CV List

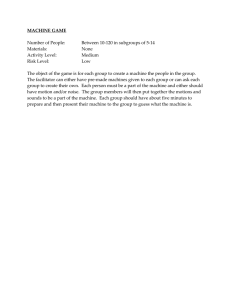

advertisement