Annexure-PFR - Environment Clearance

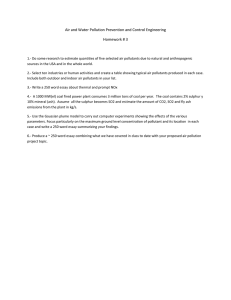

advertisement