaT

Nova

Vareo

Skylark

Diva

Ariadni

Vierti

Maestro

Maestro Wireless

Spacer System

Lyneo

Radio RA 2

HomeWorks QS

Part Number(s)

NTF-10, NTF-103P, NTF-103P-277, NTF-10-277

NF-10, NF-103P, NF-103P-277, NF-10-277

VF-10

SF-10P, SF-12P-277, SF-12P-277-3, SF-103P

DVF-103, DVF-103P-277, DVSCF-103P, DVSCF-103P-277

AYF-103P, AYF-103P-277

VTF-6AM

MAF-6AM, MAF-6AM-277, MSCF-6AM, MCSF-6AM-277

MRF2-F6AN-DV

SPSF-6A, SPSF-6A-277, SPSF-6AM, SPSF-6AM-277

LXF-103PL, LXF-103PL-277

RRD-F6AN-DV

HQRD-F6AN-DV

ARCHITECTURAL L/M-0911:14 P-34

Intense Lighting, LLC | 3340. E La Palma Ave. | Anaheim, CA 92806 | Phone: 1.800.961.5321 | Fax: 1.800.961.5322 | www.intenselighting.com

Note: Specifications and dimensions subject to change without notice.

LED LIGHT

ENGINE

BLACK - NEGATIVE

6XEPLWWLQJ$JHQF\

'HVFULSWLRQ

3URMHFW

1RWHV

7\SH

665*"""9,&+=6)

&5

2$.5,'*(/,%5$5<

JOB NAME

SS8RG2 / IC830

CATALOG NUMBER

8” Architectural Remodel LED Round Generation 2 / Open Reflector

NOTES

TYPE

10 15⁄16”

8 5⁄16”

9”

Cut-out: 8 1⁄8”

Order Matrix | Example: SS8RG22000308-27-EM

A

B

C

A Series

SS8RG2

B

1100

1500

2000

3000

C

278

308

358

408

D

D

8” Remodel LED

Recessed Round

blank

-D10V1

-D10V

-ED10V1

-ED10V01

-LUT1

-LUT

-LUT5

-EDALI1

-EDALI01

Module Lumen Output

1100 Lumen

1500 Lumen

2000 Lumen

3000 Lumen

E

Dimming

Non-Dimming

0-10V Dimming 1%

0-10V Dimming 10%

eldoLED 0-10V 1% 1

eldoLED 0-10V 0.1% 1

Lutron Hi-Lume 1%

Lutron EcoSystem 1%

Lutron EcoSystem 5%

eldoLED DALI 1% 1

eldoLED DALI 0.1% 1

Color Temperature / CRI

E

2700K / 80 CRI

3000K / 80 CRI

3500K / 80 CRI

4000K / 80 CRI

Voltage

blank 120V

27 277V

E

-EM

Option

Emergency Backup

Notes:

1. eldoLED dimming not available for 3000lm module

A Series

IC830 8” Open Reflector

B

Reflector Finish

System Wattage *

Delivered Lumens **

SS8RG21100358 / IC830C

SS8RG21500358 / IC830C

SS8RG22000358 / IC830C

SS8RG23000358 / IC830C

15.73W

18.78W

24.91W

37.48W

1163lm @ 3500K

1530lm @ 3500K

1959lm @ 3500K

2956lm @ 3500K

* System wattage include driver and LED module consumption.

** Delivered lumen output will vary depending on CCT.

LED MODULE

- Powered by OSRAM PrevaLED® Cube LED Module

- 50,000 hours at 70% lumen maintenance

- No heat, mercury or UV

- Available in 1100, 1500, 2000 and 3000 lm

- CRI = 80 & CCT 2700K, 3000K, 3500K, 4000K

ELECTRICAL SYSTEM

- Thermal protection guard protects the LED module from overheating and will dim LED module if

necessary

- Power factor >.9, 50/60Hz

- Multiple dimming options available

OPTICAL SYSTEM

Specification grade reflector with 1.2mm thickness. Reflector available in clear specular, haze or

white. Architectural, discrete polished self flange standard. Optional painted white flange is available.

Meets RP-1 requirements with controlled light distribution at a 55° cut off.

FRAME CONSTRUCTION

Heavy duty galvanized steel frame with a large access junction box. ETL listed for through wiring. LED

light engine and driver are accessible from above or below ceiling.

Reflector Matrix | Example: IC830HZ-SF

A

Catalog Number

INSTALLATION

Three high tensions springs secure fixture into ceiling with up to 5⁄8” thickness.

B

C

C

Trim

-SF Self Flanged

-SFW Self Flanged White

EMERGENCY BACKUP

Remote test switch included. Emergency driver operates LED load of up to 7.0 Watts at a nominal 450

lumens for a minimum of 90 minutes.

LISTING/WARRANTY

- ETL listed to US and Canadian standards for damp locations.

- 10-Year Intense LED Limited Warranty

C Clear

HZ Haze

W White

ARCHITECTURAL L/M-0910:14 P-31

Intense Lighting, LLC | 3340. E La Palma Ave. | Anaheim, CA 92806 | Phone: 1.800.961.5321 | Fax: 1.800.961.5322 | www.intenselighting.com

Note: Specifications and dimensions subject to change without notice.

6XEPLWWLQJ$JHQF\

3URMHFW

1RWHV

CATALOG NUMBER

NOTES

SS8RG21100358 / IC830C

Luminaire Lumens: 1162.61 lm

80°

70°

217

RC

60°

434

50°

650

867

Room Cavity Ratio

Luminaire Watts: 15.73W

TYPE

Polar Curve

8” Architectural LED Round / Open Reflector

Reflector Finish: Specular Clear

40°

10°

20°

30°

Lumens Per Watt: 73.91

RW

1

2

3

4

5

6

7

8

9

10

70

112

104

97

90

84

78

73

69

64

61

Throw Distance

Color Temperature: 3340K

Spacing Criteria: 0.86

Beam Diameter

Throw Distance (d)

8’ (2.4m)

10’ (3m)

12’ (3.7m)

Beam Diameter

6.9’ (2.1m)

8.5’ (2.6m)

10.3’ (3.1m)

Illuminance (fc)

13.5

8.7

6

Illuminance (lux)

146

93.3

64.8

SS8RG21500358 / IC830C

Polar Curve

8” Architectural LED Round / Open Reflector

Report #: L10135706

Reflector Finish: Specular Clear

Luminaire Watts: 18.78W

Luminaire Lumens: 1530.38 lm

80°

70°

281

RC

60°

563

50°

844

1125

Room Cavity Ratio

Lighting Facts

Reg. #: L5DN-8VRH5D

40°

10°

20°

30°

Lumens Per Watt: 81.49

RW

1

2

3

4

5

6

7

8

9

10

70

112

104

97

90

84

78

73

68

64

61

Throw Distance

Color Temperature: 3370K

Color Rendering Index: 83.9

Spacing Criteria: 0.88

LED Product Partner

Lighting Facts

Reg. #: L5DN-HCX7TC

Beam Diameter

Throw Distance (d)

8’ (2.4m)

10’ (3m)

12’ (3.7m)

Beam Diameter

6.9’ (2.1m)

8.6’ (2.6m)

10.4’ (3.2m)

Illuminance (fc)

17.6

11.3

7.8

Illuminance (lux)

189

121

84.1

Coefficients of Utilization

Effective Floor Cavity Reflectance = .20

80

70

50

Wall Reflectance

50 30 10 70 50 30 10 50 30 10

108 105 102 109 106 103 100 102 99 97

98 92 88 102 96 91 87 92 88 85

88 82 77 94 87 81 76 84 79 75

80 73 67 88 79 72 67 77 71 66

73 65 60 82 72 65 60 70 64 59

67 59 54 76 66 59 54 64 58 53

61 54 49 71 61 53 48 59 53 48

57 49 44 67 56 49 44 55 48 44

53 45 40 63 52 45 40 51 45 40

49 42 37 60 48 42 37 48 41 37

Zonal Lumens and Percentages

Zone

Lumens %Fixture

0-30

502.47

43.2

0-40

721.88

62.1

0-60

1099.85

94.6

0-90

1162.61

100

40-70

429.66

37

60-80

57.35

57.35

90-180

0

0

0-180 1162.61

100

Color Rendering Index: 84.7

LED Product Partner

&5

2$.5,'*(/,%5$5<

JOB NAME

Report #: L10135705

7\SH

665*"""9,&+=6)

'HVFULSWLRQ

All testing was conducted in accordance with LM-79-08, Approved Method: Electrical and Photometric Measurements of Solid-State

Lighting Products as published by the Illuminating Engineering Society of North America (IESNA).

ARCHITECTURAL L/M-0910:14 P-32

Intense Lighting, LLC | 3340. E La Palma Ave. | Anaheim, CA 92806 | Phone: 1.800.961.5321 | Fax: 1.800.961.5322 | www.intenselighting.com

Note: Specifications and dimensions subject to change without notice.

50

98

89

81

74

68

63

58

54

50

47

30

96

86

77

69

63

57

52

48

44

41

0

10

94

83

73

65

58

53

48

44

40

37

0

90

79

70

63

56

51

46

42

38

35

Zonal Lumen Summary

Zone

CP

Lumens

0

867

65.42

10

808

206.12

20

628

230.93

30

462

219.41

40

374

255.22

50

221

122.75

60

55

51.69

70

6

5.66

80

4

5.41

90

0

0

Coefficients of Utilization

Effective Floor Cavity Reflectance = .20

80

70

50

Wall Reflectance

50 30 10 70 50 30 10 50 30 10

108 105 102 109 106 103 100 102 99 97

98 92 88 102 96 91 87 92 88 85

88 82 77 94 87 81 76 84 79 75

80 73 67 88 79 72 67 76 71 66

73 65 60 82 72 65 60 70 64 59

67 59 54 76 66 59 53 64 58 53

61 54 48 71 61 53 48 59 53 48

57 49 44 67 56 49 44 55 48 44

52 45 40 63 52 45 40 51 44 40

49 42 37 59 48 42 37 47 41 37

Zonal Lumens and Percentages

Zone

Lumens %Fixture

42.9

656.99

0-30

61.8

945.85

0-40

94.5

1445.99

0-60

1530.38

100

0-90

570.32

37.3

40-70

77.91

5.1

60-80

0

0

90-180

100

0-180 1530.38

30

30

50

98

89

81

74

68

63

58

54

50

47

30

96

86

77

69

63

57

52

48

44

41

0

10

94

83

73

65

58

53

48

43

40

37

0

90

79

70

63

56

50

46

42

38

35

Zonal Lumen Summary

Zone

CP

Lumens

0

1125

84.92

10

1051

268.98

20

824

303.09

30

608

288.87

40

493

336.68

50

294

163.45

60

74

70.19

70

8

7.72

80

5

6.49

90

0

0

6XEPLWWLQJ$JHQF\

3URMHFW

1RWHV

CATALOG NUMBER

NOTES

SS8RG22000358 / IC830C

Luminaire Lumens: 1959.31 lm

80°

70°

360

RC

60°

719

50°

1079

1438

Room Cavity Ratio

Luminaire Watts: 24.91W

TYPE

Polar Curve

8” Architectural LED Round / Open Reflector

Reflector Finish: Specular Clear

40°

10°

20°

30°

Lumens Per Watt: 78.66

RW

1

2

3

4

5

6

7

8

9

10

70

112

104

97

90

84

78

73

68

64

61

Throw Distance

Color Temperature: 3370K

Spacing Criteria: 0.88

Beam Diameter

Throw Distance (d)

8’ (2.4m)

10’ (3m)

12’ (3.7m)

Beam Diameter

6.9’ (2.1m)

8.6’ (2.6m)

10.4’ (3.2m)

Illuminance (fc)

13.5

14.4

10

Illuminance (lux)

242

155

108

SS8RG23000358 / IC830C

Polar Curve

8” Architectural LED Round / Open Reflector

Report #: L10135708

Reflector Finish: Specular Clear

Luminaire Watts: 37.48W

Luminaire Lumens: 2956.45 lm

80°

70°

544

RC

60°

1089

50°

1633

2177

Room Cavity Ratio

Lighting Facts

Reg. #: L5DN-XE6FIM

40°

10°

20°

30°

Lumens Per Watt: 78.88

RW

1

2

3

4

5

6

7

8

9

10

70

112

104

97

90

84

78

73

68

64

61

Throw Distance

Color Temperature: 3290K

Color Rendering Index: 83.3

Spacing Criteria: 0.88

LED Product Partner

Lighting Facts

Reg. #: L5DN-LNSQJL

Beam Diameter

Throw Distance (d)

8’ (2.4m)

10’ (3m)

12’ (3.7m)

Beam Diameter

6.9’ (2.1m)

8.6’ (2.6m)

10.4’ (3.2m)

Illuminance (fc)

34

21.8

15.1

Illuminance (lux)

366

234

163

Coefficients of Utilization

Effective Floor Cavity Reflectance = .20

80

70

50

Wall Reflectance

50 30 10 70 50 30 10 50 30 10

108 105 102 109 106 103 100 102 99 97

98 92 88 102 96 91 87 92 88 85

88 82 76 94 87 81 76 84 79 75

80 73 67 88 79 72 67 76 71 66

73 65 60 82 72 65 59 70 64 59

67 59 54 76 66 59 53 64 58 53

61 54 48 71 60 53 48 59 53 48

56 49 44 67 56 49 44 55 48 44

52 45 40 63 52 45 40 51 44 40

49 42 37 59 48 41 37 47 41 37

Zonal Lumens and Percentages

Zone

Lumens %Fixture

0-30

839.93

42.9

0-40

1208.41

61.7

0-60

1849.29

94.4

0-90

1959.31

100

40-70

731.93

37.4

60-80

100.83

5.1

90-180

0

0

0-180 1959.31

100

Color Rendering Index: 83.9

LED Product Partner

&5

2$.5,'*(/,%5$5<

JOB NAME

Report #: L10135707

7\SH

665*"""9,&+=6)

'HVFULSWLRQ

All testing was conducted in accordance with LM-79-08, Approved Method: Electrical and Photometric Measurements of Solid-State

Lighting Products as published by the Illuminating Engineering Society of North America (IESNA).

ARCHITECTURAL L/M-0910:14 P-33

Intense Lighting, LLC | 3340. E La Palma Ave. | Anaheim, CA 92806 | Phone: 1.800.961.5321 | Fax: 1.800.961.5322 | www.intenselighting.com

Note: Specifications and dimensions subject to change without notice.

50

98

89

81

74

68

62

58

53

50

46

30

96

86

77

69

63

57

52

48

44

41

0

10

94

83

73

65

58

52

48

43

40

36

0

90

79

70

62

56

50

46

41

38

35

Zonal Lumen Summary

Zone

CP

Lumens

0

1438

108.5

10

1342

343.72

20

1052

387.71

30

776

368.48

40

630

430.32

50

378

210.56

60

96

91.06

70

10

9.78

80

7

9.19

90

0

0

Coefficients of Utilization

Effective Floor Cavity Reflectance = .20

80

70

50

Wall Reflectance

50 30 10 70 50 30 10 50 30 10

108 105 102 109 106 103 100 102 99 97

98 92 88 101 96 91 87 92 88 85

88 82 76 94 87 81 76 84 79 74

80 73 67 88 79 72 67 76 71 66

73 65 60 82 72 65 59 70 64 59

67 59 53 76 66 58 53 64 58 53

61 54 48 71 60 53 48 59 53 48

56 49 44 67 56 49 44 55 48 44

52 45 40 63 52 45 40 51 44 40

49 42 37 59 48 41 37 47 41 37

Zonal Lumens and Percentages

Zone

Lumens %Fixture

42.8

1265.67

0-30

61.6

1821.68

0-40

94.3

2787.36

0-60

2956.45

100

0-90

37.4

40-70 1106.07

155.3

5.3

60-80

0

0

90-180

100

0-180 2956.45

30

30

50

98

89

81

74

68

62

58

53

50

46

30

96

86

77

69

62

57

52

48

44

41

0

10

94

83

73

65

58

52

47

43

40

37

0

90

79

70

62

56

50

45

41

38

35

Zonal Lumen Summary

Zone

CP

Lumens

0

2177

164

10

2024

517.13

20

1583

584.54

30

1171

556

40

946

646.48

50

571

319.2

60

148

140.38

70

15

14.92

80

11

13.79

90

0

0

6XEPLWWLQJ$JHQF\

'HVFULSWLRQ

3URMHFW

1RWHV

7\SH

665*"""9,&+=6)

&5

2$.5,'*(/,%5$5<

DIMMING COMPATIBILITY

JOB NAME

CATALOG NUMBER

NOTES

0-10V DIMMING

TYPE

BLACK

- 120V or 277V

- Dims down to 1% or 10% light output

- Consult dimming manufacturer for installation instructions and power packs

INPUT

WHITE

RED - POSITIVE

DRIVER

GREEN

LED LIGHT

ENGINE

BLACK - NEGATIVE

COMPATIBLE DIMMERS

Manufacturer

HUNT

Leviton

Lightolier

Lithonia

Lutron

Synergy

Part Number(s)

PS-010-IV-120V, PS-010-WH-120V, PS-010-3W-IV-120,

PS-010-3W-WH-120V, PS-010-IV-277V, PS-010-WH-277V,

PS-010-3W-IV-277V, PS-010-3W-WH-277V,

FD-010: PS-IFC-010-IV, PS-IFC-010-WH-120/277V,

FD-010: PS-IFC-010-3W-IV, PS-IFC-010-3W-WH-120/277V,

FD-010-120V, FD-010-277V

Leviton Centura Fluorescent Control System,

IllumaTech™ IP7 Series, DPSPE-212

ZP600FAM120, MP1500FAM120, V2000FAMU

LEQ BC, LEQ LVBC, SLD LVBC, SQ1DC

DVTV, NTFTV

ISD BC 120/277

LUTRON ECOSYSTEM® DIMMING

- 120V or 277V

- Dims down to less than 1% or 5% light output

- Consult dimming manufacturer for installation instructions

0-10V

DIMMER

ECO

SYSTEM

CONTROL

(BY OTHERS)

VIOLET (+)

GREY (-)

BLACK

WHITE

RED - POSITIVE

DRIVER

GREEN

LED LIGHT

ENGINE

BLACK - NEGATIVE

COMPATIBLE DIMMERS

Product

EcoSystem

Part Number(s)

CS-1L-WM, CS-2L-WM, CS-1L-CM, CS-2L-CM,

EcoSystem ESN, Grafik Eye QS with EcoSystem, Quantum

LUTRON HI-LUME® DIMMING

- 120V or 277V

- Dims down to less than 1% light output

- Consult dimming manufacturer for installation instructions

ECO SYS

BUS

3-WIRE

CONTROL

(BY OTHERS)

VIOLET (E1)

VIOLET (E2)

BLACK

WHITE

ORANGE

GREEN

RED - POSITIVE

DRIVER

COMPATIBLE DIMMERS

Product

NovaT

Nova

Vareo

Skylark

Diva

Ariadni

Vierti

Maestro

Maestro Wireless

Spacer System

Lyneo

Radio RA 2

HomeWorks QS

Part Number(s)

NTF-10, NTF-103P, NTF-103P-277, NTF-10-277

NF-10, NF-103P, NF-103P-277, NF-10-277

VF-10

SF-10P, SF-12P-277, SF-12P-277-3, SF-103P

DVF-103, DVF-103P-277, DVSCF-103P, DVSCF-103P-277

AYF-103P, AYF-103P-277

VTF-6AM

MAF-6AM, MAF-6AM-277, MSCF-6AM, MCSF-6AM-277

MRF2-F6AN-DV

SPSF-6A, SPSF-6A-277, SPSF-6AM, SPSF-6AM-277

LXF-103PL, LXF-103PL-277

RRD-F6AN-DV

HQRD-F6AN-DV

ARCHITECTURAL L/M-0910:14 P-34

Intense Lighting, LLC | 3340. E La Palma Ave. | Anaheim, CA 92806 | Phone: 1.800.961.5321 | Fax: 1.800.961.5322 | www.intenselighting.com

Note: Specifications and dimensions subject to change without notice.

LED LIGHT

ENGINE

BLACK - NEGATIVE

7\SH

&6

2$.5,'*(/,%5$5<

3URMHFW

1RWHV

6721(/,*+7,1*&/)53&'2%

'HVFULSWLRQ

6XEPLWWLQJ$JHQF\

ALTA CEILING

-90

-75

-60

-45

!LTACEILING

5NIQUEBACkLIGHTWALLORcEILINGWASH

METALBACkPLatEWITHFrostEDOPALGLASSDIFFUSEr.(IGHQUALItYcEILING

LUMINAIre.POLISHEDCHrOMEDEcoraTIvETrIM

Features

s(IGHQUALItYStEELANDFrostEDOPALGLASs.

sBEAUTIFULSHAPe,SOFTANDcomForTABLELIGHt.

s(IGHQUALItYANDSTABLE,%$CHIPs,ENErGYSaVING

AND%cOFrIENDLy.

s.O(AZArDOUSMaterIALSSUCHASMercurYANDLeaD,

NO)2ANDNO5V.

MB4

Q13

DOB24

DOB10

,AMP

sLED DOB24$/"$rIvERONBoarDV90 CRI LUMENS

FULLY$IMMABLEWITH!,,STANDArDDIMMERSTrIAC)NcAND%LV,L6-

MoDEL

CL530

X7MEDIUMBASE)NcANDESceNt

COMPAcTFluoresceNTQUADX7

,%$$/"$/"$rIvERONBoarD

V#2)LUMENS

,%$$/"$/"$rIvERONBoarD

V#2)LUMENS

MB4

FR Frost

$/"0

$/"4

40

13

10

4

340

600

1000

0

LUMENs

K

K

3000K

3000K

CCT

5

5

>90

>90

CR)

HRs

HRs

HRs

HRs

!ver.,IFe

4”

PC POLISHEDCHrome

PC

Color/PTIONS FINISH

FR

DIMENSIONS

10ӯ

13.75ӯ

Q13

LAMPING DATA

Watts

LamP

MB4

-120

-15

35

0.0

70

105

0

140

120

15

30

105

90

75

60

45

140

70

105

35

-90 -75 -60 -45 -30 -15

0.0

0

15 30 45 60 75 90

!bovEINFoISPerlamP.ForaccuratElumeNs,MULTIPlyby#oFlamPsINFIxture.

-105

-30

CL530FRPCQ13

stonelighting.net

43

6XEPLWWLQJ$JHQF\

'HVFULSWLRQ

3URMHFW

1RWHV

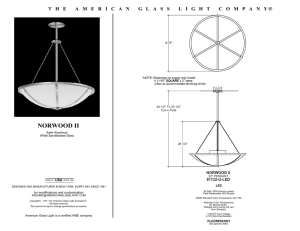

3/('/2):$70:6&819;1'02'

2$.5,'*(/,%5$5<

7\SH

'

Type

Job Name

Catalog Number

Made in USA

P8900 LED T r a n s c e n d e n t

60" or 72"

1524 or 1828.8mm

11"

279mm

24", 36" or 48"

279.4, 914.4 or 1219.2mm

8"

203.2mm

ordering - P8900 LED

series

lamp

rows

P8912

12˝ dia.

LED3LO, 3SO, 3HO*

3000k

P8920

2´ dia.

LED35LO, 35SO, 35HO*

3500k

P8930

3´ dia.

LED4LO, 4SO, 4HO*

4000k

P8940

4´ dia.

*

LO-Low Output, SOStandard Output,

HO-High Output

P8950

5´ dia.

P8960

6´ dia.

shielding

color/

finish*

CWA

concave

white

acrylic

(standard)

TMW

textured

matte

white

(standard)

VWA

convex

white

acrylic

YGW

gloss

white

FWA

flat white

acrylic

(6´ size

N/A)

circuiting

voltage

SC

single

circuit

120

DC

dual

circuit

347

277

UNV

120-277

Y_

premium

color

CC

custom

color

Construction Extruded aluminum housing rolled and welded.

Finish The standard exterior body color is gloss white (YGW) or

optional textured matte white (TMW) using polyester paint.

05

X1

exposed

T-Bar

ND

non-dimming

standard

X1T

T-Bar

ceiling

with

tegular

panels

DM10

0-10v 10%

dimming

DM01

0-10v 1%

dimming

X3B

hard

ceiling

STEP

step dimming

100-50-off

DMD

DALI dimming

EMH*

emergency

battery (11001200 raw lumens)

EML*

emergency

battery (350-600

raw lumens)

*

Consult factory for

diameters <4´

Electrical Must specify LED dimming controls. LED fixtures have

constant current driver(s) with less than 20% THD when loaded to a