Brochure

advertisement

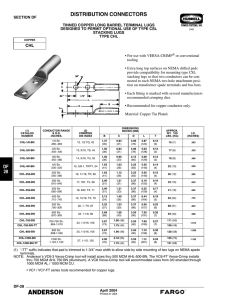

GENERAL USE VISE TYPE ALUMINUM SINGLE BOLT ALUMINUM TO ALUMINUM AND/OR ALUMINUM TO COPPER ALUMINUM GA9000 • Recommended for aluminum or aluminum to copper distribution, service or tap connections. • Add Suffix “G” to catalog number for neoprene grommets for “hot” work. Grommet holds spacer bar in place during installation. • Sealant is recommended on all connectors. • Optional snap-on cover • Optional - Class AA temperature rated per ANSI C119.4 Material: Body—Aluminum alloy Spacer—Aluminum Hardware—Stainless Steel “SS” suffix or Aluminum Alloy (std.) Options: Snap-On Cover (See Column) (B-Suffix) Torque-Head Bolts (Add “O” Suffix) Grommets “G” suffix “L” Inhibitor applied (std.) “AA” - Class AA rated Ex: GA9020GAASSB2 or GA9041GLOB3 construction “G” Grommet Suffix Optional grommet aids in positioning spacer bar for “hotstick” work or assembly. See note below. Product Data & Conductor Size SINGLE BOLT ALUMINUM CONNECTORS CONDUCTOR RANGE CATALOG NUMBER STANDARD CLASS AA RUN MAX. ACSR AL. MIN. ACSR AL. TAP A MAX. MIN. INCHES ACSR AL. or CU. ACSR AL. or CU. (MM) GA9003L** GA9003AA 4 2 Sol. 6 8 Sol. 4 2 Sol. 6 8 Sol. GA9002L** GA9002AA 2 1 Str. 6 6 Sol. 2 1 Str. 6 12 Sol. 1/0 2/0 Str. 6 6 Sol. 1/0 2/0 Str. 6 6 Sol. GA9020LSS** GA9020AASS GA9040L** GA9040AA 4/0 4/0 Str. 2 1 Str. 4/0 4/0 Str. 2 1 Str. GA9041L** GA9041AA 4/0 4/0 Str. 2 1 Str. 2/0 2/0 Str. 6 6 Sol. GA9405L GA9405AA 3/0 3/0 Str. 4 4 Str. – 4 Str. – 12 Sol. GA9400L GA9400AA 336,400 397,500 3/0 4/0 Str. 336,400 397,500 3/0 4/0 Str. GA9401L GA9401AA 336,400 397,500 3/0 4/0 Str. 4/0 266,800 6 6 Sol. GA9842L** GA9842AA 666,000 800,000 4/0 266,800 2/0 2/0 6 6 Sol. GA9843L** GA9843AA 666,000 800,000 4/0 266,800 4/0 4/0 2 1 Str. 7/8 (22.27) 1 1/8 (28.63) 1 1/4 (31.81) 1 1/2 (38.18) 1 1/2 (38.18) 1 1/2 (38.18) 2 1/16 (52.50) 2 1/16 (52.50) 2 (50.90) 2 (50.90) B INCHES (MM) 1 1/4 (31.81) 1 7/8 (47.72) 1 7/8 (47.72) 2 3/4 (69.99) 3 3/8 (85.89) 1 7/8 (47.72) 3 1/2 (89.08) 4 (101.80) 3 5/8 (92.26) 3 5/8 (92.26) INSULATED APPROX. SNAP-ON COVER WT. C EACH INCHES LBS. CATALOG (MM) (KG) NUMBER 1 3/4 (44.54) 2 1/8 (54.08) 2 3/8 (60.44) 3 1/8 (79.53) 3 1/8 (79.53) 2 1/2 (63.63) 3 1/2 (89.08) 3 1/2 (89.08) 3 3/4 (95.44) 3 3/4 (95.44) .17 (.08) .23 (.10) .34 (.15) .55 (.25) .58 (.26) .44 (.20) .78 (.35) .84 (.38) .80 (.36) .88 (.40) 2 1/8 (54.08) 4 3/4 (120.89) 4 3/4 (120.89) .39 (.18) 1.24 (.56) 1.24 (.56) GA9000B2** GA9000B2** GA9000B2** GA9000B3** GA9000B3** GA9000B2** GA9000B3** GA9000B3** GA9000B3** GA9000B3** CONNECTORS FOR SPECIAL APPLICATIONS GA9404L GA9404AA GA9844L GA9954L GA9954AA 4/0 4/0 4 4 Str. – 10 Sol. – 12 Sol. 666,000 800,000 477,000 477,000 336,400 397,500 4/0 266,800 795,000* 954,000 – 795,000 – 336,400 – 1/0 1 1/8 (28.63) 3 (76.35) 3 (76.35) 1 7/8 (47.72) 3 (76.35) 3 (76.35) GA9000B2** GA9000B5** GA9000B5** *795 ACSR 26/7 ** RUS Listed Feature: “G” – Neoprene grommets for “hotstick” work. Soft flexible grommets hold the spacer bar in position for easy installation of the run and tap. The grommets do not interfere with the smooth operation of the connector. ANDERSON™ HUBBELL® POWER SYSTEMS FARGO® AUGUST 2013 DD 1 DB-1 ALUMINUM GA9000 GENERAL USE VISE TYPE, TWO- BOLT EXTENDED RANGE ALUMINUM ALUMINUM TO ALUMINUM AND/OR ALUMINUM TO COPPER • Heavy duty construction for aluminum to aluminum or aluminum to copper conductor connections. • Sealant is recommended for all connections. Material: Body—Aluminum alloy Spacer—Aluminum Hardware—Aluminum Alloy or Stainless steel DD 2 “A” Dimension depends on bolt extension/conductor size opening. “G” Grommet Suffix Optional grommet aids in positioning spacer bar for “hotstick” work or assembly. See note below. GA9000Bx Series Snap-On Cover Product Data & Conductor Size ALUMINUM CONNECTORS FOR ALUMINUM TO ALUMINUM CONDUCTOR RANGE CATALOG NUMBER STANDARD CLASS AA RUN MAX. ACSR AL. TAP MIN. ACSR AL. ACSR MAX. AL. or CU. ACSR MIN. AL. or CU. GA9520GL* GA9520GAA* 477,000 600,000 4/0 4/0 477,000 600,000 4/0 4/0 GA9521GL* GA9521GAA* 477,000 600,000 4/0 250,000 4/0 266,800 4 4 Str. GA9820GL GA9820GAA 795,000† 800,000 336,400 477,000 795,000† 800,000 336,400 477,000 GA9821GL GA9821GAA 795,000† 800,000 336,400 477,000 397,500† 477,000 3/0 4/0 GA9100GL GA9100GAA 1,272,000 1,500,000 636,000 795,000 1,272,000 1,500,000 636,000 795,000 GA9101GL GA9101GAA 1,272,000 1,500,000 636,000 795,000 336,400 336,400 636,000 795,000 APPROX. DIMENSIONS INCHES (MM) (NOMINAL) A B C (MM) (MM) (MM) 4 4 1/4 2 1/2 (101.80) (108.16) (63.63) 4 4 1/4 2 1/2 (101.80) (108.16) (63.63) 5 1/2 4 1/2 2 3/4 (139.98) (114.53) (69.99) 5 1/2 4 1/2 2 3/4 (139.98) (114.53) (69.99) 5 3/4 6 1/4 2 7/8 (146.34) (159.06) (73.17) 5 3/4 6 1/4 2 7/8 (146.34) (159.06) (73.17) APPROX. WT. EACH LBS. (KG) 1.44 (.65) 1.52 (.69) 2.40 (1.09) 2.30 (1.04) 4.50 (2.04) 4.60 (2.09) * For insulated Snap-On Cover – order Catalog No. GA9000B4. † 26/7 ACSR Feature: “G” – Neoprene grommets for “hotstick” work. Soft flexible grommets hold the spacer bar in position for easy installation of the run and tap. The grommets do not interfere with the smooth operation of the connector. AUGUST 2013 ANDERSON™ HUBBELL® POWER SYSTEMS FARGO® GENERAL USE VISE TYPE BRONZE COPPER TO COPPER BRONZE GC5000 SERIES • For copper connections-Splice, Loop deadend or service entrance tap or grounding connections • One piece design for easier, faster installation • Bolt head design for use with standard ratchet wrench • Vise design achieves high connector pressure with low wrench force • Easily installs with live line tools Connector with Torque Head Bolt Material: Body—Copper alloy Hardware—Stainless Steel or Silicon Bronze alloy DD 3 DB-3 Options: Suffix “P” Tin-plated SIDE VIEW TOP VIEW Product Data & Conductor Size CATALOG NUMBER CONDUCTOR RANGE MAX. MIN. 2 CONDUCTORS 2 CONDUCTORS GC5008SH* #8 STR. #11 SOL. GC5006** DIA. RANGE (2 COND. COMBO.) DIA. EA. COND. MAX. – MIN. .146” - .091” (3.72-2.32) A (MM) 7/8” (22.7) B (MM) C (MM) 5/8” (15.91) WT. EA. LB (KG) .06 (.03) 1” (25.45) 5/8” (15.91) 3/4” (19.09) .09 (.04) 7/8” (22.27) .16 (.07) 1” (25.45) .18 (.08) #6 SOL. #10 SOL. .162”-.101” (4.12-2.57) GC5004** #4 STR. #8 SOL. .232”-.128” (5.9-3.26) 1 1/4” (31.81) GC5002** #2 SOL. #6 SOL. .286”-.162” (7.28-4.12) 1 3/8” (34.99) #5 SOL. .320”-.181” (8.14-4.61) 1 5/8” (41.36) 1 7/8” (47.72) GC5006SH* GC5002S** #2 STR. 3/4” (19.09) GC5020** 1/0 STR. #4 SOL. .390”-.204” (9.93-5.19) 1 1/8” (28.63) GC5020S** 2/0 STR. #3 SOL. .438”-.229” (11.15-5.83) 2” (50.90) 7/8” (22.27) 1 1/4” (31.81) GC5040** 4/0 STR. #1 SOL. .552”-.289” (14.05-7.36) 2 1/8” (54.08) 1” (25.45) 1 3/8” (34.99) BOLT HEAD (HEX.) 3/8” (10) 9/16” (14) .28 (.13) .48 (.22) * SH suffix indicates a slotted hex-head bolt. **RUS Listed For tin-plated bronze connectors, add suffix “P” to catalog number (not available on GC5008SH) Note: All connectors will accept one or two of the conductors listed and any combination in between. ANDERSON™ HUBBELL® POWER SYSTEMS FARGO® AUGUST 2013 GENERAL USE — GROUNDING AND BONDING VISE TYPE BRONZE BRONZE - GC SERIES GC100 / 200 / 5000 For copper to copper connections or conductor to conductor and conductor/cable sheath to bar. Material: Body - Copper Alloy Bolt - Stainless Steel or Silicon Bronze slotted head hex GC5000 Series Product Data & Conductor Size DD 4 CATALOG NUMBER GC271*† CONDUCTOR COMBINATIONS RUN 4-6 4 Sol – 6 Str. RANGE APPROX. DIMENSIONS INCHES CABLE SHEATH BONDING TAP 6-14 1 to 3 2 pair GC5006SH*† 6 6-14 1 to 3 2 pair GC5006†** 6 6-14 1 to 3 2 pair GC5004†** 4 4-8 1 to 3 2 pair 1 5 pair GC5002** 2 2-6 – – BOLT A (MM) 1 (25.45) 1 (25.45) 1 (25.45) B (MM) 5/8 (15.90) 5/8 (15.90) 5/8 (15.90) C (MM) 3/4 (19.08) 3/4 (19.08) 3/4 (19.08) DIA. 1/4 (6.36) 1/4 (6.36) 1/4 (6.36) WRENCH 3/8 (10) 3/8 (10) 3/8 (10) WT LB (KG) .08 (.04) .09 (.04) .09 (.04) 1 1/4 (31.81) 5/8 (15.90) 7/8 (22.26) 5/16 (7.95) 9/16 (14) .16 (.07) 1 3/8 (35.00) 3/4 (19.08) 1 (25.45) 5/16 (7.95) 9/16 (14) .18 (.08) * Slotted Head Bolt † Complies with UL-467 and ETL listed **RUS Listed For Figure 8 or IM Cable – Insulation Piercing The piercing teeth of the connector puncture the messenger insulation during tightening to form a positive ground without skinning. GC167 Product Data & Conductor Size CATALOG NUMBER GC167 GC167P DIAMETER GROUND MESSENGER TAP (MM) (MM) A (MM) B (MM) C (MM) DIA. WRENCH WT LB (KG) .146” - .312” (3.71-7.94) 1 5/8 (41.36) 1 1/4 (31.81) 1 (25.45) 5/16 (7.95) 9/16 (14) .21 (.10) .146” - .312” (3.71-7.94) APPROX. DIMENSIONS INCHES BOLT *Suffix P – Tin-Plated Bronze AUGUST 2013 ANDERSON™ HUBBELL® POWER SYSTEMS FARGO® GENERAL USE – GROUNDING AND BONDING VISE TYPE BRONZE For Bonding Ribbon, Braid and Tape Bonding ribbon or braid to bonding ribbon, braid, conductor, or bus and tape to messenger. Product Data & Conductor Size BONDING RIBBON OR BRAID CATALOG NUMBER GC164 GC164P† CONNECT Ribbon or Braid APPROX. DIMENSIONS INCHES TO Ribbon, Braid, #6 or Bus A (MM) 1 (25.45) B (MM) 5/8 (15.90) C (MM) 1 (25.45) BOLT DIA. 1/4 (6.36) WRENCH 3/8 (10) WT LB (KG) .12 (.05) GC164 † Plated Bronze For Ground Rods Conductor to ground rods, using vise-type compression connector. Product Data & Conductor Size RANGE CATALOG NUMBER GC268† ROD DIA. INCHES (MM) 1/4 – 5/8 (6.36-15.90) DD 5 DB-5 APPROX. DIMENSIONS INCHES CONDUCTOR 6-1/0 A (MM) 2 (50.80) B (MM) 1 (25.45) C (MM) 1 3/8 (35.00) BOLT DIA. 3/8 (9.54) WRENCH 9/16 (14) WT LB (KG) .43 (.19) * Torque head bolts available for tamperproof, removeable connection. †Complies with UL-467 and ETL listed GC268 For Lashing Wire Connect small diameter lashing wires to messengers. Product Data & Conductor Size MESSENGER DIAMETER RANGE CATALOG NUMBER GC166 GC166P CONNECT (MM) .245” - .500” (6.23-12.73) LASHING WIRE TO All Sizes APPROX. DIMENSIONS INCHES A (MM) 1 1/2 (38.18) B (MM) 7/8 (22.26) C (MM) 1 (25.45) BOLT DIA. 1/4 (6.36) WRENCH 3/8 (10) WT LB (KG) .16 (.07) Suffix P- Plated Bronze GC166 For Guy Strand Aluminum bodied connectors for connecting galvanized or aluminum clad strand to copper conductors. Vise Type Parallel Connector. Product Data & Conductor Size CATALOG NUMBER GA9003L** GA9002L** LC52AXB* ** LC522AXB†** STRAND RANGE (IN.) (MM) 1/4 (6.36) 1/4 – 3/8 (6.36-9.54) 1/4 – 3/8 (6.36-9.54) CONDUCTOR RANGE 4-8 4-8 2/0 – 8 APPROX. DIMENSIONS INCHES A B C (MM) (MM) (MM) 7/8 1 1/4 1 3/4 (22.26) (31.81) (44.54) 1 1/8 1 7/8 2 1/8 (28.63) (47.72) (54.08) PARALLEL GROOVE TYPE 2 3/8 1 5/8 1 3/8 (60.44) (41.36) (35.00) * Inhibitor Protected and Individually Packaged – Standard † Bimetallic Liner on Tap Side – Copper **RUS Listed ANDERSON™ HUBBELL® POWER SYSTEMS GA9000 Series WT LB (KG) .17 (.08) .23 (.10) .20 (.09) LC50 Series FARGO® AUGUST 2013 GENERAL USE – GROUNDING AND BONDING VISE TYPE— BRONZE STEEL 7956 Ground Clamp Connection is soldered to the cable sheath and mechanically clamped to the messenger wire. The bolt can be removed so that the clamp can be dropped over the messenger. Hot dip galvanized. 7956 Product Data & Conductor Size CATALOG NUMBER STEEL SIZE LENGTH BOLT SIZE APPROX. SHIP WT LBS PER 100 PIECES 7956 3/16 X 1 3/4 1 3/4 1/2 X 1 3/4 61 STEEL DD 6 5450 Ground Wire Clamp Ground Wire Clamp is used to attach ground or static wires to bayonets. No. 5450 is 1/2” J-Bolt which fits into two holes at top of bayonet. 5450 Product Data & Conductor Size CATALOG NUMBER BAYONET HOLE SPACING APPROX. SHIP WT LBS PER 100 PIECES 5450 15/16” 39 BRONZE GROUNDING CONNECTOR WIRE TO ROD OR PIPE BRONZE GC / C203 Bronze alloy ground clamp for grounding copper cable parallel to a ground rod or tube. • Suitable for Direct Burial Material: GC–Casting—Bronze Alloy Hardware—Stainless Steel C203–Casting–Galvanized Steel Hardware–Zinc Plated LISTED 261L Product Data & Conductor Size CATALOG NUMBER COPPER CABLE RANGE ROD DIA. GC4 #8 Sol.—#4 Str. 1/2 GC5G5 #10 Sol.—#2 Str. 5/8 GC6 #8 Sol.—#4 Str. 3/4 #8 Sol.—2/0 Str. 5/8 #8 Sol.—2/0 Str. 3/4 C2030344 Heavy Duty C2030345 Heavy Duty AUGUST 2013 ANDERSON™ DIMENSIONS INCHES (MM) L 5/8 (15.88) 5/8 (15.88) 3/4 (19.05) 1-1/8 (28.6) 1-1/8 (28.6) H 1-7/8 (47.62) 1-19/32 (40.39) 2-1/8 (53.98) 2-7/8 (73.0) 2-7/8 (73.0) W 13/16 (20.64) 29/32 (23.11) 1-1/32 (26.19) 1-15/32 (37.3) 1-15/32 (37.3) HUBBELL® POWER SYSTEMS J 3/8 (9.52) 3/8 (9.52) 3/8 (9.52) 1/2 (12.7) 1/2 (12.7) APPROX. WT. EACH LBS. (KG) .09 (.04) .11 (.05) .13 (.06) .34 (.15) .30 (.14) FARGO® GENERAL USE — BRONZE VISE TYPE GROUND CLAMP LIGHTNING ARRESTER GROUND BRONZE GC200 SERIES • For grounding applications conductor to conductor or plate to conductor • Provided with standard 1/2-13 threaded studs and flat surfaces for easy one wrench installation GC207 DD 7 DB-7 FIGURE 1 TYPE GC207-GC209 • NOTE: Lightning Arrester type installations, see page DC-9. Material: Body—Copper alloy Hardware—Stainless Steel Product Data & Conductor Size CATALOG NUMBER CONDUCTOR RANGE GC207+** (Fig. 1) 6 Sol. To 1/0 Str. GC208+ (Fig. 1) 4 Str. To 2/0 Str. GC209*+ (Fig. 1) 3 Sol. To 4/0 Str. BRONZE GROUNDING CONNECTOR APPROX. DIMENSIONS INCHES (MM) A B C D 1 1/4 3/4 1 7/8 1/2 (31.81) (19.09) (47.72) (12.73) 1 5/16 13/16 1 7/8 1/2 (33.40) (20.68) (47.72) (12.73) 1 1/2 1 1/8 1 3/4 1/2 (38.18) (28.63) (44.54) (12.73) E 5/16 (7.95) 5/16 (7.95) 5/16 (7.95) WT LB (KG) .21 (.10) .29 (.13) .40 (.18) *GC209 is furnished with bronze jam nut on stud. +Add Suffix “P” for Tin-plated Version (Minimum purchase quantities may apply) **RUS Listed Provides a permanent vibration proof connection. The large flat surface of the male casting provides secure mounting, while the “V” shaped conductor groove assures alignment of grounding connector. ANDERSON™ HUBBELL® POWER SYSTEMS FARGO® AUGUST 2013 BRONZE GTCL BRONZE GROUND CLAMP CONDUCTOR TO TRANSFORMER TANK TYPE GTCL: 90° GROUND CONDUCTOR MOUNT • Bronze alloy ground clamp for tapping copper conductor to transformer tank • Tapered threads at base of stud ensure positive locking and electrical contact without lockwashers Material: Casting—Bronze alloy Eyebolt—Bronze alloy Hardware—Silicon Bronze alloy or Stainless Steel Add suffix “TP” for tin-plated version. DD 8 Product Data & Conductor Size CATALOG NUMBER COPPER CABLE RANGE GTCL23A* #10 Sol. – #1 Str. GTCL34A* #8 Sol. – 2/0 Str. L 7/8 (22.22) 1 (25.4) APPROX. DIMENSIONS INCHES (MM) H W 1-1/2 1-3/8 (38.1) (34.92) 1-7/8 1-17/32 (47.62) (38.89) J 3/8 (9.52) 3/8 (9.52) APPROX. WT. EACH LBS. (KG) .20 (.09) .25 (.11) J 3/8 (9.52) 3/8 (9.52) 1/2 (12.7) APPROX. WT. EACH LBS. (KG) .29 (.13) .34 (.15) .45 (.20) *RUS Listed BRONZE GTCS GROUND CLAMP CONDUCTOR TO TRANSFORMER TANK TYPE GTCS: 90° OR STRAIGHT GROUND MOUNT • Bronze alloy ground clamp for tapping copper conductor to transformer tank • Tapered thread at base of stud ensures positive locking and electrical contact without lockwashers. Hex wrenching surface above tapered thread provides easy installation. Material: Casting—Bronze alloy Eyebolt—Bronze alloy Hardware—Silicon Bronze alloy or Stainless Steel Add suffix “TP” for tin-plated version. Product Data & Conductor Size CATALOG NUMBER COPPER CABLE RANGE GTCS21 #10 Sol. – #1 Str. GTCS34A #8 Sol. – 2/0 Str. GTCS41 #6 Sol.—250 MCM AUGUST 2013 ANDERSON™ L 1-1/8 (28.58) 1-1/4 (31.75) 1-5/8 (41.28) APPROX. DIMENSIONS INCHES (MM) H W 1-5/8 1-7/8 (41.28) (47.62) 1-7/8 2-1/4 (47.62) (57.27) 2-3/8 2-1/2 (60.32) (63.5) HUBBELL® POWER SYSTEMS FARGO® BRONZE GROUNDING POST CONNECTOR TYPES KS & K2S BRONZE KS / K2S • For copper to copper conductor connections. One or two copper conductors to steel structure or transformer for grounding. Also useful as a bar tap for cable to bus bar. Material: Copper Alloy FIGURE 1 TYPE KS FOR ONE WIRE 486A 467 FIGURE 2 TYPE K2S FOR TWO WIRES DD 9 DB-9 LISTED 261L Product Data & Conductor Size CONDUCTORS – AWG STRANDED SOLID CATALOG NUMBER FIGURE NUMBER KS6 1 #10–#7 #10-#6 1/4-20 K2S6 2 #10–#7 #10-#6 1/4-20 KS4 1 #10–#5 #10-#4 5/16-18 K2S4 2 #10–#5 #10-#4 5/16-18 KS2 1 #10–#3 #10-#2 3/8-16 K2S2 2 #10–#3 #10-#2 3/8-16 KS1 1 #8–#2 #8-#1 3/8-16 K2S1 2 #8–#2 #8-#1 3/8-16 KS10 1 #2–1/0 #2-1/0 1/2-13 K2S10 2 #2–1/0 #2-1/0 1/2-13 KS20 1 #2–2/0 #2-2/0 1/2-13 K2S20 2 #2–2/0 #2-2/0 1/2-13 KS40 1 #1–4/0 #1-4/0 5/8-11 K2S40 2 #1–4/0 #1-4/0 5/8-11 KS500 1 3/0–500 — 3/4-10 K2S500 2 3/0–500 — 3/4-10 ANDERSON™ STUD THREAD HUBBELL® POWER SYSTEMS C 1/2 (12.7) 1/2 (12.7) 9/16 (14.29) 9/16 (14.29) 5/8 (15.88) 5/8 (15.88) 5/8 (15.88) 5/8 (15.88) 3/4 (19.05) 3/4 (19.05) 3/4 (19.05) 3/4 (19.05) 1 (25.4) 1 (25.4) 1-1/4 (31.75) 1-1/4 (31.75) DIMENSIONS INCHES (MM) H 7/16 (11.11) 7/16 (11.11) 1/2 (12.7) 1/2 (12.7) 9/16 (14.29) 9/16 (14.29) 5/8 (15.88) 5/8 (15.88) 3/4 (19.05) 3/4 (19.05) 7/8 (22.23) 7/8 (22.23) 1-1/8 (28.58) 1-1/8 (28.58) 1-5/8 (41.28) 1-5/8 (41.28) FARGO® L 1-5/16 (33.34) 1-15/32 (37.30) 1-1/2 (38.10) 1-22/32 (43.63) 1-19/32 (40.46) 1-7/8 (47.63) 1-3/4 (44.45) 2 (50.80) 2-1/16 (52.40) 2-7/16 (61.91) 2-3/16 (55.57) 2-9/16 (65.09) 2-5/8 (66.68) 3-1/8 (79.38) 3-5/8 (92.09) 4-1/2 (114.30) APPROX. WT. EACH LBS. (KG) .06 (.027) .07 (.032) .08 (.036) .09 (.041) .12 (.055) .13 (.059) .13 (.059) .15 (.068) .18 (.082) .20 (.091) .26 (.118) .29 (.132) .55 (.25) .59 (.27) 1.30 (.591) 1.32 (.60) AUGUST 2013 BRONZE LAT, GC207LA LIGHTNING ARRESTER GROUNDING TERMINALS TYPE LAT AND GC207LA BRONZE DISTRIBUTION ARRESTER TERMINALS (See also Page DC9 - DC10) • This versatile bronze connector can be mounted to a drilled plate, structure or bar using a 3/8”-16 cap screw. It can also be screwed onto a 3/8”-16 bushing stud and secured in place with the included jam nut. The eyebolt can be positioned within the body to allow either vertical or horizontal conductor entrances. Material: Casting — Bronze alloy Eyebolt — Bronze alloy Hardware — Silicon Bronze alloy — Brass jam nut DD 10 Product Data & Conductor Size CATALOG NUMBER STUD SIZE LAT20 3/8” - 16 CONDUCTOR RANGE O.D. 8 Sol. - 2/0 Str. .12” - .42” O.D. LENGTH INCHES (MM) 1.69 (43) APPROX. WT. EACH LBS. (KG) 40 (18) Add suffix “TP” for tin-plated connector • This connector is intended primarily for bottom termination of lightning arresters to ground. May also be employed on top connections. Material: Casting—Bronze alloy Eyebolt—Bronze alloy Hardware—Stainless Steel NOTE: See pages DC-9 – DC-10 for application details. Product Data & Conductor Size CATALOG NUMBER STUD SIZE GC207LA 3/8” - 16 CONDUCTOR RANGE O.D. #6 Sol. - 1/0 Str. .162” - .373” (4.1 - 9.5) mm APPROX. WT. 100 LBS. (KG) 22 (9.9) Add suffix “P” for tin-plated connector AUGUST 2013 ANDERSON™ HUBBELL® POWER SYSTEMS FARGO® GENERAL USE IN-SPAN PHASE CONNECTOR AND HOUSING ALUMINUM GM128 This in-span phase connector is designed for use on open wire or multiple cable secondaries to permit aesthetic readily accessible service connections. The connector body is constructed of high strength aluminum for optimum corrosion resistance and light weight. The housing or case provides protective insulation from adjacent conductors and is formed for accessibility and ease of application. Secondary run and service tap openings are pre-cut for alignment and tap conductor insertion or removal. The connector locks in position inside the case providing one piece for assembly. DD 11 DB-11 For best performance, the connectors are supplied with Fargolene® Inhibitor protected grooves and are individually packaged in plastic bags. The Fargo GM128AKL makes an insulated phase connector system for up to four service taps and may be used with the Fargo neutral span clamps. Product Data & Conductor Size CATALOG NUMBER GM128AL (Connector Only) GM128AKL (Connector and Housing) ANDERSON™ RANGE RUN TAP 2 Str. – 350 KCMIL 4 Sol. – 3/0 Str. 2 Str. – 350 KCMIL 4 Sol. – 3/0 Str. APPROX. OVERALL DIMENSIONS INCHES LENGTH (MM) WIDTH (MM) HEIGHT (MM) 3 5/16 2 5/8 2 (84.03) (66.81) (50.90) 3 13/16 3 1/4 3 (97.03) (82.71) (76.35) HUBBELL® POWER SYSTEMS FARGO® WEIGHT LBS. (KG) 1.04 (.47) 1.20 (.54) AUGUST 2013 ALUMINUM TYPE APD ARC PROTECTION FOR COVERED PRIMARY CONDUCTOR APD • The APD helps prevent lightning induced burndowns of covered overhead aluminum primary conductors and allows users to comply with Article 276 of the National Electric Safety Code, 1981 Edition. • The device protects covered conductor by shielding it from the usual concentration of arc energy generated during a lightning strike. Without the device, such arcs can puncture the conductor cover and ground to the neutral leaving a short section of conductor strands that are either completely destroyed or badly eroded and seriously weakened. (Conventional overcurrent protection equipment does not operate fast enough to protect these lightning exposed conductors.) APD lightning protectors add mass of the correct shape to the conductor in the area where it absorbs the terminus of arc energy. It is thus a partially sacrificed component during each strike yet retains enough of its original mass and configuration to accommodate several strikes without losing effectiveness or allowing the adjacent line insulator to be splattered with damaging metallic particles. • APD lightning protectors are both laboratory tested and field proven with the same successful results. They are offered in two models. The high energy APD-80 model is designed to withstand multiple operations at 21,000 amperes fault current for ten (10) cycles without conductor damage. A low-energy APD-57 model is available for applications where fuses limit the destructive energy by clearing the fault more rapidly than circuit breakers. DD 12 Material: Castings—Aluminum Alloy Hardware—APD57—Galvanized Steel APD80—Stainless Steel Note: A radial circuit requires an APD protector on the load side of the insulator only, while other circuit configurations, such as loops, require that they be installed on both sides of the line insulator. In both situations, they must be installed on all conductor phases and positioned outside the end of a tie wire. The covering must be stripped away over this distance including the area within the confines of a tie wire. Since an arc from one phase to the neutral will often expand to fault all three phases, the device must be installed on all three phases. Product Data & Conductor Size CATALOG NUMBER (WITH INHIBITOR) (1) APD57XB (Fused circuits) APD80XB MAX. O.D. OF CABLE JACKET—INCHES 0.906 1.200 CONDUCTOR RANGE O.D. IN INCHES #1-4/0 STR. AAC #2-4/0 ACSR 0.31-0.57 2/0-556.5 Str. AAC 1/0-477 (18/1) ACSR 0.39-0.86 DIMENSION B—INCHES (MM) APPROX. WT. 100 LBS. (KG) 1.06 (27) 24 (11) 1.87 (48) 66 (30) (1) This item is suitable for use on fused circuits only. Specifically, it should not be installed on lines protected by circuit breakers because of their relatively slow interrupting rate. AUGUST 2013 ANDERSON™ HUBBELL® POWER SYSTEMS FARGO® TINNED ALUMINUM OR BRONZE TRANSFORMER SPADE TERMINALS TYPE AXS & BXS • Secured by jam nut to bushing stud. • Recommended when copper terminals are connected (Use “AXS” style for aluminum terminals.) • Terminal lug mounting holes are 9/16” diameter with 1-3/4” NEMA spacing. Jam nuts are usually supplied by the transformer manufacturer and are not furnished unless specified. BRONZE ALUMINUM BXS AXS Material: Castings – BXS - Bronze alloy (tin-plated) AXS - Aluminum alloy (tin-plated) Notes: (1) Terminals for 1-1/4” – 12 bushing studs can be furnished with a 1/4” – 20 tapped hole in the outer end to attach an insulated suspension support rod for mechanical support. Add suffix “-MS” for this option. (2) Add suffix “JN” to specify a factory applied brass jam nut. DD 13 DB-13 Product Data & Conductor Size ANDERSON™ CATALOG NUMBER BXS582N X’FORMER STUD SIZE 5/8”-11 BXS102N 1”-14 BXS584N 5/8”-11 BXS104N 1”-14 AXS584NTP 5/8”-11 AXS104NTP 1”-14 BXS582BN 5/8”-11 BXS102BN 1”-14 AXS582BNTP 5/8”-11 BXS583BN 5/8”-11 BXS103BN 1”-14 AXS103BNTP 1”-14 BXS584BN 5/8”-11 BXS104BN 1”-14 BXS123BN 1-1/4”-12 BXS124BN 1-1/4”-12 BXS126BN 1-1/4”-12 BXS128BN 1-1/4”-12 GENERAL DESCRIPTION & FIELD APPLICATION Two Holes in Line NEMA Spaced For Use With One Hole Lugs Four Holes in Line NEMA Spaced For Use With One Hole Lugs Two Sets of NEMA Spaced Holes Mounts Up to 4 Two-Holed Lugs Three Sets of NEMA Spaced Holes Mounts Up to 6 Two-Holed Lugs Four Sets of NEMA Spaced Holes Mounts Up to 8 Two-Holed Lugs Three Sets of NEMA Spaced Holes Mounts Up to 6 Two-Holed Lugs Or Up to 12 Two-Holed Lugs If Stacked Four Sets of NEMA Spaced Holes Mounts Up to 8 Two-Holed Lugs Or Up to 16 Two-Holed Lugs If Stacked Six Sets of NEMA Spaced Holes Mounts Up to 12 Two-Holed Lugs Or Up to 24 Two-Holed Lugs If Stacked Eight Sets of NEMA Spaced Holes Mounts Up to 16 Two-Holed Lugs Or Up to 32 Two-Holed Lugs If Stacked HUBBELL® POWER SYSTEMS DIMENSIONS INCHES (MM) LENGTH WIDTH HEIGHT 5.12 (130) 1.37 (35) 0.31 (8) APPROX. WT. 100 LBS. (KG) 70 (32) 5.06 (129) 1.93 (49) 0.34 (9) 142 (64) 8.50 (216) 1.37 (35) 0.31 (8) 120 (54) 8.56 (218) 1.93 (49) 0.34 (9) 215 (98) 8.50 (216) 1.37 (35) 0.31 (8) 36 (16) 8.56 (218) 2.00 (50) 0.34 (9) 65 (29) 5.37 (136) 3.50 (89) 0.25 (6) 132 (60) 5.87 (149) 3.50 (89) 0.37 (9) 260 (118) 5.37 (136) 3.50 (89) 0.25 (6) 39 (18) 6.62 (168) 3.50 (89) 0.37 (9) 256 (116) 7.00 (178) 3.50 (89) 0.37 (9) 315 (143) 7.00 (178) 3.50 (89) 0.37 (9) 94 (43) 8.37 (213) 3.50 (89) 0.37 (9) 330 (150) 8.75 (222) 3.50 (89) 0.37 (9) 362 (164) 7.12 (181) 3.50 (89) 0.37 (9) 345 (156) 9.12 (232) 3.50 (89) 0.37 (9) 445 (202) 14.00 (356) 4.00 (102) 0.50 (13) 970 (440) 17.50 (445) 4.00 (102) 0.50 (13) 1300 (590) FARGO® AUGUST 2013 GENERAL USE PARALLEL GROOVE ALUMINUM MULTI-TAP STREET LIGHT CONNECTOR ALUMINUM GO32 For: Aluminum to copper or Aluminum conductor Application The Fargo GO32 Multiple Tap Connector is designed for making street light connections in the limited space provided in tubular street light poles. DD 14 H L W Description • High strength, extruded aluminum alloy. • Permanent contact pressure provided by use of high strength steel bolt and stainless steel Belleville washer. • Run conductor can be “looped” through the connector eliminating the need to cut the conductor. • Compact design allows use in even the smallest “handholes” provided in street light poles or bases. • Optional slip-over Plastisol boot (Catalog No. GO32B) is available for insulating the phase conductor. Inhibitor loading furnished standard. Material: Body – Aluminum Alloy Hardware – Stainless Steel Product Data & Conductor Size CATALOG NUMBER GO32 CONDUCTOR RANGE* RUN TAP #6-1/0 #12-#8 DIMENSIONS INCHES (MM) L W H 1.25 0.75 1.50 (31.81) (19.09) (38.18) WT LB (KG) .09 (.04) INSULATING COVER GO32B** * GO32 will accept two (2) #6 sol. through 1/0 aluminum run conductors, as well as two (2) #12 through #8 AL/CU tap conductors. ** Order GO32K to receive connector and cover as a kit. AUGUST 2013 ANDERSON™ HUBBELL® POWER SYSTEMS FARGO® OVERHEAD TRANSFORMER PAD ADAPTER CONNECTORS TIN-PLATED BRONZE FLAG ADAPTERS USE W/EYEBOLT (GTCL/GTCS) TYPE SECONDARY BUSHING TERMINALS BRONZE VF • Bronze terminal adapter for connecting a flat pad to NEMA secondary transformer terminal • Optional for use with Type GTCL or GTCS terminals. Material: Castings – Bronze alloy – tin-plated DD 15 DB-15 Product Data & Conductor Size CATALOG NUMBER NEMA DRILLED PAD & ROD DESCRIPTION VF440 4 Hole 4” x 4” x 1/4” Pad VF640 6 Hole 3” x 5-1/4” x 1/4” Pad VF4350 4 Hole 4” x 4” x 1/4” Pad VF6350 6 Hole 3” x 5-1/4” x 1/4” Pad VF4500 4 Hole 4” x 4” x 1/4” Pad VF6500 6 Hole 3” x 5-1/4” x 1/4” Pad VF41000 4 Hole 4” x 4” x 1/4” Pad VF61000 6 Hole 3” x 5-1/4” x 1/4” Pad ANDERSON™ TRANSFORMER SIZE RATING (SINGLE PHASE) HUBBELL® POWER SYSTEMS DIMENSIONS INCHES (MM) L DIA. 5-15 KVA 2.25 (57) .50 (13) 25-50 KVA 2.75 (70) .75 (20) 75 KVA 4.00 (102) .81 (21) 100 KVA 4.00 (102) 1.00 (25) FARGO® APPROX. WT. 100 LBS. (KG) 165 (75) 180 (82) 216 (98) 231 (105) 245 (111) 260 (118) 312 (142) 327 (148) AUGUST 2013 SET SCREW BAR TRANSFORMER CONNECTORS TOGGLE LATCH ALUMINUM UTSB For connecting secondary underground applications to transformer studs. Innovative “Toggle Latch” mechanism provides unmatched ease of installation, along with superior electrical performance. One part accepts both 5/8”-11 and 1”-14 threads. Oxide Inhibiting Compound provided as standard in stud and tap holes. 5/16” allen set screws provide constant pressure on conductors. DD 16 Testing meets or exceeds ANSI C119.6 Class “A” tests. Redundant ground ports provided for use on neutral phase connections. Toggle nut is 3/4” across flats, fits standard GP223 Speed Wrench. Material: Body — Aluminum Alloy Hardware — High Strength Steel Boot/Cover — Poly-vinyl chloride (PVC) Note: Not suitable for submersible installations. Product Data & Conductor Size CATALOG NUMBER TRANSFORMER STUD SIZES UTSB8500L 5/8”-11 & 1”-14” CONDUCTOR RANGE STREET LIGHT REDUNDANT MAIN PORTS PORT GROUND #6 SOL - 500 MCM #12 SOL - 1/0 SOL 0.162” - 0.813” 0.081” - 0.325” #12 SOL - #2 SOL 0.081” - 0.258” MAIN PORTS STREET LIGHT PORTS GROUND PORTS 8 1 2 PACKAGING PER BOX WEIGHT UNITS (LBS) 12 36 NOTE: Add suffix “C” for clear PVC cover included in package “UTSB8500CL. Factory applied inhibitor (HTJC) included standard. Cover Part Number: CTL8500 AUGUST 2013 ANDERSON™ HUBBELL® POWER SYSTEMS FARGO® SET SCREW BAR TRANSFORMER CONNECTORS TOGGLE LATCH ALUMINUM UTZB For connecting secondary underground applications to transformer studs. Innovative “Toggle Latch” mechanism provides unmatched ease of installation, along with superior electrical performance. Reduced inventory; one part accepts both 5/8”-11 and 1”14 thread transformer studs. Oxide Inhibiting Compound provided as part of standard in stud and tap holes. Allen head set screws (fits 5/16” allen wrench) provide constant pressure on conductors. DD 17 DB-17 Meets or exceeds ANSI C119.6 Class “A” tests. Toggle nut is 3/4” across flats, fits standard GP223 Speed Wrench. Material: Body — Aluminum Alloy Set Screws —Aluminum Alloy Hardware — High Strength Steel Boot/Cover — Poly-vinyl chloride (PVC) Note: Not suitable for submersible installations. Units are expressed in inches (millimeters) Product Data & Conductor Size CATALOG NUMBER TRANSFORMER STUD SIZES UTZB6500L 5/8”-11 & 1”-14” CONDUCTOR RANGE STREET LIGHT REDUNDANT MAIN PORTS PORT GROUND #6 SOL - 500 MCM #12 SOL - 1/0 SOL 0.162” - 0.813” 0.081” - 0.325” #12 SOL - #2 SOL 0.081” - 0.258” MAIN PORTS STREET LIGHT PORTS GROUND PORTS 6 1 2 PACKAGING PER BOX WEIGHT UNITS (LBS) 12 32 NOTE: Add suffix “C” for kit with stud bar & clear PVC cover (UTZB6500CL). Factory applied inhibitor (HTJC) included standard. Cover Part Number: CZTL6500 ANDERSON™ HUBBELL® POWER SYSTEMS FARGO® AUGUST 2013 SET SCREW BAR TRANSFORMER CONNECTORS ALUMINUM HABW Features: • Designed for easy connection to/from transformer stud mounts, Slip Fit. • Oxide Inhibiting Compound provided as standard in stud hole. • High-Strength Aluminum Alloy provides constant bolting pressure on connectors. • Testing meets or exceeds ANSI C119.4 Class “A” tests. • Allen head socket set screws provided for use with 5/16” allen wrenches. Material: Body — Aluminum Alloy Hardware — High Strength Aluminum Alloy Boot/Cover — Poly-Vinyl Chloride (PVC) DD 18 Note: Not suitable for submersible installations. Product Data & Conductor Size DIMENSIONS INCHES LENGTH WIDTH HEIGHT 6.00 0.88 1.25 CATALOG NUMBER HABW4350 CONDUCTOR RANGE NO. OF PORTS 4 STUD SIZE 5/8” HABW6350 #12 350 MCM 6 5/8” 8.00 0.88 8 5/8” 10.00 HABW83501 8 1” HABW6500 6 HABW8350 HABW650058 HABW8500 HABW850058 #6 500 MCM BOOT NO. (COVER) SBC4350 KIT NO. (BAR & BOOT) CABW4350 1.25 SBC6350 CABW6350 0.88 1.25 SBC8350 CABW8350 10.50 1.38 1.51 SBC83501 CABW83501 1” 8.00 1.38 1.64 SBC6500 CABW6500 6 5/8” 7.50 1.00 1.50 SBC650058 CABW650058 8 1” 10.00 1.38 1.64 SBC8500 CABW8500 8 5/8” 9.50 1.00 1.50 SBC850058 CABW850058 “L” suffix - inhibitor protected ports. “SL” suffix - Street Light Tap with inhibitor protected ports. NOTES: All street light applications are inhibited. For street light tap, add suffix “SL” (ex: HABW4350SL, CABW4350SL). For inhibited ports and no street light tap, add suffix “L” (ex: HABW4350L, CABW4350L). AUGUST 2013 ANDERSON™ HUBBELL® POWER SYSTEMS FARGO® SET SCREW BAR PEDESTAL CONNECTORS ALUMINUM HABC Features: • Oxide Inhibiting Compound provided as standard. • High-Strength Aluminum Alloy provides constant bolting pressure on connectors. • Testing meets or exceeds ANSI C119.4 Class “A” tests. • Allen head socket set screws provided with 5/16” allen wrenches. Material: Body — Aluminum Alloy Hardware — High Strength Aluminum Alloy Note: Not suitable for submersible installations. DD 19 DB-19 Product Data & Conductor Size CATALOG NUMBER HABC4350L HABC6350L HABC8350L HABC6500L HABC8500L CONDUCTOR RANGE #12 350 MCM #6 500 MCM DIMENSIONS INCHES NO. OF PORTS 4 LENGTH 4.00 WIDTH 0.88 HEIGHT 1.25 6 6.00 0.88 1.25 8 8.00 0.88 1.25 6 6.00 1.38 1.64 8 8.00 1.00 1.50 “L” suffix - inhibitor protected ports. ANDERSON™ HUBBELL® POWER SYSTEMS FARGO® AUGUST 2013 ALUMINUM SET SCREW BAR TRANSFORMER CONNECTORS ZABW Features: • Designed for easy connection to/from transformer stud mounts. • One part accepts both 5/8”-11 and 1”-14 thread transformer studs. • Street Light Port provided as standard. • Oxide Inhibiting Compound provided as standard. • High-Strength Aluminum Alloy provides constant bolting pressure on connectors. • Testing meets or exceeds ANSI C119.4 Class “A” tests. • Allen head socket set screws provided with 5/16” allen heads. Material: Body — Aluminum Alloy Hardware — High Strength Aluminum Alloy Boot/Cover — Poly-Vinyl Chloride (PVC) DD 20 Note: Not suitable for submersible installations. Product Data & Conductor Size CATALOG NUMBER ZABW6500L Note: CONDUCTOR RANGE MAIN STREETLIGHT #12 SOL #6 - 500 MCM #2 SOL MAIN PORTS S.L. PORT 6 1 LENGTH 5.7 (143.8) DIMENSIONS INCHES (MM) WIDTH 2.2 (55.6) HEIGHT 2.8 (71.7) PACKAGING PER BOX UNITS WEIGHT (LB.) 24 52 Add suffix “C” for kit with stud bar & clear PVC cover (ZABW6500CL). Factory applied inhibitor included standard. KITTING INFORMATION CATALOG NUMBER ZABW6500L AUGUST 2013 BOOT NO. (COVER) ZBC6500 ANDERSON™ KIT NO. (BAR & BOOT) ZABW6500CL HUBBELL® POWER SYSTEMS FARGO® GENERAL USE PRESSURE SCREW BRONZE BRONZE E • For copper to copper conductor connection. Material: Body—Copper Alloy Hardware—Silicon Bronze Product Data & Conductor Size CONDUCTOR RANGE (AWG) MIN. MAX. CATALOG NUMBER E8 #10 Sol. Cu #8 Str. Cu E6** #8 Sol. Cu #6 Str. Cu E4** #6 Sol. Cu #4 Str. Cu *E2 #4 Str. Cu #2 Str. Cu L 3/8 (9.53) 7/16 (11.11) 1/2 (12.70) 21/32 (16.67) DIMENSIONS INCHES (MM) H 9/16 (14.29) 21/32 (16.67) 25/32 (19.84) 31/32 (24.61) J #10 (4.04) 1/4 (6.35) 5/16 (7.94) 3/8 (9.53) APPROX. WT. EACH LBS. (KG) .018 (.01) .026 (.01) .035 (.02) .073 (.03) *Does not have slotted head. **RUS Listed GENERAL USE PRESSURE SCREW W/SEPARATOR BRONZE BRONZE EPW • For copper to copper conductor connection. Material: Body—Copper Alloy—tin-plated Hardware—Silicon Bronze Product Data & Conductor Size CATALOG NUMBER CONDUCTOR RANGE (AWG) MIN. MAX. EPW4 #6 Sol.—#4 Str. Cu #6 Sol.—#4 Str. Cu EPW2 #4 Str.—#2 Str. Cu #4 Str.—#2 Str. Cu ANDERSON™ W 1/2 (12.70) 21/32 (16.67) HUBBELL® POWER SYSTEMS DIMENSIONS INCHES (MM) H 49/64 (19.45) 31/32 (24.61) FARGO® J 5/16 (7.94) 3/8 (9.53) APPROX. WT. EACH LBS. (KG) .037 (.02) .076 (.03) AUGUST 2013 DD 21 DB-21 GENERAL USE VISE TYPE PARALLEL GROOVE BRONZE BRONZE GC8000 • For copper to copper conductor -splice, loop deadend or service entrance taps Material: Castings—Copper Alloy Hardware— Stainless Steel Galvanized Steel Silicon Bronze DD 22 Suffix Construction: “G” = Grommets — holds spacer during OH installs “L” = Inhibitor Applied @ Factory Product Data & Conductor Size *CONDUCTOR RANGE (AWG) MAIN APPROX. DIMENSIONS INCHES CATALOG NUMBER SOL. STR. MIN. SOL. GC8002 2 3 8 GC8010 1/0 1 8 GC8020 3/0 2/0 8 GC8040** 4/0 4/0 6 A (MM) 1 3/8 (34.99) 1 1/2 (38.18) 1 3/4 (44.54) 2 3/8 (60.44) B (MM) 1 1/4 (31.81) 1 3/8 (34.99) 1 3/8 (34.99) 1 1/2 (38.18) C (MM) 7/8 (22.27) 1 (25.45) 1 1/8 (28.63) 1 1/2 (38.18) BOLT SIZE 5/16 (7.95) 5/16 (7.95) 5/16 (7.95) 3/8 (9.54) BOLT HEAD (HEX) 9/16 (14.32) 9/16 (14.32) 9/16 (14.32) 9/16 (14.32) WT. LBS. (KG) .16 (.07) .24 (.11) .33 (.15) .62 (.28) *For Tin-plated Connectors add Suffix “P” to the Catalog Number desired. **RUS Listed Conductor Range Each size will close on two of the maximum size conductors, one minimum and one maximum size, or combinations in between. Hot Stick Installation All connectors are available with flexible neoprene grommets to hold spacer bar in position so run and tap connectors may be installed with ease. Grommets positioning spacer do not interfere with smooth operation of connector. If clamps are to be equipped with grommets, please specify by adding suffix “G” to the catalog number. Inhibitor Protected and Bagged Connectors are available with Factory installed Fargolene inhibitor and individually packaged. When ordering add the Suffix “L” to catalog number. AUGUST 2013 ANDERSON™ HUBBELL® POWER SYSTEMS FARGO® GENERAL USE PARALLEL GROOVE ALUMINUM MULTIPLE U-BOLTS WITH COPPER LINER ALUMINUM LCC For aluminum to copper conductor connections only. Sealant (XB) is recommended on all connections Material: Body—Top member 356-T6 Aluminum Alloy Spacer—Aluminum Alloy with a metallurgically bonded Copper liner Bottom Member—High Strength Bronze Hardware—Galvanized Steel FIGURE 2 FIGURE 1 Product Data & Conductor Size CATALOG NUMBER FIGURE NUMBER LCC111XB 1 LCC221XB 1 LCC222XB 2 LCC231XB 1 LCC242XB 2 LCC332XB 2 DIMENSIONS INCHES (MM) W 2-5/16 (58.74) 2-11/16 (68.26) 2-3/4 (69.85) 2-11/16 (68.26) 2-11/16 (68.26) 3-1/16 (77.79) CONDUCTOR RANGE MAIN #6 Sol.—2/0 Str. AAC #8 Sol.—2/0 (6/1) ACSR 1/0 Str.—400 MCM AAC 1/0 (6/1)—397.5 (18/1)ACSR 1/0 Str.—400 MCM AAC 1/0 (6/1)—397.5 (18/1) ACSR 1/0 Str.—400 MCM AAC 1/0 (6/1)—397.5 (18/1) ACSR 1/0 Str.—400 MCM AAC 1/0 (6/1)—397.5 (18/1) ACSR 336.4—954 MCM AAC 300—795 MCM ACSR TAP #8 Sol.—2/0 Str. CU #4 Sol.—4/0 Str. CU #4 Sol.—4/0 Str. CU 1/0 Str.—500 MCM CU 400—800 MCM CU 1/0 Str.—400 MCM CU L 2 (50.80) 2-1/2 (63.50) 3-7/8 (98.43) 2-1/2 (63.50) 4-1/8 (104.78) 4-5/8 (117.48) H 3-1/2 (88.90) 4 (101.60) 4 (101.60) 4 (101.60) 4-1/4 (107.95) 4-5/8 (117.48) GENERAL USE PARALLEL GROOVE ALUMINUM THREE CENTER BOLTS WITH COPPER LINER APPROX. WT. EACH LBS. (KG) .77 (.35) 1.11 (.50) 1.68 (.76) 1.24 (.56) 2.10 (.95) 2.88 (1.31) ALUMINUM LC600 For aluminum to copper conductor connections only. Sealant (XB suffix) is recommended on all connections Material: Body—356-T6 Aluminum Alloy Hardware—Hot Dip Galvanized Steel Tap Liner—Copper, Metallurgically Bonded Product Data & Conductor Size CATALOG NUMBER LC677XB DIMENSIONS INCHES (MM) CONDUCTOR RANGE MAIN 1/0 (19)—336.4 MCM AAC 1/0—300 MCM ACSR ANDERSON™ TAP 1/0 (7)—250 Str. CU L 4-3/8 (111.13) HUBBELL® POWER SYSTEMS W 2-5/16 (58.74) H 2-1/2 (63.5) FARGO® J 1/2 (12.7) APPROX. WT. EACH LBS. (KG) 1.35 (.61) AUGUST 2013 DD 23 DB-23 GENERAL USE – PARALLEL GROOVE – ALUMINUM SINGLE CENTER BOLT ALUMINUM LC50 & LC80 For aluminum to aluminum and aluminum to copper conductor splice/tap connections. Sealant (XB) is recommended on all connections. FIGURE 1 Material: Body—Aluminum alloy Hardware—Galvanized steel Notes: 1) For connectors without sealant, delete suffix “XB.” 2) Add suffix “GP” for a tin-plated connector. 3) Plastic Cover Available. (See Type PTC Cover) FIGURE 2 Product Data & Conductor Size CATALOG NUMBER DD 24 FIGURE NUMBER MAIN TAP LC51AXB** 1 #8 Sol.—1/0 Str. AAC #8—1/0 ACSR LC51CXB** 1 #8 Sol.—1/0 Str. AAC #8—1/0 ACSR LC52AXB** 1 #8 Sol.—2/0 Str. AAC #8—2/0 ACSR LC52CXB** 1 #1 Sol. —400 MCM AAC #1—336.4 MCM ACSR LC53AXB** 2 #1 Sol. —400 MCM AAC #1—336.4 MCM ACSR LC83AXB** 2 397.5—954 MCM AAC 336.4—795 MCM ACSR **RUS Listed ALUMINUM LC500 & LC800 #8 Sol.—#2 Str. AAC #8—#2 ACSR #8 Sol.—#2 Str. Cu #8 Sol.—1/0 Str. AAC #8—1/0 ACSR #8 Sol.—1/0 Str. Cu #8 Sol.—2/0 Str. AAC #8—2/0 ACSR #8 Sol.—2/0 Str. Cu #8 Sol.—2/0 Str. AAC #8—2/0 ACSR #8 Sol.—2/0 Str. Cu #1 Sol. —400 MCM AAC #1—336.4 MCM ACSR #1 Sol.—400 MCM Cu #8 Sol.—2/0 Str. AAC #8—2/0 ACSR #8 Sol.—2/0 Str. Cu DIMENSIONS INCHES (MM) W H J APPROX. WT. EACH LBS. (KG) 1-1/8 (28.58) 1-13/32 (35.72) 1-1/2 (38.10) 5/16 (8.0) .14 (.06) 1-1/4 (31.76) 1-17/32 (38.89) 2 (50.80) 3/8 (9.53) .19 (.09) 1-3/8 (34.93) 1-21/32 (42.07) 2 (50.80) 3/8 (9.53) .22 (.10) 2 (50.80) 2-11/32 (51.60) 2-1/4 (57.15) 3/8 (9.53) .28 (.13) 2 (50.80) 2-11/32 (59.53) 2-1/2 (63.50) 1/2 (12.70) .41 (.19) 1-1/2 (38.1) 2-17/32 (64.29) 2-3/4 (69.85) 1/2 (12.70) .54 (.24) CONDUCTOR RANGE L GENERAL USE – PARALLEL GROOVE – ALUMINUM SINGLE CENTER BOLT WITH COPPER LINER For aluminum to copper conductor connections only. Sealant (XB) is recommended on all connections. Material Body—Aluminum Alloy Hardware—Galvanized Steel Tap Liner—Copper metallurgically bonded FIGURE 2 FIGURE 1 Product Data & Conductor Size CATALOG NUMBER FIGURE NUMBER LC511AXB** 1 LC522AXB** 1 LC542XB 1 LC811AXB** 1 LC822XB 2 LC833XB** 2 **RUS Listed AUGUST 2013 CONDUCTOR RANGE MAIN #6 Sol.—1/0 Str. AAC #8—1/0 ACSR #6 Sol.—1/0 Str. AAC #8—1/0 ACSR #6 Sol.—1/0 Str. AAC #8—1/0 ACSR #1 Sol.—400 MCM AAC #1—336.4 MCM ACSR #1 Sol.—400 MCM AAC #1—336.4 MCM ACSR 397.5—954 MCM AAC 336.4—795 MCM ACSR ANDERSON™ TAP #8 Sol.—#2 Str. Cu #8 Sol.—1/0 Str. Cu 1/0 Str.—4/0 Str. Cu #8 Sol.—1/0 Str. Cu #8 Sol.—2/0 Str. Cu #8 Sol.—2/0 Str. Cu L 1-1/8 (28.58) 1-3/8 (34.93) 1-3/16 (30.16) 1-1/4 (31.75) 2-1/4 (57.15) 2-1/2 (63.50) DIMENSIONS INCHES (MM) W H 1-5/16 (33.34) 1-21/32 (42.07) 1-25/32 (45.24) 2-1/32 (51.59) 2-7/32 (56.36) 2-17/32 (64.29) 1-1/2 (38.10) 2 (50.80) 2 (50.80) 2-1/4 (57.15) 2-1/2 (63.50) 2-3/4 (69.85) HUBBELL® POWER SYSTEMS J 5/16 (8.0) 3/8 (9.53) 3/8 (9.53) 3/8 (9.53) 1/2 (12.70) 1/2 (12.70) APPROX. WT. EACH LBS. (KG) .14 (.06) .22 (.10) .24 (.11) .29 (.13) .46 (.21) .54 (.24) FARGO® GENERAL USE PARALLEL GROOVE – ALUMINUM MULTIPLE CENTER BOLTS ALUMINUM LC60 / GA600 For aluminum to aluminum and aluminum to copper conductor splice/tap connectors. Sealant (XB) is recommended on all connections. FIGURE 1 Material: Body—Aluminum alloy Hardware—Galvanized steel Notes: 1) For connectors without sealant, delete suffix “XB.” 2) Add suffix “GP” for a tin-plated connector. FIGURE 2 Product Data & Conductor Size CATALOG NUMBER FIGURE NO. GA670L 1 LC66AXB 1 LC67AXB 2 LC68AXB 2 DIMENSIONS INCHES (MM) L 3-1/4 (82.71) 3-1/2 (88.90) 5-1/4 (133.35) W 2-1/4 (57.26) 2-3/8 (60.44) 2-5/8 (66.80) H 2-3/4 (69.85) 2-3/4 (69.85) 2-1/2 (63.5) J 3/8 (9.53) 1/2 (12.70) 1/2 (12.70) APPROX. WT. EACH LBS. (KG) .60 (.27) 1.10 (.50) 1.30 (.59) 5-1/4 (133.35) 2-13/16 (71.44) 2-1/2 (63.5) 1/2 (12.70) 1.90 (.86) CONDUCTOR RANGE MAIN 1/0—400 AAC 1/0—336.4 (18/1) ACSR TAP 1/0—400 AAC 1/0—336.4 (18/1) ACSR 1/0 (19)—400 MCM AAC 1/0—397.5 (18/1) ACSR 1/0 (19)—400 MCM AAC 1/0—397.5 (18/1) ACSR 1/0 Sol.—400 MCM Cu 350 —556.5 MCM AAC 336.4 (18/1)—477 (30/7) ACSR 350—556.5 MCM AAC 336.4 (18/1)—477 (30/7) ACSR 350—550 MCM Cu GENERAL USE PARALLEL GROOVE – ALUMINUM SINGLE U-BOLT ALUMINUM LC70 For aluminum to aluminum and aluminum to copper conductor splice/tap connections and also aluminum or ACSR loop dead-ends. Sealant (XB) is recommended on all connections, except loop dead-ends. Material: Body—Top, spacer & bottom members— Aluminum Alloy Hardware—Galvanized steel Product Data & Conductor Size CATALOG NUMBER LC71B** LC72B LC73B LC74B** LC75B LC77B DIMENSIONS INCHES (MM) CONDUCTOR RANGE MAIN #6 Sol.—2/0 Str. AAC #8—2/0 ACSR #6 Sol.—2/0 Str. AAC #8—2/0 ACSR 1/0 Sol.—400 MCM AAC 1/0—336.4 MCM ACSR 1/0 Sol.—400 MCM AAC 1/0—336.4 MCM ACSR 336.4—954 MCM AAC 300—795 MCM ACSR 336.4—1033.5 MCM AAC 300—954 (45/7) ACSR TAP #6 Sol.—2/0 Str. AAC #8—2/0 ACSR #6 Sol.—2/0 Str. AAC #8—2/0 ACSR #6 Sol.—1/0 Str. AAC #8—1/0 ACSR 1/0 Sol.—400 MCM AAC #2—336.4 MCM ACSR #6 Sol.—1/0 Str. AAC #8—1/0 ACSR 336.4—1033.5 MCM AAC 300—954 (45/7) ACSR L 2 (50.80) 2-1/4 (57.15) 2-3/4 (69.85) 2-3/4 (69.85) 3-1/4 (82.55) 3-1/2 (88.90) W 2 (50.80) 2-1/4 (57.15) 2-5/8 (66.68) 2-5/8 (66.68) 3 (76.20) 3-3/8 (85.73) H 3-1/4 (82.55) 3-3/8 (85.73) 4 (101.60) 4 (101.60) 4-5/8 (117.48) 5-3/8 (136.53) J 3/8 (9.53) 1/2 (12.70) 1/2 (12.70) 1/2 (12.70) 1/2 (12.70) 5/8 (15.88) APPROX. WT. EACH LBS. (KG) .43 (.20) .77 (.35) 1.12 (.51) 1.21 (.55) 1.43 (.65) 1.97 (.89) **RUS Listed ANDERSON™ HUBBELL® POWER SYSTEMS FARGO® AUGUST 2013 DD 25 DB-25 GENERAL USE PARALLEL GROOVE – ALUMINUM TWO U-BOLT ALUMINUM LCU10 For aluminum to aluminum and aluminum to copper conductor splice/tap connections. Sealant (XB) is recommended on all connections. Material: Body—Top, spacer & bottom members— aluminum alloy Hardware—Aluminum alloy Note: For connectors without sealant, delete suffix “XB.” Product Data & Conductor Size DD 26 CATALOG NUMBER LCU13XB LCU15XB LCU16XB AUGUST 2013 DIMENSIONS INCHES (MM) L W H J APPROX. WT. EACH LBS. (KG) 4-1/8 (104.78) 2-11/16 (68.26) 4-1/2 (114.30) 1/2 (12.70) 1.07 (.49) 4-5/8 (117.48) 3-1/16 (77.79) 4-7/8 (123.83) 1/2 (12.70) 1.84 (.83) 4-5/8 (117.48) 3-7/16 (87.31) 5-1/2 (139.70) 5/8 (15.88) 1.86 (.84) CONDUCTOR RANGE MAIN 1/0 Str.—400 MCM AAC 1/0—397.5 (18/1) ACSR 336.4—954 MCM AAC 300—795 MCM ACSR TAP 1/0 Str.—400 MCM AAC 1/0—397.5 (18/1) ACSR 1/0 Str.—400 MCM Cu 1/0 Str.—400 MCM AAC 1/0—397.5 (18/1) ACSR 1/0 Str.—400 MCM Cu 336.4—954 MCM AAC 300—795 MCM ACSR 350—900 MCM Cu ANDERSON™ HUBBELL® POWER SYSTEMS FARGO® GENERAL USE PARALLEL GROOVE – ALUMINUM 3 U-BOLT ALUMINUM LCU700 For aluminum to aluminum and aluminum to copper conductor splice/tap connections. Sealant (XB) is recommended on all connections. Material: Body—Top, spacer & bottom members— Aluminum alloy Hardware—Aluminum alloy DD 27 DB-27 Product Data & Conductor Size CATALOG NUMBER LCU70055 MAIN 450—800 MCM AAC 397.5—715.5 MCM ACSR LCU70063 LCU70064 LCU70065 750—1033.5 MCM AAC 605—900 MCM ACSR LCU70066 LCU70074 LCU70076 1113—1351.5 MCM AAC 954—1192.5 MCM ACSR LCU70077 LCU70085 LCU70086 LCU70087 1431—1750 MCM AAC 1272—1590 MCM ACSR LCU70088 LCU7001006 LCU7001007 DIMENSIONS INCHES (MM) CONDUCTOR RANGE 2000—2500 MCM AAC 1780—2156 ACSR LCU7001010 ANDERSON™ TAP 450—800 MCM AAC 397.5—715.5 MCM ACSR 4/0 Sol. — 350 MCM AAC 3/0 — 336.4 (18/1) ACSR 350—477 MCM AAC 336.4—397.5 MCM ACSR 450—715.5 MCM AAC 397.5 — 605 MCM ACSR 750—1033.5 MCM AAC 605—900 MCM ACSR 350—477 MCM AAC 336.4—397.5 MCM ACSR 750—1033.5 MCM AAC 605—900 MCM ACSR 1113—1351.5 MCM AAC 954—1192.5 MCM ACSR 450—715.5 MCM AAC 397.5 — 605 MCM ACSR 750—1033.5 MCM AAC 605—900 MCM ACSR 1113—1351.5 MCM AAC 954—1192.5 MCM ACSR 1431—1750 MCM AAC 1272—1590 MCM ACSR 750—1033.5 MCM AAC 605—900 MCM ACSR 1113—1351.5 MCM AAC 954—1192.5 MCM ACSR 2000—2500 MCM AAC 1780—2156 MCM ACSR L 5-7/8 (149.23) 6-3/4 (171.45) 6-3/4 (171.45) 6-3/4 (171.45) 6-3/4 (171.45) 8 (203.20) 8 (203.20) 8 (203.20) 9-3/4 (231.78) 9-3/4 (231.78) 9-3/4 (231.78) 9-3/4 (231.78) 10 (254.0) 10 (254.0) 10 (254.0) HUBBELL® POWER SYSTEMS W 3-1/8 (79.38) 3-5/16 (84.14) 3-5/16 (84.14) 3-5/16 (84.14) 3-5/16 (84.14) 3-7/8 (98.43) 3-7/8 (98.43) 3-7/8 (98.43) 4-1/8 (104.78) 4-1/8 (104.78) 4-1/8 (104.78) 4-1/8 (104.78) 4-3/8 (111.12) 4-3/8 (111.12) 4-3/8 (111.12) H 4-11/16 (119.06) 5-1/8 (130.18) 5-1/8 (130.18) 5-1/8 (130.18) 5-1/2 (139.70) 6 (152.40) 6 (152.40) 6-3/8 (161.93) 5-3/4 (146.05) 6-3/8 (161.93) 6-3/8 (161.93) 6-3/8 (161.93) 7 (177.8) 7 (177.8) 7 (177.8) FARGO® J 5/8 (15.88) 5/8 (15.88) 5/8 (15.88) 5/8 (15.88) 5/8 (15.88) 3/4 (19.05) 3/4 (19.05) 3/4 (19.05) 3/4 (19.05) 3/4 (19.05) 3/4 (19.05) 3/4 (19.05) 3/4 (19.05) 3/4 (19.05) 3/4 (19.05) APPROX. WT. EACH LBS. (KG) 2.87 (1.30) 3.25 (1.47) 3.25 (1.47) 3.50 (1.59) 3.50 (1.59) 6.35 (2.88) 6.50 (2.95) 6.50 (2.95) 8.50 (3.86) 8.50 (3.86) 8.75 (3.97) 8.75 (3.97) 7.85 (3.53) 7.85 (3.53) 6.85 (3.08) AUGUST 2013 GENERAL USE BONDING CLAMPS ALUMINUM G50 SERIES Bonding Clamps make a dependable mechanical and electrical pressure contact between guy strand and anchor rod when the guy is part of the grounding system. Used on Thimbleye® and Angle-Thimbleye bolts to keep hardwareto-guy contacts tight, prevent excessive wear on guy strands and protect galvanizing. Maintains electrical continuity. Material: Body—Cast aluminum Hardware—Galvanized steel DD 28 Product Data & Conductor Size CATALOG NUMBER **G5067 FOR POWER INSTALLED SCREW ANCHORS (PISA®) ROD TYPE AND SIZE INCHES THIMBLEYE, 1/2 & 5/8 APPROX SHIP WT. LBS. PER 100 PIECES 22 **G5068 THIMBLEYE, 3/4 &1 36 G5069 TWINEYE, 5/8, 3/4, & 1 38 C2030148 TRIPLEYE, 5/8, 3/4, & 1 41 Product Data & Conductor Size CATALOG NUMBER **G5060 EXPANDING ANCHORS & ROCK ANCHORS ROD TYPE AND SIZE INCHES THIMBLEYE, 1/2 & 5/8 APPROX SHIP WT. LBS. PER 100 PIECES 6.5 **G5061 TWINEYE, 5/8, 3/4, & 1 13 **G5063 TRIPLEYE, 3/4 & 1 21 Product Data & Conductor Size CATALOG NUMBER G5065 FOR NO-WRENCH SCREW ANCHORS ROD TYPE AND SIZE INCHES THIMBLEYE, 3/4 &1 APPROX SHIP WT. LBS. PER 100 PIECES 15 G5063 TRIPLEYE, 3/4 & 1 21 **RUS Listed AUGUST 2013 ANDERSON™ HUBBELL® POWER SYSTEMS FARGO® GENERAL USE SPLIT BOLT WITH SEPARATOR BAR: ALUMINUM AND BRONZE BRONZE/ALUMINUM SBS For aluminum to aluminum or copper conductors. Material: Type SBS — Copper Alloy, Electro Tin-Plated Note: VERSA-SEAL® oxide inhibiting compound is recommended for use with Al/Cu parallel connectors. * Hex Head design for maximum tool ease of use. DD 29 DB-29 LISTED 261L Product Data & Conductor Size CATALOG NUMBER CONDUCTOR RANGE OF EQUAL MAIN & TAP (AWG OR MCM) MAIN TAP MIN. TAP WITH ONE MAX. MAIN BOLT SIZE SBS6 8 6* 14 7/16 SBS4 8 4 10 1/2 SBS2 6 2 14 9/16 SBS10 4 1/0 10 11/16 SBS20 2 2/0 8 3/4 SBS30 1 3/0 8 7/8 SBS250 1 250 8 1 SBS350 2/0 350 1/0 1-1/2 SBS500 300 500 2/0 1-5/8 F 5/8 (15.88) 13/16 (20.63) 7/8 (22.22) 15/16 (23.81) 1-1/16 (26.97) 1-1/4 (31.75) 1-3/8 (34.93) 1-1/2 (38.01) 1-3/4 (44.45) DIMENSIONS INCHES (MM) W .49 (12.45) .71 (18.03) .75 (19.05) .79 (20.07) .87 (22.10) 1.10 (27.94) 1.10 (27.94) 1.22 (30.99) 1.34 (34.04) H 1.06 (26.92) 1.24 (31.5) 1.44 (36.58) 1.73 (43.94) 1.71 (43.43) 2.13 (54.10) 2.22 (56.39) 2.56 (65.02) 2.95 (74.93) APPROX. WT. EACH LBS. (KG) 0.06 (.03) 0.09 (.04) 0.12 (.05) 0.18 (.08) 0.21 (.10) 0.35 (.16) 0.39 (.18) 0.60 (.27) 0.85 (.39) *AL9CU (90° C Rated) •• Not UL Listed or CSA certified for aluminum to copper connections. UL listed for copper connections only. ANDERSON™ HUBBELL® POWER SYSTEMS FARGO® AUGUST 2013 GENERAL USE SPLIT BOLT CONNECTOR — BRONZE BRONZE SBN For copper to copper 2-wire conducor connection. Material: Body — Copper Alloy LISTED 261L Product Data & Conductor Size CATALOG NUMBER DD 30 CONDUCTOR RANGE OF EQUAL MAIN & TAP (AWG OR MCM) MIN. MAX. MIN. TAP WITH ONE MAX. MAIN BOLT SIZE SBN8 10 8 16 3/8 SBN6 8 6* 16 7/16 SBN4 8 4 14 1/2 SBN2 6 2 14 9/16 SBN10 4 1/0 14 11/16 SBN20 2 2/0 14 3/4 SBN30 1 3/0 8 7/8 SBN250 1 250 8 1 SBN350 2/0 350 1/0 1-1/2 SBN500 300 500 2/0 1-5/8 C750 350 750 8 1-15/16 C1000 500 1000 8 2-1/4 *Solid Conductor F 9/16 (14.29) 5/8 (15.88) 13/16 (20.63) 7/8 (22.22) 15/16 (23.81) 1-1/16 (26.97) 1-1/4 (31.75) 1-3/8 (34.93) 1-1/2 (38.01) 1-3/4 (44.45) 2-1/8 (53.97) 2-1/8 (53.97) DIMENSIONS INCHES (MM) W .47 (12) .49 (12.45) .71 (18.03) .75 (19.05) .79 (20.07) .87 (22.10) 1.10 (27.94) 1.10 (27.94) 1.22 (30.99) 1.34 (34.04) 1.94 (49.28) 2.25 (57.15) H .85 (21.59) .91 (23.11) 1.16 (29.46) 1.25 (31.75) 1.54 (39.12) 1.69 (42.93) 2.09 (53.09) 2.09 (53.09) 2.36 (59.94) 2.83 (71.88) 3.56 (90.42) 4.03 (102.36) APPROX. WT. EACH LBS. (KG) 0.04 (.02) 0.05 (.02) 0.08 (.04) 0.09 (.04) 0.14 (.06) 0.19 (.09) 0.30 (.14) 0.34 (.15) 0.51 (.23) 0.73 (.33) 1.76 (.80) 2.8 (1.27) GENERAL USE PARALLEL GROOVE – BRONZE SINGLE CENTER BOLT BRONZE ST For copper (Cu), Copperweld (CW) and guy strand (GS) connections. Material: Body—High strength Bronze Aloy Hardware—Silicon Bronze or Stainless Steel Add Suffix “TP” for Tin-Plated Version. Product Data & Conductor Size CATALOG NUMBER ST3 ST4 AUGUST 2013 DIMENSIONS INCHES (MM) L W H J APPROX. WT. EACH LBS. (KG) 7/8 (22.2) 1-1/2 (38.1) 1-1/2 (38.1) 5/16 (7.9) .22 (9.98) 15/16 (23.8) 1-7/8 (47.6) 1-1/2 (38.1) 3/8 (9.5) .30 (13.61) CONDUCTOR RANGE (AWG) MAIN #8 Sol.—2/0 Str. Cu #8 A—2/0 F CW 1/8”—7/16” CW/GS .125”—.438 #6 Sol.—4/0 Str. Cu #6A—4/0 F CW 1/4”—9/16” CW/GS .162”—.562” TAP #8 Sol.—2/0 Str. Cu #9 1/2D—2/0 F CW 1/8”—7/16” CW/GS .125”—.438” #6 Sol.—4/0 Str. Cu #6A—4/0 F CW 1/4”—9/16” CW/GS .162”—.562” ANDERSON™ HUBBELL® POWER SYSTEMS FARGO® GENERAL USE – PARALLEL BRONZE BRONZE K, K_L For copper to copper conductor connections. Material: Body—High strength bronze alloy Retaining Ring—Neoprene rubber Hardware—Silicon bronze LISTED 261L “TP” = Tin-Plated Version. Product Data & Conductor Size DIMENSIONS INCHES (MM) CONDUCTOR RANGE (AWG) CATALOG NUMBER MAIN TAP K1 #4 Str.—1/0 Str. Cu #8 Sol.—1/0 Str. Cu K2 #3 Str.—2/0 Str. Cu #8 Sol.—2/0 Str. Cu K3 #1 Str.—4/0 Str. Cu #8 Sol.—4/0 Str. Cu K41 2/0 Str.—350 MCM Cu #8 Sol.—350 MCM Cu K5 3/0 Str.—500 MCM Cu #8 Sol.—500 MCM Cu K6 350—800 MCM Cu #8 Sol.—800 MCM Cu K7 500—1000 MCM Cu #8 Sol.—1000 MCM Cu L 15/16 (23.81) 1-1/16 (26.99) 1-1/8 (28.58) 1-3/8 (34.93) 1-1/2 (38.10) 1-5/8 (41.28) 2 (50.80) W 1-5/16 (33.34) 1-5/8 (41.28) 1-3/4 (44.45) 2-1/8 (53.98) 2-1/4 (57.15) 2-1/2 (63.50) 3 (76.70) H 1-5/16 (33.34) 1-21/32 (42.07) 1-15/16 (49.21) 2-3/8 (60.33) 2-11/16 (68.26) 3-3/16 (80.96) 3-11/16 (93.66) J 5/16 (7.94) 3/8 (9.53) 3/8 (9.53) 1/2 (12.70) 1/2 (12.70) 1/2 (12.70) 5/8 (15.88) APPROX. WT. EACH LBS. (KG) .125 (.06) .29 (.13) .40 (.18) .655 (.30) .80 (.36) 1.00 (.45) 2.13 (.97) * For equal length bolts (Separable), Add “L” Suffix. For Tin-Plating, Add “TP” Suffix – Consult Factory. GENERAL USE – PARALLEL BRONZE WITH SEPARATOR BRONZE KR For copper to copper conductor connections. Material: Body—High strength bronze alloy Separator—Copper alloy Retaining Ring—Neoprene rubber Hardware—Silicon bronze LISTED 261L Product Data & Conductor Size CONDUCTOR RANGE (AWG or MCM) MAIN TAP CATALOG NUMBER KR1 #4 Str.—1/0 Str. Cu #8 Sol.—1/0 Str. Cu KR2 #3 Str.—2/0 Str. Cu #6 Sol.—2/0 Str. Cu KR3 #1 Str.—4/0 Str. Cu #6 Sol.—4/0 Str. Cu KR4 2/0 Str.—350 MCM Cu #4 Sol.—350 MCM Cu KR5 3/0 Str.—500 MCM Cu #4 Sol.—500 MCM Cu KR6 350—800 MCM Cu #2 Str.—800 MCM Cu KR7 450—1000 MCM Cu 1/0 Str.—1000 MCM Cu DIMENSIONS INCHES (MM) L 15/16 (23.81) 1-1/16 (26.99) 1-1/8 (28.58) 1-3/8 (34.93) 1-1/2 (38.10) 1-5/8 (41.28) 2 (50.80) W 1-5/16 (33.34) 1-5/8 (41.28) 1-3/4 (44.45) 2-1/8 (53.98) 2-1/4 (57.15) 2-1/2 (63.50) 3 (76.70) H 1-1/2 (38.10) 1-25/32 (45.24) 2-1/8 (53.98) 2-9/16 (65.09) 2-15/16 (74.61) 3-7/16 (87.31) 4 (101.60) J 5/16 (7.94) 3/8 (9.53) 3/8 (9.53) 1/2 (12.70) 1/2 (12.70) 1/2 (12.70) 5/8 (15.88) APPROX. WT. EACH LBS. (KG) .18 (.08) .35 (.16) .43 (.19) .78 (.35) .86 (.39) 1.25 (.57) 2.45 (1.11) * For equal length bolts (Separable), Add “L” Suffix. For Tin-Plating, Add “TP” Suffix – Consult Factory. ANDERSON™ HUBBELL® POWER SYSTEMS FARGO® AUGUST 2013 DD 31 DB-31 GENERAL USE PARALLEL GROOVE BRONZE SINGLE U-BOLT BRONZE LC1000 For copper to copper conductor connections. Material: Body Halves—High strength Bronze alloy Separator—Copper alloy Hardware—Silicon bronze Product Data & Conductor Size DD 32 CATALOG NUMBER CONDUCTOR RANGE (AWG OR MCM) MAIN TAP LC1002* #2 Sol.—2/0 Str. Cu #2 Sol.—2/0 Str. Cu LC1003* #1 Sol.—4/0 Str. Cu #1 Sol.—4/0 Str. Cu LC1004 1/0 Sol.—300 MCM Cu 1/0 Sol.—300 MCM Cu DIMENSIONS INCHES (MM) L 1-1/2 (38.10) 1-3/4 (44.45) 2 (50.80) W 1-15/16 (49.21) 2-5/16 (58.74) 2- 7/16 (61.91) H 2-3/4 (69.85) 3 (76.20) 3-1/2 (88.90) J 3/8 (9.53) 1/2 (12.70) 1/2 (12.70) APPROX. WT. EACH LBS. (KG) .65 (.29) 1.00 (.45) 1.15 (.52) * Add “TP” Suffix for Tin-Plated Connector GENERAL USE PARALLEL GROOVE BRONZE 2 U-BOLT BRONZE LC1100 For copper to copper conductor connections. Material: Body Halves—High strength Bronze alloy Separator—Copper alloy Hardware—Silicon bronze Product Data & Conductor Size CATALOG NUMBER CONDUCTOR RANGE (AWG OR MCM) MAIN TAP LC1133 #1 Sol.—4/0 Str. Cu #1 Sol.—4/0 Str. Cu LC11445 1/0 Sol.—350 MCM Cu 1/0 Sol.—350 MCM Cu LC1155 4/0 Sol.—500 MCM Cu 4/0 Sol.—500 MCM Cu LC1166 300—750 MCM Cu 300—750 MCM Cu LC1177 500—1000 MCM Cu 500—1000 MCM Cu AUGUST 2013 ANDERSON™ DIMENSIONS INCHES (MM) L 2-3/4 (69.85) 3-1/4 (82.55) 3-3/8 (85.73) 3-5/8 (92.08) 4 (101.60) W 1-15/16 (49.21) 2-1/2 (63.50) 2-5/8 (66.68) 2-15/16 (74.61) 3-1/16 (77.79) H 3 (76.20) 3-3/4 (92.25) 4 (101.60) 4-1/2 (114.30) 5 (127.00) HUBBELL® POWER SYSTEMS J 3/8 (9.53) 1/2 (12.70) 1/2 (12.70) 1/2 (12.70) 1/2 (12.70) APPROX. WT. EACH LBS. (KG) 1.60 (.73) 2.25 (1.02) 2.40 (1.09) 2.90 (1.32) 3.62 (1.64) FARGO® GENERAL USE PARALLEL GROOVE – 4 WAY, 2/4 BOLT BRONZE BRONZE XP® For copper to copper conductors cross, tee, parallel or end to end connections. Material: Body Members—High strength bronze Separator—Copper alloy Hardware—Silicon bronze or Stainless Steel Note: Add suffix “TP” for tin-plated connector. DD 33 DB-33 LISTED 261L FIGURE 1 FIGURE 2 Product Data & Conductor Size CATALOG NUMBER FIGURE NO. MAIN TAP XP024024 1 #1 Str.—4/0 Str. Cu #1 Str.—4/0 Str. Cu XP050050 2 4/0 Str.—500 MCM Cu 4/0 Str.—500 MCM Cu XP100050 2 500—1000 MCM Cu 4/0 Str.—500 MCM Cu XP100100 2 500—1000 MCM Cu 500—1000 MCM Cu ANDERSON™ DIMENSIONS INCHES (MM) CONDUCTOR RANGE (AWG OR MCM) HUBBELL® POWER SYSTEMS L 1- 7/8 (47.63) 2 (50.80) 2 (50.80) 2-1/2 (63.50) W 1- 7/8 (47.63) 2 (50.80) 2 (50.80) 2-1/2 (63.50) H 2-9/16 (65.09) 3-3/16 (80.96) 3-3/8 (85.73) 3-11/16 (93.66) FARGO® J 3/8 (9.53) 3/8 (9.53) 3/8 (9.53) 3/8 (9.53) APPROX. WT. EACH LBS. (KG) .70 (.32) 1.40 (.64) 1.70 (.77) 2.40 (1.09) AUGUST 2013 GENERAL USE PARALLEL GROOVE BRONZE MULTIPLE CENTER BOLT BRONZE LC400 For copper to copper conductor connections. Material: Body—High strength bronze alloy Hardware—Silicon bronze or Stainless Steel Add suffix “TP” for tin-plated Connector. FIGURE 1 FIGURE 2 DD 34 Product Data & Conductor Size DIMENSIONS INCHES (MM) CONDUCTOR RANGE (AWG OR MCM) CATALOG NUMBER FIGURE NO. MAIN TAP LC402 1 #4 Sol.—4/0 Str. Cu #4 Sol.—4/0 Str. Cu LC4025 1 #4 Sol.—4/0 Str. Cu #4 Sol.—4/0 Str. Cu LC4035 1 #2 Sol.—300 MCM Cu #2 Sol.—300 MCM Cu LC404 2 4/0 Str.—500 MCM Cu 4/0 Str.—500 MCM Cu LC406 2 500—1000 MCM Cu 500—1000 MCM Cu L 2-9/32 (57.94) 2-13/16 (71.44) 3-1/8 (79.38) 4-3/8 (111.13) 5-1/8 (130.18) W 1-27/32 (46.83) 2 (50.80) 2-1/4 (57.15) 2-5/8 (66.68) 3-1/2 (88.90) H 2-1/4 (57.15) 2-1/4 (57.15) 2-1/4 (57.15) 2-5/8 (66.68) 3-3/8 (85.73) APPROX. WT. EACH LBS. (KG) .82 (.37) 1.38 (.62) 1.79 (.81) 2.99 (1.36) 4.70 (2.13) J 3/8 (9.53) 1/2 (12.70) 1/2 (12.70) 1/2 (12.70) 1/2 (12.70) GENERAL USE PARALLEL GROOVE BRONZE SINGLE CENTER BOLT BRONZE LC1600 For copper to copper conductor connections. Material: Body—High strength Bronze Alloy Hardware—Silicon Bronze or Stainless Steel Add suffix “TP” for tin-plated Connector. Product Data & Conductor Size CATALOG NUMBER CONDUCTOR RANGE (AWG OR MCM) MAIN TAP LC1601 1/0 Sol.—4/0 Str. Cu #8 Sol.—#1 Str. Cu LC1602 1/0 Sol.—400 MCM Cu #8 Sol.—3/0 Str. Cu AUGUST 2013 ANDERSON™ DIMENSIONS INCHES (MM) L 2 (50.80) 2-3/8 (60.33) W 1-3/4 (44.45) 2-1/4 (57.15) H 2 (50.80) 2-3/4 (69.85) HUBBELL® POWER SYSTEMS J 3/8 (9.53) 1/2 (12.70) APPROX. WT. EACH LBS. (KG) .58 (.26) 1.05 (.48) FARGO® GENERAL USE SETSCREW LUGS ALUMINUM ALUMINUM DA & DU Type DA, UL Listed for one aluminum or copper conductor. Type DU, UL Listed for two aluminum or copper conductors. AL9CU (90°C Rated) LISTED 261L Material: Body—Aluminum alloy—tin-plated Slotted Head Hex Socket T K W L FIGURE 4 FIGURE 3 FIGURE 2 FIGURE 1 D Product Data & Conductor Size CATALOG NUMBER FIGURE ALUMINUM OR COPPER NO. CONDUCTOR RANGE (AWG OR MCM) DA6 1 #14 Sol.—#6 Str. DA2 1 #14 Sol.—#2 Str. DA0 1 #14 Sol.—1/0 Str. DA20 1 #14 Sol.—2/0 Str. DA250 2 #6 Sol.—250 MCM DA300 2 #6 Sol.—300 MCM DA350 2 #6 Sol.—350 MCM DA500 2 #4 Str.—500 MCM DA600 2 #2 Sol.—600 MCM DA800 2 300—800 MCM DA1000 2 500—1000 MCM DA600S 3 One—#4 Str.—600 MCM Two—1/0 Str.—250 MCM DU0 4 #14 Sol.—1/0 Str. DU20 4 #14 Sol.—2/0 Str. DU250 4 #6 Sol.—250 MCM DU350 4 #6 Sol.—350 MCM DU600S 4 #2 Sol.—600 MCM DU800 4 300—800 MCM DU1000 4 350—1000 MCM ANDERSON™ PAD BOLT SIZE 1/4” (6.35) 1/4” (6.35) 1/4” (6.35) 1/4” (6.35) 5/16” (7.94) 5/16” (7.94) 3/8” (9.53) 3/8” (9.53) 3/8” (9.53) 5/8” (15.88) 5/8” (15.88) 3/8” (9.53) 1/4” (6.35) 1/4” (6.35) 3/8” (9.53) 1/2” (12.70) 1/2” (12.70) 5/8” (15.88) 5/8” (15.88) DIMENSIONS INCHES (MM) L 1- 1/16 (26.99) 1-5/32 (29.37) 1-15/32 (37.31) 1-15/32 (37.31) 2 (50.80) 2 (50.80) 2-1/4 (57.15) 2-13/16 (71.44) 3-3/16 (80.96) 3-1/2 (88.90) 3-1/2 (88.90) 2-13/16 (71.44) 1-15/32 (37.31) 1-15/32 (37.31) 2-9/16 (65.09) 2-7/8 (73.03) 3-3/16 (80.96) 3-1/2 (88.90) 3-1/2 (88.90) HUBBELL® POWER SYSTEMS D 11/16 (17.46) 11/16 (17.46) 27/32 (21.43) 27/32 (21.43) 1 (25.40) 1 (25.40) 1-1/8 (28.58) 1-19/32 (40.48) 1-13/16 (46.04) 1-7/8 (47.63) 1-7/8 (47.63) 1-1/2 (38.10) 27/32 (21.43) 27/32 (21.43) 1-9/16 (36.69) 1-3/4 (44.45) 1-13/16 (46.04) 2 (50.80) 1-7/8 (47.62) K 1/4 (6.35) 5/16 (7.94) 7/16 (11.11) 7/16 (11.11) 15/32 (11/91) 15/32 (11/91) 31/64 (12.3) 3/4 (19.05) 25/32 (19.84) 7/8 (22.23) 7/8 (22.23) 5/8 (15.88) 27/64 (10.72) 27/64 (10.72) 7/8 (22.23) 7/8 (22.23) 5/8 (15.88) 13/16 (17.53) 7/8 (22.23) W 1/2 (12.70) 1/2 (12.70) 5/8 (15.88) 5/8 (15.88) 1 (25.40) 1 (25.40) 1-1/8 (28.58) 1-1/4 (31.75) 1-1/2 (38.10) 1-3/4 (44.45) 1-3/4 (44.45) 1-3/8 (34.92) 1-3/8 (34.92) 1-1/4 (31.75) 1-41/64 (41.67) 1-59/64 (48.82) 2 (50.80) 3-1/2 (88.90) 3-1/2 (88.90) FARGO® T .093 (2.36) .100 (2.54) .1875 (4.76) .1875 (4.76) .25 (6.35) .25 (6.35) .25 (6.35) .312 (7.92) .438 (11.13) .500 (12.70) .500 (12.70) .3125 (7.94) .1875 (4.76) .1875 (4.76) .25 (6.35) .25 (6.35) .438 (11.13) .500 (12.70) .500 (12.70) APPROX. WT. EACH LBS. (KG) 1.5 (.68) 2 (.90) 4 (1.81) 5 (2.26) 14 (6.34) 14 (6.34) 20 (9.07) 39 (17.68) 45 (20.40) 40 (18.14) 36 (16.32) 45 (20.40) 6.2 (2.81) 7.0 (3.17) 25 (11.33) 30 (13.60) 70 (31.74) 75 (34.01) 81 (36.74) AUGUST 2013 DD 35 DB-35 GENERAL USE — DISTRIBUTION SETSCREW — GUTTER TAPS ALUMINUM ALUMINUM GPT For aluminum to aluminum, aluminum to copper or copper to aluminum conductor parallel/tap connections. Material: Body and Keeper—Aluminum alloy—tin-plated H Note: See type GTC if insulating cover is required. L AL9CU (90°C Rated) W LISTED 261L Product Data & Conductor Size DD 36 CATALOG NUMBER GPT2 GPT0 GPT250 AUGUST 2013 CONDUCTOR RANGE (AWG OR MCM) MAIN TAPS #14—#4 Str. Cu #12—#2 STR. Al/Cu #12—#4 Str. Al #14—1/0 Str. Cu #2—1/0 Str. Al/Cu #12—1/0 Str. Al 1/0 Str.—250 MCM Al/Cu ANDERSON™ #6 Str.—250 MCM Al/Cu L 1-13/32 (35.72) 1-3/4 (44.45) 2-9/32 (57.94) DIMENSIONS INCHES (MM) W 5/8 (15.88) 3/4 (19.05) 1-1/16 (26.99) HUBBELL® POWER SYSTEMS H 7/8 (22.23) 1 (25.40) 1-5/16 (33.34) APPROX. WT. EACH LBS. (KG) .06 (.03) .10 (.04) .22 (.10) FARGO® GENERAL USE SETSCREW PAD LUGS ALUMINUM For one to four aluminum or copper conductors to two and four hole flat pads. ALUMINUM L_M2 LISTED 261L AL9CU (90°C Rated) Material: Aluminum alloy—tin-plated 1-3/4” L D K T W 1-3/4” FIGURE 1 FIGURE 2 FIGURE 3 FIGURE 4 Product Data & Conductor Size CATALOG NUMBER FIGURE NO. L3M210* 1 L3M2250 1 L1M2350 4 L3M2350 1 L3M2500 1 L3M4500 2 L4M4500 3 PAD BOLT SIZE 3/8” (9.53) ALUMINUM OR COPPER CONDUCTOR RANGE (AWG OR MCM) #14—1/0 Str. #6 Str.—250 MCM #6 Str.—350 MCM 1/2” (12.70) #4 Str.—500 MCM DIMENSIONS INCHES (MM) L 2 15/16 (74.68) 4-1/4 (107.95) 4-1/2 (114.30) 4-1/4 (107.95) D 2-3/16 (55.63) 3 (76.20) K 11/32 (8.64) 5/8 (15.88) 3 (76.20) 5/8 (15.88) 4-11/16 (119.13) 3-5/16 (84.14) 5/8 (15.88) W 2 (50.80) 3 (76.20) 1-1/4 (31.75) 3-1/2 (88.90) T 1/4 (6.35) 5/16 (7.94) 3-3/4 (95.25) 7/16 (11.11) 5 (127.00) APPROX. WT. EACH LBS. (KG) .27 (.12) .52 (.24) .26 (.12) .77 (.35) 1.10 (.50) 1.05 (.47) 1.06 (.48) * Pad holes on 1” centers GENERAL USE SETSCREW GROUND LUGS ALUMINUM Designed for use on conduit grounding bushings. Open face design allows installer to quickly lay-in the grounding conductor as a jumper to multiple rigid conduits. For aluminum or copper conductors. Material: Aluminum alloy—tin-plated LISTED 261L ALUMINUM LI_S H T Slotted L W Hex Head Product Data & Conductor Size CATALOG NUMBER ALUMINUM OR COPPER CONDUCTOR RANGE (AWG OR MCM) PAD BOLT SIZE LI50S* #14—#4 Str. #10 DIMENSIONS INCHES (MM) L 1-3/32 (26.19) T 5/32 (3.97) W 3/8 (9.53) H 25/32 (19.84) APPROX. WT. EACH LBS. (KG) .016 (.007) * Slotted head set screws. ANDERSON™ HUBBELL® POWER SYSTEMS FARGO® AUGUST 2013 DD 37 DB-37 GENERAL USE SETSCREW TERMINAL PADS ALUMINUM ALUMINUM L_D_ For one, two, three and four aluminum or copper conductors to two and four hole flat pads. Material: Aluminum alloy—tin-plated 1-3/4” T DD 38 1-3/4” W FIGURE 2 FIGURE 1 FIGURE 4 FIGURE 3 LISTED 261L AL9CU (90°C Rated) Product Data & Conductor Size CATALOG NUMBER FIGURE NO. L1D2250 1 L1D2350 1 L2D2350 2 L1D2600 1 L2D2600 2 L3D4600 3 L4D4600 4 L1D2800 1 L3D4800 3 L4D4800 4 L2D21000 2 L3D41000 3 PAD BOLT SIZE ALUMINUM OR COPPER CONDUCTOR RANGE (AWG OR MCM) #6 Str.—250 MCM #6 Str.—350 MCM DIMENSIONS INCHES (MM) L 5-5/16 (134.94) 5-1/2 (139.7) D 3 5/16 (84.14) 3-1/4 (82.55) 5-5/16 (134.94) 3-1/16 (77.79) 5-1/2 (139.7) 3-1/4 (82.55 6-3/16 (157.16) 3-7/16 (87.38) K 300—800 MCM 350—800 MCM 500—1000 MCM T 1-1/4 (31.75) #2 Str.—600 MCM 1/2” (12.70) W 5/8 (15.88) 2-5/16 (58.74) 1-1/2 (38.10) 2-3/4 (69.85) 4-3/16 (106.36) 5-9/32 (134.14) 1-7/8 (47.63) 4-15/16 (125.41) 6-5/8 (168.28) 3-1/2 (88.90) 5-5/16 (134.94) 3/8 (9.53) APPROX. WT. EACH LBS. (KG) .45 (.20) .50 (.22) .85 (.38) .50 (.23) .89 (.40) 1.36 (.61) 2.81 (1.27) .67 (.30) 2.11 (.95) 2.84 (1.28) 2.10 (.95) 3.09 (1.40) * Except with 2-Hole Pad AUGUST 2013 ANDERSON™ HUBBELL® POWER SYSTEMS FARGO® GENERAL USE 600V INSULATING COVER PLASTIC PLASTIC GTC Material: Thermoplastic H LISTED 261L AL9CU (90°C Rated) L W Product Data & Conductor Size APPROX. WT. EACH LBS. (KG) .025 (.011) .035 (.016) .080 (.036) DIMENSIONS INCHES (MM) CATALOG NUMBER INSULATING COVER FOR CATALOG NUMBER COLOR GTC2 GPT-2 Yellow GTC10 GPT-0 Gray GTC250 GPT-250 Red L 2-1/4 (57.15) 2-5/8 (66.68) 3-7/16 (87.31) W 1-7/8 (47.63) 2-3/16 (55.56) 3-3/16 (80.96) H 1-1/8 (28.58) 1-9/32 (32.54) 1-5/8 (41.28) GENERAL USE SETSCREW BUTT SPLICES ALUMINUM ALUMINUM SR H Material: Aluminum alloy—tin-plated L LISTED 261L AL9CU (90°C Rated) W FIGURE 1 FIGURE 2 Product Data & Conductor Size CATALOG NUMBER FIGURE NO. CONDUCTOR RANGE AL/CU STRIP LENGTH SR2 1 #14—#2 Str. 5/8 SR0 1 #14—1/0 Str. 7/8 SR250 2 #6 Str.—250 MCM 1-15/16 SR350 2 #6 Str.—350 MCM 2-1/16 SR500 2 3/0 Str.—500 MCM 2-7/16 SR750 2 250—750 MCM 3-1/16 ANDERSON™ HUBBELL® POWER SYSTEMS DIMENSIONS INCHES (MM) L 1-3/8 (34.93) 1-29/32 (48.42) 3-15/16 (100.01) 4-3/16 (106.36) 5 (127.00) 6-1/4 (158.75) W 1/2 (12.70) 3/4 (19.05) 1 (25.40) 1-1/8 (28.58) 1-3/8 (34.93) 1-5/8 (41.28) FARGO® H 9/16 (14.29) 3/4 (19.05) 1-1/8 (28.58) 1-3/16 (30.16) 1-1/2 (38.10) 1-3/4 (44.45) APPROX. WT. EACH LBS. (KG) .03 (.01) .09 (.04) .33 (.15) .40 (.18) .74 (.34) 1.043 (.47) AUGUST 2013 DD 39 DB-39 GENERAL USE SETSCREW STEP LUGS – ALUMINUM ALUMINUM PV For two, three and four aluminum or copper conductors to two and four hole flat pads. LISTED 261L AL9CU (90°C Rated) Material: Aluminum alloy—tin-plated H T L D K W FIGURE 5 FIGURE 4 *TYPICAL FIGURES 4 & 5 FIGURE 3 FIGURE 2 FIGURE 1 FIGURE 6 Product Data & Conductor Size DD 40 CATALOG NUMBER FIGURE NO. PV2300 1 PV2500 4 PV2600 4 PV2750 4 PV3300 3 PV3500 6 PV3600 6 PV3750 6 PV4300 2 PV4500 5 PV4600 5 PV4750 5 PAD BOLT SIZE 5/16” (7.94) 3/8” (9.53) 3/8” (9.53) 3/8” (9.53) 5/16” (7.94) 3/8” (9.53) 3/8” (9.53) 3/8” (9.53) 5/16” (7.94) 3/8” (9.53) 3/8” (9.53) 3/8” (9.53) ALUMINUM OR COPPER CONDUCTOR RANGE (AWG OR MCM) #6 Str.—300 MCM #2 Str.—500 MCM #2 Str.—600 MCM 1/0 Str.—750 MCM #6 Str.—300 MCM #2 Str.—500 MCM #2 Str.—600 MCM 1/0 Str.—750 MCM #6 Str.—300 MCM #2 Str.—500 MCM #2 Str.—600 MCM 1/0 Str.—750 MCM DIMENSIONS INCHES (MM) L D 3 (76.20) 4-29/32 (124.62) 4-29/32 (124.62) 4-29/32 (124.62) 3 (76.20) 4-29/32 (124.62) 4-29/32 (124.62) 4-29/32 (124.62) 3 (76.20) 4-29/32 (124.62) 4-29/32 (124.62) 4-29/32 (124.62) K 1 (25.40) 2-11/32 (59.35) 2-11/32 (59.35) 2-11/32 (59.35) 1 (25.40) 2-11/32 (59.35) 2-11/32 (59.35) 2-11/32 (59.35) 1 (25.40) 2-11/32 (59.35) 2-11/32 (59.35) 2-11/32 (59.35) 15/32 (11.90) 3/8 (9.53) 3/8 (9.53) 3/8 (9.53) 15/32 (11.90) 3/8 (9.53) 3/8 (9.53) 3/8 (9.53) 15/32 (11.90) 3/8 (9.53) 3/8 (9.53) 3/8 (9.53) W H 1 (25.40) 1-1/2 (38.10) 1-1/2 (38.10) 1-1/2 (38.10) 2-1/8 (53.93) 2-1/2 (63.50) 2-1/2 (63.50) 2-27/32 (72.23) 2-1/8 (53.93) 2-1/2 (63.50) 2-1/2 (63.50) 2-27/32 (72.23) T 2 (50.80) 3 (76.20) 3 (76.20) 3 (76.20) 2 (50.80) 3 (76.20) 3 (76.20) 3 (76.20) 3 (76.20) 3 (76.20) 3 (76.20) 3 (76.20) 1/2 (12.70) 3/4 (19.05) 3/4 (19.05) 3/4 (19.05) 1/2 (12.70) 3/4 (19.05) 3/4 (19.05) 3/4 (19.05) 1/2 (12.70) 3/4 (19.05) 3/4 (19.05) 3/4 (19.05) GENERAL USE SETSCREW LUGS – ALUMINUM ALUMINUM SG L FIGURE 1 1-1/2”-2” Designed with slotted mounting holes on 350 MCM and above wire range for varied mounting arrangements. K T W .26 (.18) 1.004 (.46) .86 (.39) .80 (.36) .66 (.30) 1.781 (.81) 1.86 (.84) 1.88 (.85) .56 (.25) 1.706 (.77) 1.785 (.81) 1.60 (.72) LISTED 261L AL9CU (90°C Rated) 1” D APPROX. WT. EACH LBS. (KG) FIGURE 3 FIGURE 2 *TYPICAL FIGURES 2 & 3 Material: Aluminum alloy—tin-plated Product Data & Conductor Size CATALOG NUMBER FIGURE NO. SG250 1 SG350 2 SG500 2 SG1000 3 AUGUST 2013 PAD BOLT SIZE 3/8” (9.53) 1/2” (12.7) 1/2” (12.7) 1/2” (12.7) ALUMINUM OR COPPER CONDUCTOR RANGE (AWG OR MCM) 3/0 —250 MCM #4—350 MCM 400 Str.—500 MCM 350—1000 MCM ANDERSON™ DIMENSIONS INCHES (MM) L 3 (76.20) 4-11/16 (119.06) 4-11/16 (119.06) 6-1/64 (152.80) D 2 (50.80) 3-5/16 (84.14) 3-5/16 (84.14) 3-7/16 (87.31) K 1 (25.40) 1-1/2 (38.10) 1-1/2 (38.10) 1-1/2 (38.10) W 1 (25.40) 1-1/4 (31.75) 1-1/4 (31.75) 1-5/8 (41.28) HUBBELL® POWER SYSTEMS T 1/4 (6.35) 7/16 (11.11) 7/16 (11.11) 9/16 (14.29) APPROX. WT. EACH LBS. (KG) .14 (.06) .54 (.24) .56 (.25) .88 (.40) FARGO® GENERAL USE SETSCREW TERMINAL PADS BRONZE 2 OR 3 CABLES TO PAD BRONZE LU2 & LU3 UL Listed for two or three copper conductors. Material: Body—Bronze alloy Hardware—Plated steel 1-3/4” W 1-3/4” T K DD 41 DB-41 D L FIGURE 1 FIGURE 3 FIGURE 2 FIGURE 4 LISTED 261L Product Data & Conductor Size CATALOG NUMBER FIGURE NO. COPPER CONDUCTOR RANGE (AWG OR MCM) PAD BOLT SIZE LU2102N 1 #4 Sol.—1/0 Str. 1/2 LU23002N 1 2/0 Str. —300 MCM 1/2 LU25002N 1 4/0 Str.—500 MCM 1/2 LU35002N 3 4/0 Str.—500 MCM 1/2 LU25004N 2 4/0 Str.—500 MCM 1/2 LU35004N 4 4/0 Str.—500 MCM 1/2 *LU310004N 4 500—1000 MCM 1/2 DIMENSIONS INCHES (MM) L 4 (101.6) 4-1/8 (104.78) 4-1/2 (114.30) 4-1/2 (114.30) 4-1/2 (114.30) 4-1/2 (114.30) 5-3/16 (131.76) D 3-9/16 (90.49) 3-1/2 (88.90) 3-7/8 (98.43) 3-5/8 (92.08) 3-3/4 (95.25) 3-5/8 (92.08) 3-7/8 (98.43) K 5/8 (15.88) 5/8 (15.88) 5/8 (15.88) 5/8 (15.88) 5/8 (15.88) 5/8 (15.88) 5/8 (15.88) W 1-1/2 (38.10) 2 (50.80) 2-1/2 (63.50) 2-1/2 (63.50) 3 (76.20) 3 (76.20) 3-1/4 (82.55) T 1/4 (6.35) 1/4 (6.35) 1/2 (12.70) 5/8 (15.88) 3/8 (9.53) 1/2 (12.70) 5/8 (15.88) APPROX. WT. EACH LBS. (KG) 38 (17.23) 117 (53.05) 184 (83.44) 227 (102.94) 205 (92.96) 247 (112.01) 512 (232.19) *Not UL Listed or CSA Approved. ANDERSON™ HUBBELL® POWER SYSTEMS FARGO® AUGUST 2013 GENERAL USE SETSCREW LUGS BRONZE BRONZE KA-H UL Listed for copper conductor. Material: Body—Copper or bronze alloy Hardware—Plated steel LISTED 261L Compacted, economical, high copper alloy terminal for joining a wide range of cable to equipment pads or terminal blocks. DD 42 FIGURE 1 FIGURE 2 FIGURE 3 Product Data & Conductor Size CATALOG NUMBER FIGURE NO. COPPER CONDUCTOR RANGE (AWG OR MCM) PAD BOLT SIZE KA8CH 1 #14 Sol.—#8 Str. #10 KA4CH 1 #14 Sol.—#4 Str. 1/4 KA25H 2 #4 Str.—1/0 Str. 3/8 KA252TC38H 3 #4 Str.—1/0 Str. 3/8 KA28H 2 #1 Str.—4/0 Str. 3/8 KA34H 2 4/0 Str.—500 MCM 1/2 DIMENSIONS INCHES (MM) C 3/8 (9.55) 9/16 (14.29) 3/4 (19.05) 3/4 (19.05) 15/16 (23.81) 1-3/8 (34.95) H 5/8 (15.87) 3/4 (19.05) 15/16 (23.81) 15/16 (23.81) 1-1/4 (31.75) 2-3/32 (53.18) J #12 5/16 (7.94) 1/2 (12.7) 1/2 (12.7) 5/8 (15.87) 13/16 (20.64) K L N 7/32 13/16 3/16 (5.56) (20.64) (4.76) 9/32 1-1/8 1/4 (7.14) (28.57) (6.35) 27/64 1-1/16 3/8 (10.72) (26.99) (9.55) 27/64 2-13/16 3/8 (10.72) (71.44) (9.55) 27/64 1-15/16 7/16 (10.72) (49.21) (11.11) 9/16 2-9/16 9/16 (14.29) (65.09) (14.29) T 3/32 (2.38) 7/64 (2.78) 1/8 (3.17) 1/8 (3.17) 3/16 (4.75) 9/32 (7.14) RECOMMENDED TIGHTENING TORQUE IN-LB 25 45 200 200 275 375 APPROX. WT. EACH LBS. (KG) 1 (.45) 3 (1.36) 13 (5.90) 15 (6.80) 22 (9.98) 71 (32.21) Listed torque values are for maximum conductor sizes accommodated. Consult UL486 Tables 7-4, 7-5, 7-6 for smaller conductor sizes. AUGUST 2013 ANDERSON™ HUBBELL® POWER SYSTEMS FARGO® SNAP TAP™ PLASTIC COVER PLASTIC PTC PTC1 & 2 Snap-on covers for aluminum compression taps. PTC51 & 52 Snap-on covers for mechanical center bolt taps. Material: Black plastic DD 43 DB-43 PTC51 PTC1 Product Data & Conductor Size CATALOG NUMBER PTC1** PTC51** DESCRIPTION For use on “O” die AC’s or any H-frame connectors up to 1 3/4” long For use on “D” die AC’s or any H-frame connectors up to 2 1/2” long, VCP-43A, VCP-44 VAC-1040 and VAC-4040 For use on center bolt connectors LC-51A, LC-51C, LC52A, LC511A and LC-522A PTC52** For use on center bolt connectors LC-52C, LC-81A, LC-811A, LC-542 PTC2** APPROX. WT. EACH LBS. (KG) .045 (.0204) .070 (.0318) .052 (.0236) .082 (.0372) **RUS Listed ANDERSON™ HUBBELL® POWER SYSTEMS FARGO® AUGUST 2013