SB6 SF6 Circuit Breaker Datasheet | 123-245 kV

advertisement

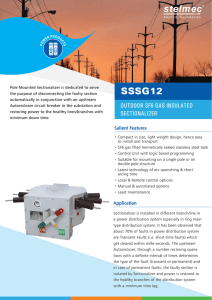

Transmission & Distribution SB6 123-245 kV - SF6 circuit breaker SB6 SF6 circuit breaker with gas – dynamic operating mechanism Powerful Up to 50Ka Isc 10.000 CO mechanical endurance Simple Poles are delivered complete and ready to operate: Fit them onto the simple structure Fill up the SF6 gas Plug-in the electrical connectors ……….operate Integrated pole + operating mechanism,self – contained architecture Free lay – out Reliable Protected stoperating mechanism Only static SF6 to air seals “Sealed for life” concept 40 years experience of puffer interrupter Safe All moving parts housed Tested seismic capability 0,5g A. B. C. D. E. F. Interrupter Insulating, support column Operating mechanism Local Control Cubicle Interconnection cables Support structure DESIGN Each breaker consists of three identical poles, each one is a complete functional unit comprising the interrupter, the insulating column and a power actuator driven by the SF6 gas of the pole in a closed cycle. Each pole is installed over a small simple lattice structure. A local control cubicle (LCC) provides for the control of the three-pole unit, connected to each pole via cable(s) with plug-in gas-tight connector(s). The density switch of each pole is installed inside the operating mechanism enclosure. A glass window allows to see the mechanical position indicator. A design combining simplicity, reliability and safety Only one technique provides insulation, current interruption and contacts operation. The breaking chambers and the operating mechanism are totally enclosed, assembled and factory tested, for minimum on site works and optimized maintenance. Static interfaces between SF6 and atmosphere : no dynamic revolving or sliding joints. Routine maintenance is unnecessary and environment is protected. Safety is improved as there are no accessible moving parts. No mechanical assembly on site related to operating mechanism ( no pipes, no ganging, no setting). Application Outdoor installation in AIS substations Protection of lines, cables, reactors and capacitors Standards : IEC 60056 and 62271-100 GAS DYNAMIC OPERATING MECHANISM PRINCIPLE The energy for actuating the main contacts is provided by SF6 pressure differential between : The volume formed by interrupter and the insulating column (1) The volume of the operating mechanism enclosure (2) Opening (fig 1): The interrupter (1) is at rated normal SF6 pressure for insulation and interruption. The mechanism (2) is low pressure rated. Opening (fig 2): On control signal, the valve group (3) directs the gas in the front of piston (4) to open the contact. At the end of the operation the driving gas inside the cylinder is released to expansion volume (2). Gas recovery (fig 3): A sealed compressor (5) housed inside the expansion enclosure (2) restores the pressure in the upper chamber. Closing (fig 4): On control signal, the valve group (3) directs the gas behind the piston (4) to close the contact. At the end of the operation the driving gas inside the cylinder is released to expansion volume (2). Closing (fig 5): The sealed compressor (5) restores the pressure in the upper chamber. A. B. C. D. E. F. G. H. I. J. K. L. M. N. O. P. Q. R. S. T. U. A. B. HV terminal Fixed arcing contact Nozzle Moving main contact Upper porcelain insulator Insulating rod Opening valve group Closing valve group Auxiliary contacts Compressor Gas filling valve Plug-in electric connector Density switch Spring toggle device Double effect piston Filter Lower porcelain insulator Moving arcing contact Fixed main contact Molecular sieves Coils High pressure volume Low pressure volume s MAIN CHARACTERISTICS Rated voltage Ur kVrms 123 145 170 Interrupters / pole nr 1 1 1 SB6 123 SB6 145 Type Rated frequency Fr SB6 170 245 SB6 245 50 / 60 Hz Insulation levels - Power frequency - BIL 1,2/50ms kVrms 230 275 325 460 (*) kVp 550 650 750 1050 (**) Rated continuous current Ir Α 3150 3150-4000 Symmetrical breaking capacity Isc kA 31,5 - 40 31,5 - 40 -50 Making capacity kAp 2,5 times Isc (50Hz) - 2,6 times Isc (60Hz) s 1-3 Rated break time ms 50 Rayed closing time ms Duration of short circuit <70 O-0,3s-CO-3min-CO or O.0,3s-CO-1min-CO or CO-15s-CO Operating sequence Minimum creepage distance mm/kV according to pollution levels of IEC 60815 Ambient temperature range °C -25 to + 55 Seismic capability g 0,3 / 0,5 (*) a version is also available for 530kV to earth and / or across open gap (**) a version is also available for 1200kVp to earth and / or across open gap Installation easy erection pole by pole transported as a complete unit installation without need of a specialist (no adjustments no dismantling or re-assembly) extremely simple civil works (no need of tight tolerances) pre-wired LCC half a day installation time simplified adaptation to existing civil works Tests CB type tested according to IEC Standards Seismic tested 0,5g before delivery each CB must pass routine tests in accordance with IEC for each CB a routine test report is issued with actual test results Maintenance for many applications , interrupters can be considered maintenance free(electric endurance >800kA cumulated under short circuit conditons) only periodic non-invasive checks suggested inspection after 5000 operations Notes modules and columns are transported with SF6 at 0.04 barg ; 1st filling gas cylinders remain customer's property gas and / or support structure can be excluded from the supply on request primary and earthing clamps can be supplied on request the factory is certified Limits of standard supply The supply normally includes : poles with brown porcelains standard insulator creepage 25mm/kV support structure per pole LCC and cables to poles SF6 gas for 1st filling set of accessories for site assembly (no standard tools included) aluminium terminal pads drilled to IEC/NEMA, single sided earthing connection points on structures standard centre-line distances O-CO-CO stored operations a.c. motor supply Dimensions: type/mm SB6 123 / 145 SB6 170 SB6 245 SB6 245 extended Main options overpressure relief device on poles extended creepage 31mm/kV and higher synchronized switching grey porcelains customized phase distances different terminal pads or double sided undervoltage tripping coil specific versions for –30° or –35°C d.c. supply for the motor A B C D E F G I CB mass kg 2575 3900 5350 800 1800 390 620 2200 1800 2575 4090 5730 800 1800 390 620 2500 2160 2575 4535 6520 800 1800 390 620 3200 2700 2575 4735 7020 800 1800 390 620 3200 3050 Design, data, dimensions are indicative and subject to change without notice SB6g-A-EN VA TECH Transmission & Distribution GmbH & Co KEG Penzinger Straße 76, A-1141 Vienna Tel.: ++43/1/89 100, Fax: ++43/1/89 100-196 E-Mail: contact@vatech-td.at, www.vatech-td.com VA TECH T&D Spain Calle Consejo de Ciento,304 2 2 08007 Barcelona Telf. +34 93 2724250 Fax +34 93 2724251 E-mail: td@td.vatech.es