controldesign.com

AVOID A PRESSING

PROBLEM

CATCH UP ON

PROGRAMMABLE

SAFETY

MAKE YOUR DIGITAL

NETWORK RELIABLE

Mosaic of

Modules

FEBRURARY 2012

Modular Machines and Production

Lines Inspire Builders to Combine

Equipment in More Innovative Ways

Test Measurement & Control

Compact Non-Contact Infrared

Temperature Transmitter

OS151-USB Series

Starts at

$

593

• Configurable Settings From a PC via Software

and USB Cable (Included)

• Features Max, Min Average and Instantaneous

Readings; Peak or Valley Hold; Reflected Energy

Compensation

• OPC Server Capabilities

Visit omega.com/os151-usb

DIN Rail Mounting Linear

Power Supplies

Adjustable Temperature Switches

1⁄ 8 DIN

Universal Process Panel

Meter with Built-In USB

Visit omega.com/dp63100

PSDIN-41000R and

PSDIN-42000B Series

Starts at

$

72

DP63100

Starts at

$

332

TSW Series

Starts at

$

160

MADE IN

USA

MADE IN

Visit omega.com/psdin-40000

Visit omega.com/tsw

®

USA

omega.com

®

© COPYRIGHT 2012 OMEGA ENGINEERING, INC. ALL RIGHTS RESERVED

Name

Dr. Laurel Watts

Job Title

Principal Software

Engineer

Area of Expertise

Chemical Engineering

LabVIEW Helped Me

Control multiple

instruments operating in

harsh conditions

Latest Project

Engineer the ultimate

storm chaser

NI LabVIEW

LabVIEW makes me better because the

with hardware is so seamless

>>

Find out how LabVIEW can make you better at ni.com/labview/better

©2010 National Instruments. All rights reserved. LabVIEW, National Instruments, NI, and ni.com are trademarks of National Instruments.

Other product and company names listed are trademarks or trade names of their respective companies. 2807

800 453 6202

CONTENTS

FEBRUARY 2012

FEATURES

24 Cover Story

Mosaic of Modules

Modular Machines and Production Lines Enable Quick Disconnects

and Speedy Changeovers. This Flexible Approach Inspires Builders

to Combine Modular Equipment in Ever More Innovative Ways

Jim Montague, executive editor

Volume 16, No. 2

33 Measurement, Sensing and Vision

Avoid a Pressing Problem

Aluminum Extruder Uses Smart Cameras to Prevent Machine

Damage

24

Mike Bray, CPU Automation

38 Product Roundup

Mobility, Efficiency Push HMI Growth

New Packaging Requirements Also Will Increase HMI Demand

COLUMNS

7 ControlDesign.com

23 Embedded Intelligence

Resolutions So Far

Software Guy, Know

Thy Limits

9 Editor’s Page

33

Lawyer Meets Machine

37 TechFlash

New Game for

Programmable Safety

11 Machine Builder Mojo

Pick Right, and Service

Is Free

50 OEM Insight

13 Live Wire

Push and Pull

of Electronic Drives

Find and Foster Innovation

HOT BUTTONS

44

CONTROL DESIGN, (ISSN: 1094-3366) is published 12 times a year by

Putman Media, 555 West Pierce Rd., Suite 301, Itasca, Illinois 60143.

(Phone 630/467-1300; Fax 630/467-1124.) Periodical postage paid at

Itasca, IL, and at additional mailing offices. Address all correspondence to

Editorial and Executive Offices, same address. Printed in the United States.

©Putman Media 2012. All rights reserved. The contents of this publication

may not be reproduced in whole or part without consent of the copyright

owner. POSTMASTER: Send address changes to Control Design, Post Office

Box 3430, Northbrook, Illinois 60065-3430. SUBSCRIPTIONS: To apply

for a free subscription, fill in the form at www.ControlDesign.com/subscribemag. To non-qualified subscribers in the Unites States and its possessions,

subscriptions are $96.00 per year. Single copies are $15. International subscriptions are accepted at $200 (Airmail only.) Putman Media also publishes

CHEMICAL PROCESSING, CONTROL, FOOD PROCESSING, INDUSTRIAL

NETWORKING, PHARMACEUTICAL MANUFACTURING and PLANT SERVICES. CONTROL DESIGN assumes no responsibility for validity of claims in

items reported. Canada Post International Publications Mail Product Sales

Agreement No. 40028661. Canadian Mail Distributor information: World

Distribution Services, Inc., Station A, PO Box 54, Windsor, Ontario, Canada

N9A 6J5. Printed in the United States.

15 OEM Spotlight

Candymaker Combines,

Simplifies Controls

44 Real Answers

Digital Network Reliability

48 Product Showcase

16 InDiscrete

Manufacturing Technology

Orders Up 74%

February 2012 Control Design

5

| TS11-03USA |

TwinSAFE:

Machine Safety Simplified.

Combine safety PLC Terminals, safety I/O and

standard I/O on one EtherCAT network.

www.beckhoff.com/TwinSAFE

TwinSAFE from Beckhoff: from I/O to drives it's the universal and flexible safety system.

TwinSAFE I/O for the EtherCAT Terminal system makes optimum use of the exceptional

performance offered by EtherCAT:

Compact: Safety PLC in a 12 mm terminal block

Powerful: up to 128 safety devices per Safety PLC

Versatile: integrated function blocks for emergency stop, protective door, two-hand control

Modular: standard and safety I/Os integrated in a single system

Flexible: “fieldbus-neutral” communication, eliminates dedicated safety networks

Certified: solution up to SIL 3 according to IEC 61508, EN 954 Cat. 4 and

DIN EN ISO 13849 PLe (approved for use throughout North America)

Safety inputs

Safety PLC

IPC

I/O

Motion

Automation

Standard PLC

Safety outputs

Safety Drives

Resolutions So Far

CREATE ERROR-FREE INTERCARRIAGE CONNECTIONS

Learn to provide both high

bandwidth and security, and

remove the need to configure

the access point (AP) upon

carriage reformation.

IF YOU READ my December

evidence about how to be more

‘11 column (“A New Resolu-

efficient as a machine builder,

tion,” www.ControlDesign.com/

or how to put green standards

resolution), you know that for

into practice, check out some of

2012 I resolved to improve my

our articles and get a head start

cybersecurity, sustainability and

on your 2012 green and better

efficiency knowledge. I have kept

efficiency path.

THE TRUTH ABOUT ENERGYEFFICIENT MOTORS

This paper delves into the

confusing area of motor

efficiency and how it relates to

saving energy.

2012 PRODUCT RESEARCH AND

BUYING HABITS STUDY

www.ControlDesign.com/

habits12

DID YOU KNOW YOU CAN

RECEIVE CONTROL DESIGN

ELECTRONICALLY? Subscribe

to the digital issue of Control

Design and download a highquality PDF of the magazine

exactly as it appears in print.

We’ll email you each month

when it’s ready.

www.ControlDesign.com/

digital.html

operation and dynamic perfor-

my daily To-Do list and I try

mances might help you find the

to accomplish everything I list

answer. In the white paper “En-

there. My To-Do list consists of

ergy Efficiency for Machines:

personal and professional goals

The Smart Choice for Motoriza-

such as posting daily news and

tion,” Schneider Electric gives

products on ControlDesign.

engineers efficient, economic

com, motivating my coworkers

and competitive solutions

(Jim gets cookies, though he

to help them select efficient

says he’ll work for peanuts) to

industrial motors. Read this

post Machine Builder Forum

white paper at www.ControlDe-

(MBF) entries (www.ControlDe-

sign.com/schneidermotor and

sign.com/mbf), and running

learn how using synchronous

my daily three miles.

motors with higher dynamic

I’ve also become more sustainable with my efficiency plan;

not printing that To-Do list, but

performances can generate at

least 20% energy savings.

Learn the difference between

instead tracking it digitally. My

active and passive energy ef-

lunches are packed in reusable

ficiency, and why companies

containers; there are no more

need to adopt active energy ef-

paper or Styrofoam cups for my

ficiency as the standard to meet

coffee; and if the Chicago winter

greenhouse gas emission goals

weather permits, I run my three

set within the Kyoto Protocol.

miles outside, consuming less

Read “Making Permanent Sav-

electricity at home or at the

ings Through Active Energy Ef-

gym and minimizing my carbon

ficiency” (www.ControlDesign.

footprint.

com/ActiveEnergyEfficiency) to

I’m off to a great start, but

learn this and much more.

I wonder if you set up similar

Lastly, if you want to learn

resolutions for this year, and

ways to improve energy effi-

if you are succeeding as well.

ciency of belt and roller convey-

Do you plan to improve your

ors, you must read “Optimizing

efficiency plans this year? Do

Energy Efficiency of Conveyors”

you have green goals to accom-

at www.ControlDesign.com/

plish? Stop by our forum and let

conveyors. Don’t be the last one

me know (www.ControlDesign.

to read about smart solutions

com/greenresolutions).

that can result in significant

However, if you need some

controldesign.com

at your machine, its modes of

efficient. Every day I type up

savings on a conveying line.

February 2012 Control Design

7

kbonfante@putman.net

CAN YOU TEACH INNOVATION?

www.ControlDesign.com/

innovate

motor technology? A close look

In 2012, I’ve become more

t

WHICH OF THESE WILL

CHANGE YOUR GAME?

www.ControlDesign.com/game

accomplish the rest.

managing editor, digital media

SPECIAL TO THE WEB

to choose the most suitable

t

To download PDF papers,

go to ControlDesign.com/

whitepapers.

Do you know the best way

I still have 10 more months to

Katherine Bonfante

CONDITION MONITORING:

ORDER ANALYSIS OVERVIEW

Stop unscheduled

outages, optimize machine

performance, and reduce

both repair time and

maintenance costs.

up with some of my resolutions.

CONTROLDESIGN.COM

NEW WHITE PAPERS

Technology by THE INNOVATORS

Generic

Motion Control

` Maximum system productivity through exceptional

performance and system synchronization

` Supports advanced manufacturing technologies by

integrating CNC, robotics and motion control with

integrated safety technology

` Easy implementation of machine options because of

software compatibility across all drive technologies

` Supports all machine topologies through the use of

centralized and decentralized drive technology

` 5HGXFHGKDUGZDUHFRVWVDQGVLPSOLÀHGVHUYLFH

Perfection in Automation

www.br-automation.com

Lawyer Meets Machine

555 W. Pierce Rd., Suite 301

Itasca, Illinois 60143

630/467-1300

Fax: 630/467-1124

A DISCUSSION OF product liabil-

Engineering standards are critical,

ity issues facing U.S. manufacturers

even if not expressly adopted as

highlighted a session at Rockwell

the law, as elements of proof that

EDITORIAL TEAM

Automation’s Safety Automation

your product is not defective if

Forum this past November.

you followed the standards.”

EDITOR IN CHIEF

JOSEPH FEELEY

jfeeley@putman.net

EXECUTIVE EDITOR

JIM MONTAGUE

jmontague@putman.net

AARON HAND

ahand@putman.net

MANAGING EDITOR, DIGITAL MEDIA

on how to minimize the risks of

and Don Segal, attorney at law,

product liability.

Segal, McCambridge, Singer and

No. 1, know the rules about how

Mahoney, discussed the liability

you build your products and how

potentials when man—and law-

you build them safely and comply

yer—meets machine.

with standards. “It’s tricky, particularly here in the U.S., because

the murkiness of these issues. “I

there are issues about what sorts

SARAH CECHOWSKI

scechowski@putman.net

have machines in the field, built

of rules apply,” Ballesteros admit-

to the standards at that time, and

ted. “So one common denominator

grandfathered in as OK, but the

that is effective is to follow the

standards have changed and so

engineering standards associated

there now are a few elements in the

with machine building and prod-

changes that could improve things.

uct manufacturing.”

SENIOR TECHNICAL EDITOR

DAN HEBERT

dhebert@putman.net

LORI GOLDBERG

lgoldberg@putman.net

COLUMNIST

JEREMY POLLARD

jpollard@tsuonline.com

If you go ahead and do what’s right

Proper warning is also a key

in new design elements and field

element. “There’s not a product

DESIGN/PRODUCTION

changes, are you liable for every-

liability case in which the issue of

SENIOR PRODUCTION MANAGER

thing that’s out there?”

ANETTA GAUTHIER

ART DIRECTOR

This issue, said the lawyers,

DEREK CHAMBERLAIN

can demonstrate that sometimes

SUBSCRIPTIONS

the law actually displays some

CUSTOMER SERVICE

common sense. “It often fits the

888/644-1803

CIRCULATION

AUDITED JUNE 2011

Air & Gas Compressors

872

Engineering & Systems

Integration Services

8,472

Engines & Turbines

1,560

Food Products Machinery

1,848

Industrial Fans, Blowers

& Air Purification Equipment

719

Industrial Heating, Refrigeration

& Air Conditioning Equipment

1,377

Industrial Process Furnaces & Ovens

928

Machine Tools

5,622

Materials Handling, Conveyors

& Conveying Equipment

1,595

Metalworking Machinery

3,866

Mining Machinery & Equipment

699

Oil & Gas Field Machinery & Equipment 1,254

Packaging Machinery

929

Paper Industries Machinery

405

Printing Trades Machinery & Equipment 506

Pumps & Pumping Equipment

927

Rolling Mill Machinery & Equipment

210

Semiconductor Manufacturing

Machinery

1,211

Textile Machinery

242

Woodworking Machinery

308

Other Industries & Special Industrial

Machinery & Equipment NEC

6,470

TOTAL

40,020

jfeeley@putman.net

EDITORIAL ASSISTANT

t

ASSOCIATE EDITOR, DIGITAL MEDIA

editor in chief

An audience question recognized

t

KATHERINE BONFANTE

kbonfante@putman.net

The presenters offered advice

dent, law, Rockwell Automation;

Joe Feeley

MANAGING EDITOR

Gary Ballesteros, vice presi-

EDITOR’S PAGE

controldesign.com

“There’s not a product

liability case in which the

issue of warnings doesn’t

come up.”

criteria for making what’s known

as ‘subsequent remedial mea-

warnings doesn’t come up,” Balles-

sures’ that the courts recognize

teros said. “It’s an area where you

as a well-intended improvement,

want to have good expert advice.”

and can’t be used to prove what I

Refining the quest for expert

did before was wrong,” Ballesteros

help, Ballesteros added, “It’s the

said. “If the law of common sense

‘Goldilocks and the Three Bears’

says it’s the right thing to do

advice. Not too much, not too

today, and even if you implement

little; you have to get it just right.”

it only partially because it’s not

The presenters identified some

economically feasible to do it all,

due diligence items that help with

how can that be a bad thing?”

hazard analysis, although one of

Ballesteros reminded the audi-

them is a double-edged sword.

ence, many of whom identified

“Look at what competitors do,

themselves as engineers, that

but don’t assume that they are

the law understands who knows

smarter than you. It’s a useful

about these issues the best. “The

touch point, that’s all.”

law follows you engineers on

this,” he said. “I can’t think of any

state that hasn’t incorporated the

National Electrical Code as law.

February 2012 Control Design

9

Brad

Bundled

Automation

Solutions

®

WHAT WE BRING TOGETHER

IS WHAT SETS US APART

You’re looking for proven solutions for your automation requirements. Distribution boxes. Gateways.

Network I/Os. Or modular wiring systems. We

provide a complete suite of Brad automation products for connectivity, communications, control and

www.molex.com/brad/cd

power. All bundled together to deliver the right solutions for your needs every time. With us, you know

you’re getting products known for their innovative

designs, reliability in harsh environments and worldwide reputation for setting the standard.

Pick Right, and Service Is Free

customers lower their total automation spend,

charge for technical support? Do you think this

while also being able to quickly troubleshoot.

service should be free, or at least built into the

We work hard to maintain a very efficient

cost of the original product? If so, read on and find

business model, so we can offer not only free

out how to get free service.

support, but also detailed documentation and

Before you get too excited, we’re talking about

free technical support here, and not about free

online learning tools.”

Another company that offers free technical

engineering services. The line between technical

phone support is Opto 22 (www.opto22.com),

support and engineering services can be blurry,

and it throws in free software and training as

but you probably know when you’re about to

well. “Our control programming software is

cross it, as do most automation suppliers that

available as a free download,” says Tom Ed-

you’re dealing with.

wards, senior technical advisor at Opto 22.

“Beyond our standard and free product sup-

“Another free piece of software lets OEMs run

the strategies they’ve created in an environment

services,” notes Ron Baysinger, market develop-

that simulates an actual controller. We also

ment manager for control and industry solu-

provide no-charge hardware and software train-

tions at Phoenix Contact (www.phoenixcontact.

ing at our corporate headquarters in Southern

com). “These instances include custom applica-

California. This consists of a three-day class in

tion support, complex solution integration and

which we cover configuration, networking, diag-

on-site service.”

nostics and troubleshooting.”

Many software suppliers charge for service,

ucts, but you should be able to judge upfront if

typically via annual licensing fees, but there are

prices are fair. “Some of the cost of free phone

exceptions.

but it’s Delta’s view that providing good service

is an investment that promotes good long-term

customer relations,” says Bill Savela, market-

t

dhebert@putman.net

ing director at Delta Computer Systems (www.

In theory, the best prices are offered

by firms that provide no service, or

by those that charge for service. In

practice, this isn’t the case.

deltamotion.com).

In theory, the best prices are offered by com-

“Support shouldn’t be a profit center for the

panies that provide no service, or by those that

supplier,” asserts Marcia Gadbois, president of

charge for service. In practice, this isn’t the case.

InduSoft (www.indusoft.com).

Almost all automation firms feel compelled by

“Support needs vary among our customers,

machine builder, robot builder and process skid

but what never changes is the need for knowl-

builder OEMs to offer service—albeit at varying

edgeable support staff familiar with every

levels of quality and price.

aspect of the software,” Gadbois adds. “It’s not

In the traditional automation sales model, the

only the availability of the support that matters

local distributor provides free service, with the

to customers, but the quality. In order to guar-

vendor providing backup assistance, often for a

antee service to all who need it, we maintain

fee. For those vendors using a different distribu-

a network of exceptional support team mem-

tion model, service could be free.

bers, and we’re able to offer free support during

“Our direct-sales model means we don’t have

normal business hours, as well as a paid option

field personnel, so free telephone support is

for 24/7 support. The fee for 24/7 assistance is

critical,” says Stewart Terhorst, member of a

intended to cover time and labor, rather than to

business development team at AutomationDi-

generate profit.”

rect (www.automationdirect.com). “We consider

Price and performance are key drivers when

this part of our responsibility to our custom-

purchasing automation components, and service

ers, as it helps them get the most out of our

is becoming a driver, too, particularly as OEMs

products. Our free technical support helps our

learn to run leaner.

controldesign.com

February 2012 Control Design

senior technical editor

service is built into the price of the products,

t

Free service often means higher-cost prod-

Dan Hebert, PE

port, there are instances requiring billable

MACHINE BUILDER MOJO

DOES IT ANNOY you when automation suppliers

11

WE DIDN’T INVENT

CONTROL,

WE’RE

PERFECTING IT.

Since 1976, c3controls has been perfecting the

engineering, manufacturing, and delivery of

electrical control products with a single goal in

mind—to far exceed your expectations.

c3controls Series DS leads the way offering a wide

range of non-fused disconnect switches, certified

as manual motor controllers—delivering superior

performance in the most demanding applications.

We make it easy—one part number includes handle,

shaft, and base, all shipped same-day guaranteed.

By keeping it simple you, the OEM, are provided

with an ever expanding opportunity to gain greater

control of your business.

What would you do with more control?

Go now to c3controls.com/DS to learn more

and receive a special offer.

LIFETIME WARRANTY

GUARANTEED SAME-DAY SHIPPING

FACTORY DIRECT PRICING

Check out our amazing

Disconnect Switch offer.

800.560.8560 ∙ www.c3controls.com

Find and Foster Innovation

tions, and never get anything to work,” Stoltz says.

competition. Key to the competition was innova-

“You get all sorts of things that you need to deal

tive thinking. They had to develop an innovative

with. There are cultural differences. Some people

idea related to food safety. They also had to come

speak up, and some are more aggressive. But that

up with innovative ways to capture points on the

doesn’t mean that one’s more innovative than

playing field with their robot. But what exactly

another. You have to get all things out in the air. All

qualifies as “innovative” and, more importantly,

ideas are okay without judgment or exclusions. You

how should we—whether FLL coaches or engi-

have to be able to shield the innovative people.”

We hear a lot about innovation. There seemed

Promoting innovation within a group has a lot to

do with choosing the right combination of people,

culture. “Whether the company believes in stan-

address last month, U.S. President Barack Obama

dardization, keeping things the same, or there’s an

mentioned innovation repeatedly, even saying, “In-

openness from management to try new things and

novation is what America has always been about.”

sometimes fail—the effect of innovation or not is

But what’s the best way to “promote” innova-

very strongly linked to company culture.”

tion? Working with the 9- and 10-year-olds to

PopTech (www.poptech.org) is a non-profit

come up with innovative ideas, I and the other

organization that tries to promote innovation by

coaches struggled with the best way to help the

bringing innovators together from many different

kids move in the right (“right”) direction without

fields. One recent find came from 13-year-old Aidan

simply coming up with the ideas ourselves.

Dwyer, who won a national science competition for

It was hard to keep the young kids on task. One

or two of the youngsters had a tendency to come

up with ideas that were so far in left field, they

could never be achieved. Our one fifth grader was

quick to shoot down any idea that anyone else

Promoting innovation within a group

has a lot to do with choosing the right

combination of people, but it also has

to do with company culture.

had, arguing that it wouldn’t work or that wasn’t

how it had been done in the past. Neither sce-

his research showing that solar panels arranged

nario got us headed in the right direction.

like leaves on a tree collect sunlight 20-50% more ef-

I chalked it up to the hazards of working with

such a young group of kids, but the innovation

process isn’t so different for machine builders in the

ficiently than traditional solar arrays. Dwyer spoke

at PopTech’s recent gathering of innovators.

What struck me most about Dwyer was his de-

real world, according to Hendrik Stoltz, director of

termination to continue to innovate and improve

Elopak Equipment Supply (www.elopak.com) in New

on his design despite those who seemed to want

Hudson, Mich. Elopak makes equipment to package

to squash his spirit. “The lesson that I learned is

yogurt and other liquid foods, so I got in touch with

that sometimes the Internet is not a substitute for

Stoltz to run our innovation project by him (which

peer review,” Dwyer quipped at PopTech.

used temperature-sensitive ink to show whether

Dwyer is continuing his research. “I’ve been

packaged yogurt had been compromised by rising

asked to work at the Resilience Research Center in

above refrigeration temperatures while in transit).

Madison, Wis., to design Fibonacci arrays that mid-

Not only did Stoltz say his company had consid-

dle school students can use for research,” he said.

ered a similar solution themselves for measuring

“I’m also collaborating with a professor of design at

whether the “cold chain” had been broken, but

Purdue University to create a Fibonacci array that

he said that any innovation team typically faces

combines technology with functional art.”

similar problems, depending on the personalities

What’s the best way to teach people how to keep

involved. Not everybody is a good fit for an innova-

moving ahead with their ideas—or when it’s time

tion group. “Sometimes you have people who say,

to give up and move on to the next idea?

controldesign.com

February 2012 Control Design

13

ahand@putman.net

but Stoltz says it also has to do with company

Steve Jobs died in October. In his State of the Union

t

to be no end to the discussion when Apple founder

managing editor

neering leaders—promote and foster innovation?

t

somebody might come up with 10 different solu-

graders preparing for FIRST Lego League (FLL)

Aaron Hand

‘It won’t work. It won’t work.’ But on the other side,

LIVE WIRE

IF YOU WERE anywhere near me last fall, you

would’ve heard little else besides talk of fourth

For decades, ABB variable speed drives and Baldor

motors have set the standard for quality, reliability and

energy savings. Now, industrial customers in the U.S.

can buy these products and receive expert support

from a single source. Call 479-646-4711 to locate the

district office nearest you.

Two trusted names. One local source for sales and

support. Only from ABB and Baldor.

baldor.com

©2011 Baldor Electric Company

Local Sales & Support

Energy Efficiency

Industrial Motors & Drives

Unmatched Customer Service

Scan with your smartphone to watch a

motor and drive energy efficiency video

or go to http://bit.ly/mSM0JV.

Candymaker Combines, Simplifies Controls

OEM SPOTLIGHT

Cama Handles Chocolates With an Integrated Approach That Needs

Only One Controller for Three Delta Robots

CHOCOLATES MIGHT NOT

seem especially delicate, but

that’s only because human

hands are still unappreciated

miracles of material handling.

However, even with a sophisticated packaging machine,

such confections are marked up

CAMA GROUP

or deformed easily. To ensure

gentle handling, machine builders often use delta-type robots

because they can pick up products precisely without interrupting production.

One of these is Cama Group

(www.camagroup.com) in

OF ONE MIND

Cama’s compact loading unit combines three delta robots under one

controller, enabling high-speed chocolate sorting.

Lecco, Italy, near Lake Como,

which has been manufacturing

sign team has 30 engineers who

unit with three integrated delta

individual machines and com-

collaborate with customers to

robots allows us to achieve the

plete robotic production lines

design the most appropriate

speed our customer needed,”

for the secondary packaging

and cost-effective machine or

says Daniele Bellante, Cama’s

industry for 30 years. Its robotic

line that will produce the best

CEO. “And we saved consider-

packaging lines are used for

quality, most attractive pack-

able space when compared to

handling primary packaging,

age for their product with the

a solution consisting of delta

such as pouches, cups, cans

least wasted material.

robots connected in series,

and other containers in applica-

To meet requests for simpler

each with its own control

tions from picking through to

and better coordinated robots

cabinet.” Besides using fewer

palletizing foods, cosmetics

and controls, Cama’s packaging

robot controllers, Bellante

and other consumer products.

and robotics divisions recently

adds, Cama also implemented

collaborated to build a loading

modular, dual-axis drives from

veteran Paolo Bellante in

machine that can employ up to

Bosch, which reduced cabling

1981, Cama is now run by his

four of its delta-type Triaflex

up to 40%, cut the machine’s

children, Daniele and Annalisa,

robots. Instead of using one

footprint in half, and shrank

who joined the family business

controller per robot, Cama was

the control cabinet by 40%.

in 1994. They continued their

able to integrate them all and

father’s mission after he died of

perform load balancing with

can control up to 16 kinemat-

cancer in 2004, but they’ve also

just one of Bosch Rexroth’s

ics simultaneously, each with a

remodeled the firm to meet

combined motion logic and

maximum of eight interpolating

customers’ needs in the future.

robotic control units. Because

axes and up to four synchronous

one Triaflex robot can run at

belts, Cama’s loader doesn’t re-

build about 150 machines and

120 cycles per minute and a

quire the usual communication

40 integrated packaging lines

“multi-picks” gripper system

interfaces between individual

per year for candy and bak-

allows simultaneous picking of

robot controls that traditionally

ing companies worldwide, but

several products, Cama’s load-

are needed to ensure transmis-

mostly in the U.K. and France.

ing machine can handle up to

sion of camera system informa-

Because every application is

300 products per minute.

tion and to coordinate robot

Founded by cartoning

The company’s 130 staffers

different, Cama reports, its decontroldesign.com

“Our new compact loading

Because its single controller

units to prevent collisions.

February 2012 Control Design

15

INDISCRETE

Manufacturing Technology Orders Up 74%

THOUGH ORDERS FELL

machine orders, which totaled

in metal cutting equipment

almost 28% from 2011’s high in

about $372 million, have fallen

was countered by acceleration

September, U.S. manufacturing

more than 13% since October,

in the fabricating sector, and

technology orders in Novem-

and more than 31% since Sep-

contributed to an increase over

ber reached more than $430

tember. Orders for metal forming

2010 of nearly 75%. Backlogs for

million, which was up almost

and fabricating machines actu-

2012 are very healthy at this

27% compared with November

ally rose in November, however,

point and growing longer.”

2010, according to the Ameri-

to almost $58 million. That’s up

can Machine Tool Distributors’

72% from October. That sector

USMTO showed that all U.S. re-

Assn. (AMTDA) and the Assn.

hit its high in July with nearly

gions fell in November orders,

for Manufacturing Technology

$105 million in orders.

with the Western region hit the

Reporting regionally, the

hardest with a 14.6% drop from

(AMT). Year-to-date orders total

“Manufacturing technol-

close to $5 billion, up about 74%

ogy orders slowed slightly in

October. But the region is up

over the same period in 2010.

November, but maintained

34.3% from November 2010. The

The numbers are based on

their sprint toward the 2011

Northeast region fell the least

data reported by companies

finish line thanks to the bonus

in November, down just 1.8%

participating in the U.S. Manu-

depreciation tax incentive,”

from October, but also down by

facturing Technology Orders

said Peter Borden, AMTDA’s

nearly the same amount from

(USMTO) program. Metal cutting

president. “The order slowdown

November a year ago.

U.S. Manufacturing Technology Orders

$M

$700

$600

$500

$400

$300

$200

$100

$0

Nov-10

Dec-10

Jan-11

Feb-11

Mar-11

Apr-11

Metal Cutting Machines

May-11

Jun-11

Jul-11

Aug-11

Sep-11

Oct-11

Nov-11

Metal Forming & Fabricating Machines

YEAR-OVER-YEAR RISE

Orders for metal forming and fabricating machines hit their high in July, but metal cutting machines, making up the

bulk of manufacturing technology orders, reached their peak in September.

PLCs Make Speedy Recovery

GLOBAL REVENUES from PLCs were nearly 30%

levels to occur until 2013. PLC business was back on

higher in 2010 than they were in 2009, reaching

track three years earlier than expected, however; in

more than $8 billion, according to a 2011 edition

some countries in developing regions, such as China

of IMS Research’s PLC report. This indicates a re-

and India, revenues grew even in 2009.

covery from the downturn that came much earlier

“Although the recovery was unexpected, it

than had been generally expected. Growth contin-

is not hard to explain,” said Alex Hong, market

ued in 2011, though at a lower rate than in 2010.

research analyst in IMS Research’s industrial fac-

After the economic crisis of 2009, most PLC suppli-

tory automation group. “The demand for automa-

ers had been pessimistic about the returning growth

tion products in many ongoing projects stagnated

of their business, not expecting recoveries to 2008

16

Control Design February 2012

continued on page 20

controldesign.com

©2012 Siemens Industry, Inc.

SIMATIC HMI Comfort Panels

Brilliant – Intelligent – Practical

SIMATIC HMI Comfort Panels provide universal high-end

IXQFW

LRQDOLW

\ Z LW

K μWR μK LJK UHVROX

W

LRQZ LGHVFUHHQ

displays that can be optimally adapted to any application.

%ULOOLD

QW P LOOLR

QF RORUG LVSOD

\ VZ LW

K/ ( ' E DFNOLJKW

UHYHDO

crisp images and graphics and also provide up to 40% more

screen area than comparable 4:3 displays, allowing

information and controls on each screen.

6LHP HQV¶E HVWLQFOD

VVG HVLJQI HDW

XUHVD UXJ J HGF DVW

aluminum bezel for installations that require the highest

level of durability.

Open communications are accomplished by an

LQW

HJ UDW

HGWZ RS RUW

3 52 ) ,1 ( 7VZ LW

FKD QGD 3 52 ) ,%86VHULDO

port with both supporting additional third party

communication drivers. Information availability is ensured

ZKHQGDWDORJVDODUPDUFKLYHVDQGRWKHUÀOHVDUHVWRUHG

RQVW

DQGDUGP HP RU\ G HYLFHVE \ X W

LOL]

LQJ 8 6%3 RUW

VR U6 '

memory card slots. In case of device damage the

DSSOLF

DW

LRQF DQE HT XLFNO\UHVW

RUHGWRD UHSOD

FHP HQW

G HYLFH

YLD6 ' 0 HP RU\ F DUGG UDVW

LFDOO\

UHGXFLQJ G RZ QW

LP H

The device family incorporates versions for practical

RSHUDWLRQYLDWRXFKVFUHHQRUIUHHO\FRQÀJXUDEOHWDFWLOH

NH\ V 6 ,0 $7,&+ 0 ,& RP IRUW

3 DQHOV

P DNHX VHR ID OOW

KH

DGYDQW

DJ HVR I3 52 ) ,1 ( 7 WKH( W

KHUQHW

VW

DQGDUGI RU

automation, and support PROFIenergy. The new panels are

HQJ LQHHUHGZ LW

K6 ,0 $7,&: LQ&&9 Z KLFKF DQE HLQVW

DOOH

G

stand-alone or seamlessly integrated into the new

HQJ LQHHULQJ I UDP HZ RUN7 RW

DOO\

, QW

HJ UDW

HG$ XW

RP DW

LRQ

(TIA) Portal.

There is an ideal solution available for any applications thanks to

the integrated functionality of the SIMATIC HMI Comfort Panels

with different display sizes from 4” to 12”.

www.usa.siemens.com/comfort-panels

FLASHBACK 1997-2012

Feb. 9, 1997: “The Simpsons” became the

longest-running prime-time animated series.

“The Flintstones” held the record previously.

Feb. 13, 1997: Astronauts on the space shuttle Discovery brought

the Hubble Space Telescope aboard for a tuneup, enabling the

telescope to see further into the universe.

Feb. 22, 1997: Scottish scientist Ian Wilmut and colleagues

announced that an adult sheep had been successfully cloned.

Dolly, who had been born July 5, 1996, was the first mammal to

have been successfully cloned from an adult cell.

Feb. 10, 1998: A man became the first to be convicted

of committing a hate crime in cyberspace. The college

dropout had emailed threats to Asian students.

Feb. 27, 1999: Colin Prescot and Andy Elson set a new hot air

balloon endurance record when they had been aloft for 233 hours

and 55 minutes in an attempt to circumnavigate the Earth.

Feb. 7, 2000: California’s legislature declared that

Feb. 13 would be Charles M. Schulz Day. Schulz died

Feb. 12, 2000, and his last original Sunday “Peanuts”

comic strip appeared in newspapers the next day.

Feb. 11, 2000: The space shuttle Endeavor took off to gather

information for the most detailed map of Earth ever made.

Feb. 12, 2001: The space probe NEAR landed on the asteroid Eros,

marking the first time any craft had landed on a small space rock.

Feb. 15, 2002: Honda’s Asimo humanoid robot rang the opening

bell at the New York Stock Exchange.

Feb. 19, 2002: NASA’s Mars Odyssey spacecraft began using its

thermal emission imaging system to map Mars.

Feb. 1, 2003: NASA’s space shuttle Columbia

exploded while re-entering the Earth’s atmosphere.

All seven astronauts on board were killed.

Feb. 10, 2005: North Korea publicly announced for the first time

that it had nuclear arms. The country also rejected attempts to

restart disarmament talks in the near future, saying that it needed

the weapons as protection against an increasingly hostile U.S.

Feb. 14, 2005: YouTube was born when three former PayPal

employees started a website that let people upload and share

videos.

Feb. 16, 2005: The Kyoto global warming pact went into effect in

140 nations.

Feb. 10, 2009: Russian and American

satellites collided over Siberia.

18

Control Design February 2012

controldesign.com

Raise Your Industry Standards

Honeywell Sensing and Control offers cutting-edge products

for every industry to enhance precision, increase productivity,

and improve the performance of your design.

MICRO SWITCH™ Toggle Switch

Rugged and dependable, these

sealed and unsealed offerings

provide exceptional reliability.

Wireless Global Limit Switch

New, cost-saving alternative to use without

limitations of traditional tethered devices or

where wiring is physically difficult.

MICRO SWITCH™ Heavy Duty

Limit Switch

Unique all-metal drive train for

superior durability even in the most

extreme environmental conditions.

TruStability™ Board Mounted

Pressure Sensor

Industry-leading stability with analog

or digital output measuring absolute,

differential and gage pressures.

Get your total Honeywell solution

@ alliedelec.com/honeywellsc

THINK ALLIED

SM

1.800.433.5700

© Allied Electronics, Inc 2012. ‘Allied Electronics’ and the Allied Electronics logo are trademarks of Allied Electronics, Inc.

An Electrocomponents Company.

when investment funding dried

The customers for PLC manu-

restart of projects discontinued

up in the economic downturn.

facturers, mostly builders or

in 2009 and the start of new ones

However, government econom-

users of industrial machinery,

contributed to the high growth

ic stimulus in several countries

had more access to funding to

of the PLC market in 2010.

helped to make money more

purchase more PLCs and other

available at different levels of

automation products to continue

mained high in 2011, though

industry.”

with their projects. Both the

industrial markets differed by

Global PLC revenues re-

region. In Europe, despite the

continuing and worsening Eurozone sovereign debt crisis, Germany (the most important market for industrial automation

products) continued to grow at

a healthy rate. In the Americas,

large projects from some end

users and growing domestic

demand enabled the PLC market

to grow, though the market in

Latin America is still underdeveloped. In Asia, the markets in

the growing economies of China

and India have performed quite

well, though that of Japan was

affected by the earthquake ear-

Together, we can eliminate downtime,

reduce development time and get you

to your tee time.

lier in the year. In general, the

growth of the global economy

in 2011 underpinned the global

growth of the PC market.

PLC suppliers and their

industrial customers are uncertain whether growth will

Try Parker’s Xpress and experience the benefits

of the first truly integrated family of machine

control solutions:

• SCADA

• Motion Control

• Machine HMI

• Ethernet-based Servos

• Machine Control • Smart Motors

So go ahead — focus on your ROI and time to market, and

we’ll take care of making sure it all works together seamlessly.

continue into 2012. Many factors—including Europe’s unresolved sovereign debt crisis,

tightening economic policy in

China, and the consequences

of the earthquake in Japan and

the recent floods in Thailand—

are affecting the market.

IMS Research contends that

the PLC market will continue to

grow in 2012, mainly because

many large and important PLC

markets, such as Germany,

France, China and the U.S., are

still performing well. In addition, emerging markets, such as

1 800 358-9068

www.parker.com

Brazil and India, which already

account for half the entire PLC

market, will be the main driving

force for future growth.

controldesign.com

MERGERS, ACQUISITIONS

& ALLIANCES

ABB (www.abb.com) will acquire Thomas &

Betts (www.tnb.com) for about $3.9 billion. The

complementary combination of Thomas & Betts’

electrical components and ABB’s low-voltage

protection, control and measurement products will

create a broader low-voltage portfolio.

Mersen (www.mersen.com) acquired Eldre (www.

busbar.com), adding laminated busbars to Mersen’s

existing range of fuses and cooling products for power

electronics applications.

Linear Technology (www.linear.com) acquired Dust

Networks (www.dustnetworks.com), which provides

low-power wireless sensor network technology.

ATEX II3G

IECEx

Cost optimized

DIN-rail

power supplies

in compact rugged metal case

for harsh industrial environment.

International safety approval package

NOTEWORTHY

The umbrella trade association for the Robotic

Industries Assn. (RIA, www.robotics.org), AIA

(formerly Automated Imaging Assn., www.

visiononline.org), and the Motion Control Assn. (MCA,

www.motioncontrolonline.org) changed its name from

the Automation Technologies Council to the Assn. for

Advancing Automation (A3).

WinSystems (www.winsystems.com), which designs

and manufactures industry-standard PC/104, EPIC, EBX,

SUMIT-ISM and STD Bus computer boards, I/O modules,

and enclosures for use by OEMs and system integrators,

celebrates its 30th anniversary this year. In 2007,

WinSystems became an employee-owned company.

TSP-3P Series

240 – 960 Watt

for 3-phase power systems

• Low cost-weight-size

alternative to 3-phase transformers

• Input voltage ranges: 3 AC 320 – 440 V or 400 – 550V

• 200 % boost power for motors, valves,

solenoids and other short peak loads

• Power-back immunity

PLCopen Extends

Motion Control Spec

and over-temperature protection

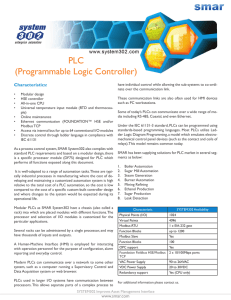

THE SUITE OF PLCopen Motion Control Specifications

has been extended with the release of Part 5 and Part

6. The organization released version 2.0 of the basic

specification, and also extended the suite of functionalities to new areas such as homing procedures and

fluid power. The new specifications can be downloaded at www.plcopen.org.

Part 5 enables users to create their dedicated homing procedures by combining harmonized functionalities. The release of Part 6 adds fluid power as an

application, making the PLCopen Motion Control easy

TSPC Series

80 – 480 Watt

for single phase power systems

• Vibration and shock proof

• Optional decoupling module

• Overload and over-temperature protection

to use in hydraulics. It also enables the merge in the

software environments of electrical and hydraulic

www.tracopower.com

systems, providing a harmonized look and feel.

controldesign.com

ALLIED ELECTRONICS 800-433-5700 www.alliedelec.com

POWERGATE LLC 866-588-1750 www.powergatellc.com

Power Sources Unlimited 800-966-7784 www.psui.com/traco

Tough Application

Ingenious Solution

Exactly

Mastering challenges together — Rexroth makes it easy to implement automation.

Our many years’ experience in a wide range of industries has given us extensive application

knowledge. We offer this comprehensive understanding to the tasks you bring us, leading

to ingenious solutions.

Regardless of the drive technology used, we thought ahead and integrated intelligence

throughout. This consistency makes you more efficient — from planning to start-up and

daily operation. Your benefits are real: Increased productivity, improved energy efficiency

and maximum machine safety. You can count on Rexroth to have the appropriate drive and

control solution to meet your needs exactly.

Bosch Rexroth Corporation

www.boschrexroth-us.com

Software Guy, Know Thy Limits

I configured the array from scratch, and put in a

second drive, and it needed verifying. Three hours

better monitor that system. Now, here’s a story

later, it was done and I rebooted. “Recovering er-

about education, tools and resources regarding

rors,” it said. Cool, until it finished and the “boot

servers and server-based functions.

sector error” message popped up. More reading.

A server-based operating system is not a

Again, starting from scratch with both drives

workstation OS like Windows XP or Windows 7.

and using the IBM ServerGuide install disk, I

Windows 2000 server and desktop systems used

created the array with Windows 2000 server.

the same files and structure. A simple registry

I discovered that IBM also has a tool called

switch can change them back and forth. Windows

ServeRAID. Where have you been all my server

2003/2008 are entirely server-based and provide

life? Now things were coming into focus. With

server functionality such as Active Directory, user

this interface you readily can see what the drives

management, and file and web services, along

were and what they were doing, and when you

with functions such as RAID.

put in a second drive to fix a broken one, and it is

Now, I’m a software guy. My customer needed

RAID drive controllers for redundant data. No

not configured, it tells you.

So I installed it on XP. Oops, again. It’s only for

server platforms. I found some drivers for XP, but I

CD that makes this a breeze, and Windows 2000

couldn’t get it to work. After three and a half weeks,

server was put on the machine.

I had put way too much into this, but I learned a lot.

It was decided later to use Windows XP for

Sometimes we know enough to be dangerous. The backup server was running different

based OS, and certain drivers are designed for

software for a SQL database application, which I

server use and some are not.

needed to virtualize. I ripped out one of the drives

jpollard@tsuonline.com

Some RAID drivers are not. The customer

wanted redundant server hardware so that in

case of a failure, the RAID drives could be moved

from one server to another. It’s not as easy as you

might think.

The first thing I learned was that setting up

The first thing I learned was

that setting up RAID in the SCSI

BIOS is not the same as using a

software-based interface.

RAID in the SCSI BIOS is not the same as using

to take home and extract the image. I put in the

a software-based interface. Drive initialization,

spare drive. Wasn’t configured! The drive lights

array configuration and verification can be done.

were flashing in a very strange way. I took out the

Allocating a drive as a hot spare? I have to tell the

recently inserted drive and replaced it with the

system I have put a drive in? And that it was a

original. So I took the whole server home from

spare? Tried that, and it blew up the original array

my customer’s site to get the image. I screwed up

and the data. Oops.

both drives, since neither would boot. After more

More reading. When a drive is configured as

reading, I found Bart’s PE bootable recovery CD.

a simple volume disk (like a workstation disk),

The registry was messed up on both drives, and I

there is no RAID information written on the disk.

had to fix it. That was three days all on its own.

Oh, there’s information written to the disk? Ap-

There is a fine line between tenacity and

parently, and it is serialized to the machine and

stupidity. I crossed that line many times, but

drive controller so you can’t simply transfer one

learned. It remains to be seen if it was worth it.

drive to another machine.

So I talked to a few IT guys, and searched on rep-

Moral of the story: Stick to your knitting. Laugh

about it when you don’t.

licating server hardware. No one had done it, and

the forums weren’t much help. Trial and error time.

I was to have the backup server in place two

JEREMY POLLARD has been writing about technology and

software issues for many years. Publisher of The Software

days after I took the hardware. Although I wasn’t

User Online, he has been involved in control system

working at it constantly, I was at two weeks now.

programming and training for more than 25 years.

controldesign.com

February 2012 Control Design

t

some terminal services. But XP is not a server-

Jeremy Pollard, CET

problem. IBM server hardware comes with a setup

EMBEDDED INTELLIGENCE

LAST MONTH I WROTE about fixing a network

nightmare. Additional tools now are in place to

23

by Jim

agu e

M o nt

, e xe c

utive

editor

Modular Machines and Production Lines Enable Quick Disconnects and

Speedy Changeovers. This Flexible Approach Inspires Builders to Combine

Modular Equipment in Ever More Innovative Ways

D

sensitive to impurities or oxidization,” says Mike Rice,

be busted up into approachable, workable pieces.

dation Engineering division. “As a result, we now have

Dividing machines, production lines, related equip-

more sequence chambers that must be under vacuum.

ment and accessories into standardized sections and

Users also are applying eight or 10 layers on some

blocks not only simplifies overall system construc-

microprocessors, where they once applied just two or

tion, it more importantly improves their operation by

three, so they need even faster and more precise tools

allowing much quicker changeovers and maintenance

that can complete 20–40 recipes for particular steps.”

ivide and conquer. It’s true in war, and it’s

“Films are getting thinner, and so they’re even more

also good advice for machine building. Any

seemingly insurmountable project often can

vice president and general manager of Applied’s Foun-

for increased throughput.

Three to nine reactors usually are arranged around

Applied’s Endura mainframe, and they carry out many

Extreme Thin Film

of the intra-tool, sequential processing steps required

For instance, 20 nm geometries and fi lm

to manufacture semiconductor chips, especially those

depositions that are just two to four

recent years, these mainframe and reactor modules

tor manufacturers to combine more

have been designed to conform to increasingly strict

process steps in a vacuum environment. Consequently, Applied Materials (www.appliedmaterials.com) in

Santa Clara, Calif., is hooking up

and pumping the air out of more

of its wafer-handling mainframe

chambers, robotic interfaces

and 40 different reactor units.

24

that can’t be exposed to atmosphere (Figure 1). In

atomic layers thick push semiconduc-

Control Design February 2012

mechanical, electrical and software standards, so any

chamber can be located next to any other. This uniformity is crucial because Applied Materials typically

ships wafer-handling machines just a month after

they’re ordered, and then assembles and has them

running a month after delivery.

Many aspects of modular machine building are

enabled by fieldbuses and Ethernet flavors of networkcontroldesign.com

ing that simplify cabling by replacing former

tions,” says John Dillon, division president of

point-to-point wiring, and by servo motors,

control solutions at Wynright (www.wynright.

amplifiers, drives and controls that remove

com) in Elk Grove Village, Ill., which operates

much of the traditional need for dedicated and

its Automotion (www.automotionconveyors.com)

less flexible cams, chains and belts. However, just as

division in Oak Lawn, Ill. “To gain more flexibility,

it’s crucial to evaluate the need for automation itself,

we developed our AutoRoll+ conveyor that uses

it’s equally important to determine if modularization

motor-driven rollers (MDRs). This technology embeds

will deliver enough return on investment (ROI) for

the conveyor motor in the rollers, so we can localize

individual machines or processes.

both the controller card and power into 5 ft zones

“To us, modularity means starting with a base

in the conveyor. This gives our end users modular

packaging machine and our common bill of materials

conveyor beds that we can program, plug and

(BoM) with standard modules that define standard

play like Legos, and daisy chain in straight and

equipment and parts, and then bringing other BoMs

curved sections. This also creates a highly sus-

into the machine for voltage components, PLC types

tainable solution because they run at 24 V, have

and different stations and options, such as cappers

fewer moving parts, and are inherently safe.”

and film functions,” says Scott Bivens, electrical

Wynright’s AutoRoll+ has two driven roll-

engineering manager at Oystar North America (www.

ers in a 5 ft zone, which are controlled by an

oystar-group.com) in Covington, Ky., and Daven-

enhanced route switch controller (ERSC) card.

port, Iowa. “It’s a lot like building a pizza. With our

This card houses the fi rmware for each section’s

modularity, all our designs, BoMs and programs are

local control and motor commutation to manage

tested and saved until they’re needed. Then, when

incoming power and keep the rollers running at

a particular project order comes along, we can run

consistent speeds.

through a check sheet, and get most of the engineer-

Similarly, detection, measurement and testing

ing in place within eight to 10 hours. Traditional, non-

systems have long been modular because they’re

modular building means just redoing or copy building

usually wheeled up and plugged into machines or

a machine that’s been done before, and then adding or

built into production lines that make everything

subtracting required functions. However, because it’s

from automotive blocks to medical devices. However,

not standardized, copy building can take 24–160 hours

many of these testing devices also are improving

to do the engineering, depending on the project.”

their modularity and speed by establishing simpler

connections and automatic program loading. Uson

Basic Blocks

(www.uson.com) in Houston builds leak-detection

While modular methods help builders design and

and measurement instruments and turnkey leak-

construct their machines, they’re even more beneficial

testing systems, mainly for manufacturers of medi-

to users. For instance, many production lines and mate-

cal devices and automotive parts, which must be

rial-handling systems typically used conveyors in 200 ft

tested individually. These users require more

sections, each with a continuous belt or chain running

capable testers and systems, especially

throughout, and each driven by a 480 V or similar motor.

for detecting pressure decay

“Over the years, we

grew up with old

conveyors that were

oily, dirty and difficult to reuse because

they were customized

for specific applica-

controldesign.com

in their production systems and

fi nished parts.

“In the past 10–12 years, we’ve

been giving our instruments

more flexible tools for testing

a wider variety of shapes, and

adding quick-change-out tooling, so they can be moved faster

between production lines,” says

Joe Pustka, Uson’s technical

support manager. “Previously,

operators had to connect and

disconnect 10–20 color-coded

lines, but now they’re all on one

leak-tight connector manifold,

APPLIED MATERIALS

which saves a lot of time and

increases throughput. This improved modularity helps customers justify buying detectors and

testing systems. When a system

is modular, it’s easier for them to

sell to their management.”

Servos Move Modules

Though many technologies enable

A CHANGE IN ATMOSPHERE

Figure 1: Applied Materials’ Endura semiconductor manufacturing system includes

a central mainframe chamber surrounded by three to nine reactors. More of these

modules must run in a vacuum to prevent impurities from damaging the ever-thinner

film depositions on wafers.

modular machine building and

operations, none are more helpful

double-gripper system, and the

combined motors and drives make

than servo motor and drive sys-

machine is configurable with sev-

it easy to configure our pouch

tems. As servos have grown more

eral tandem filling stations. Each

machine in different ways.”

sophisticated and able to handle

machine uses eight to 16 motion

more varied tasks, they allow

axes to form seals, index pouch

A Soft Modularity

machine builders to deliver more-

material, cut and open pouches,

To handle its own widely varied

capable machines.

grip and pucker them, apply a top

tasks, Jakob Graphic Services

seal, and pick and place them on a

(www.jakob-gmbh.eu) in Pfung-

popular standup pouch contain-

conveyor. As a result, Innopouch

stadt, Germany, developed its

ers, KHS Flexible Packaging (www.

uses a servo and pneumatics-

RC-500J jumbo-roll collator, which

khs.com) in Sarasota, Fla., recently

based system to improve flexibility

uses servo motors and an auto-

developed its Innopouch K-Series

for timing, make changes on the

mation software suite to collate,

form, fill and seal (FFS) machine,

fly, link functions, and speed up

glue, label, fold and cut insurance

which is servo-driven, has electri-

setup and changeover. Previously,

forms, mailers with cut inserts,

cally integrated pneumatics, and

it might take two to four hours to

brochures with or without a fin-

can handle standup and fin-seal

change pouch sizes, but its new

ish, calendars and similar printed

pouches. Because pouches come

servo and pneumatic system takes

products. Its servos and software

in so many sizes and types, KHS

only a few seconds.

allow functions to be easily di-

To help its customers shift to

says, Innopouch’s four models had

“A servo platform, which is

vided up and assigned, such as al-

to be flexible and modular, have

modular in itself, allows us to put

lowing servo-based cutter format

fast setup and changeover times,

that modularity throughout the

adjustments, and even complete

and be easy to expand.

machine,” explains Randy Uebler,

retooling changeovers in just a few

general manager at KHS. “The

seconds. Unlike traditionally rigid

Pouches are handled by a linear,

26

Control Design February 2012

controldesign.com

I DON’T HAVE TIME TO WASTE.

My success is measured by the minute.

I can’t depend on products that aren’t up to my

standards or don’t arrive when I need them.

Failure is not an option.

Fluid automation solutions. Right. Now.

When it comes to fluid control and fluid power, today both original equipment manufacturers and end

users must have the exact products that meet their needs — and their most demanding deadlines.

ASCO Numatics provides tens of thousands of industry-leading valves, air preparation equipment, and

actuation products. These days, we’re also setting records for service and delivery. Examples include

callbacks within 4 hours and onsite technical response within 24 hours, plus shipment of many popular

valves, regulators, and manifolds within 1 to 3 days with our ASCO Today and Numatics Express programs.

Searching for a fluid automation supplier that won’t waste your time? You’re looking at it: ASCO Numatics.

The ASCO Numatics logo is a trademark of Automatic Switch Co. The Emerson logo is a trademark and service mark of Emerson Electric Co. © 2011 ASCO Numatics.

1-800-972-ASCO (2726) | www.asconumatics.com/RightNow | e-mail: info-valve@asco.com

monitors their more and more complex movements.

machines, RC-500J’s use of servo motors means users

“Machines and production lines have been mechan-

are no longer tied down to changing cylinders and

gearwheels to handle different paper formats because

ically modular for many years, but the cabling and

the drive control of the cross cutting or perforating

electronics that ran through them wasn’t modular,”

cylinder now occurs without a shaft.

says Darren Elliott, global technical resource manager

for Rockwell Automation’s (www.rockwellautomation.

Company engineers report that the collator’s primary

design challenge was to ensure that, whatever the

com) OEM Group. “However, as machine builders kept

printing format, its cylinder would allow for variable

driving down costs, they eliminated a lot of point-to-

cut-off formats and easy adjustment of the printed, con-

point wiring by moving to Ethernet, made electronics

tinuous paper webs. For example, the automation suite

and controls more modular, and have used ISA’s S88

supplied by Kollmorgen ensures that a 378 mm calendar

and OMAC’s PackML standards to create control soft-

block is increased by 50 mm during continuous printing,

ware in more modular sections and standalone code

so a common inch format is applied in the process.

for those functions. As all these machines become

“Time-consuming, manual retooling or setup

more modular and data-centric, they’re able to run

measures are a thing of the past thanks to our elec-

more SKUs with minimum energy and scrap. But us-

tronic servo technology,” says Hans-Peter Jakob, sales

ers can’t balance all those KPIs on a clipboard, and so

manager and general manager at Jakob. “Setbacks

software is really modularity’s final frontier.”

Wynright’s Dillon adds, “We began to apply MDR

caused by errors are excluded, and commissioning

technology about 10 years ago, but in just the past

has become a formal procedure.”

couple of years it’s become a mainstream product for

Always Ethernet

us. ControlLogix allows the ERSC cards in each bed to

Two other crucial enablers of modular machine build-

talk to hundreds of others via Ethernet. Previously, all

ing are fieldbus and Ethernet networking, as well as

of the local conveyor control and sensor data had to be

the programming software that determines, runs and

wired back to a PLC. However, we began using Ethernet

REASONS TO BE MODULAR—OR NOT

8IJMFUIFSFBSFNBOZCFOFmUTUPNPEVMBSNBDIJOFCVJMEJOHBOEJUTFGGFDUPOPQFSBUJPOTUIFSFBSFTPNFPCTUBDMFTBOE

QPTTJCMFESBXCBDLTUPP"TBSFTVMUJUTWJUBMUPDPOTJEFSUIFQSPTBOEDPOTBTUIFZSFMBUFUPZPVSNBDIJOFBOEJUTVTFSTBOE

UIFOBOTXFSTPNFJNQPSUBOURVFTUJPOTCFGPSFEFDJEJOHUPVOEFSUBLFBNPEVMBSNBDIJOFSFEFTJHOPSJOTUBMMBUJPO

Pros:

t4JNQMJmFTQIZTJDBMEFTJHOBOEDPOTUSVDUJPO

t3FEVDFTXJSJOH

t*NQSPWFTDPOmHVSBUJPOnFYJCJMJUZ

t4QFFETVQDIBOHFPWFST

Cons:

t*ODSFBTFTEFTJHODPNQMFYJUZPGDPOUSPMTBOETPGUXBSF

t"EETIJHIFSJOJUJBMDPTUT

t3FRVJSFTNPSFUSBJOJOHGPSPQFSBUPSTBOEUFDIOJDJBOT

Crucial questions:

t)PXNBOZEJGGFSFOUQSPEVDUTJ[FTBOEQSPEVDUUZQFTXJMM

UIFFOEVTFSSVOBOEIPXGBTUEPFTUIJTOFFEUPIBQQFO

t)PXPGUFOBSFDIBOHFPWFSTQFSGPSNFEBOEIPXDPNQMFY

BSFUIFZUPEP )PXNVDIUJNFDBOCFTBWFEXJUINPEVMBS

FRVJQNFOURVJDLEJTDPOOFDUTBOEQSFQSPHSBNNFE

SFDPOmHVSBUJPOT

28

Control Design February 2012

t)PXNBOZNFDIBOJDBMMJOLBHFTBOEIPXNVDIEFEJDBUFE

DBCMJOHEPFTUIFGPSNFSNBDIJOFQPTTFTT $BOJUCF

TVDDFTTGVMMZBOETBGFMZSFQMBDFEXJUITFSWPNPUPSTBOE

QSPHSBNNBCMFESJWFT

t8IBULJOETPGQPXFSDPOOFDUJPOTQOFVNBUJDMJOFT

DPNNVOJDBUJPOTXJUDIFTBOEPUIFSOFUXPSLJOHBOE

EJTUSJCVUJPODPNQPOFOUTBSFJOUIFFYJTUJOHNBDIJOF $BO

UIFZCFTJNQMJmFEXJUImFMECVTFTBOE&UIFSOFUUPNBLF

RVJDLEJTDPOOFDUVOJUTXPSLBCMF

t*GTQBDFJTBUBQSFNJVNJOUIFVTFSTGBDJMJUZXPVMEJUCF

QPTTJCMFUPSVOUXPPSNPSFQSPEVDUTPOPOFNBDIJOF

JOTUFBEPGUSZJOHUPBEEBTFDPOENBDIJOF

t%PFTUIFBQQMJDBUJPOIBWFFOPVHIQPUFOUJBMWPMVNF

BOEUISPVHIQVUUPCFHBJOFEUPNBLFNPEVMBSJ[BUJPOB

XPSUIXIJMFJOWFTUNFOU

t)PXNVDIUSBJOJOHBSFUIFVTFSTPQFSBUPSTBOE

UFDIOJDJBOTHPJOHUPOFFEUPSVOBOENBJOUBJOUIFJSOFX

NPEVMBSFRVJQNFOUBOETPGUXBSF

controldesign.com

Cube67+

to complement this approach about

can be switched out easily on a ma-

a year ago, and recently went exclu-

chine or production line, but many

sively Ethernet in conjunction with

machine builders don’t stop there,

AutoRoll+, which also reduced

and keep seeking more time-saving

field wiring costs by about 30%.

innovations. This quest even leads

Because we have

some to investigate

more local control

reintegrating some

through the ERSC

modular functions

cards in each zone,

back into their

programming time

machines.

Though it

firmware handles

doesn’t deviate

basic functions

from the basic

such as monitor-

types of machines

does build some plug-and-play

This also creates new possibilities

stations that can be replaced

for real-time diagnostics, such as

quickly with other units on some

the health of the drive rollers.”

of its machines and production

To help builders organize their

lines. Its FP Series 2x6 cup-filling

modular designs, B&R Automation

machine (Figure 2) works with cup

(www.br-automation.com) reports,

de-nesting and drop stations that

its Automation Studio software

have quick-disconnect power and

uses a master project to which

pneumatic lines, so they can usu-

different hardware configura-

ally handle a couple of different

tions and options can be added.

cup diameters.

Likewise, the software’s modular

“A lot of customers want faster

applications section allows several

and even tool-less changeover,”

engineers to develop control code

Bivens says. “These stations peel

at the same time in different sec-

off the bottom cup and drop it into

tions, and link them together with

the machine, but our machines use

predefined interfaces.

chain-driven platens to hold the

B&R has been working with EMT

cups, so different diameters and

Int’l (www.emtinternational.com)

cup materials mean a different in-

in Hobart, Wis., on its year-old

dex pattern and moving the chain

Chameleon modular finishing

to meet the new profile. Nowadays,

machine. It has at least 10 modules

we can authorize index changes

that can be combined in any way

on our HMI. In general, we’re doing

to perforate, cut, web tension,

more electronic changeover with

punch holes, stack and finish

servos when we can, but there are

documents after digital printing.

always a few mechanical changes

All of the modules can be brought

that still need to be made.”

together in Automation Studio,

ÁlKyOBzOMKBJiOiOl_}`zTny

alz}BiiB}anlz½~v}nä

åâkO}Oyz

Ál}O_yB}OM}`OylO}za}K`Tny

daisy chain installations

it builds, Oystar

communications and flow control.

ÁlalKyOBzOMl~kJOynTknM~iOz

- up to 32 on one node

Á"nM~iOzKBlJOalz}BiiOMB}Bl

position on the communication

cable

is reduced as the

ing sensors, motor

The plus stands for increased

]O

aJaia}alMOKOl}yBiaOM

installation technology with

even more modules, longer

cables and higher performance

with...

Though the cup-drop station

and use a PLC to run the motors,

is plug-and-play, Bivens explains

I/O components and other devices.

that the rectangular metal platens

Divide, Then Recombine

ly have one or two rows of 12 holes

It’s both useful and productive to

cut in them to hold the cups before

have standardized equipment that

filling, and so these still must be

in the main filling machine usual-

controldesign.com

February 2012 Control Design

29

1400 Northbrook Parkway, Suite 300

Suwanee, GA 30024

P: 770-497-9292 F: 770-497-9391

murrinc.com

MEASUREMENT

COMPUTING

switched out manually to change

of Novatec’s Resin

cup sizes. However, because many

Systems Controls

users typically run only two sizes

Group. “We used to

of cups, Oystar can mechanically

have just modular

alternate between two platens on

hardware and com-

LOW - COST

DAQ

the same chain in one FP Series

mon equipment,

machine. “This is done by install-

but now we have

ing the two different platens in

modular controls

sequence on the machine, and

and software, and

then phase-shifting the servos, so

so we can organize

Engineered with

Innovation.

each cup size can leapfrog through

and assemble them

the line with its proper platen,” he

to meet any need.”

says. “This option makes FP Series

He estimates that

longer, but both cup sizes can run

Novatec’s modular

on one line instead of perhaps

method saves it

requiring two machines, and its

about 30–40% on labor, while de-

automatic changeover is faster

livering a typical vacuum convey-

than doing it manually.”

ing system takes about one-third

For over 20 years Measurement

Computing has offered quality

DAQ solutions that are not only

priced right, but are engineered to

exceed the needs and expectations

of our customers.

✓ 150 DAQ Products

under $500

✓ Support for Linux ,

®

Windows®, Mac®

✓ Unmatched

Warranties

✓ Free Tech Support

✓ OEM Options

✓ Out-of-the-Box

Software & Drivers

Likewise, Baltimore-based No-

or four weeks now from 10–12

added PLCs from Siemens Industry

weeks before.

(www.usa.siemens.com/industry) to its FlexTouch (FTS) central

Design, Build, Live Modular

control system, and added Profinet

Once modular methods are ad-

I/O controllers to it FlexXpand (FXS)

opted, veteran practitioners report,

expandable control system. These

it becomes a philosophy that goes