X Ray Regulation - University of Windsor

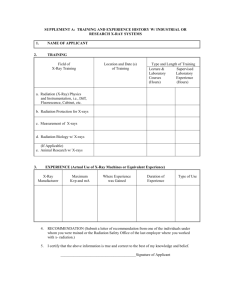

advertisement